International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN:2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN:2395-0072

1Head of the institute 2Assistant Professor in Mechanical Engineering Department, 3,4,5,6Students of D. A. Degree Engineering & Technology, Mahemdabad-Gujarat ***

Abstract - This review is focused on performance of various fuels used in internal combustion engine. The Conventional fuels used are Petrol, CNG and Diesel, while new alternative fuels for petrol, CNG and diesel are Biodiesel, ethanol, hydrogen, ethanol blended with petrol and diesel. Each of these alternative have different effect on performance on internal combustion engine. The use of these alternativesis due to limited amount of petroleum available. These alternative fuels can help petroleum last longer, because fuels like hydrogen are very much in abundant quantity, while fuels like ethanol can be produced as per needs and requirements. Effectiveness of petrol machine is substantially related to contraction rate of the machine. Typically contraction rate of petrol machine ranges around 6 to 9 when contraction rate is increased beyond 9.3 possibility of eruption will be increased. Applying the affair value from the trials and with the help of fine formulas brake power, specific energy consumption, energy mass inflow rate, and brake thermal effectiveness were measured.

Keywords: Internal Combustion Engine, Bio- diesel, hydrogen,Petrol,Diesel,CNG.

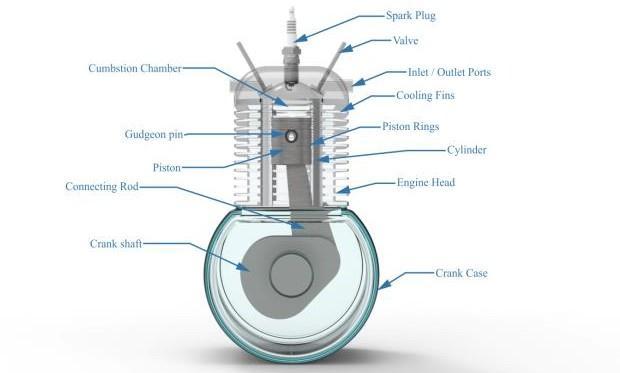

Aninternalcombustionmachine(ICEorICmachine)isa heat machine in which the combustion of an energy occurs with an oxidizer(generally air) in a combustion chamber that's an integral part of the working fluid inflow circuit. In an internal combustion machine, the expansion of the high- temperature and high-pressure feasts produced by combustion appliesdirect force to some element of the machine. The force is generally applied to pistons (piston machine), turbine blades (gas turbine), a rotor (Wankel machine), or a snoot (spurt machine).

This force moves the element over a distance, transubstantiating chemical energy into kinetic energy which is used to propel, move or power whatever the machine is attached to. This replaced the external combustionmachineforoperationswheretheweightor sizeof amachinewasmoreimportant.Energiesusedin ICE are generally produced from primary coffers. To

convert a sourcetoanenergy andbring this energy toa vehicle, well to tank (WTT) analyzes are made in terms ofenergyconsumption and hothousegas emigrations

Gasoline or petrol is a transparent, petroleum- deduced ignitable liquid that's used primarily as an energy in utmost spark- ignition internal combustion machines (also known as petrol machines). It consists substantially of organic composites attained by the fractional distillation of petroleum, enhanced with a varietyofcomplements.[5]

Ethanol can be produced from any substance that is convertible either to molasses or synthesis gas (which hasCOandH2). [8]Ethanolislargelysharp.Butchange in machine set up isn’t required as manufacturers allow mixing of small amount of ethanol with petrol directly. [4] Worldwide bio- ethanol production was increased from50billionlitersin2007toapproximately97billion liters in 2015. [9] Ethanol fuel has a "gasoline gallon equivalency"(GGE)valueof1.5USgallons(5.7L),which means1.5gallonsofethanolproducestheenergyofone gallonofgasoline.[10]

1 Dr.Dipesh Patel, 2 Mr. Priyank Machhi, 3 Patel Bhupendra, 4Amin Bhargav, 5Shrotriya Shrey, 6 Vanzara RajeshInternational Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN:2395-0072

Naturalgasisalsogainedfromfossilfuel,whichissimilar toliquidfuelanddiesel.Herenaturalgas can be recycled as itis essentially methane.

[11] Natural gas consists mainly of methane with small amount of ethane, propane, and butane. Very small concentrationsofinertgasessuchasN2andCO2arealso present.[12]

Vegetable canvases are chemically complex esters of adipose acids. These are the fatsnaturally present in oil painting seeds, and known astri-glycerides of adipose acids. Becauseof their high molecular weights these fats have high density causing major problems in their use as energies in CI machines. These motes have to be resolve into simpler motes so that they've density and other parcels similar to standard diesel canvases. Modifying the vegetable canvases (to make them lighter) can be achieved in numerous ways, including; Pyrolysis, Micro emulsification, Dilution and Transesterification. Among these, Transesterification is the most generally used marketable process to produce clean and environmentally friendly light vegetable oil paintingenergyi.e.biodiesel.[3]

Although hydrogen the most common element in the world and it doesn't live in nature in its pure state, so it has to be produced from sourceslike water and natural gas. The environmental impact and energy effectiveness of hydrogen depends on how it's yield. Hydrogen has been studied as an indispensable gas energy for a long time. Hydrogen has not some problems associated with liquid energies, similar as vapor cinch, cold wall quenching,shyvaporizationand spare mixing.Hydrogen has clean burning actions. As hydrogen is burned, it products substantially water. The combustion of hydrogen doesn't bring out poisonous products similar as hydrocarbons, carbon monoxide and carbon dioxide. The most important advantageof hydrogen is that it does not produce CO gas, which is one of the most important sources of global warming. In addition, hydrogenhasawiderlimitofflammabilitythangasoline, diesel and natural gas. (2) Hydrogen always sounded seductive from several points of view it mixes fluently withair,theperformingadmixturehaswideflammability limits,isfluentlyburnedandhasalargehoneyspeed.(7)

The chemical formula for propane energy is C3H8.Propane is extensively known as Deicedpetroleum gas (LPG) or bus gas in Europe. Propane is a gas at

normal temperatures and pressures. It's stored onboard a vehicle in a tankpressurized to around 300 pounds per square inch about twice the pressure as in anexaggerated truck tire. Under this pressure, propane becomes a liquid with an energy viscosity 270 times lesser than the gassy form.Agallonofpropanehasabout25lowerenergythana gallonofgasoline.In liquid form propane turns into a tintless & odorless liquid. Aspressure is released, the liquid propane vaporizes and turns into gas that's used for combustion.Anodorant,ethylmercaptan,isaddedforleak discovery. In liquid state, propane are fast to cache & the tank to store liquid propane is affordable but the avail of propane is less compared to gasoline LPG and other gassy energies have common parcels that give them some advantagesanddisadvantagesrelativetogasoline.Propane has lower viscosity and stoichiometric energy – air rate than gasoline, therefore it could reduce the specific energy consumption(sfc). propane can be used at advancedcontractionratesduetoadvancedoctanenumber as a consequence of this property, machine performance, power and thermal effectiveness would be bettered. [1] There are also disadvantages of LPG fuel application to internal combustion engines. Major issues might include a higher thermal load of the combustion chamber due to a higher combustion temperature of light hydrocarbons and virtuallynolubricityofgaseousfuels.[13]

Octane Number of Different Fuels [14]

Fuel Type Octane Number Petrol/Gasoline 91-93 Bio-Ethanol 108 CNG 135 Bio-Diesel 45-67 Hydrogen 130 LPG/Propane 112

Table1forOctaneNumber

Literature Review

1. Review of energies for internal combustion machines in the aspect of frugality, performance, terrain and sustainability. Advantages anddisadvantages of each type of energies in terms of economics, performances, and surroundings were bandied. Reviews of colorful types of energies including reactionary energies like gasoline and diesel and indispensable energies like LPG, CNG, Alcohol, Bio-diesel and P- series energies. The hunt for indispensable energies which promise a harmonious correlation with sustainable development, energy conservation, effectiveness and terrain preservation has come largely important. Developed and developing countries which warrant of crude oil painting reserve

International Research Journal of Engineering

Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN:2395-0072

countries spend huge quantum of plutocratto buycrude petroleum oilpainting.(1)

2 Hydrogen increases the effectiveness of combustion, reducesemigrationsandgiveshighperformance,whenis added as 20 to energies. Ethanol can be used as pure energy or mixed with different energies in internal combustion machines. Indispensable energies for new ICEoperations.(2)

3. A review of the machine performance using indispensableenergiesforinternalcombustionmachines has been published in the journal Accoutrements moment.ThestudywasconductedbyDrVenkataSundar Rao, aprofessor at the Basaveshwar EngineeringCollege, Bagalkot-587102,India.(3)

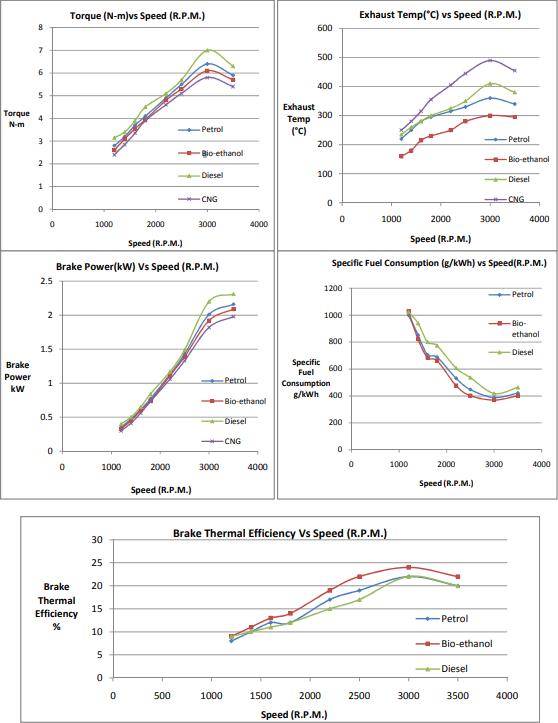

4. The author(s) of this publication are Faisal Kader, Abdullah Noor- e- Mostofa andMohammadReyadArefin Shuvo at the Islamic University of Technology in Dhaka and the Military Institute of Science and Technology in Chittagong ,Bangladesh independently. Compressed Natural Gas (CNG) has lower exhaust temperature (300 °C) and advanced boscage thermal effectiveness (24) compared to petrol. CNG is cost-effective and good for terrain,but it also has the loftiest affair necklace (5.8 Nm)andboscagepower(1.98kW).[4]

5. Hydrogen as an energy in Internal Combustion machinesisaresultforthenearfuturetorealizezeroCO 2 emigrations. The paper gives an overview of the developmentofhydrogenfueledICmachinesbythemost importantautomanufactures(Ford,Bewitch.). Hydrogen can be used as an energy for business by replacing reactionary energy machines with hydrogen- powered bones. There are several reasons to consider converting gasoline, diesel or natural gas machines into hydrogen powered bones. There are four generations in development of hydrogen powered machines forelectric vehicles.(5)

6. The trouble posed by climate change and the seekingforsecurityofenergyforceareissueshighonthe political docket. A number of manufacturers are now leasing demonstration vehicles to consumers using hydrogen- fueled internal combustion machines (H 2 ICEs)aswellasenergycellvehicles.(6)

7. Journal of Hydrogen Energy, Vol 1, pp. 153- 172. published in Northern Ireland. A detailed discussion is givenofthethermaleffectivenessofhydrogenmachines. No emigrations are slightly small for energy- air parity ratesbelow0.55.(7)

8. Ethanol has been the most extensively delved alcoholicenergyinICmachine.They'vebroughtintolight the parcels of ethanol and the effect of colorful ethanol blends on the performance of. spark- ignition machines.

It also examines the parameters concentrated for this study, including the machine boscage necklace, machine volumetriceffectiveness,thermaleffectivenessandthermal effectiveness.(8)

9. Ethanol(C2H5OH) arefavorableforIC Machines due to their high- octane standing, burning rapidity, and wider flammability limits. When alcohol- gasoline energy compositeswereusedtheboscagepowerdroppedandthe boscage specific energy consumption increased as compared to those of gasoline energy. Theenergy that's used in internal combustion machines will fulfill all the musts of cost effectiveness, maximum thermal effectiveness, excellent machine performance and still remaincleansufficienttocovertheterrain.(9)

10 StudyofModifiedInternalCombustionEnginetoRun with' Ethanol' August 2017. Ethanol can replace conventional gasoline to be used as an energy for automotive. The optimal application of ethanol in the modified gasoline machine was done by changing the contractionrateofthemachine.StudyofModifiedInternal Combustion Engine to Run with' Ethanol' is published in theInternational Journal of Engineering andApplied lore’s (IJEAS) ISSN 2394-3661,Volume-4,Issue-8August2017. Ethanol canreplaceconventional gasolinetobe usedas an energy forautomotive machines. CarburetorofIC machine was modified so as to maintain proper stoichiometric rate whichbetteredenergyeffectivenessandavail.(10)

11. The author(s) are Musthafah Mohd. Tahir, M.A. Salim, RosliA. Bakar, M.Z. Hassan, Abdul MuhaiminM.S. Khatib, Hang Tuah Jaya, 76100 Durian Tunggal Melaka, Malaysia. It was presented at the 2nd International Conference on Sustainable Energy Engineering and Application. Peer- review under responsibility ofScientific Committee of ICSEEA 2014 356. Musthafah Mohd Tahir etal. / Energy Procedia 68(2015) 355 – 362. The main dangerous emigration from liquid energy are CO and NOx emigration(11).

12 CompressedNaturalGas(CNG)hastheimplicittogive a good concession ineffectiveness, cost, and emigration. Due to its advanced octane number, machine effectiveness canbeincreasedthroughadvancedcontractionrates.Ithas lower product of adulterants when burned and is cornucopiainnature.Naturalgashasanimportantposition among indispensable energies and an eventuality for low emigrationofadulterantswhenusedICmachines.Ingassy stateit'slighterthanair,tintless,andodorfree.(12)

13. PerformanceofInternalCombustionEngineFueledby Liquefied Petroleum Energy with Water Addition. The results of empirical exploration have been presented, i.e., the energyconsumption and contaminant emigration. An attempthasbeenmadetodissectwateradditionincolorful forms to the operating medium of an LPG fueled machine. It's estimated that the addition of water has a salutary

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN:2395-0072

effect on the thermal effectiveness of rotation, and the reduction of carbon monoxide, hydrocarbons and nitrogenoxidesemigration.(13)

14. Maejo International Journal of Science and Technology- May 2019 Composition Enzymatic hydrolysis of small- unfolded nuts edge (Cyperus difformis) with alkaline pretreatment for bioethanol product. Author(s)RameshprabuRamarajMaejo

University, Chiang Mai 50290, Thailand and Yuwalee Unpaprom,Mijst.Bioethanolisagoodcoverforgasoline due to itsrenewable nature, high octane number and high energy content. It can be produced from different kindsofbiomasssimilarassugar-andbounce-grounded crops, lignocellulosesbiomassandalgalbiomass.(14)

Fig.2Performanceofdifferentfuel

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN:2395-0072

Comparison of alternative Fuels with Petrol and Diesel [4]

R.P.M. (Rev/min)

1200

Fuels Torque (Nm)

Temperature °C Brake Power (kW)

Time for 8ml(s)

Brake Power Rate(kg/hr) Brake Power (g/kWh)

BrakePower%

Petrol 2.80 220 0.35 61.45 0.35 1000 8

Bio-ethanol 2.60 160 0.33 63.3 0.34 1030.3 9

Diesel 3.15 235 0.40 58.45 0.41 1025 9

CNG 2.40 250 0.30 - - - -

Petrol 3.20 250 0.47 53.76 0.4 851.06 10

Bio-ethanol 3.10 180 0.45 57.87 0.37 822.22 11

1400

Diesel 3.40 260 0.50 51.12 0.47 940 10

CNG 2.85 280 0.41 - - - -

Petrol 3.70 280 0.61 49.5 0.43 704.91 12

Bio-ethanol 3.55 215 0.60 52.44 0.41 683.33 13

1600

Diesel 3.90 280 0.65 46.45 0.52 800 11

CNG 3.35 315 0.56 - - - -

Petrol 4.10 295 0.77 39.87 0.53 688.31 12

Bio-ethanol 3.95 230 0.74 44.12 0.49 662.16 14

1800

Petrol 4.90 315 1.13 36.9 0.58 531.27 17

Bio-ethanol 4.80 250 1.11 40.18 0.53 477.48 19

Diesel 4.50 300 0.84 37.22 0.65 773.8 12 CNG 3.90 355 0.73 - - -2200

Diesel 5.10 325 1.17 34.15 0.71 606.84 15

CNG 4.60 405 1.06 - - - -

Petrol 5.50 330 1.43 33.25 0.64 447.53 19

Bio-ethanol 5.30 280 1.39 38.21 0.56 402.88 22

2500

Diesel 5.70 350 1.49 30.18 0.8 536.91 17

CNG 5.10 445 1.33 - - - -

Petrol 6.40 360 2.01 27.45 0.78 388.06 22

Bio-ethanol 6.10 300 1.92 30.14 0.71 369.79 24

3000

Diesel 7.00 410 2.20 26.11 0.92 418.18 22

CNG 5.80 490 1.82 - - - -

Petrol 5.90 340 2.16 23.3 0.91 421.3 20

Bio-ethanol 5.70 295 2.09 25.66 0.84 401.91 22

3500

Diesel 6.30 380 2.31 22.45 1.07 463.2 20

CNG 5.40 455 1.98 - - - -

Table1.Differentfuelsindifferentparameters

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN:2395-0072

1. Ethanol is still far from being economically competitive when compared to energiesdeduced from fossilenergies.

2. Biodiesel canachievean energy rateaslow asthree to one. The product of biodiesel from crops, similar as soybean,canaffectinadverseenvironmentalgoods.

3. Hydrogen is a largely ignitable substance and explosive in nature; it cannot be fluently transported fromoneplacetoanotheranditcanbe generated by the hydrolysis of water butit'saveritablypreciousprocess.

4. Petroleum is unfriendly to the terrain. The transportation of petroleum tumbles. Petroleum is a skimp resource. Petroleum releases dangerous poisons. Petroleumcontributestoacidrain

In the overall concept wecame to understand that these various fuels have different efficiencies in internal combustion engine. Whilediesel gives more torque and brakepower, bio- ethanol has leastexhaust temperature and specific fuel consumption and hydrogen is least harmfultoenvironmentinthesevariousfuels.

[1] Review Of Fuels For Internal Combustion Engines In The Aspect Of Economy, Performance, Environment And Sustainability M. Faizala,B, M. H. Hamzahb , A. Navaretsnasinggam B Aadp, Taylor's University Lakeside Campus, 47500 Selangor,Malaysia

[2] AlternativeFuels forInternal CombustionEngines

Submitted: August 22nd, 2018, published: April 9th, 2019 Written by Mehmet Ilhanilhak, Selimtangoz, SelahaddinorhanakansuandNafizkahraman

[3] Pmme 2016 A Review on Performance of The Ic Engine Using Alternative Fuels Mr. Venkatasundar Rao.K,Dr.S.N.Kurbet,Dr.VinayV.Kuppast

[4] Study Of I.C. Engine Performance Using Different Fuels Faisal Kader, Abdullah Noor-E- Mostofa And MohammadReyadarefinshuvo

[5] Hydrogen Fuelled Ic Engine – An Overview, Vvn Bhaskar, Dr. R. Hari Prakash, Dr. B. Durga Prasad, December2013

[6] Hydrogen-Fueled Internal Combustion Engines, SebastianVerhelst,December2009

[7] Performance And Emissions Of Hydrogen Fueled Internal Combustion Engines? P. C. T. De Boer, W. J. Mclean and H. S. Homan Cornell University Ithaca, Ny 14853,U.S.A.

[8] Effects of Ethanol Blends on Performance of Spark Ignition Enginea Review Prakhar Chansauriaa, R. K. Mandloib,2017

[9] An Overview On Ethanol Use In Ic Engine As Alternative Fuel, Mr. Ravindra Deshpande, N. S. PoonawalaDr.MaheshP.Nagarkar,June2021

[10] Study Of Modified Internal Combustion Engine To Run With Ethanol, Sajag Poudel,Dipan Deb, August 2017

[11] Performance Analysis of a Spark Ignition Engine Using Compressed Natural Gas (Cng) As Fuel Musthafah Mohd.Tahira,M.S.Alia,M.A.Salima, Rosli A. Bakarb, A. M. Fudhaila, M.Z.Hassanc, Abdul Muhaimin M. S., 2014

[12] UseofNatural GasinInternal Combustion Engines, BruceChehroudi,January1993

[13] Performance Of Internal Combustion Engine FueledByLiquefiedPetroleumFuelWithWaterAddition, Maciej Paczuski, ZdzisławChłopek, Marcin Marchwiany, Paweł Bukrejewski, Jacek Biedrzycki, Piotr Wójcik, September2016

[14] Enzymatic hydrolysis of small-flowerednuts edge (Cyperusdifformis)withalkalinepretreatment for bioethanol production, Rameshprabu Ramaraj, YuwaleeUnpaprom,May2019

1)Name:Asst.professor, Mr.Priyank Machhi

EducationalQualification:MEIn Thermal

Engineering.

2) Name:PatelBhupendra R

EducationalQualification: Diplomain Toolanddesignengineering(IGTR) BEMechanicalEngineering.(GTU) Skills:SolidWorksMechanical

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN:2395-0072

3)Name:AminBhargav.D EducationalQualification:BE MechanicalEngineering.(GTU)

Skill:BasicSolidWorks Mechanical&FDM

4)Name:ShrotriyaShrey.J EducationalQualification:BE MechanicalEngineering.(GTU)

Skill:BasicSolidWorksMechanical &3DPrinter

5)Name:VanzaraRajesh.N EducationalQualification:BE MechanicalEngineering.(GTU)

Skill:BasicSolidWorksMechanical &Autocad