International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

1 M.Tech (Construction Management) Student, Srinivas University Institute of Engineering and Technology. Mukka, Mangalore

2 Associate Professor, Dept of Civil Engineering, Srinivas University Institute of Engineering and Technology. Mukka, Mangalore ***

Abstract - This project thesis titled “A study on the qualitative analysis of materials management in Kerala construction industry” is an attempt made on studying and assessingthematerialmanagementprinciplesandpracticesin constructionindustryinKerala.Theobjectiveofthestudyisto understandabouttheproblemsoccurringintheorganization because of improper application of materials management and to find the factors affecting material management in construction projects. In the construction industry, material management is critical for the successful and timely completion of a project. When the planning, material identification, and material management systems are inadequate, the project's cost rises. Labor productivity will suffer as a result of material shortages and insufficient storage. A good material management system on a construction site can help to avoid project delays and cost variations. This results in better planning, higher labor productivity, accurate schedules, and lower project costs.

Key Words: Materials Management, Construction, Civil Engineering, Storage, Planning.

MaterialsManagementistheprocessofplanning,executing, andcontrolling fieldactivitiesinconstruction, The goal of material management is to ensure that construction materialsareavailablewhenneeded.Materialmanagement is concerned with the principles and practises that effectively reduce the cost of materials used in a project. Materialmanagementisthelineofresponsibilitythatbegins with supplier selection and ends when the material is deliveredtoitsdestination.

Materials Management is concerned with the planning, acquisition,storage,andprovisionofappropriatematerials ofthe appropriatequalityandquantityattheappropriate locationand timeinorder tocoordinate and schedule the construction activity. Materials management is a single manpower organisation concept that encompasses all activitiesandlineresponsibilitythatbeginwiththeselection and personnel primarily concerned with the flow of materialsintoandwithinanorganisation.

Materials Management is a critical component of project management. Materials are a major expense in a construction project, so lowering procurement costs increasesthechancesofloweringoverallprojectcosts.Poor material management can lead to increased construction costs.Efficientmaterialmanagementcanresultinsignificant project cost savings. Budget overruns, delays, and claims plaguefartoomanyconstructionprojects.Awell-executed materials management programme can ensure the timely deliveryofmaterialsandequipmenttothejobsite,allowing forbetterworkfaceplanning,increasedlabourproductivity, betterschedules,andlowerprojectcosts

Material management is defined as “The function responsible for the coordination of planning, sourcing, purchasing,moving,storingandcontrollingmaterialsinan optimummannersoastoprovideapre-decidedserviceto thecustomerataminimumcost.”

TheInternationalFederationofPurchasingandMaterials Managementacceptthedefinitionofmaterialsmanagement as “Materials Management is a total concept having its definite organization to plan and control all types of materials,itssupply,anditsflowfromrawstagetofinished stage so as to deliver the product to customer as per his requirementsintime”.

1.2 Different stages of material management are:

PlanningandScheduling

MonitoringandControlling

OrganizationandPersonnel

Procurement

Delivery

StorageandStorageFacilities

Usage

SurplusandWasteControl

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

The first and most important process in any project is planning. Material planning, a critical function of material management, is inextricably linked with project planning andcontrolsetup.Theentirematerialprogrammemustbe planned in order to meet the project deadline. Indeed, planningandschedulingareimportantintermsofincreasing productivity,profit,andensuringthatconstructionprojects arecompletedontime.

All construction activities in material management are monitoredandcontrolledtoensurethattherightmaterials with the exact quality are available at the right time and placesuitableforthelowestcostconstructionprocess.Itisa stepinwhichfacilities,personnel,resources,andcapitalare monitored and controlled to have a significant impact on constructionprojectoperations.

The material management process is structured in such a waythatitallowsforintegratedplanningandcoordination of material flow in order to maximise resource utilisation andminimisecosts.Theorganisationmustbedesignedto ensure that work is completed on time, with material personnel located at an appropriate level of project managementandinfluencingdecision-making.

Floatingenquiryindentsconductprimaryinvestigationsto developsourcesformaterialprocurement.Itisprocessedby thematerialprocurementresponsiblepersonnelinorderto invitequotationswithmaterialsampleswhereapplicable.

Delivery ensures the efficient use of workforce and productionorprocessinconstructionprojectsbyorganising themovementofvehicles,people,andmaterials.Oneofthe major factors influencing cost and time during the constructionstageismaterialrouting.

Theprovisionofrequiredspace,protection,andcontrolof buildingmaterialsandcomponentsheldonsiteduringthe construction process is referred to as material storage. A goodandsystematicstorageofmaterialsallowsforbetter materialmanagementinconstruction.

Material usage is the facilitation that allows for their movement and placement. The construction industry employs a wide range of building materials for various

aspects of home construction. Architects work with structural engineers to determine the load-bearing capabilitiesofthematerialstheyrecommend.

Wastereductioncanbeaccomplishedthroughazero-waste attitude, proper design decisions, site management, and proper standardisation of construction materials. Waste management on construction projects can also help to reduce waste. Every construction personnel involved in minimisingtheoverallwastegenerationattheprojectmust plan the project activities at each stage. The waste rate estimation method can be used to improve material handling,reducewaste,andincreaseproductivity

Tomanageinterfaceproblemsbetweenfunctions,amaterial managementfunctionisestablished.Thebenefitsthatcanbe expected from the use of material management are those that arise when a systems approach is used to handle an organization'sday-to-dayactivitiesasinterconnectedparts oftheoverallprocess.

Theseadvantagesinclude:

• Improvedcoordinationofactivities.

• Reducedsub-optimization

• Increasedflexibility

• Balancedstocksandfewerobsoletestocks

• Lower purchase prices and better delivery conditions

• Lowerstorageandtransportationcosts

Theobjectiveofthepaperistostudythedifferentmaterial management procedures practiced currently in local constructionprojectsandalsoidentifythefactorsaffecting materialmanagementinconstructionprojectsinthestateof Kerala. The primary goal of material management is to reducethecostofmaterialstothegreatestextentpossibleso that the final products are more competitive and the organization'sprofitincreases.Thisstudywillgeneratealist ofrootcausesforineffectivematerialmanagementthatcan be used as a benchmark tocontrol the existing and future projects.Furthermorethemostconcerningissueslikecost overrunanddelayintermsofprojectdeliveryanditsrelation withthecurrentmaterialmanagementpracticewillreveal theweaknessinthecurrentmaterialmanagementpractices tothestakeholders.Apartfromthisresearchbeingusefulto the field professionals, this study will be valuable for the academicianstoo.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

Theprojectfocusesonthefollowingobjectives:

• To identify the problems faced in material management.

• To identify the critical factors in various stages of materialmanagement

• Recommendationstoreducetheproblemsfacedin materialmanagement.

[1]NarimahBintiKasim(2008):Thisresearchfocusesonthe creationofatooltohelpconstructionprojectsimprovetheir materials managementconcepts and practices. Integrating materials management and resource modelling allows for investigation. This development will be based upon management recognition of the significance of materials management, combined with extensive pressure upon the costs and efficiency in the functions which make up the materials management systems .The incorrect control of materials during project execution is a critical element negatively affecting project performance. The case studies under discussion involve procedures used in construction projectsthathavemajorissueswithmaterialsmanagement.

[2] Anusha Rajendran K (2011): This study examines the implementationofMaterialCodingandMaterialRequirement Planning on a residential project. It also emphasises enhancingtheprojectsite'smaterialstorageefficiency.The study does not include non-consumable products, and the workwascompletedinashortamountoftime.Thework's outputdoesnotincludeathoroughexaminationofeachand everyprojectitem;rather,onlyafewsignificantelementsare examined.

[3] Abhilin G B, and Vishak M S” (2017): Poor material managementisoneoftheleadingcausesofbuildingproject delays.Thematerialmanagementplanaimstoensurethat the right quality and quantity of materials are identified, purchased,transported,andhandledonsiteinatimelyand cost-effective manner. Time, money, and quality are three interrelated concerns in every building job. Control and management are required. It is necessary to change the material management process in order to make a profit. Using information and communication technologies technology,accuratematerialusage,stockingmaterial,and materiallocationmayallbefound.Itsavestimeandmoney byreducinglabour-intensiveerror

[4] Harsh Soni (2016) this study explored the current practice of Material Management in construction industry and analyzed using ABC, SDE, & EOQ inventory control technique.Thepurposeistofindoutthewaysofmanaging theinventoryproperly,sothattherewouldbealittleimpact on the profits. They conclude that ABC analysis provides identifying those items that make the largest impact on a

company’soverallinventorycostperformance.SDEanalysis inveryusefulinknowingpresentdayscarcityofmaterials,in lead time and deciding upon purchase strategies. EOQ maintainsthesufficientmaterialsafetystockinperiodshort supply and reduced material wastage. Economic Order Quantitytotalinvestmentisreducedandnooforderismore in a year. So, Rate of Interest is increasing in actual site orderedmaterial.

A literature review is typically conducted to better understand the topic, identify the problem, and provide appropriatesolutionssuggestedbyvariousresearchersinthe project. Various researches in material management and inventory management are studied to learn about the problemsencounteredintheindustryaroundtheworld.It aidsindiscoveringandcomprehendingthevariouspossible solutionsthatcanbeobtainedfromliteratureresearch.

The research approach adopted in this project is qualitativemethodology.Inthisstudythequestionnairewas preparedfollowed byliterature reviewrelated to material management. Information collected through the literature review was used to generate questionnaire surveys. The structuredquestionnaireismostlikelythemostwidelyused datacollectiontechniqueforsurveyresearch.Questionnaires havebeenwidelyusedindescriptiveandanalyticalsurveys togatherfacts,opinions,andpointsofview.

Methodologyofthestudyisasfollows.

Questionnaires have been widely used in descriptive and analytical surveys to gather facts, opinions, and points of view. It improves confidentiality, strengthens internal and externalvalidity,simplifiesanalysis,andsavesresources.Asa source of primary data, a questionnaire survey was conducted.Thedatagatheredfromtheliteraturereviewwas used to create questionnaire surveys. This is a set of questions that have been developed to provide useful

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

answerstoresearchers.Thesurveywasdividedintosections basedontheresearchgoalsandobjectives.Eachsectionwas given a title that reflected its purpose and purpose, and questionswereusedtocoverthemainareasofresearch 4.2 Questionnaire:

MATERIAL STORAGE

Piling up of inventory items and controlling of the same is most difficult taskatsite. 22. Management of surplus materials consumesalotofspaceandincurscost

Storageconstraints 24. Problems with de-centralized processingofmaterialstoandfromthesite tostorage 25.Inadequatetrainingpracticesgivento thestoreincharge 26.Difficultyindeliveryoflongleadtime materials

SITEFACTORS 27. Regulation consideration: the permission from local authority to deal with materials delivery into the constructionsite

28.Projectsizechallenge:Thescale/sizeof the project and physical access problems withtrafficoverflowandsurroundinglocal roadsneartheconstructionsite

29.Improperhandlingofmaterials:Thisis related to poor handling of materials by sitelabor.

30. No proper stock yard available for storing of materials (steel and shuttering material’s)leadingtomaterialwastage.

31. Site access problems: The single site accesspointledtotrafficcongestionwhen many vehicles come to the construction siteatthesametime.

32. Small loading area: This leads to constraintsintheloadingandunloadingof materials

34. Change in design according to site conditions leading for change in level differenceduringexcavation

35. Inaccessibilitytothesiteareaduring harshweatherconditions.

36. Work diversion of personnel’s.Concentrationofthemanagementtowards otherblocksinthesameprojectsleadingto workdiversion.

37. Rework due to inevitable reasons occurred

38.Materialunavailabilityatsite

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

The weight and authenticity of the research are heavily reliant on the validity and dependability of the data collected. Data are frequently thought of as 'the facts,' or things that are known to be true. But data are social products. The records produced are not reality in and of themselves; rather, they are the result of researchers' attempts to observe or measure traces or evidence of phenomenaoccurringwithincomplexsystems.Dataforthis studyweregatheredusingprimarydatacollectionmethods.

For this study the primary data was collected using questionnairesbythehelpof‘Googleform’aswellasdirect communicationwiththeeStakeholders.Thequestionnaires wastransmittedtothetargetedrespondentsandtheywere expectedtofillthisformandtosubmitthesame.

Eachstatementinthesequestionsshouldberatedonascale fromstronglyagreetostronglydisagree,startingwiththe ratingsystemwasgivenasfollow;

Stronglyagree–5,Agree–4,Satisfactory–3,Disagree–2 stronglydisagree–1.

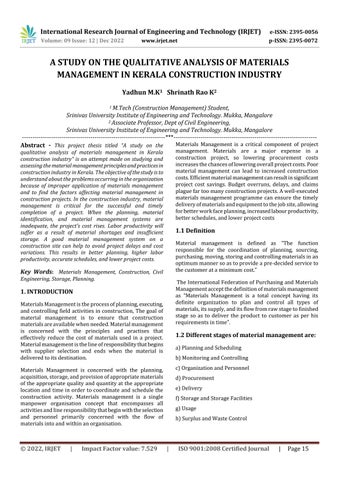

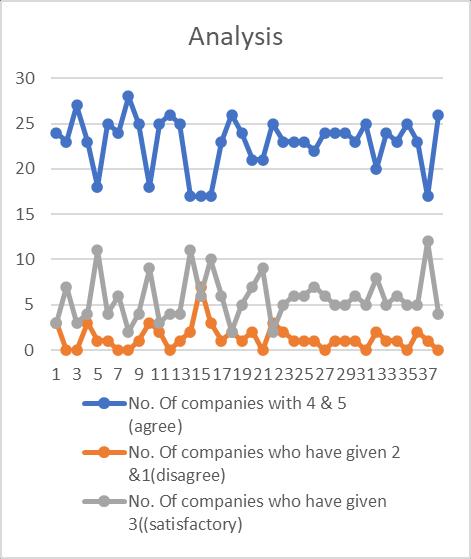

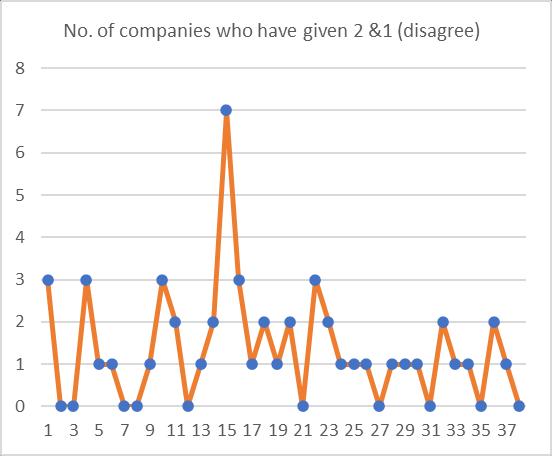

Table -2: ResultAnalysisChart

Question No No.Ofcompanies with4&5(agree) No.Ofcompanieswho havegiven2&1(disagree) No.Ofcompanieswho havegiven3((satisfactory) 1 24 3 3 2 23 0 7 3 27 0 3 4 23 3 4 5 18 1 11 6 25 1 4 7 24 0 6 8 28 0 2 9 25 1 4 10 18 3 9 11 25 2 3 12 26 0 4 13 25 1 4 14 17 2 11 15 17 7 6 16 17 3 10 17 23 1 6 18 26 2 2 19 24 1 5 20 21 2 7 21 21 0 9 22 25 3 2 23 23 2 5 24 23 1 6 25 23 1 6 26 22 1 7 27 24 0 6 28 24 1 5 29 24 1 5 30 23 1 6 31 25 0 5 32 20 2 8 33 24 1 5 34 23 1 6 35 25 0 5 36 23 2 5 37 17 1 12 38 26 0 4

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

Chart -4-OverallResultAnalysis

Thepurposeofthisstudywastoidentifythefactorsaffecting materialsmanagementinconstructionprojectsintheState of Kerala and their effects and solution. The factors were compiledintoaquestionnaire,andresponseswereobtained fromstakeholdersinvolvedinresidentialprojectsinKerala. BasedontheresearchintheKeralaconstructionindustry,I have discovered top 15 most common factors affecting material management. Based on the response from the stakeholders,afteranalysingbasedonthefeedbacksofthe questionnairesurvey,wecanconcludethatdifferentfactors affecting at each stage of material management and are treatedindifferentform.

Thefollowingconclusionsare:

1.Poorlydefinedrolesandresponsibilitieswereidentified as a major issue during the material planning stage of materialmanagement.

2. Supply chain challenge also be considered at material planningstageofmaterialmanagement

3.Poorcoordinationandcommunicationbetweencontractor and material supplier was identified as the major issue duringthevendoranalysisstageofmaterialmanagement.

4.Localissuescausingmaterialdelaysandunavailabilityare regarded as the major problem during the material purchasingstageofmaterialmanagement.

5. The main issue in the storage and inventory stages of material management is a lack of modern equipment and methodsforhandling.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

6.Damagetomaterialonsiteandalackofonsitematerial control were identified as major issues during the supply anddistributionstagesofmaterialmanagement.

7. Project size challenge, Site access problems and Small loading area are regarded as the problem at site factors stagesofmaterialmanagement.

Recommendationsaremadebasedontheconclusionsand issuesdiscoveredduring mystudy. These suggestions are intended to improve materials management and reduce projectcomplexity.

•Makingchangesintheplansorthematerialsusedshould beavoidedbytheownersasmuchaspossible

• Proper and clear contracts must be written to make the missionsandresponsibilitiesofcontractors,consultant,and managementteam

•Donotutilizesubstandardmaterialsinconstruction

•Avoidofbuyingmoreorlessamountofmaterialsthanthat areneededforconstruction

• Experienced Construction Manager should be hired for tasks like selecting appropriate construction methods or materials, managing costs and time, observing the constructionprocess,andorganisingcontracts.

•Hiringtrainedandskilledlabourspeedsuptheprocessand eliminates the possibility of defective work and repeated works.

•Toavoidcommunicationissues,itisrecommendedthatall indents,requests,notes,andrecordsbekeptinwriting.

• Material handling equipment such as conveyor belts, trolleys,cranes,andsoonshouldbeusedtoreducewaste causedbyimpropermaterialhandling.

• Every construction firm should use the EOQ technique beforeplacinganyordertoreduceprojectcostoverruns

•Toavoidmanualerrorsinmaterialmanagement,software suchasMSP,PRIMAVERA,ERP,SAP,andothersshouldbe used.

[1].N.Hamzah,M.A.Khoiry,I.Arshad,N.M.tawil,andA.I.Che Ani (2011) “Causes of Construction Delay” “Theoretical Framework”,ProcediaEngineering.

[2]..MohamedM.Marzouk *,TarekI.El-Rasas,“Analysing delaycausesinEgyptianconstructionprojects”,Journalof AdvancedResearch(2014)5,49–55.

[3].MeghaDesai,RajivBhattP.G.Student,“CriticalCausesof Delay in Residential Construction Projects”, International JournalofEmergingTechnologyandAdvancedEngineering, (ISSN2250-2459,ISO9001:2008CertifiedJournal,Volume 3,Issue3,March2013).

[4]. Ajibade Ayodeji Aibinu and Agboola Odeyinka (2006) “ConstructionDelaysandtheircausativefactorsinNigeria”, Journal of Construction Engineering and Management, Vol.132,No.8,PageNo.667-677

[5].AssafSA,Al-KhalilM,Al-HazmiM.“Causesofdelaysin large building construction projects.” ASCE J Manage Eng. 1995;11(2):45–50.

[6]. M.E. Abd EI-Razek, H.A. Bassioni, And A.M. Mobarak (2008)“CausesofDelayinBuildingConstructionProjectsin Egypt” Journal of Construction Engineering and Management,Vol.134,No.11,PageNo.831-841.

[7].PabloGonzalez,VicenteGonzalez,KeithMolenaarPh.D. M ASCE and Francisco Orozco Ph.D. (2013) “Analysis of causes of delay and times performance in construction projects”, Journal of Construction Engineering and Management.

[8].ThillaiA.Rajan,GovindGopinathandMonalisaBehera (2013) “PPPs and Project Overruns: Evidence from Road ProjectsinIndia”JournalofConstructionEngineeringand Management.

[9].CeciliaGravinadaRachaandSergioLuizKemmer(2013) “Method of Implement Delayed product Differentiation in Construction of High-Rise Apartment Building Projects” JournalofConstructionEngineeringandManagement.

[10].HemantDoloi,AnilSawhney,K.C.Iyer,SameerRentala “Analysing factors affecting delays in Indian construction projects”,International Journal ofProjectManagement 30 (2012)479–4.

Yadhun M. K. is pursuing M.Tech Construction Management at Srinivas University Institute of Engineering&Technology,Mukka, Mangaluru.AfterBachelorDegree in Civil Engineering, Yadhun has worked as Civil Engineer at M. K. Associates,Kannur(Kerala,India) for3years.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 12 | Dec 2022 www.irjet.net p-ISSN: 2395-0072

Shrinath Rao K is working as AssociateProfessorintheDeptof Civil Engg at Srinivas University Institute of Engineering & Technology,Mukka,Mangaluru.He has7yearsofworkexperienceat Abroad and 14 years at India includingTeaching,Review &ReDesign of Syllabus, Quality Assurance in Higher Educational Institutions and Construction Industry.