International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

2

1Research Scholar BM College of Technology, Indore RGPV, BHOPAL

2Professor BM College of Technology, Indore RGPV, BHOPAL ***

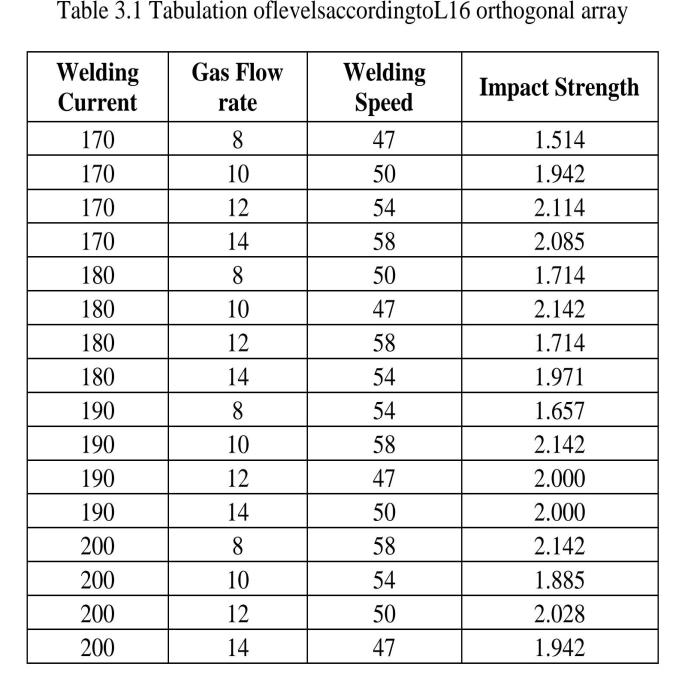

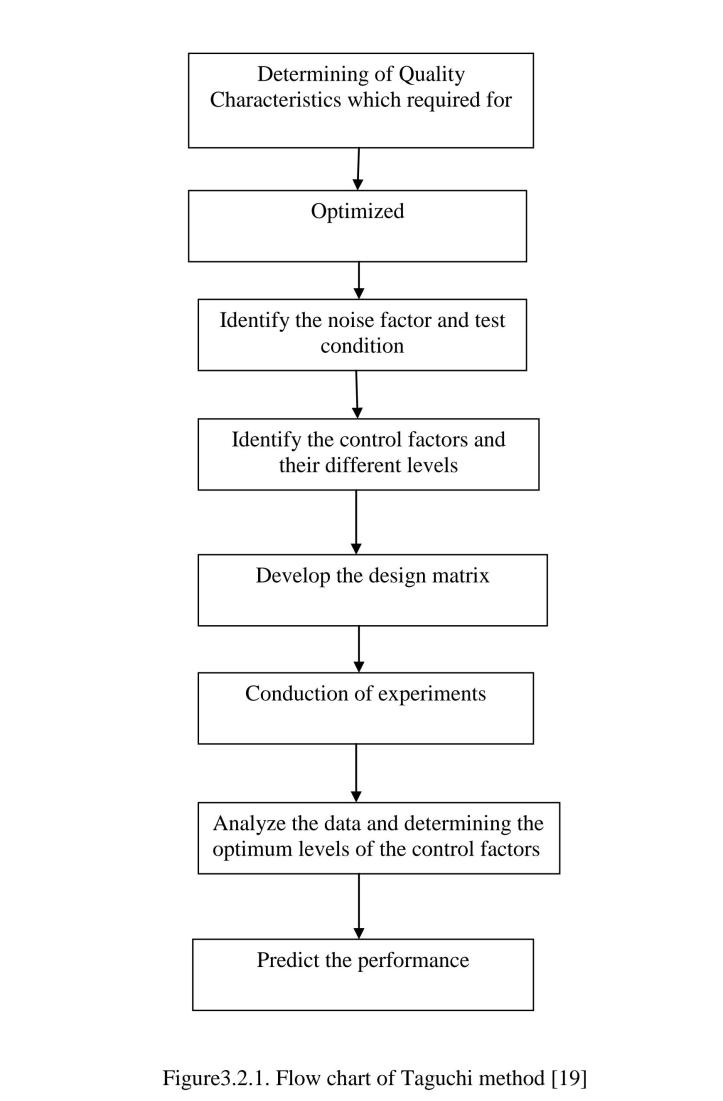

Abstract - This research paper discusses the experimental and numerical results of AA6061 TIG welding. The purpose of this research is to determine the best process parameters for GTAW of Argon, which is used as an inert gas in the aluminium alloy AA6061. The Taguchi method was used to optimize TIG welding process characteristics such as gas flow rate, welding current, and welding speed for connecting AA6061 plates. The Taguchi technique is used to obtain the Optimization parameters of Welding with tungsten inert gas on 6061 aluminium alloy. After examining the influence of various components with ANOVA and regression analysis, the Taguchi technique was used to find a desirable combination.

Key Words: Hybrid laser-TIG welding Response surface methodology(RSM)Desirabilityapproach,aluminiumalloy AA6061,weldingcurrent,gasflowrate

ThegeneralprincipleTIG(tungsteninertgas)welding,also knownasGTA(gastungstenarc)intheUnitedStatesand WIG(Wolframinertgas)inGermany,isaweldingprocess usedtoproducehighqualitymaterialsofvarioustypesUsed for welding, specifically, stainless steel, titanium and aluminium.

● AC/DCPowerSource

● TIGTorch

● WorkReturnWeldingLead

● Shieldinggassupplyline,(normallyfromacylinder)

● FootControlUnit(commonoption)

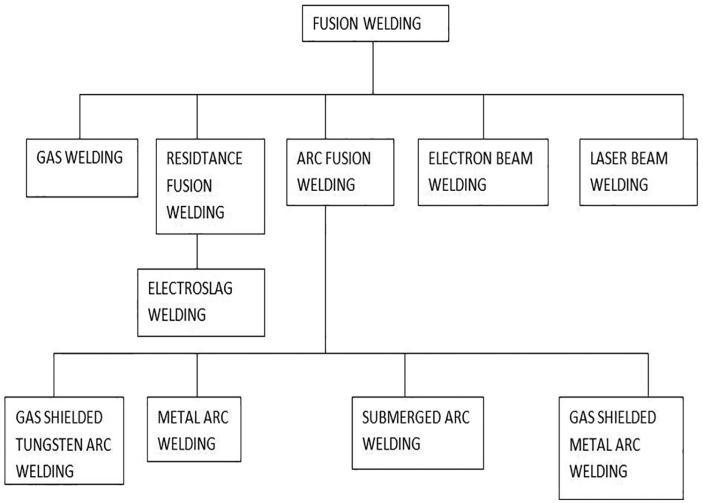

Weldingistheprocessofjoiningmetalstogether,eitherwith orwithoutfiller,toformcoal'sessence.Weldingisamethod ofpermanentlyjoiningmaterials.Shipbuilding,autos,andoil andgasarejustafewoftheindustriesthatemployit.Arc weldingisaprocessthatinvolvescreatinganarcbetween theelectrodeandtheworkpiece,whichwarmsandmeltsthe metal. Electrodes can be consumable or non-consumable. Fluxisusedtoprotectweldmetalfromenvironmentalgases. The procedure can be carried either automatically or by hand.Intheshipbuildingbusiness,arcwelding,whichwas pioneeredinthenineteenthcentury,becamecommercially

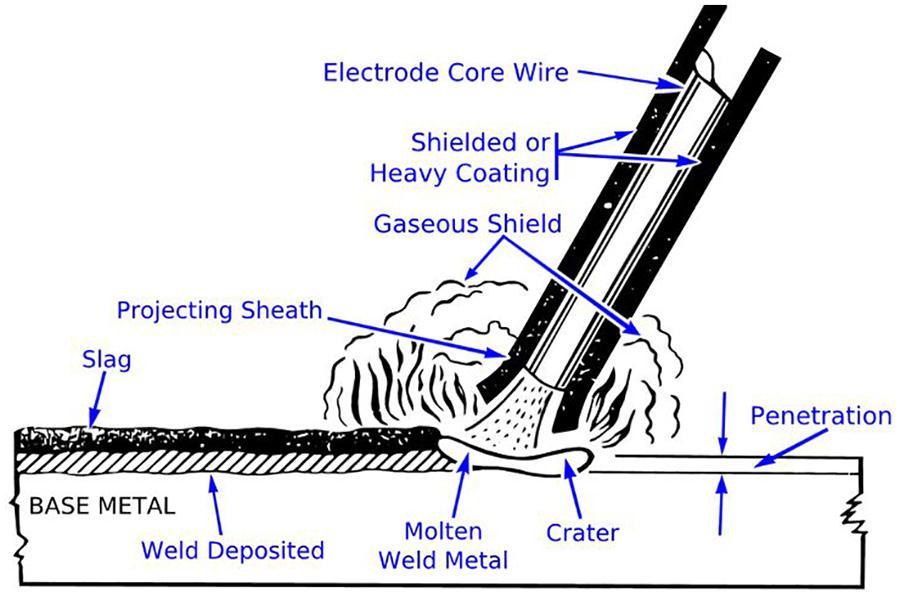

vitalduringWWII.It'sstillutilisedinthemanufacturingof steelpipelinesandautomobilestoday.[2]Figure1.1Metal arcweldingwithaconsumableelectrodeshield.Themost popular,dependableandcost-effectiveweldingtechnologyis shieldedarc welding,oftenknownasmanualarc welding. The consumable electrode utilised in this application is compatiblewithflux-coatedweldedsteel.Anelectriccurrent isutilisedtostrikeanarc whentheelectrodeisscratched alongtheworkpiece.

Figure1.1Classificationoffusionweldingprocesses.[46]

Figure1.2Shieldedmetalarcweldingprocess[46]

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

Welding is a permanent joining process that uses heat, pressure, and filler materials to connect two or more materials,typicallymetalsorthermoplastics.Tungsteninert gasweldingisanelectricarcweldingmethodthatusesnonconsumable tungsten electrodes to create an arc between the electrode tip and the work piece. To prevent contamination of the weld with air, inert gases (argon, helium,etc.)areused.

Amixtureofanytwoofthegasesdescribedaboveisoften used. TIG welding is one of the most flexible welding methodsavailabletoday,capableofconnectingtoalmostany metal or metal alloy. This welding method is popular because of its inherent benefits, such as high-quality and betterwelds,lessdeformation,asmallerheat-affectedzone, and the absence of slag or spatter. TIG welding is widely usedinindustrialindustriessuchasautomobiles,airplanes, nuclear power plants, food processing plants, precision manufacturing plants and maintenance and repair work. [45]

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

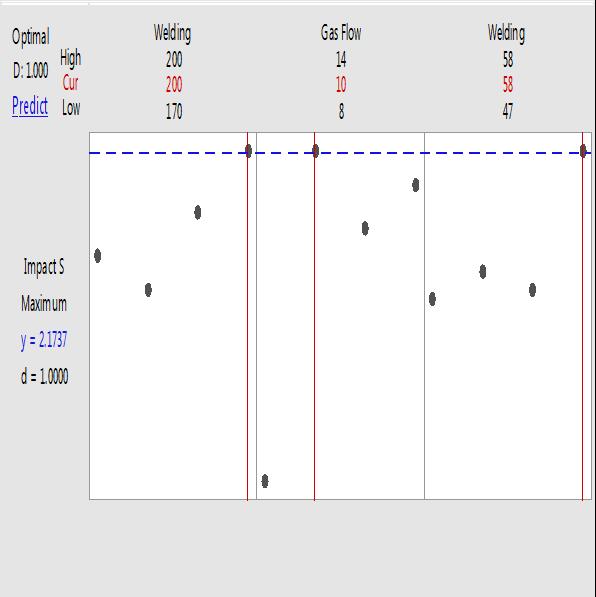

OptimalControl Parameters Level Optimal Level Experimental Predicted (RSM) Error (%)

Welding Current(A)

A A4 B2 C4 2.251 2.1737 5.3

Gas flow rate (L/min) B

Welding Speed (mm/s) C

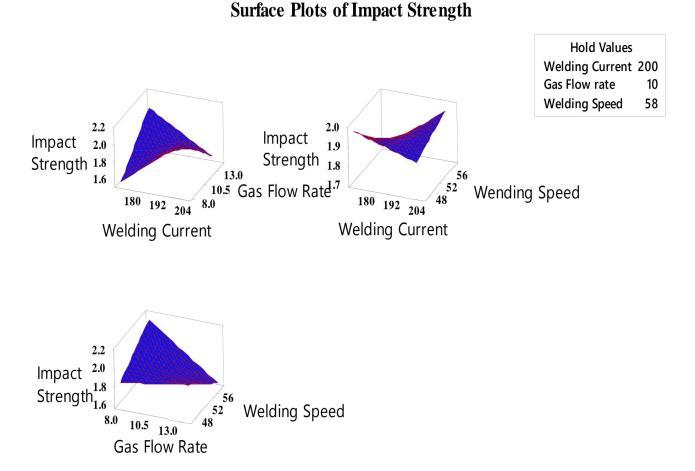

Fig.5.2TheeffectoftheprocessparametersontheImpact strength:(a)weldingcurrentandgasflowrate(b)Welding speedandweldingcurrent(c)gasflowraterandwelding speed.

Fig.5.1OptimizationresultsofimpactstrengthbyRSM

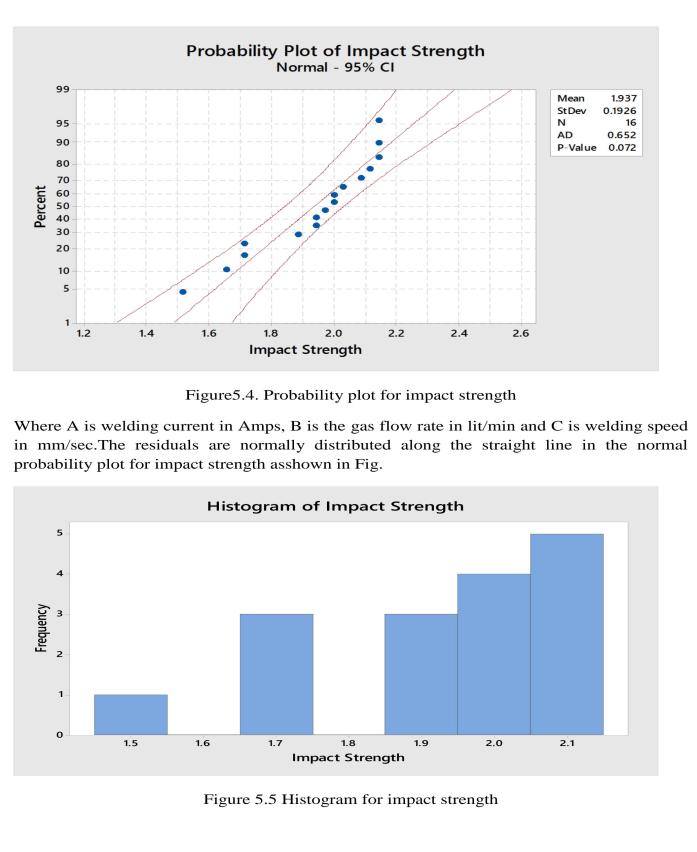

The optimization results obtained have been validated by performing confirmatory experiments. Table 6 represents theresultsofconfirmatorytests thatareconductedinoptimalconditions.Itisseenfromthe table that the error in terms of percentage between the estimatedandexperimentalresultsisverysmallandisless than 1%. This indicates that the optimized TIG welding processparametershigher NTSandUTSof316Lstainless steel can be obtained. Three fresh experiments are conductedforconfirmationofmodelsEqs.(3)And(4),with achievedoptimalvaluesofcuttingparameters.Theaverage of measured values for surface roughness and kerf taper anglearetabulatedinTable6.Theaccuracyofthemodels isanalyzedonthebasispercentageerror.Theseerrorsare foundtobe1.18and2.24%forsurfaceroughnessandkerf taper angle, respectively. It is possibly due to some vibrationsduringmachiningwhichaffectsthemeasurement techniques.Sincetheerrorislessthan10%,itisevidently provedthatthereisagoodagreementbetweenexperimental andpredictedvalues[38].

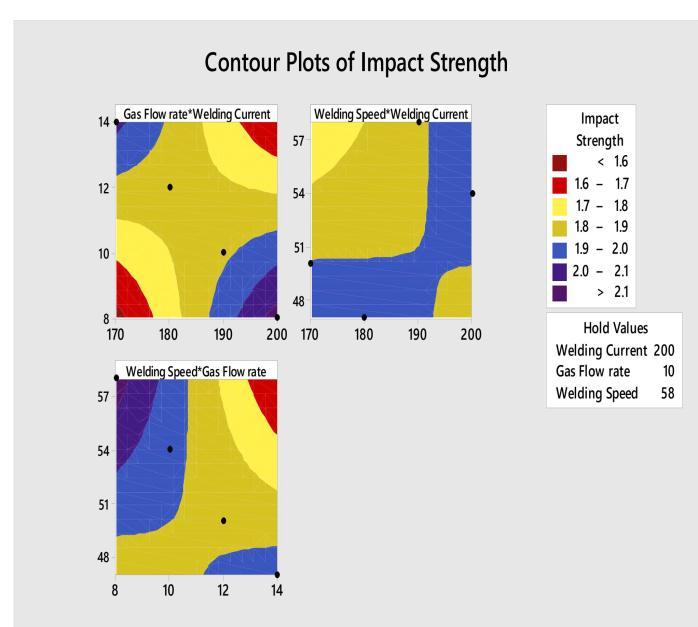

Fig.5.3Impactpowercontourplot(A)weldingcurrentand gasflowrate)(B)andweldingspeedandweldingcurrent(C) gasflowrateandweldingspeed

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

Figure6-8showsthelimitsofimpactstrength(A)against weldingcurrent(L/min),weldingspeed(mm/s)against gas flow rate (L / min), and welding speed (mm / s) (A) againstthecontourbandweldingcurrentshownin(a).As shown in fig. 6, the impact strength is greater when the currentis190Aandthegasflowrateis10L/min.According to Fig.7, maximum impact strength is obtained at high weldingspeeds(54mm/s)withagasflowrateof13L/min.

6.AccordingtotheANOVAanalysis,gasflowrateisthemost important factor influencing the impact strength of TIG weldedAA6061joints,followedbyweldingspeed.

[1] NabenduGhosh et.al. Parametric Optimization of Gas Metal Arc Welding Process by using Taguchi method on Ferritic Stainless Steel AISI409. Elsevier, Materials Today: Proceedings4(2017)pg.2213–2221

[2] BhrudinHrinjica et.al.Welded Joint Tensile Strength Testing Of New And Used Material. 16th International Research/ExpertConference,TMT2012,Dubai,UAE,10-12 September2012,pg87-90

[3] Amit Pal. Mig Welding Parametric Optimization Using Taguchi’s Orthogonal Array And Analysis Of Variance. International Journal Of Research Review In Engineering Science & Technology, Volume-4, Issue-1, April-2015, pg.211-217

[4] VivekSaxena et.al. Optimization Of MIG Welding Parameters On Tensile Strength Of Aluminium Alloy By TaguchiApproach.InternationaljournalofEngg.

[5] M. Ragavendran, N. Chandrasekhar, R. Ravikumar, R. Saxena,M.Vasudevan,A.K.Bhaduri.Optimizationofhybrid laser - TIG welding of 316LN steel using response surface methodology(RSM).Optics and Lasers in Engineering 2017 (94),27–36.

[6] Dinesh Mohan Arya, Vedansh Chaturvedi, JyotiVimal (2016),ParametricoptimizationofMIGprocessparameters usingTaguchiandGreyTaguchianalysis.International

1.Responsesurfacemethodology(RSM)hasbeenfoundto be extremely useful in the current study's optimization process.Inthiscase,thepredictedvaluefromthemodelsis veryclosetotheexperimentalvalue.

2.Themostimportantweldingparameteraffectingultimate tensile strength is gas flow rate, which is followed by weldingcurrentandweldingspeeds.

3. The most important factor influencing percentage elongationisweldingcurrent,withgasflowratecomingin second,followedbyweldingspeed.

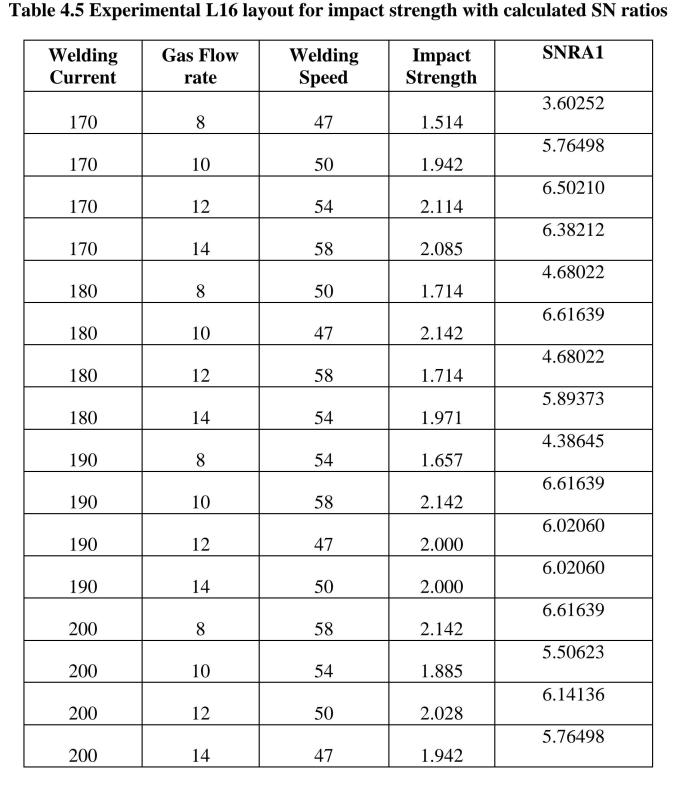

5.ImpactstrengthANOVAresult(J).Itisdiscoveredthatthe mostsignificantinfluenceonimpactstrengthistheGasflow rate (L/min) (P=0.393) (32.62%), followed by Welding Speed(mm/s)(P=0.859)(6.90%)andtheleastsignificant influence is the Welding Current (A) (P=0.900) (5.22%). Weldingcurrentisaninsignificantfactorforimpactstrength inthecurrentstudy.

Journal of Research in Engineering and Applied Sciences, 3(6),1–17.

[7]NabenduGhosh,PradipKumarPal,GoutamNandi(2016), ParametricoptimizationofMIGweldingon316Laustenitic stainless steel by Grey-based Taguchi method. Procedia Technology,25,1038–1048.

[8] Doniavi A., Hosseini A., Ranjbary G. (2016), Prediction and optimization of mechanical properties of St52 in gas metal arc weld using response surface methodology and ANOVA,InternationalJournalofEngineeringTransactionsC: Aspects,29(9),1307–1313.

[9] AbhishekPrakash, Raj Kumar Bag, PapinOhdar, Siva SankarRaju(2016),Parametricoptimizationofmetalinert gas welding by using Taguchi approach. IJRET, 5(2), 176–181.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |