International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

Abheek Shah1 , Jahnvi Sheth2

1

2

This reviewstudyfocuses onautomated manufacturing in theautomotiveindustry,withanemphasisonIndustry4.0 technologies. We go over particular Industry 4.0 technologies that are being implemented in manufacturing organizations, such as improved robotic devices, 3D printing, the Internet of Things, and automated production. Manufacturing enterprises in the automotive sector that operate in Slovakia and the Czech Republicmadeupourresearchsample.Bothcountriesare major actors in the global automobile manufacturing industry. We created an electronic questionnaire and constructedquestionsbasedonatheoreticalevaluationof prior studies and research to collect data. Two assumptions were made, and the average degree of technologyuse was usedto verifythem. We also lookedat the level of automation and other Industry 4.0 technologies that have been implemented. Sensors, programmable devices such as PLCs and HMIs, and industrial robots were all used often, according to the findings. According to another examination of the data, largeindustrialorganizationsuseautomationaspectsata higherlevelthanmediumandsmallbusinesses.

Key Words: Industry 4.0, Automation, Industrial Revolution,LevelsofAutomation

Automated features can be found in modern technology employed in modern automotive production. Automation has a number of advantages for manufacturing. It simplifies procedures and streamlines production, resulting in reduced time and personnel costs. On the market, we can find technologies that are bothcheaperandmorecapableofacceleratingtheriseof completely automated production. Automation in the manufacturingindustrycanincreasequality,reducelead times, streamline production, and streamline workflow. In the automotive business, automation is crucial. Technology in the field of automotive automation is constantlyimproving.Sector4.0presentschallengesand opportunities that have shifted the automotive industry dramaticallysincethefirstindustrialrevolution.Wemay distinguish four significant phases of the industrial revolution , each of which introduced new discoveries

andtechnological advancements.Thecommencementof the industrial revolution can be traced back to the 18th century's 60s. The commencement of the first industrial revolution is symbolized by the use of a new source of energy, the steam engine. With the discovery of electricityandtheadoptionofassemblylines,thesecond industrial revolution improved output. Computer technologies, such as computers or PLC programmable devices, ushered in the third industrial revolution. Advanced robotic devices, 3D printing, the Internet of Things, and automated production are all introduced into manufacturing enterprises during the fourth industrial revolution. Since the start of the second industrial revolution, a good foundation has been established for the adoption of technologies in the automobile sector that are continually growing and progressing. The automobile business segment is quite appealing, and the market is essentially global. When adopting 4th industrial revolution technologies, automobile firms have a lot of options for using automation features, which can considerably simplify the manufacturing process. Artificial intelligence, automation, and sensors will almost certainly lead to a slewofnewvehicleadvances."Industry4.0"referstothe confluence of these new technologies. The automotive industry isseenasa forerunner ofIndustry4.0,withan annual investment of roughly 65 billion dollars in innovative industrial technologies. In the perspective of industry 4.0, we define automation as a set of technologies that enable machines and systems to operate without requiring considerable human intervention. Thisisalso themostsignificantdistinction from manual labor. [10] HMI panels (Human Machine Interface),SCADAvisualization(SupervisoryControland DataAcquisition),PLCprogrammabledevices,industrial robots, autonomous logistics devices, and other systems are examples of such systems. Robots have the most important representation since they are self-contained, can be programmed, and have security mechanisms. In many European countries, as well as around the world, the automotive sector is currently dominant. The productionsectoraccountsforthemajorityofstateGDP, particularly in Slovakia and the Czech Republic. In our research, we decided to assess firms' level of adaption and development in implementing 4th Industrial Revolution technology and automation aspects. On the basisof theoretical knowledge, professional andcurrent

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

writings in the field, as well as personal experience and observationintheautomobilesector, wedevelopedtwo hypotheses. Automotive manufacturing companies and their Operations/Technical Managers received the questionnaire. We tested and compared the average level in different sorts of firms to confirm the assumptions (small, medium-sized and large). The following is a breakdown of the paper's structure. We cover developments related to Industry 4.0 after a brief introduction in the literature review. We give a brief overviewandhistoryofindustrialrevolutions,aswellas thecurrentdirectionandtechnologiesofIndustry4.0for the automotive manufacturing industry, in this section. Thedataandmethodologyofourstudyaredescribedin the following section. The section Results presents and summarizes the study and analytical findings. Our significantfindingsaresummarizedandconcludedinthe finalsection.

experiencedanother"boom,"resultinginthestartofthe fourth industrial revolution. IoT (Internet of Things), artificial intelligence features, enhanced robots, completelyautomatedproduction,3Dprinting,andhighspeednetworkconnectionsviaopticalfiberareallbeing included into the manufacturing process. Predictive maintenance, in which intelligent sensors detect issues ahead of time and hence dramaticallyreduce outages, is also gaining traction. The production process and expenses can be easily optimized with these technologies. It's important to remember that the 4th Industrial Revolution impacted manufacturing companies across the board, including logistics, management, and marketing. Man can be removed from the production process as a productive force, and intelligentmachinescancommunicatewithoneanother.

The characteristics of each epoch of the industrial revolution, the cross-section of technological developments, and individual milestones may all be found in the literature. The first industrial revolution began in the 18th century, when steam engines and factory production using new technologies were introducedtothetextilesector.Machineproductiontook the role of manual labor. Efficiency and productivity of work have been increased several times. The steamer was also a significant change in the transportation industry. Other characteristics include worker specialization and the use of new materials like steel. In the nineteenth and twentieth centuries, the second industrial revolution occurred. The invention of electricity and the concept of using an assembly line were the fundamental foundations of this period. In the automotive business, Henry Ford introduced belt production, which once again offered up the possibility of boosting production capacity while lowering prices. Computers were also invented at the same time as the first automated operations. In the middle of the twentieth century, the third industrial revolution began. Digital technologies, such as programmable logic controllers (PLCs) or robotics, are the most prominent features. As a result, automation, such as the peak of industrial production, became possible. Devices can connect with one another over a network and with the rest of the world via the Internet. The first computers and computer systems are also available; analogue connections have been converted to digital connections.

[5] The human workforce is being replaced by automation. In the twenty-first century, technology

[11]Automotivecompanieswillalmostcertainlyneedto combine a number of innovative technology to succeed today. CASE (connectivity, autonomy, shared mobility, and electrification) technologies are those that are drivingsignificantchangesintheworldwideautomotive industry.

Agile supply chain - technologies can help with logisticsconceptslikeJITinaveryeffectiveway (just-in-time).Itispossibletochangeordersfast and easily, reply swiftly, and tailor the process toyourneeds-whetheryouaretheprovideror thecustomer.

Prediction and monitoring tools - production firmstypicallyrun24hours a day,sevendays a week, therefore IT systems and production technologies must be able to prevent breakdowns or interruptions in output. Robust monitoring technologies, which aid in the early detection of problems or breakdowns on particularsystems,areidealinthecontextofthe Industry4.0concept.

Systemadaptability-previously,therewaslittle room for change in the manufacturing process. Industry4.0technologiesmakeitfeasibletoset upandprogramdevicessothatmanymodelsof a manufactured product (different colors, different components on the line, etc.) can be producedonthesameline atthesametime - in theexpectedsequence,ofcourse.

Network technology flexibility - this isn't just aboutconfiguringnetwork elementsintermsof communication speed, which is critical in the

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

manufacturing process. However, it is also a meansofconnectingtoandcommunicatingwith the outside world. As a result, the entire manufacturing process becomes more compatible and dynamic. Of course, while communicating outside the organization, the relevantsecurityregulationsmustbefollowed.

Document and process digitization - this can be viewed as a requirement for the adoption of automation procedures. The horizontal (supplier - company - customer) as well as the vertical (supplier - company - customer) chains should be digitized (across departments of the organization).

circumstance, there will be a natural demand for the appropriate vehicle. Countries including the United States,India,Germany,China,SouthKorea,andJapanare currentlythemarket'sbiggestparticipants.

Increased production capacity and efficiencyIndustry 4.0 technologies may be used to optimize energy usage, the production process itself, better resource redistribution, create higher quantities on the production line, and find areas for future enhancements all at the sametime.

Anotherbenefitthatwecanalwaysargueiscostsavings. Regular maintenance and timely monitoring ensure the availability of technologies, preventing unexpected outages and the consequences of such outages, such as equipment damage and downtime, which results in a negative figure in the cumulative production plan. The frequency of errors and accidents at work is automatically reduced as a result of correctly working technologies. Automation, high-speed networking, machine learning, and low-cost computing are highlighted as current problems and relevant topics in Deloitte's current resources and insights in the automobile industry's Industry 4.0 concepts. One of the most important prerequisites for today's firms' success is to digitize all processes and invest in the most up-todate technologies. New technologies offer new ways to gain a competitive edge. The firm also lists critical questions that a business should consider if it wants to succeedinIndustry4.0:Whatwillcustomersdemandin the future? Which benefits of innovation will have the greatest impact on the automobile industry? How will we fund necessary development and research investments?Theautomobileindustry'spresentfocusin terms of manufacturing will be mostly on electric cars andalternativeformsofmotordrives.Hybriddrivesand electric motors are replaced by gasoline and diesel engines. Self-driving cars with their own control algorithms are a distinct phenomenon. A functioning infrastructure in the country, including as charging stations,isa keyprerequisiteforthesaleandsuccessful operation of such cars. The state, on the other hand, should provide substantial assistance. In this

The term "automation" in the context of Industry 4.0 refers to a set of technologies that allow machines and systems to operate without requiring considerable human intervention. This is the most significant distinction from manual labor. The following features should be present in such a system or device: sufficient information regarding the device's running / operating mode,warningsofdangerousdangers,andthepotential ofmanualrestrictionorhumanintervention.HMIpanels (HumanMachineInterface),SCADAvisuals(Supervisory Control and Data Acquisition), PLC programmable devices, industrial robots, autonomous logistics devices, andothersystemsareexamplesofsuchsystems.There's also the possibility of automated processes convergent at the system level. These systems either perform, backup, or monitor (automatic) something. Individual production terminals have varied qualities that allow them to communicate with one another, as well as be optimized, programmed, and monitored. There are also devices that can control themselves or be controlled remotely. Because they are autonomous and can be programmed, robots have the most important representation.Theyalsohavesecuritymechanisms. On assembly lines or, for example, during welding, such robots can take the position of humans. It's crucial to emphasize supporting technologies like IoT, cloud computing, big data analysis, 3D printing, artificial intelligence, process simulation, or monitoring when discussing automation within Industry 4.0. The Internet of Things (IoT) is a term that refers to various types of communication between terminal equipment (physical objects) and the Internet. The notion of IIoT (Industrial IoT) applies to industrial production and types of communication within manufacturing plants in manufacturing industries. It's also worth mentioning M2M (machine-to-machine) communication, which is a type of wireless or fixed network connection between twodifferentdevices.Theterm"smartfactory"refersto a manufacturing company that uses Industry 4.0 concepts. All devices, services, network technologies, applications, sensors, software, and storage systems can beincludedintheIIoT.Theymaykeeptrackofindustrial processesandequipment,aswellastheircurrentstatus. They improve production efficiency and analyze realtimeprocessoperation.TheInternetofThings(IoT)isa requirement for integrating automation in the manufacturingbusiness.Specifically,wefindavarietyof technologies in the automobile industry, including industrial robots, programmable PLC devices, HMI

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

stations, visualization technologies (SCADA), logistics solutions (logistics platform 4.0), and localization technologies such as RFID and RTLS. Such devices are capable of immediately exchanging data and receiving feedback,alarms,orotherwarnings.Theyarealsolinked to the command and control systems. Within logistics technology, the door is opening for cost reduction and optimization solutions through the improvement of existingroutes.Devicescanalsosaverecords,whichare referred to as logs and can be reviewed by service management.However,one ofthemajordownsidesand concernsisthesecurityriskandvulnerabilityassociated with network connection within these Industry 4.0 devices.

Many European countries, as well as the rest of the world, are today dominated bytheautomotive industry. The production sector accounts for the majority of state GDP,particularlyinSlovakiaandtheCzechRepublic.The technologies of the fourth industrial revolution are giving this segment a whole new dimension and propelling it forward by leaps and bounds. These two countries have consistently led the world in terms of automobile production per capita. In our research, we decided to assess firms' level of adaption and development in implementing 4th Industrial Revolution technology and automation aspects. We think this research to be valuable, especially for the automotive industry, because we do not yet have a similarly concentratedstudyatthislevel.Thegoalofourarticleis to determine the extent to which technology is being used in industry 4.0, with a focus on assisting automation,inasampleofSlovakandCzechautomotive enterprises. We also included questions about automation deployment, IT service delivery, network outages,andIndustry4.0supportingtechnologiesinthe survey. On the basis of theoretical knowledge, professional and current papers in the field, as well as personal experience and observation in the automobile market, we developed two hypotheses. We give the results,whichdemonstratetheaveragelevelofadoption of individual automation aspects across different size groups of firms, to aid verification. The sample was separated into three groups based on the size of the company (micro/small, medium-sized, and large). The elementsinvariousquestionsweregraded ona scaleof 1 (not yet implemented), 2 (basic level of implementation), 3 (medium level of implementation), and 4 (highest/advanced level of implementation).

Assumption 1: Across the whole automobile sector, robots and programmable devices are the most extensivelyemployedpartsinautomatedmanufacturing.

Assumption 2: Large manufacturing organizations employ more advanced automation techniques than mediumandsmallbusinesses.

To gather information, we created an anonymous questionnaire poll that allowed companies to freely express themselves. The questionnaire was created to provide a more thorough picture of the automotive manufacturing business in the Slovak Republic and Czech Republic while also protecting the companies' know-how. We decided to use an electronic questionnaire to obtain the data. We used a theoretical evaluation of prior studies and research to formulate queries. With an emphasis on production, we looked at firms in the automobile industry in Slovakia and the Czech Republic. We split them into three groups for research purposes: small, medium-sized, and large businesses.Thequestionnairewasissuedtoaround300 Slovakia and Czech Republic-based companies. FinStat.sk, ivéfirmy.cz, and azet.sk were used to choose companies from Slovak and Czech databases. The questionnaire was given to Operations and Technical Managers. We chose the following categories (SK NACE 29)forthespecifiedautomotiveindustry:manufacturing of motor vehicles, manufacturing of various parts and components for motor vehicles, manufacturing of modules (module supplier), and manufacturing of electroniccomponentsformotorvehicles.Atotalof106 respondents correctly completed the questionnaire. Companies were classified into categories for research reasons based on their size, age, and fundamental businesslifecycle.Table1summarizestheresultsofthe sample distribution. The majority of respondents (46) were from huge corporations, with only 18 from micro and small businesses. Companies that have been on the market for more than 15 years (79) and those that are nowinthegrowthphaseoftheirlifecyclewerethemost common among those questioned. We believe that such organizations have a better chance of implementing Industry 4.0 concepts because they have a solid understanding of the market, external and internal conditions, suppliers' networks, competent personnel, andin-houseresearch.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

Table -2: ResearchSample

Variable Category Number Age <15years 5 5-15years 22 15+years 79 Total: 106

Table -3: ResearchSample

Variable Category Number Life Establishment 2 Growth 52 Stabilization 46 CriticalPhase 6

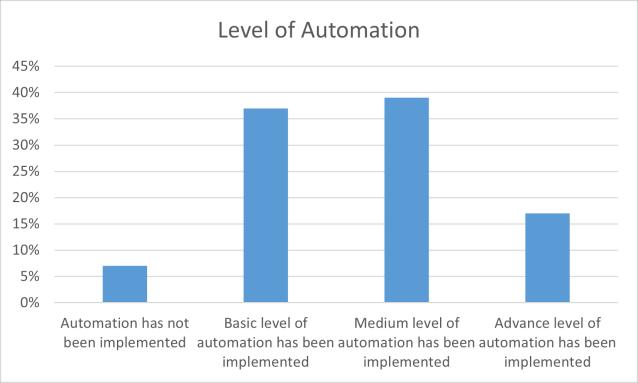

We looked at the degree to which automation aspects were used in the manufacturing process in the first section. Industrial robots, programmable devices, autonomous devices, logistics technologies, localization technologies,SCADAsystems,andautomatedmonitoring areallincludedinthiscategory.Thefollowingscalewas used:1-wedonotuseautomatedmanufacturing,2-we useitatabasiclevel,3-weuseitatamediumlevel,and 4 - we use it at the highest / most advanced level. Only 8% of organizations reported a low level or no deploymentofsuchautomatedaspects,asseeninFigure 1. Almost the same amount of businesses (37 percent and39percent,respectively)chosethebasicormedium level of implementation, while 17% chose the advanced level.Largeandmedium-sizedbusinesseswithahistory of more than 15 years on the market validated the sophisticated level of application. In terms of these companies' life cycles, the growth period was the most important. As expected, micro and small businesses in the stabilization phase (5-15 years on the market) responded by using automation technology sparingly or not at all. Motor vehicle manufacturers and enterprises that make additional parts and components for motor vehicles have the greatest / advanced level of automation deployment, according to the industry category.

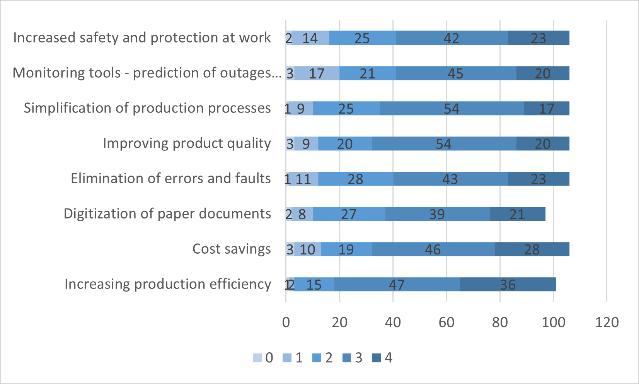

In the following section, we looked at the advantages that organizations obtain by implementing automated production. We observed the following advantages: improved production efficiency, cost savings, and digitization of paper documents. Errors and flaws are eliminated, product quality is improved, production procedures are simplified, monitoring tools are used to predict outages and provide an overview of the present status of production, and finally, workplace safety and protection are improved. The evaluation was given on a scaleof0to4,with0denotingnobenefitand4denoting a significant/key benefit. The total results for all examined companies are shown in Figure 2. The following categories received the highest ratings (on a scale of 1 to 3): boosting production efficiency, cost savings, enhancing product quality, and simplifying production processes. The favorable effect was boosted by features such as the removal of errors, monitoring systems,andthedigitizationofpaperdocuments(inthe scale mostly 3 and 2 ranking). The features of greater safetyandprotectionatwork,aswellasthereductionof errors, dominated the scale rated 1 and 2. The most essential factors for medium and big enterprises, according to the analysis by number of employees, are production efficiency, digitization of paper manufacturing, simplification of production processes, andmonitoringsystems.It'salsoworthemphasizingthe cost-cutting criterion, which was imposed by the majority of small businesses. In the theoretical section, wediscussedtheindividual benefitsandcauses.Eachof these advantages, on the other hand, is an important aspect of any company's daily operation on the market. Cost savings and improving product quality were the mostimportantconsiderationsforenterpriseswithalife cycleofmorethan15yearsandoperatingonthemarket duringthestabilizationandgrowthperiod.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

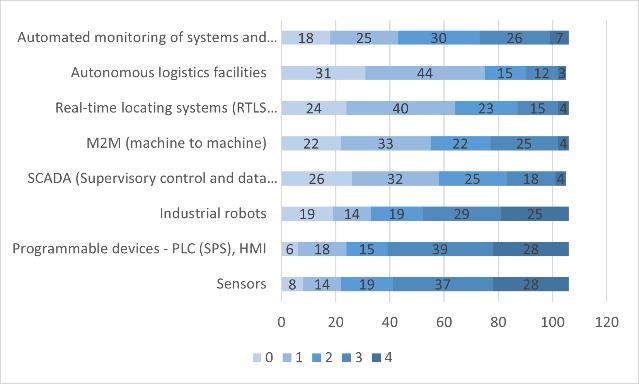

Other technologies that complement automated manufacturing - IoT, cloud computing, big data, 3D printing, artificial intelligence, process simulation, energymonitoring,andothers-wereinvestigatedatthe application level. The evaluation was based on a Likert scaleof0to4,with0denotinglittleorlimiteduseand4 denoting advanced use. The results in Figure 3 demonstrated that sensors, programmable devices, and industrial robots were used at an advanced level. These technologies were generally employed in huge organizations with a 5-15 year history on the market that were still in the early stages of their operations. Medium-sized businesses affirmed the lower degree of use (on a scale of 0 to 1) of SCADA, M2M, and autonomous logistics facilities during the stabilization phase. SCADA is a system that aids firms in operational production but is not widely employed. It may monitor energy use and hence give input data for prospective system optimizations, in addition to reporting current status in manufacturing. Finally, the benefits of automated monitoring in manufacturing organizations can be summarized as follows: lower equipment maintenance costs, higher system availability, fewer outages, and early error identification. Energy consumption efficiency can also be monitored using monitoring tools. The absence of these systems in manufacturingorganizationsmightresultinanumberof disadvantages when compared to competitors in the industry. As a result, organizations must adapt to these developmentsandprepareforthedifficultiesahead.

Chart -3:LevelofuseofIndustry4.0components

Two assumptions were made. To help with verification, we'veincludedTable2,whichdisplaystheaveragelevel of utilization of individual automation aspects across different company sizes. We can view and compare the differences in size between three groups of companies basedonthestudiedresults.

Table -4: Averagevaluesoftheimplementationlevelof automationelements

Micro Medium Large

Sensors

1.61 2.40 3.15

Programmabledevices 1.38 2.43 3.26

Industrialrobots 1.17 2.05 2.87

SCADA 0.94 1.19 1.89 M2M 1.05 1.38 1.98

Real-timelocatingsystems 1.22 1.16 1.65

Autonomous logistics facilities 1.00 0.83 1.52

Automated monitoring of systems 1.50 1.45 2.24

Numberofcompanies 18 42 46

Level of automation implementation 2.27 2.38 3.04

Assumption 1: Across the whole automobile sector, robots and programmable devices are the most extensively employed element in automated manufacturing. We can observe from the data (Table 2) that large businesses use each technology at a higher level than medium and small businesses. It's also true that sensors and programmable devices in medium and

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

big businesses obtained the highest level in each category. On the third place, industrial robots were mostly deployed in large and mediumsized businesses. As a result, the supplied assertion in assumption 1 is incorrect. However, only part of the statement is true: programmable devices are the most widely utilized component in the automotive sector. Assumption 2: Large manufacturing organizations use more advanced automation techniques than medium and small businesses.Wecanseefromthedata(Table2)thatlarge organizationshaveahigherlevelofautomation(3.04on a scale of 1 to 4, with 4 being the highest and 3 being a mediumlevel ofimplementation).In largefirms,wecan witness a better level of implementation in all components.Itisalsotruethatmedium-sizedbusinesses employ automation aspects at a higher rate than small businesses and micro-businesses. On average, none of the components are implemented at the highest / most sophisticated level. Result: Hypothesis no. 2 is correct, and major manufacturing organizations apply automation aspects at a higher level than medium and smallbusinesses.

The importance of automated production was underlined in the article, which opens the door to manufacturing enterprises. Production procedures are vitalforbusinesses,accordingtostudy,especiallyifthey wanttoincreasetheirefficiencyandfluidity. Companies in the manufacturing business attempt to reduce excessive downtime and errors by preventing rather than solving accidents. As a result, investing in the proper, dependable, and supported technologies should beagiven.ThecorrectorderintheoperationofITILcan beintroducedintheprocessesthemselves,intermsofIT and technology, by service management, which is regularly updated for the demands of servicespresentlythe4thgenerationofideas.Wediscoveredthat sensors and programmable devices are the most commonly utilized elements in the automobile industry, and that major manufacturing organizations apply automation elements at a higher degree than small and medium-sized businesses, based on the verification of our hypotheses. Because smaller businesses have fewer resources, particularly in terms of capital, we may highlight the benefits of collaborating with external partners [21] such as research institutions, universities, orbusinessincubators.Theseformsofcollaborationcan be less expensive than conventional market vendors; early costs were one of the most significant barriers to technology adoption. There's also room for wholly new technologies to be developed, existing systems to be improved, and industrial processes to be automated. Automation, high-speed networking, machine learning, and low-cost computing are contemporary technologies

in Industry 4.0 in the automotive industry, according to current resources and insights from consulting firm Deloitte [12]. One of the most important prerequisites for today's firms' success is to digitize all processes and invest in the most up-to-date technologies. Not only to stay ahead of the curve, but also to invest in our own research,becausenewtechnologiesarenewcompetitive advantagecarriers.Co-botsarecurrentlyreferredtobea newgenerationofautonomousrobotsthataregradually replacing traditional industrial robots. In this segment, investments in new and accurate technology provide competitiveadvantages.Co-botsarefarmoreadaptable, safe, and sophisticated than traditional robots. They are simple to use and integrate with existing systems. It's also possible to improve the quality or speed of the manufacturingprocess.Ontheglobalmarket,largefirms like BMW and Nissan can already boast of this technology.Weattemptedtoemphasizetheutilizationof technology and its positive impact on the company in this report. However, we must not overlook the drawbacks that this stage of the industrial revolution brought with it,suchassecurityvulnerabilities,thecost of operational inquiries, the need to change business processes,and,most recently,the disruptionandfailure ofwirelesscommunication directlyinproduction.These arealsoworthwhileareastoinvestigatefurtherinterms ofresearchquestions.

[1]. Tilley, J. (2017) “Automation, robotics, and the factory of the future.” Retrieved from: https://www.mckinsey.com/businessfunctions/operatio ns/our-insights/automation-robotics-andthe-factory-ofthe-future

[2] Patra, K.K., and Bhattacharjee, D. (2012) “Engineering, Economics and Costing.” S Chand Publishing: New Delhi. Retrived from: https://books.google.sk/books?id=oXCa96h2KbQC&pg= PA256&lpg=PA256&dq=automation+simplifi ed+production&source=bl&ots=Vq4 _9coPlP&sig=ACfU3U1FhpRfGIzJkPn8bi6ESf1grRBMlA& hl=sk&sa=X&ved=2ahUKEwjAnLh6rxAhXH8bsIHTxvD8 YQ6AEwB3oECAsQAw#v=onepage&q=automation%20s implified%20production&f=false

[3] Salajová, N., and Kohnová, L. (2019) „Industrial Revolutions and their impact on managerial practice: Learning from the past.” Problems and Perspectives in Management17(2):462-478.

[4]. Cejnarová,A.(2015)“Od1.průmyslovérevoluceke 4.” Retrived from: https://www.technickytydenik. cz/rubriky/ekonomika-byznys/od-1- prumysloverevoluce-ke4_31001.html

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056 Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

[5]. Kohnová, L., Papula, J., and Salajová, N. (2019) "Internal factors supporting business and technological transformationin thecontextofIndustry4.0." Business: TheoryandPractice20:137-145.

[6] Helper, S., Martins, R. and Seamans,R.(2019)“Who ProfitsfromIndustry4.0?TheoryandEvidencefromthe Automotive Industry” NYU Stern School of Business. Retrievedfrom:https://ssrn.com/abstract=3377771

[7]. Agrawal, G., Goldfarb. (2018) “PredictionMachines: TheSimpleEconomicsofArtificialIntelligence.”Harvard BusinessReviewPress:Boston,MA.

[8] Cassia,F.andFerrazzi,M.(2018)“TheEconomicsof Cars”NewcastleuponTyne:AgendaPublishing.

[9] Geissbauer, R., Vedsø, J. and Schrauf, S. (2016) “Industry 4.0: Building the digital enterprise” London: PricewaterhouseCoopers.

[10]. Akogbe, M. (2015) “Brief Overview of Automated Industrial Plant: A Review.” Retrieved from: https://www.researchgate.net/publication/282199407

[11].Popkova,E.andRagulina,Y.andBogoviz,A.(2019) “Industry4.0:IndustrialRevolutionofthe21stCentury”

[12] Dut, D., Wilson, A., Natarajan, V. and Robinson, R. (2020) “Steering into Industry 4.0 in the automotive sector” Retrived from: https://www2.deloitte.com/us/en/insights/industry/au tomotive/industry-4-0-future-ofautomotiveindustry.html

[13]. Geissbauer, R., Schrauf, S., Koch, V. and Kuge, S. (2014) “Industry 4.0 – Opportunities and Challenges of the Industrial Internet” Retrieved from: https://www.pwc.nl/en/assets/documents/pwcindustrie-4-0.pdf

[14] Masters,K.(2017)“TheImpactofIndustry4.0 on the Automotive Industry.” Retrieved from: https://blog.flexis.com/the-impact-ofindustry-4.0-onthe-automotive-industry

[15]. Weg (2019) “How Companies Can Reduce Costs with Industry 4.0 Implementation” Retrieved from: https://www.weg.net/institutional/US/en/news/produ cts-and-solutions/how-companies-canreduce-costswith-industry-4-0-implementation

[16] Vitale, J. and Giffi, C. (2020) “Industry 4.0 in automotive. Digitizing the end-to-end automotive value chain” https://www2.deloitte.com/content/dam/insights/us/a

rticles/automotivenews_industry-4-0-inautomotive/DI_Automotive-NewsSupplement.pdf

[17] Bahrin,M.,Othman,M.,Azli,N.andTalib,M.(2016) “Industry 4.0: Review on Industrial Automation and Robotic”JournalTeknologi137-143.

[18] Radziwon, A., Bilberg, A., Bogers, M. and Madsen, E.S.(2014)“TheSmartFactory:ExploringAdaptiveand FlexibleManufacturingSolutions“,ProcediaEngineering, 69: 1184-1190, ISSN 1877- 7058, https://doi.org/10.1016/j.proeng.2014.03.108.

[19] Lampropoulos, G., Siakas, K. and Anastasiadis, T. (2019)“InternetofThingsintheContextofIndustry4.0: An Overview.” International Journal of Entrepreneurial Knowledge.(7):4-19.doi:10.2478/ijek-2019-0001.

[20] Tenghong, L., Rong, Y. and Huating, Ch. (2012) “Research on the Internet of Things in Automotive Industry.”InternationalConferenceonManagementofeCommerceandeGovernement.

[21]. Volná, J. and Papula, J. (2013) “Analysis of the behavior of Slovak enterprises in the context of low innovation performance“ Procedia - Social and BehavioralSciences99:600-608

Aspiring Industrial Engineer, currently pursuing B.Tech in MechanicalEngineering(4th year) from Dwarkadas J. Sanghvi CollegeofEngineering,VileParle, Mumbai

Aspiring Data Science Engineer, currently pursuing B.Tech in MechanicalEngineering(4th year) from Dwarkadas J. Sanghvi CollegeofEngineering,VileParle, Mumbai