International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

1Research Scholar BM College of Technology, Indore RGPV, BHOPAL

2Professor BM College of Technology, Indore RGPV, BHOPAL ***

Abstract - An industrial air compressor has a wide range of applications in manufacturing and assembly. The intake valve body is a major component of an industrial air compressor that performs a variety of functions such as regulating the amount of air into the compressor for pressurization and preventing oil backflow. The intake valve of an air compressor should be strong enough to withstand high pressure exerted on walls. This strength can be increased by changing the material or optimizing the existing design. The goal of current research is to improve the strength of intake valves through design optimization and material substitution. The ANSYS FEA simulation package is used for the numerical investigation of the intake valve. The impact of design variables and MMC material on structural and thermal performance is assessed using FEA and optimization results.

Key Words: Intakevalve,FEA,Optimization,MMC

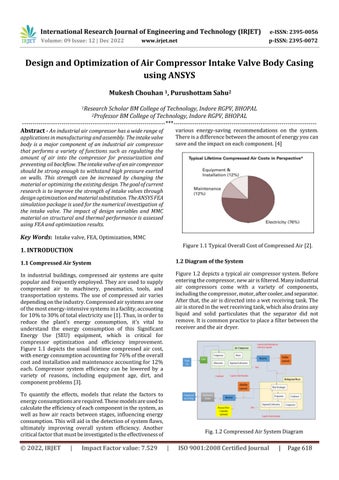

In industrial buildings, compressed air systems are quite popularandfrequentlyemployed.Theyareusedtosupply compressed air to machinery, pneumatics, tools, and transportation systems. The use of compressed air varies dependingontheindustry.Compressedairsystemsareone ofthemostenergy-intensivesystemsinafacility,accounting for10%to30%oftotalelectricityuse[1].Thus,inorderto reduce the plant's energy consumption, it's vital to understand the energy consumption of this Significant Energy Use (SEU) equipment, which is critical for compressor optimization and efficiency improvement. Figure 1.1 depicts the usual lifetime compressed air cost, withenergyconsumptionaccountingfor76%oftheoverall costandinstallationandmaintenanceaccountingfor12% each. Compressor system efficiency can be lowered by a variety of reasons, including equipment age, dirt, and componentproblems[3].

To quantify the effects, models that relate the factors to energyconsumptionsarerequired.Thesemodelsareusedto calculatetheefficiencyofeachcomponentinthesystem,as well as how air reacts between stages, influencing energy consumption.Thiswillaidinthedetectionofsystemflaws, ultimately improving overall system efficiency. Another criticalfactorthatmustbeinvestigatedistheeffectivenessof

various energy-saving recommendations on the system. Thereisadifferencebetweentheamountofenergyyoucan saveandtheimpactoneachcomponent.[4]

Figure1.1TypicalOverallCostofCompressedAir[2].

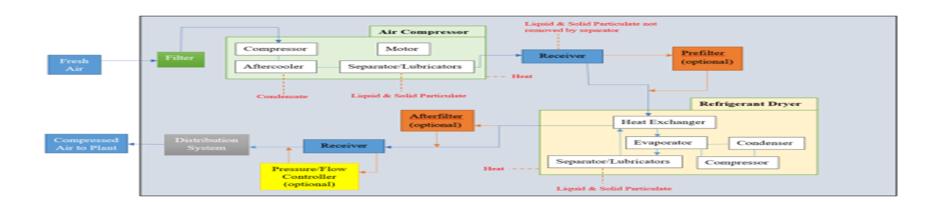

Figure1.2depictsa typical aircompressorsystem.Before enteringthecompressor,newairisfiltered.Manyindustrial air compressors come with a variety of components, includingthecompressor,motor,aftercooler,andseparator. Afterthat,theairisdirectedintoawetreceivingtank.The airisstoredinthewetreceivingtank,whichalsodrainsany liquid and solid particulates that the separator did not remove.Itiscommonpracticetoplaceafilterbetweenthe receiverandtheairdryer.

Fig.1.2CompressedAirSystemDiagram

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

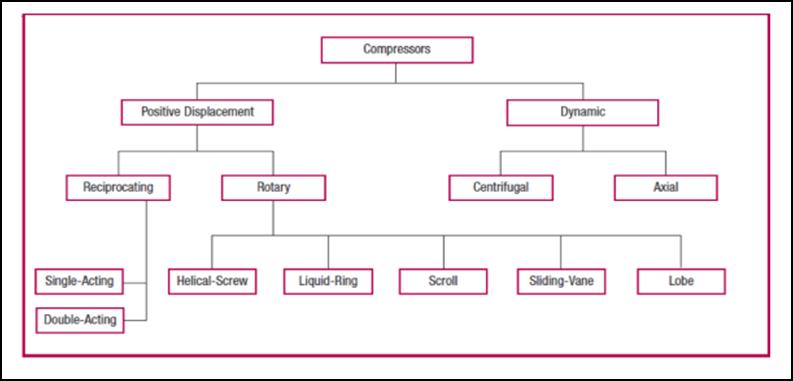

Themostbasiccomponentofacompressedairsystemisan aircompressor.Aircompressorscomeinavarietyofshapes and sizes. Figure 1.3 depicts the various types of air compressors'categoriesandsubcategories.

theairbeforeitreachestheHigh-Pressurecylinderafterit exitstheLow-Pressurecylinder.Thisincreasescompressor

efficiency and guarantees that the temperature of the air receiverexitvalvesisjustperfectforoptimaloperationof thecompressor'stools.Sheetmetalplatepartsoratabular coremakeuptheintercooler.TheTypeVT4compressorisa two-stage,two-cylinderreciprocatingaircompressorthatis commonly used in industrial and underground mining applications. Purpose the varied efforts of numerous researchers are highlighted in this study. According to numerousstudies,increasingthesizeoftheintercoolerwill prevent heating in the High-Pressure Cylinder in the long term.”[8]

Fig.1.3.

[1]

Airdryersareoneofthemostcommonwaystoimproveair quality.Theirprimaryfunctionistoconvertairintoaform thatcanbeusedinavarietyofapplications.Moisturemust bekeptoutofcompressedair.Wetcompressedairrunning throughthesystemwouldharmthemachinesiftherewere noairdryers.Becauseofthemoistureintheair,partsofthe machines would rust and tear. However, excessively dry compressedairwouldwasteenergyandmoney.

TheFEMtechniqueisausefultoolforsolvingmathematical equationsinavarietyofengineeringproblems.Themethod was proposed in the aerospace industry as a tool for assessinganxietyindifficultjetsystems.Itisderivedfrom thematrixanalysisprocedureusedinaircraftdesign.Intheir respectivefields,eachresearcherandpractitionerhasmade significant progress. The main principle of finite element methodology is to break down a body or structure into smaller,finite-sizecomponentsknownaslimitedelements.' Intheinitial frameandstructure,thevariablesassociated withalimitedsetofconnectionsknownasnodesornodal pointsareinvestigated.

Shashank Gurnuleet. al. [8] have emphasized on the intercooling process of air compressor. The intercooling enhancestheefficiencyofcompressor.Compressionisdone in more than one step to "improve the efficiency of the system,"andanintercoolerisgivenbetweeneachstage.In the final stage, the intercooler enhances air quality and lowersinletairtemperature.Theintercooler'sjobistocool

Kanwar J.S Gillet. al. [9] Have worked on 2 stage reciprocatingaircompressordesign.Thecompressordesign was made of structural steel frame mounted over foundation. The unit comprised of air receivers and stabilizingtanks.Duringthetest,the"realvolumeoffreeair providedbythiscompressoris0.020m3/secwithawork done of 77 N-m" was discovered. Furthermore, it was discoveredthatwhenthecompressor'sisothermalefficiency is 45 percent, the compressor's capacity to supply air is around 1.02 kg/minute. An intercooler with a capacity of 2.049 kilojoules/kg of heat rejection can be particularly constructed.”[9].

VijaykumarFPipaliaet.al.[10]haveworkedoninvestigating theeffectofundesirableheatingoncompressorfunctioning. Thedesignandmaterialmodificationsaresuggestedbythe author to mitigate the heating effect and ensure efficient design development. The water cooling sources, ethylene glycolcoolantsareusedinaircompressorareinvestigated usingexperimentaltechniques.

International Research Journal of Engineering

Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

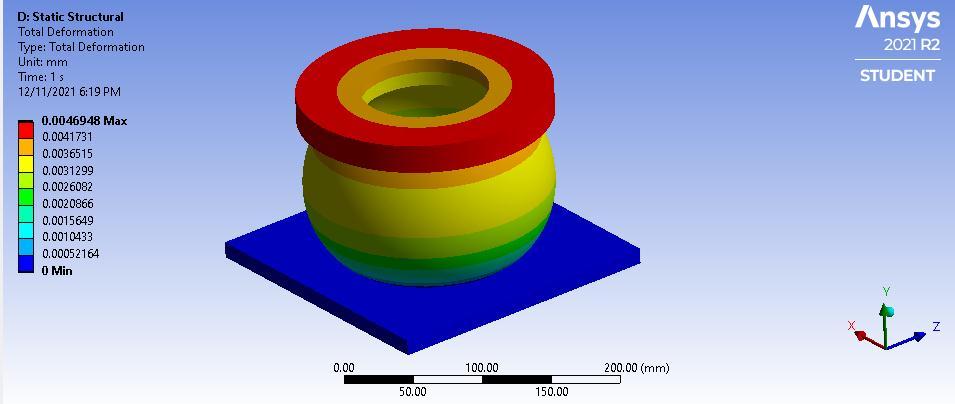

Thecoupledfieldanalysisisconductedonintakevalveusing P100/6061 Al MMC material. The total deformation,

equivalent stress and safety factor are determined. The maximum deformation obtained from the analysis is .00469mm at the top free end of the intake valve as representedinredcolor.

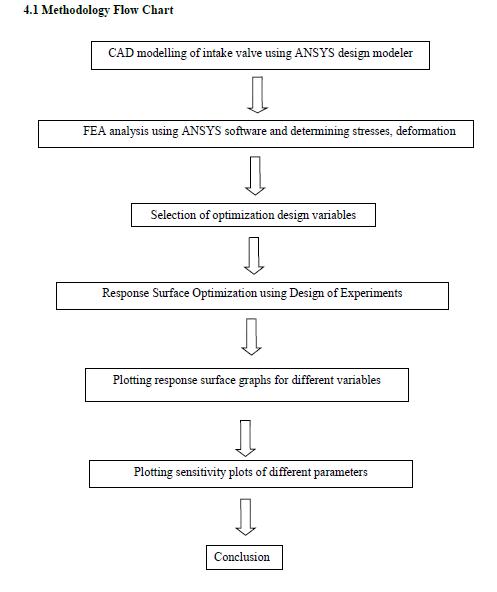

TheFEAisausefultoolfordeterminingthestructuraland thermal properties of a compressor's intake valve. The critical areas of high stress and the safety factor are identified. To generate dimensions, the optimization variablesarechosenandTaguchidesignofexperimentsis used.

1.Accordingtocoupledfieldanalysis,heatflowisgreatestat the edge region, with a magnitude of.00138W/mm2. The heatfluxdecreasesuntilitreaches.000614W/mm2.

2. The topmost region of the intake valve exhibits the greatest deformation. The coupled field analysis yielded a maximumdeformationof.221mm.

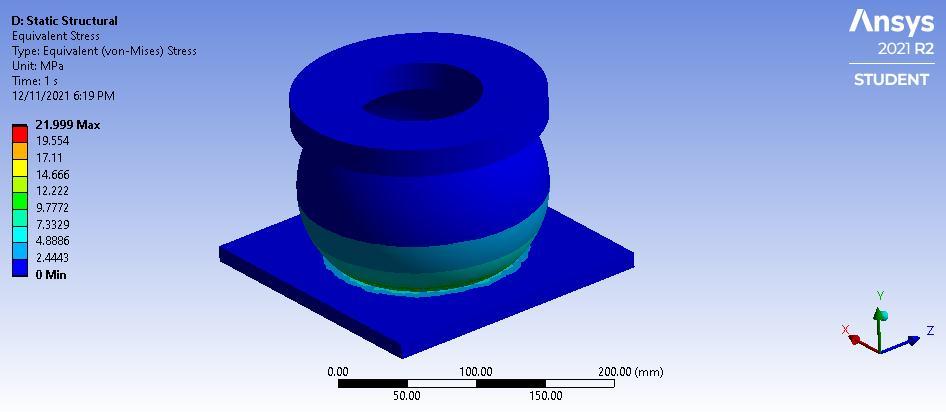

3.Theequivalentstressisgreatestatthepointwhere the baseandcirculargeometrymeet.Theanalysisyielded the maximumequivalentstress.

Themaximumequivalentstressisobtainedatthecontact regionbetweenbottomsupportandcylindricalregionwith magnitudeof9.77MPa.

4.Theouterdiahasa sensitivitypercentage of77.369 for total deformation, while the inner dia has a sensitivity percentageof26.873.Asaresult,theouterdiahasalarger effectontotaldeformationandtheinnerdiahasasmaller effectontotaldeformation.

5.Theouterdiahasa sensitivitypercentage of65.125 for equivalent stress, while the inner dia has a sensitivity percentageof67.678.Asaresult,theinnerdiahasagreater effect on total deformation and the outer dia has a lesser effect.

[1] C. Beals, J. Ghislain, H. Kemp et al., “Improving compressed air system performance,” US Department of Energy,2003.

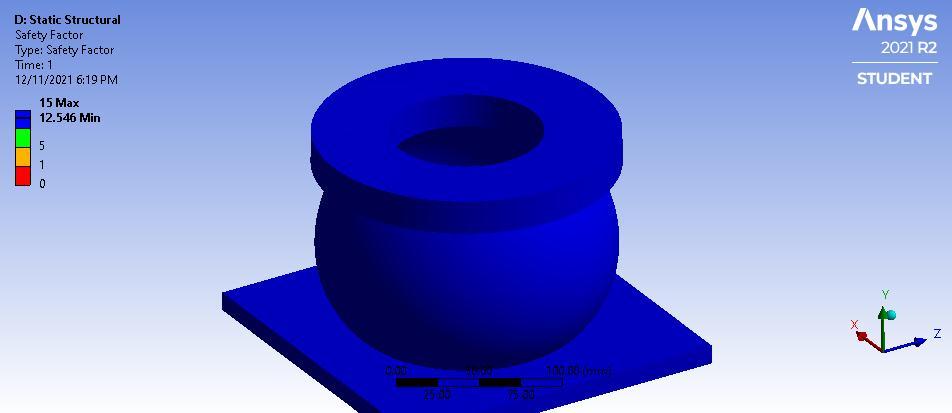

Figure5.23EquivalentstressusingP100/6061AlMMCThe safetyfactorplotisgeneratedusingAlMMCmaterial.The safetyfactorishighwithuseofP100/6061AlMMCmaterial withmagnitudeof12.546.

[2]U.SDepartment ofEnergyEnergy Star, Determinethe Cost of Compressed Air for Your Plant, 2016 (accessed October 9, 2016), https://www.energystar.gov/ia/business/industry/compre ssedair1.pdf.

[3] R. Prakash and R. Singh, “Mathematical modeling and simulation of refrigerating compressors,” International CompressorEngineeringConference,pp.274–285,1974.

[4] G. Maxwell, “Dynamic simulation of compressed air systems,” ACEEE Summer Study on Energy Efficiency in Industry,pp.146–156,2003.

[5] Rotary Screw Air Compressors, 2016 (accessed November12,2016),https://en.wikipedia.org/wiki/Rotaryscrewcompressorcitenote-3.

Figure5.24SafetyfactorusingP100/6061AlMMC

[6] CAGI. Preformance Verification: Data Sheets, 2017 (accessed March 13, 2017),

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056 Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

http://www.cagi.org/performance-verification/datasheets.aspx

[7] B. J. Abels and K. Kissock, “Optimizing compressed air storageforenergyefficiency,”SAEInternationalJournalof Materials and Manufacturing, vol. 4, no. 1, pp. 477–485, 2011.

[8] ShashankGurnule, RiteshBanpurkar, "Design, Modification&AnalysisofIndustrialAirCompressor(Type–VT4)–AReview",SSRGInternationalJournalofMechanical Engineering(SSRG-IJME),V4(12),PageNos.3–7December 2017.ISSN:2348–8360.

[9] Kanwar J.S Gill, Surinder Pal Singh, Gurpreet Singh &MalinderSingh,"DesigningandFabricationofIntercooler and Control of Three-Phase Digitalized Reciprocating Air Compressor Test Rig with Automatic Control Drive Unit", International Conference of Advance Research and Innovation(ICARI-2015).

[10] Vijaykumar F Pipalia, Dipesh D. Shukla and Niraj C. Mehta,"InvestigationonReciprocatingAirCompressors-A Review",InternationalJournalofRecentScientificResearch Vol.6,Issue,12,pp.7735-7739,December2015.

[11]SuprasannaRaoRavur,Subbareddy.E.V,"Experimental Investigation to Increase the Efficiency of the Air Compressor by Changing the Coolants in Inter Cooler", International Journal for Research in Applied Science & Engineering Technology (IJRASET) Volume 3 Issue IX, September2015.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal