International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN:2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN:2395-0072

KONKALA ANJANEYULU1 , Dr.K.NAGA SREENIVASA RAO2

1PG Scholar (Structural Engineering)

2Professor & HOD (Civil Engineering Department)

Chalapathi Institute Of Technology, Andhra Pradesh, India. ***

ABSTRACT:- Black Rice Husk Ash (BRHA) is an agroindustrialwasteobtainedbyincineratingthericehuskand has a high content of unburnt carbon. Consequently, the use of BRHA as a construction material is very limited, even though it has high silica content about 90%. But, someresearchershavereportedthattheadditionofBRHA inconcretehasimproveditsdurabilityproperty.

The objective of the present study was to develop geopolymerconcretemixturesusingGGBSandBRHA.The investigationutilizedGGBSasthebasematerialformaking the control geopolymer concrete. Then BRHA was used to replace GGBS in the mix in three different proportions, from 10- 30%, for the rest of the mixes used in the study. The GPC specimens were subjected to a range of test methods to ascertain their performance in different strengthanddurabilityconditions.

It was observed from the test results that the strength of GPC increased with the increase in concentration of sodium hydroxide as well as the curing temperature. Addition of BRHA beyond 10% in GPC retarded its strength development. However, the strengths were well abovethetargetstrengthupto20%replacementlevelsof BRHAinGPC.

Concreteisthemostpredominantlyusedconstruction materialintheworld.Thebasicingredientofconcretethat is Ordinary Portland Cement (OPC) is a major contributor ofglobalwarming.Theyearlyglobalcementproductionof 1.6billiontonsisresponsibleforabout7%ofthetotalCO2 emissionintotheatmosphere.Therawmaterialsrequired forcementproductionarenon-renewableanddepletingat a rapid rate. At the same time, a lot of industrial and agro wastes with inherent cementations properties are produced abundantly but mostly dumped into landfills. Employing such by products as alternates for cement has multiple benefits including conservation of environment,

sustainability of resources and solving the disposal problem of by-products. Extensive researches are being carried out to assess the feasibility of utilizing industrial wastes as complete replacement for OPC and generating superior binders from the same. One such successful attempt is Geopolymer concrete which entirely eliminates theuseofOPCinconcreteproduction.

In 1978, Joseph Davidovits (1999) recommended that it is conceivable to create fasteners coming about because ofthepolymerizationresponsebetweenantacidfluidsand source materials that are wealthy in silica and aluminum. Heinstitutedtheterm'geo-polymer'toportraythisgroup of mineral folios that have a compound creation like zeolites however showing an undefined microstructure. Paloma et al (1999) proposed that pozzolanic materials like impact heater slag can be enacted with the assistance of antacid fluids to deliver folios which could totally supplant OPC in concrete creation. Differentiating to OPC concrete (OPCC), the essential fasteners in GPC are not calcium-silicate-hydrates (C-S-H). Rather, an aluminosilicate polymeric gel shaped by tetrahedrally-fortified silicon and aluminum with oxygen molecules partook in the middle of acts the folio. The two vital constituents of GPC are source materials and antacid fluids. The source materials must be wealthy in silicon (Si) and aluminum (Al). These could be of geographical birthplace like metakaolin or side- effect materials like fly fiery debris, Ground Granulated Blast heater Slag (GGBS), silica smolder, rice-husk powder, and so forth. The basic fluids are based from dissolvable antacid metals for the most part being sodium or potassium. The most widely recognized soluble fluid utilized is a blend of sodium or potassium hydroxide alongside sodium or potassium silicatecorrespondingly.BlackRiceHuskAsh(BRHA)isan agro-industrialwastegeneratedfromricemillingindustry. It is obtained by burning rice husk in the incinerator. The ash obtained as a result of this combustion process has a highcontentofunburntcarbon.HencetheuseofBRHAas a construction material is very limited, even though it has

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN:2395-0072

high silica content about 90%. But several researchers including Chatweera and Lertwattanaruk (2011) and Piyaphanuwat and Asavapisit (2009) reported that the addition of BRHA in concrete has improved its durability property. In Geopolymer concrete, most of the research workshavebeen madeonFlyashbasedgeopolymersand in this present study, industrial waste which is Ground Granulated Blast furnace Slag(GGBS) and the agro waste which is Black Rice Husk Ash(BRHA) are used as source materials for Geopolymer concrete. GGBS was kept as the base material in which BRHA was replaced at different percentagesanditseffectonthecompressive,flexuraland tensile strengths and other durability properties like sorptivity, chloride permeability and resistance to acceleratedcorrosionwerestudied

To create geopolymer concrete mixtures utilizing GGBSandBRHA.

Tostudy the impactofnotableparameterson the compressive quality of the geopolymer concrete which incorporate restoring temperature and concentrationofsodiumhydroxideutilizedforthe basicarrangement.

Tostudytheexecutionofthegeopolymerconcrete under various toughness measure like sorptivity, chloride penetration, quickened consumption, corrosiveandoceanwaterobstruction.

To recognize a reasonable mix extent for the geopolymer concrete regarding level of GGBS, BRHA and furthermore on the ideal relieving temperature and concentration of sodium hydroxideutilizedastheantacidarrangement.

Tolookattheassemblingexpensesofgeopolymer concretewithregularconcrete.

Ground Granulated Blast Furnace Slag (GGBS) :- GGBS adjusting to the particulars of IS 12089-1987 was utilized as the essential cover to create GPC in which BRHA was supplanted from 0% to 30%. GGBS was gotten from JSW cementslimited,India.

S.No Property Value

1.

Silicon-di-Oxide(SiO2) 31.25%

2. Aluminiumtrioxide(Al2O3) 14.06%

3. FerricOxide(Fe2O3) 2.80%

4. CalciumOxide(CaO) 33.75%

5. MagnesiumOxide(MgO) 7.03%

6. LossonIgnition 1.52%

7. Specificgravity 2.61

8. Blainefineness 4550cm2/g

Black Rice Husk Ash (BRHA) :- BRHAwasacquiredfrom a rice factory. It was finely ground in a ball-factory for 30 minutes and went through 75µ strainer (Rashid et al, 2010) preceding utilizing in GPC generation. The compound organization and physical properties of BRHA weretried(accordingtoASTMD3682-01)inLaboratories, andaregiveninTable2.

S.No Property Value

1. Silicon-di-Oxide(SiO2) 93.96%

2. Aluminiumtrioxide(Al2O3) 0.56% 3. FerricOxide(Fe2O3) 0.43% 4. CalciumOxide(CaO) 0.55% 5. MagnesiumOxide(MgO) 0.40%

6. LossonIgnition 9.79%

7. Specificgravity 2.14

8. Blainefineness 5673cm2/g

Aggregates :- Characteristicwaterwaysandfittinginwith ZoneIIaccordingtoIS383(1987)withafinenessmodulus of3.54andaparticulargravityof2.61wasutilizedasfine aggregate.Pulverizedstonecoarseaggregatefittinginwith IS: 383 (1987) was utilized. Coarse aggregate of most extremeostensiblesize20mm,withaparticulargravityof 2.72 and fineness modulus of 6.29 was utilized. The aggregatesweretriedaccordingtoIS2386(1963).

Alkaline Solution :- A mixture of sodium hydroxide and sodium silicate was utilized as the basic arrangement. Business grade sodium hydroxide in pellets structure

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN:2395-0072

(97%-100% immaculateness) and sodium silicate arrangement having an organization of 14.7% Na2O, 29.4% SiO2 (all out solids = 45.4%) and 55.6% water by mass were utilized. The antacid fluid to folio ratio was fixed as 0.4 and the ratio of sodium silicate to sodium hydroxidewastakenas2.5inthewakeofdirectingagreat deal of preliminaries with conformance to functionality and quality. The concentration of sodium hydroxide was fixedat8Mforeveryoneofthetestsasidefromthestudy because of sodium hydroxide on the compressive quality wherethreediverseNaOHconcentrationswereutilized.

MIX PROPORTIONS :-Since there are no standard codal arrangementsaccessibleforthemixdesignofgeopolymer concrete,thedensityofgeopolymerconcretewasexpected as 2400 kg/m3 and different figurings were made dependentonthedensityofconcreteaccordingtothemix design given by Lloyd and Rangan (2010). The consolidated complete volume involved by the coarse and fine aggregates was thought to be 77%. The antacid fluid to folio ratio was taken as 0.40. As there are no standard mixdesigntechniquesaccessibletoappraisetheobjective qualityofGPCwhat'smorethisbeingagenerallynewsort of concrete that is still in formative stage, least target quality was taken as 30 MPa, considering it as a normal quality concrete. GGBS was kept as the base material for makingthecontrolGPCexamples(GP).AtthatpointBRHA was utilized to supplant GGBS in the mix in three distinct extents, 10% (GPR1), 20% (GPR2) and 30% (GPR3), for theremainderofthemixesutilizedintheexamination.

Compressive Strength Test:- The compressive strength ofthegeopolymerconcretewastestedasperIS516:1959. Cube specimens of size 150 mm were cast for each proportion and tested for their compressive strength at theagesof3,7and28days.Allthespecimensweretested using Compression Testing Machine (CTM) of 2000 kN capacity under a uniform rate of loading of 140 kg/cm2 /min until failure and the ultimate load at failure was takentocalculatethecompressivestrength.

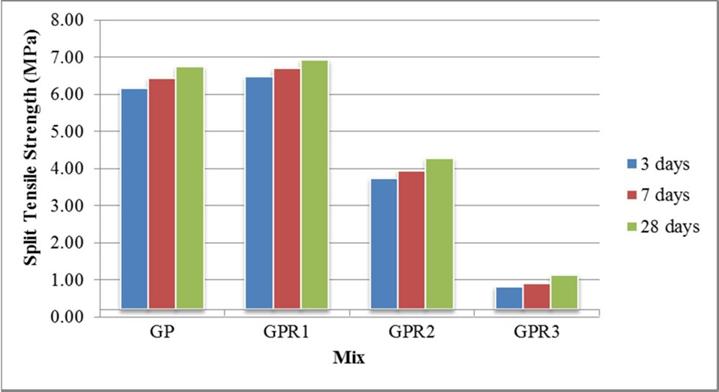

The split tensile strength test was carried out as per IS 5816:1999.Cylindricalconcretespecimensofsize150mm diameter and 300 mm height were cast. The specimens were then tested for their splitting tensile strength using UniversalTestingMachine(UTM)attheagesof3,7and28 days.

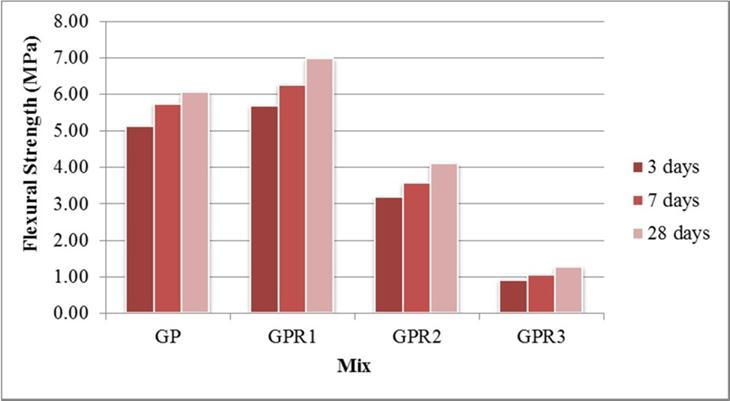

The flexural strength of the geopolymer concrete was carried out as per IS 516:1959. Beams of size 150 mm × 150 mm × 700 mm size were cast and then subjected to the flexural strength test using Universal Testing Machine (UTM)attheagesof3,7and28days.

Sorptivity Test:- The sorptivity test was done in accordancewithASTMC158504.Sorptivityisthemeasureofthecapillaryforceexerted by the concrete pore structure which causes the fluids to be drawn inside the body of the concrete. Concrete slices of 100 mm diameter and 50 mm thickness were used for thetest.Thesidesofthespecimenwerewaxedandsealed with a plastic sheet and then the initial mass of the specimenwastaken.Thespecimenwasthenkeptinatray with2to5mmofthedepthbeingimmersedinwater.The mass of the specimen was then measured at 1 minute, 5 minutes, 10 minutes, 20 minutes, 30 minutes, 1 hour, 2 hours, 3 hours, 4 hours, 5 hours and 6 hours after taking out and bloating off the excess surface water. Sorptivity valuewascalculatedusingtheformulas=I/t1/2,wheres issorptivityinmm/min;tistheelapsedtimeinmin;andI is the cumulative absorption given by I = ∆m/Ad where Äm is the increase in mass, A is the surface area of specimen through which water penetrates and d is the density of the medium, i.e. water. The cumulative absorption values were plotted against the square root of time and sorptivity was given by the slope of the best fittinglineoftheplot.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN:2395-0072

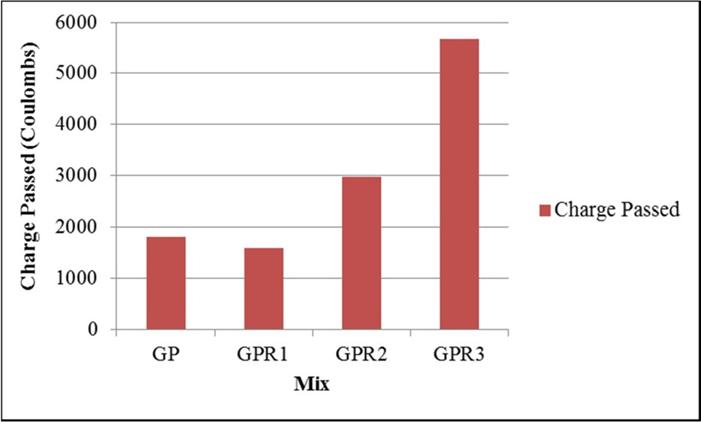

Rapid Chloride Permeability Test :-The Rapid Chloride Permeability Test (RCPT) was done in accordance with ASTMC1202-97.Thistestistherapidmeasurementofthe electrical conductance of the concrete with respect to its resistance against chloride ion penetration. Cylindrical specimensofsize100mmdiameterand50mmthickwere used for this test after 28 days from the date of casting. A potential difference of 60 V was maintained across the ends of the specimen for about 6 hours. One end was mounted to a cell containing 3% sodium chloride solution and the other end was mounted to a cell containing 0.3 N sodiumhydroxidesolution.

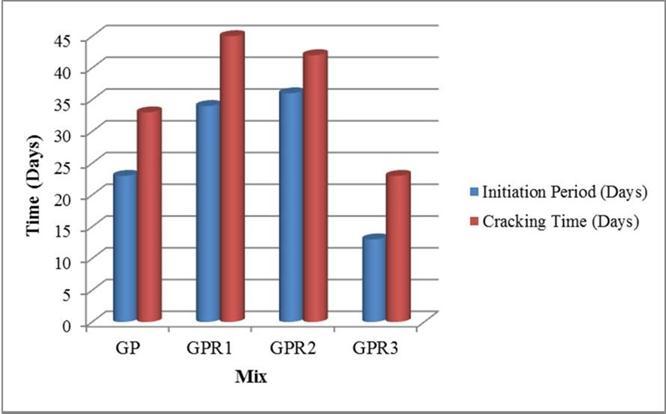

The accelerated corrosion test was conducted on cylindrical specimens of 100 mm diameter and 200 mm height with a 14 mm diameter steel rod embedded centrally so that equal cover was maintained on all the sides.Thespecimenswereovencuredat60°Cfor48hours after casting and then further cured in room temperature for28days.Thecylindricalspecimenswerethenplacedin individual containerseachcontaining4%sodiumchloride solution. The level of the solution was maintained at 75 mm from the bottom of the specimen throughout the test. A stainless steel plate was placed in each container which acted as the cathode whereas the steel rod embedded in concreteservedastheanodeandtheywereconnectedtoa constant DC supply of 6V so that the setup acted as an electrochemical cell. The voltage was maintained constantly throughout the test and current passing through each specimen was measured daily. At the instanceoftheappearanceoffirstcrackoneachspecimen, the specimens were stopped off the current supply and removed from the test setup respectively. Once the test was completed for all the specimens, a graph was plotted for the current passed in mA versus time in days to determine the corrosion initiation and propagation periods.

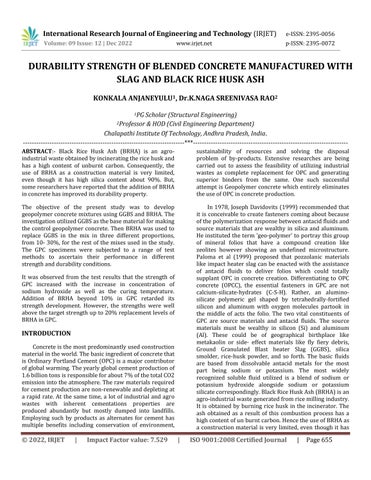

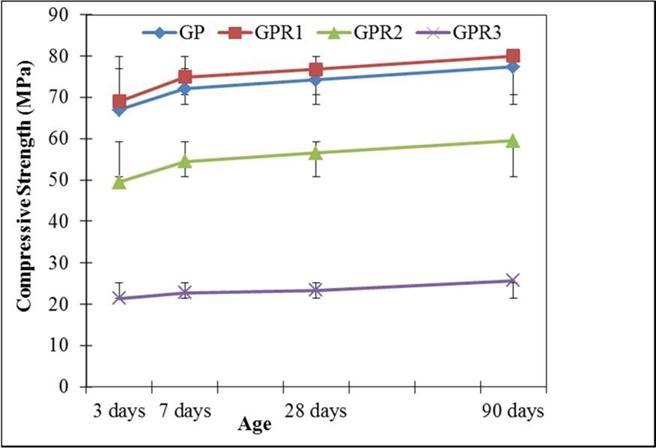

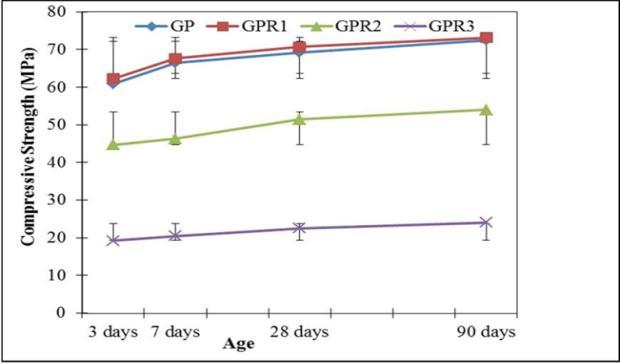

Compressive strength test:- From the results, it can be seen that the compressive strength of GPC increased with increase in NaOH concentration. At 28 days, the strength increaseofcontrol specimen(GP) ranged from10 to 18% forthecorrespondingriseinmolaritystartingfrom5Mto 8Mandthento11M.TheincreaseinNaOHconcentration could have increased the rate of dissolution of silica and alumina ions in the alkaline solution resulting in the compressivestrengthgain.Inthecurrentstudy,atallthree levels of NaOH molarity, the control GPC specimen (made

fully with GGBS) exceeded the 28th day strength of both the GGBS based GPC and the conventional concrete of the literature referred above. This again shows that the performance of GPC is better than conventional concrete andthisfacthasbeenprovedbyvariousotherresearchers also.

Figure 1 Compressive strength of GPC at 5 M NaOH concentration

Figure 2 Compressive strength of GPC at 8 M NaOH concentration

Figure 3 Compressive strength of GPC at 11 M NaOH concentration

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN:2395-0072

When comparing the 10% BRHA replaced mix GPR1 with control mix GP, there was a slight improvement in both split tensile and flexural strengths. The heat curing of the specimens along with a suitably increased SiO2/Al2O3 ratio and higher fineness of BRHA particles might have assisted the dissolution of ions and polycondensation mechanismofthegeopolymerframework.

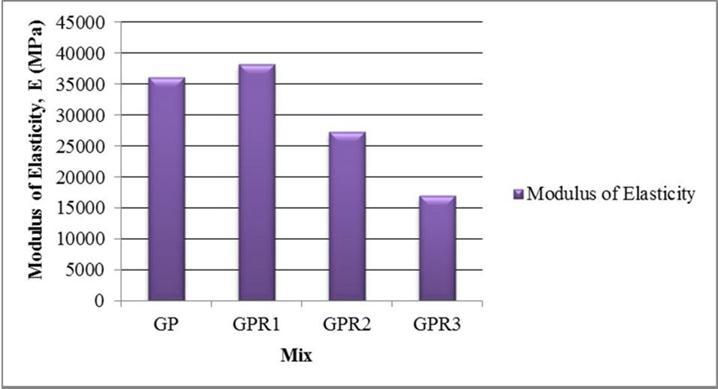

show reduced elastic modulus in comparison with the controlmix.Thepossiblereasonforthedecreaseinelastic modulus could be attributed to the reduction in strength due to inappropriate silica-alumina ratio from excessive additionofBRHA.

Modulus of Elasticity Test:- The10%BRHAreplacedmix GPR1hasahigherelasticmodulusthanthecontrolmixGP. TheincreaseinEvaluewasabout5.7%forGPR1.Boththe mixesGPandGPR1showedEvaluesashighas36155MPa and38183MParespectively.Thepossible reasonforsuch highvaluesofelasticmoduluscouldbetheco-existenceof the secondary C-S-H phase along with the primary geopolymer phase. The other two mixes GPR1 and GPR2

Rapid Chloride Penetration Test (RCPT):- BRHA replacement at a suitable level reduces the chloride ion penetrationofgeopolymerconcretewhichischaracterized by the micro filler effect of the fine BRHA particles. However, BRHA being silica rich, its excessive addition leads to an inappropriate silica-alumina ratio. This affects the dissolution mechanism of Si and Al ions and the subsequent rate of polycondensation thus leading to incompletealuminosilicate geopolymermatrix.Asa result of this, the structural compactability of the resulting geopolymer might not be dense which was what was believed to have caused the higher ion transport through the concrete. At 30% BRHA replacement, the structural compactability of GPC was clearly deteriorated which was evidentfromthefactthatitattainedverylowcompressive strengthunderalltheparametersconsidered.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN:2395-0072

GPC in RCPT. At lower strengths there is a higher ion transport through the concrete but it gets reducedasthestrengthofGPCincreases.

AdditionofBRHAbeyond20%isnotbeneficialin geopolymer concrete. The 30% BRHA replaced specimens neither achieved significant strength norprovedtobedurable.

From the cost perspective, there is a definite saving of cost in the production of GPC over conventional concrete. While comparing, as the grade of the conventional concrete increases the cost saving also increases for the corresponding GPCmix.

The experimental results show that it is possible to produce geopolymer concrete possessing substantial strength and durability using GGBS andBRHA.

The reflection of cost savings can be more significantifthevolumeofproductionofconcrete ismassive.

Increase in NaOH concentration increased the compressivestrength.

Abdelalim,A.M.K.,Abdelaziz,G.E.,andZahran,R. (2004). “Transport and microstructure properties of rice husk ash concrete.” Scientific Bulletin of Faculty of Engineering,AinShamsUniversity,Vol.39,pp.21-34.

The strength increase ranged between 10 to 18% for the corresponding rise in molarity starting from5Mto8Mandthento11M.

Albitar, M., Visintin, P., Mohamed Ali, M. S., and Drechsler, M. (2014). “Assessing behaviour of fresh and hardenedgeopolymerconcretemixedwithclass-Fflyash.” KSCEJournalofCivilEngineering, Vol.19,No.5,pp.14451455,DOI:10.1007/s12205-014-1254-z.

While comparing oven curing at a temperature of 60°C and ambient curing, the strength increase at 28dayswas45%forGPR1andnearlythreetimes forGPR2specimens.

ASTM C1202 - 10 Standard Test Method for ElectricalIndicationofConcrete'sAbilitytoResistChloride IonPenetration.

Increaseincuringtemperatureto90°Chadonlya moderate increase in the compressive strength. Hence oven curing at 60°C could be preferred for theGPCwhenBRHAisadded.

ASTM C1585 - 04 Standard Test Method for MeasurementofRateofAbsorptionofWaterbyHydraulicCementConcretes.

Addition of BRHA beyond 10% had a retarding effectonthecompressivestrength.Althoughupto 20% replacement, the target compressive strengthwassurpassedandstrengthashighas51 MPawasreachedat28days.

Seemingly a very good correlation exists between the compressive strength and charge passed for

ASTM C642 - 06 Standard Test Method for Density,AbsorptionandVoidsinHardenedConcrete.

Bernal,S.A.,Provis,J.L.,Rose,V.,andGutierrez,R. M. (2011). “Evolution of binder structure in sodium silicate-activatedslagmetakaolinblends.”CementConcrete Composites, Vol. 33, pp. 46- 54, DOI: 10.1016/j.cemconcomp.2010.09.004.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN:2395-0072

Chatweera, B. and Lertwattanaruk, P. (2011). “Durabilityofconventionalconcretescontainingblackrice husk ash.” Journal of Environmental Management, Vol. 92, pp. 59-66, DOI: 10.1016/j.jenvman. 2010.08.007. Davidovids, J. (2011). “Geopolymer chemistry and applications 3rd Edition.” Institut Géopolymèr, SaintQuentin,France.

Davidovits, J. (1999). “Chemistry of geopolymeric systems, terminology.” Geopolymere ’99 Conference, Sain Quentin,France,pp.9-22.

Duxon,P.,Provis,J.L.,Lukey,G.C.,Mallicoat,S.W., Kriven, W. M., and Van Deventer, J. S. J. (2005). “Understanding the eelationship between geopolymer composition, microstructure and mechanical properties, colloidsandsurfaces.”A.PhysicochemicalandEngineering

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page661