International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

1Research Scholar BM College of Technology, Indore RGPV, BHOPAL

2Professor BM College of Technology, Indore RGPV, BHOPAL ***

Abstract - In this study, a GRA-based mathematicalapproach is used to perform multi-functional optimization. This GRA is used when several variables are optimized for more than one response characteristic at the same time. The primary focus is on solving the non-linear problem of multi-objective optimization with limited data.

The results of the confirmationexperiment at optimallevels a2 b2 c1 d3 and e1 show that the machiningforce decreasedfrom 17 19 to 15 92 n, the delamination factor decreased from 1 0063 to 1 0045, and the improved from 5 288 to 5 971 mm3/min. It explains how the DOE taguchi technique can be used to improve process outcomes in productionplanningand analysis. The analysis was conducted to evaluate the influences of the machining factors on the responses in order to determine the significant effect of the parameters on the quality characteristics of the test. This analysis was carried out with a 5% level of significance, i.e. with a 95% level of confidence. Surface roughness ANOVA result This study was carried out with a 5% level of significance, i.e. with a 95%level of confidence. Surface roughness ANOVA result The Cutting Tool (P=0.003) (47.73%%) has the greatest influence on the machining force. Spindle speed (P= 0.048) (18.30%) was followed by Feed rate (0.098) (13.30%) and Depth of cut (0.136) (11.27%). Surface roughness is a significant factor in the parameters of the current study.

Key Words DOE taguchi method, MRR, Grey relation analysis,glassfiberreinforcedpolymer,surfaceroughness andmachiningforce

GRA-based Taguchi optimization technique using experimentaldesignassistsincontrolling/reducingvarious errorsduringmanufacturingofGFRPcompositegear.

(3) Selection of various parameters for ranking has been donethroughresponsetable.Thep-valueisbelow0.02and henceitisfoundalltheprocessparametershavesignificant effect on the performance characteristics of GFRP. Rotary feed,cuttingspeed,cuttingfluidratioandcuttingfluidflow rate are identified as key significant parameters of gear shaper machine which control the performance characteristics. The optimum machining parameters are calculatedasrotaryfeed0.15mm/stroke,cuttingspeed240

strokes/min,cuttingfluidratio12%andcuttingfluidflow rate 30 ml/min. The significant parameters effect the performancecharacteristicsareat96%confidencelevel.The variation in predicted and experimental grey relational gradeisveryless(1.5%)andhencetheresultsarevalidated.

From the review of existing literature it is apparent that manyresearchhavebeencarriedoutonpolymercomposite gears performance based on milling machine by varying reinforcement, process routes, gear pair combinations of different materials but no study available on single optimization of cutting parameters of milling machine for minimumvariation/deviationofsurfaceroughnessoftooth whichaffectsthenoise,vibrationandloadcarryingcapacity. Root diameter deviation affects the root fillet radius, responsible for tooth beam strength; Tooth thickness variationcontrolsthepropermeshingofteeth,responsible for noise, vibration; Surface roughness affects the friction andlifeofteethinwear.

Due to anisotropic and heterogeneous structures of compositesmachiningofsuchmaterialswithconventional machiningprocessesoftenresultsinmaterialfailuressuch asmatrixcrackingfiberpulloutswellinganddelamination holesurfacefailure.[2]

In milling, machining force is regarded as one of the most importantparametersthataffectsoverallmachiningandhas a significant impact on the surface quality of the milled surface. To achieve appropriate machining results, it is critical to minimize machining forces; this is influenced directly or indirectly by all milling process input variables suchasspindlespeed,feedrate,anddepthofcut,cuttingtool geometry, workpiece material, tool-workpiece interface characteristics,tooltemperature,andmachiningvibrations.

Moreresearchhasbeenconductedinthefieldofmachining, whichincludesbothtraditionalproceduressuchasturning, milling, and drilling and unusual processes such as laser ablationandwaterjetcutting.[14]

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

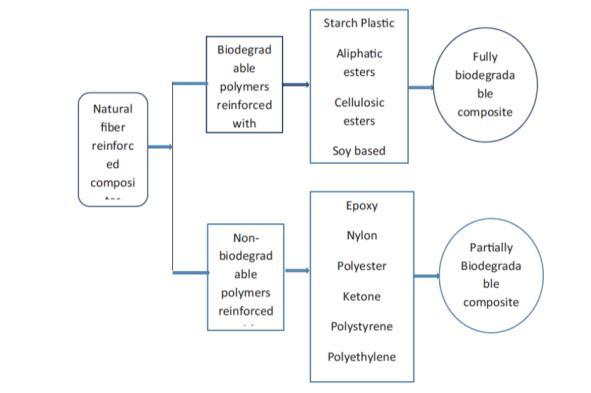

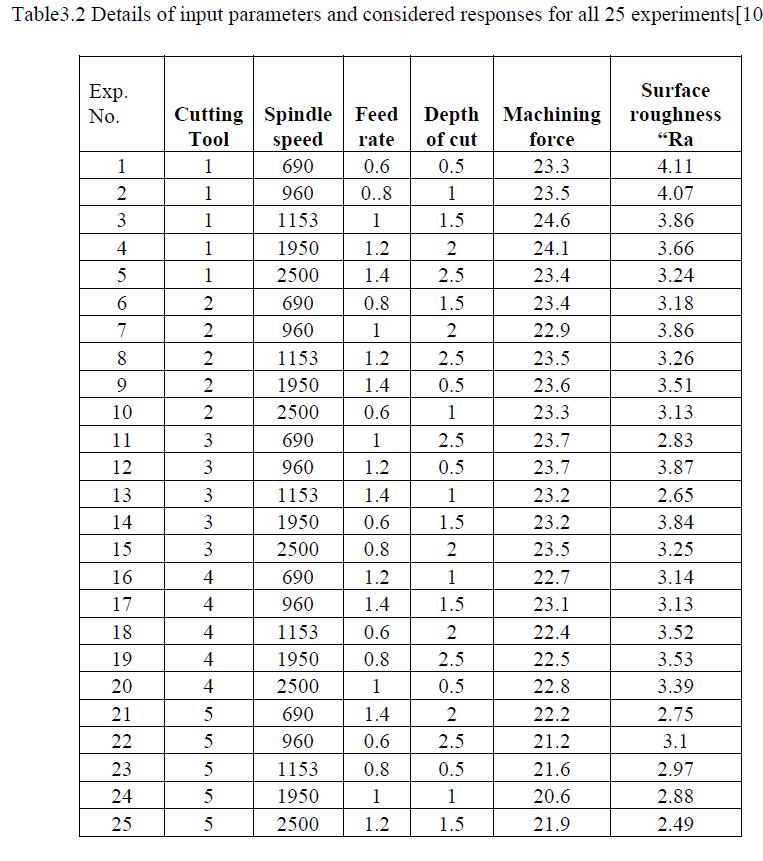

The current work focuses on investigating the effects of spindlespeed,feedrate,depthofcut,andcuttingtooltype, i.e.,geometry,onmilledsurfaceperformanceintermsofFm and Ra. Table 2 contains information about all of the combinations tested, as well as the machining force and surfaceroughnessvaluesforeachexperiment[10]. 2. Fig.2TypesofpolymersVscomposites[2]

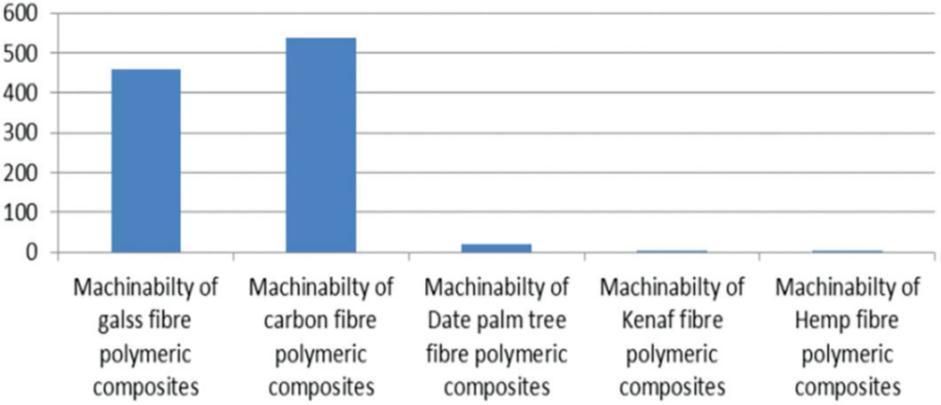

Thispaperhasprovidedacomprehensiveliteraturereview on cfrp machining covering scientific and technological achievements over the past 30 yr. in terms of machining processconditionsandcharacteristicscuttingtheoriesand thermal/mechanicalresponses.

From literature minimize all the output factors during drilling model optimization is carried out by setting the objectivesandadesirabilitybasedapproachisusedtoselect the optimum condition The objective function/optimizing variable bounds and optimum values of the factors are presentedintable7aspindlespeedof1070rpmfeedof01 mm/rev tool angle of 900 and tool diameter of 8 mm is optimumconditionsfordrilling[16]

TheresultsofANNconcludedthatexperimentno3obtained relativelymoreerrorthanremainingthedeviationbetween experimentalvaluesandpredictionvaluesarefoundinthe rangeof37%Depthofcutfactorhasmoderatesignificance 2292%.

Thefitsummaryrecommendedthatthequadraticmodelis statisticallysignificantforanalysisofdelaminationtheresult ofthequadraticmodelfordelaminationintheformofAnova

Theassociatedpvalueforthemodelislowerthan005ie a¼ 0 05 or 95 per cent confidence which shows that the model is considered to be statistically significant further factor a b c and b2 only have significant effects on delamination.[17]

In this experimental study conducting the Anova and considering to checking the results of the machining of customizedcarbidetippedtool2whybecauseitgivesthe

betterperformanceamongtheotherthreetools.Therewas good reliability made between the prediction and experimental values for both of two performance characteristics the machining force and the surface roughness.Aspertaguchioptimummachiningparameters availed and according to s/n ratios in comparison with actual parameters there was improvement of machining forceandsurfaceroughnessare063dband060db[18]

1.3.1

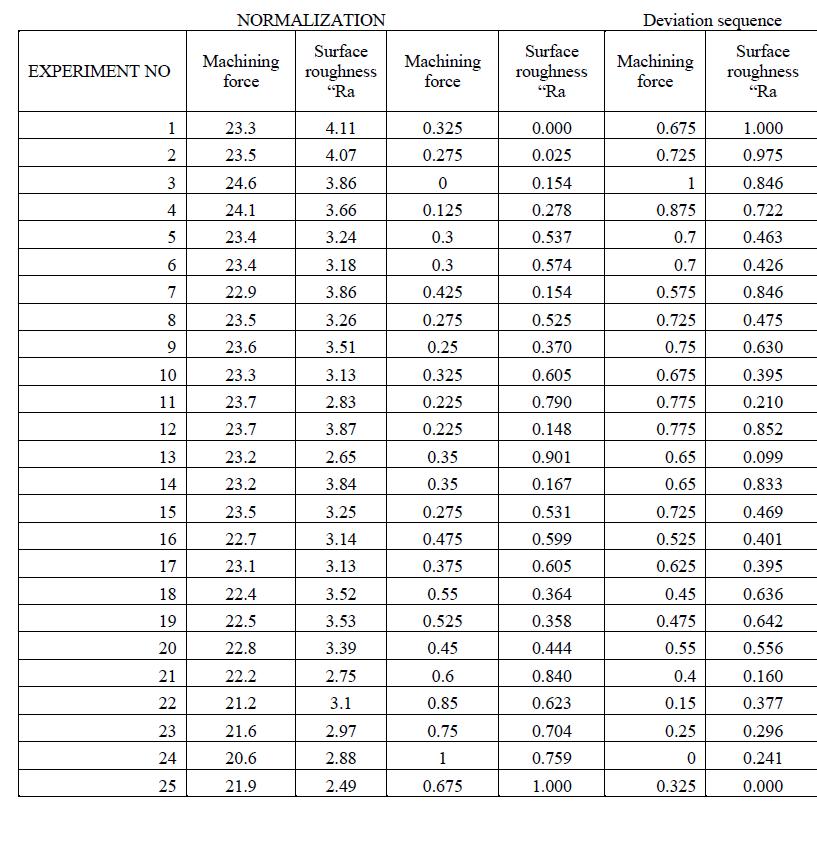

Atotalof25testswerescheduled.TheL25orthogonalarray architecture developed by Taguchi was used. Four critical parameters were considered when organizing the tests: spindlespeed,feedrate,depthofcut,andtypeofmillingtool usedinthemillingprocess;eachparameterwasadjustedat five levels. During the Taguchi study, the average value of experimentalresponseanditsrelatedsignal-to-noise(S/N) ratioforeachrunwereobtainedtoinvestigatetheeffectsof variousmachiningprocessparameters.

TheS/NratiowaschosenfortheTaguchianalysisbecauseit aids in describing the trial data's average (mean) and variables(standarddeviation).Thegoalofthisstudywasto achievethelowestmachiningforceandsurfaceroughness possible byoptimizingtheinputprocessparameters.Asa result,theS/N ratio will fall intothecategoryof"lower is better."Experimentswerecarriedoutonauniversalmilling machine with a spindle power of 10 kW and a maximum speedof3000rpm.Tokeeptheworkpiececentralandavoid vibrations,aspeciallydesignedfixturewasused.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

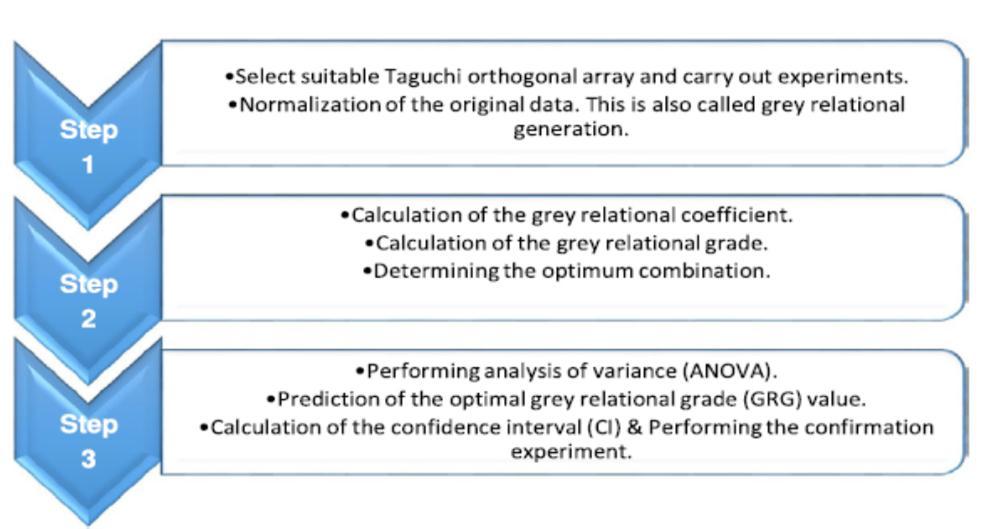

Fig3.2FlowChartStepsforgreyrelationalanalysis[2]

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

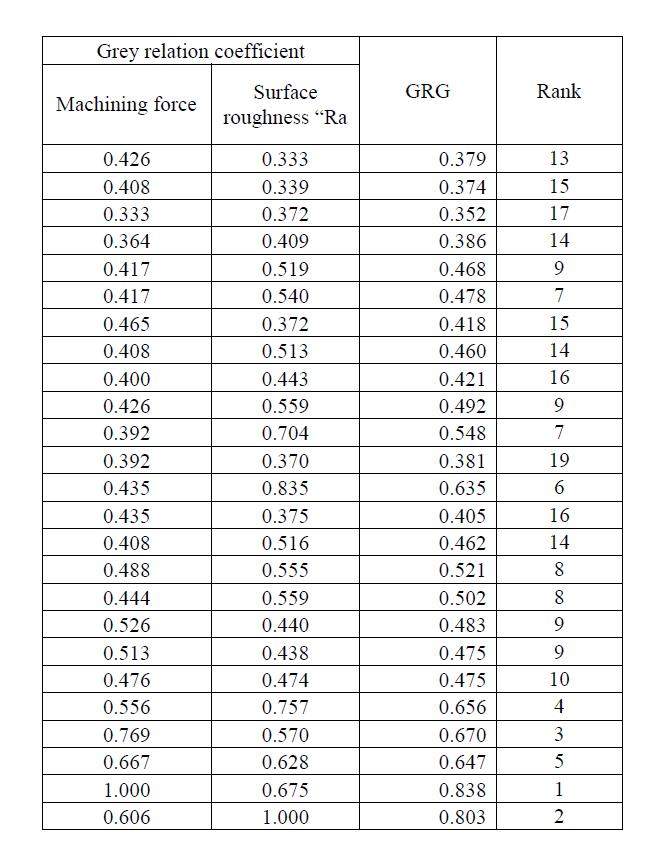

TheTaguchiOrthogonal Array(OA) technique,whichwas usedtodesigntheexperimentallayout,wasusedtoobtain the response values of Machining force and Surface roughness"Ra."Experiment24wasdeterminedtohavethe highestvalueofgreyrelationalgradeandwasrankedfirst. Thefactorsforexperimentnumber24aremachiningforce "Fm"(N)20.6,surfaceroughness"Ra"(m)2.88.

relationship.Now,theR-Sq(adj)valueis74.52%,indicating thatthedataarewellfittedforthenewsetsofvariables.

[1]S. Ghalme, A. Mankar, and Y. J. Bhalerao, “Parameter optimization in milling of glass fiber reinforced plastic (GFRP)usingDOE-Taguchimethod,”Springerplus,vol.5,no. 1,2016,doi:10.1186/s40064-016-3055-y.

[2]M. Altin Karataş and H. Gökkaya, “A review on machinabilityofcarbonfiberreinforcedpolymer(CFRP)and glassfiberreinforcedpolymer(GFRP)compositematerials,” Def. Technol., vol. 14, no. 4, pp. 318–326, 2018, doi: 10.1016/j.dt.2018.02.001.

[3]F.K.A.O.H.Alazemi,M.N.Abdullah,M.K.A.MohdAriffin, F.Mustapha,andE.E.Supeni,“OptimizationofCuttingTool GeometryforMillingOperationusingCompositeMaterial–A Review,” J. Adv. Res. Mater. Sci., vol. 76, no. 1, pp. 17–25, 2021,doi:10.37934/arms.76.1.1725.

Hencethegreyrelationalanalysisbasedontaguchimethod fortheoptimizationoftheAparticularlyimportanttoolis multi-responseproblems.ForpredictingtheMachiningforce andsurfaceroughness.

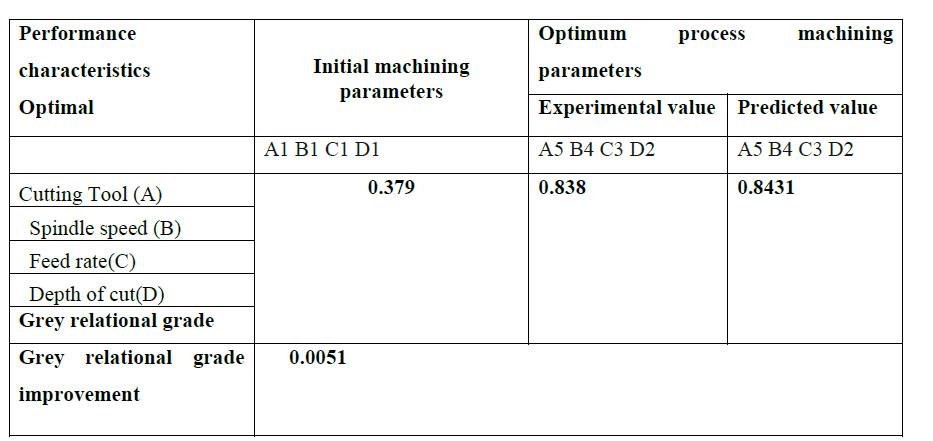

The improvement of grey relational grade from initial parameter combination (A1–B1–C1 D1 to the optimal parametercombination(A5B4C3D2)isfoundtobe0.0051

1.ThespindlespeedandfeedratehavenoeffectontheSR andMachiningforceofCFRPcompositelaminates.

2. The Grey-Taguchi method can be used to simplify and improve the optimization of numerous common performance criteria. According tothe responsetable,the maximumsettingfortheGRGforspindlespeedis4000rpm, feedrateis200mm/min,andcutdepthis0.5mm(A5B4C3 D2).

3.Thedepthofcutisthemostimportantfactorinfluencing theSRandDLF.TodeterminetheSRandDLF,cuttingdepth is a critical parameter that interacts heavily with spindle speed.

4.MachiningforceANOVAresultTheCuttingTool(P=0.003) (47.73%%) has the greatest influence on the machining force.Spindlespeed(P=0.048)(18.30%),Feedrate(0.098) (13.30%),andDepthofcut(0.136)(11.27%) arethe next mostsignificantfactorsforsurfaceroughnessinthecurrent study.

5. The R -sq value is 91.51%, indicating good agreement betweentheinputandoutputrelationships.Itdemonstrates that the input and output variables have a strong

[4]S.S.R.Raj,J.E.R.Dhas,andC.P.Jesuthanam,“Challenges on machining characteristics of natural fiber-reinforced composites–Areview,”J.Reinf.Plast.Compos.,vol.40,no. 1–2,pp.41–69,2021,doi:10.1177/0731684420940773.

[5]A.Sharma,M.L.Aggarwal,andL.Singh,“Investigationof GFRPGearAccuracyandSurfaceRoughnessUsingTaguchi andGreyRelationalAnalysis,”J.Adv.Manuf.Syst.,vol.19,no. 1,pp.147–165,2020,doi:10.1142/S0219686720500080.

[6]R.K.Thakur,K.K.Singh,andK.Kumar,“Investigationof millingcharacteristicsingraphene-embeddedepoxy/carbon fibrereinforcedcomposite,”Mater.TodayProc.,vol.33,no. xxxx, pp. 5643–5648, 2020, doi: 10.1016/j.matpr.2020.04.022.

[7]F.Authors,“Articleinformation :Optimizationofprocess parametersonmachiningforceandMRRduringEndmilling ofGFRPcompositesusingGRA,”2017.

[8]N. Deshpande, H. Vasudevan, and R. Rajguru, “Investigation of the machinability characteristics of GFRP/vinylestercompositeusingdesignofexperiments,” Int.J.Mach.Mach.Mater.,vol.15,no.3–4,pp.186–200,2014, doi:10.1504/IJMMM.2014.060549.

[9]J. P. Mugundhu, S. Subramanian, and A. Subramanian, “Analysis and optimisation of machinability behavior of GFRP composites using fuzzy logic,” Multidiscip. Model. Mater. Struct., vol. 11, no. 1, pp. 102–119, 2015, doi: 10.1108/MMMS-04-2014-0020.

[10]I.S.N.V.R.Prasanth,D.V.Ravishankar,M.M.Hussain,C. M.Badiganti,V.K.Sharma,andS.Pathak,“Investigationson performancecharacteristicsofGFRPcompositesinmilling,”

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Int.J.Adv.Manuf.Technol.,vol.99,no.5–8,pp.1351–1360, 2018,doi:10.1007/s00170-018-2544-2.

[11]R. Vinayagamoorthy, “A review on the machining of fiber-reinforced polymeric laminates,” J. Reinf. Plast. Compos., vol. 37, no. 1, pp. 49–59, 2018, doi: 10.1177/0731684417731530.

[12]I.S.N.V.R.Prasanth,S.Nikitha,R.Pulsingh,M.Sampath, S.Bazee,andC.M.Badiganti,“InfluenceofMillingProcess Parameters on Machined Surface Quality of Carbon Fibre Reinforced Polymer (CFRP) Composites Using Taguchi AnalysisandGreyRelationalAnalysis,”Int.J.Integr.Eng.,vol. 13,no.6,pp.76–88,2021,doi:10.30880/ijie.2021.13.06.

[13]D. Che, I. Saxena, P. Han, P. Guo, and K. F. Ehmann, “Machiningofcarbonfiberreinforcedplastics/polymers:A literaturereview,”J.Manuf.Sci.Eng.Trans.ASME,vol.136, no.3,2014,doi:10.1115/1.4026526.

[14]N.Shetty,S.M.Shahabaz,S.S.Sharma,andS.Divakara Shetty,“Areviewonfiniteelementmethodformachiningof compositematerials,”Compos.Struct.,vol.176,pp.790–802, 2017,doi:10.1016/j.compstruct.2017.06.012.

[15]G.Khavin,M.Gasanov,A.Permyakov,andV.Nevludova, A Numerical-Analytical Model of the Temperature Field DistributionDuringOrthogonalCuttingofComposites,vol.1. 2020.

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page617