International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

1

, Prof. A.K.Battu2

1ME Mechanical Design Engineering student at DYCOE Akurdi ²Assistant Professor at DYCOE Akurdi ***

Abstract - Solar is a free source of energy found in nature, and most modern technologies, from vacuum cleaners to electric vehicles, are powered by it. Solar collectors are now being used to develop energy usage in both residential and industrial applications of water heating systems.Despitethe fact that solar water heaters come in a variety of configurations, they all use absorber tubes with a circular cross section. This study investigates the effects of different diameters and shapes of absorberplatetubes(zigzag,u-bent double parallel, etc.) on thermal performance. In the analysis, consistent area of cross section along flow channel and constant perimeter of tube flow path will be used as comparison criteria for different designs. This research allows us to create a prescription for the size and shape of various absorber tubes' cross sections.

Key Words: - Solar, Flat plate collector, Heat transfer & CFD.

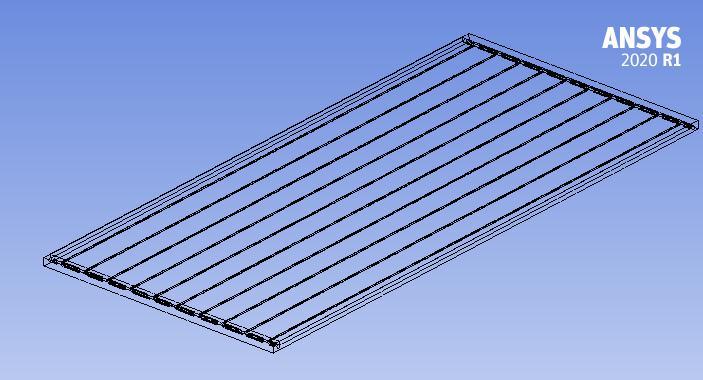

Solarflatplatecollectorisadevicewhichaccumulate availablesunenergyorraysandtransfigureitintorequired usefulenergyusingwaterorairasworkingmedium.Solar flat plate collector has main two parts – metal plate , absorberplateandbesideswhichinternaltubingstructure, size and material of tube are main factors for improving efficiencyofsolarflatplatecollector.

Here,weusewaterasworkingmediumandbychanging tubestructure,sizeandmaterial weare tryingtocheck reliabilityandperformanceofSolarcollectorwiththehelp ofANSYSsoftware–CFDDomain comparewithphysical model.

Heat transfer is defined as the movement of thermal energy from one region of space to another. Conduction, convection, and radiation are the three primary ways of heattransport.ModelingConductiveandConvectiveHeat Transfer physical models containing simply conduction and/orconvectionarethesimplest,but buoyancy-driven flow or natural convection Natural Convection and Buoyancy-Driven Flows Theory, and radiation models ModelingRadiationaremorecomplicated.

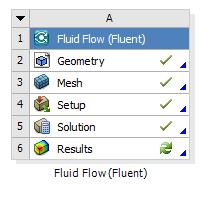

2.1.1 Procedure for Ansys Workbench CFD analysis

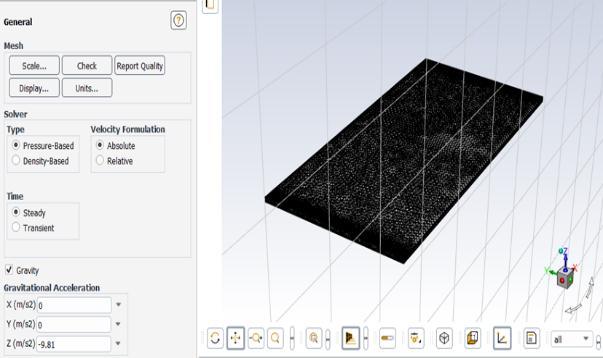

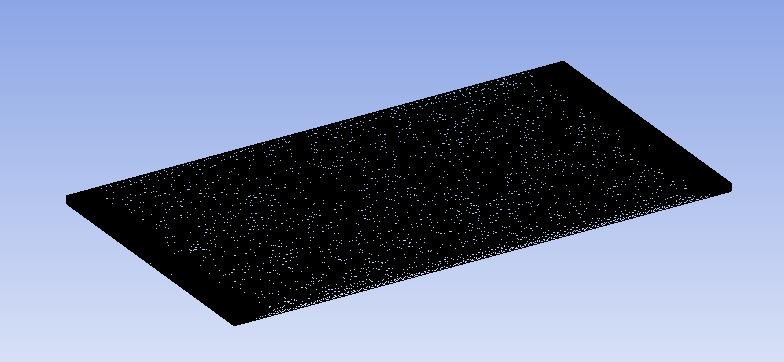

1.The first step in Ansys CFD model is to Import the geometry file, may be STP or IGS file from the created formatofsoftwarewillberequired.

Figure3AnsysCFDmodule–Importationof geometryfile

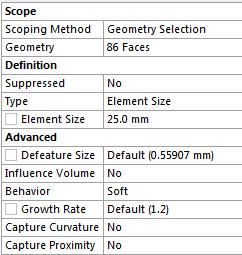

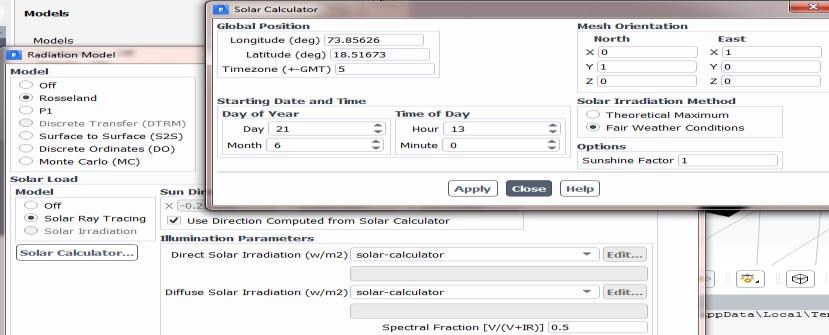

2.1.2 Mesh generation & named selection

Figure4meshmodule

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

Figure6nodesandelements

2.1.3 Setting up the problem to its boundary condition.

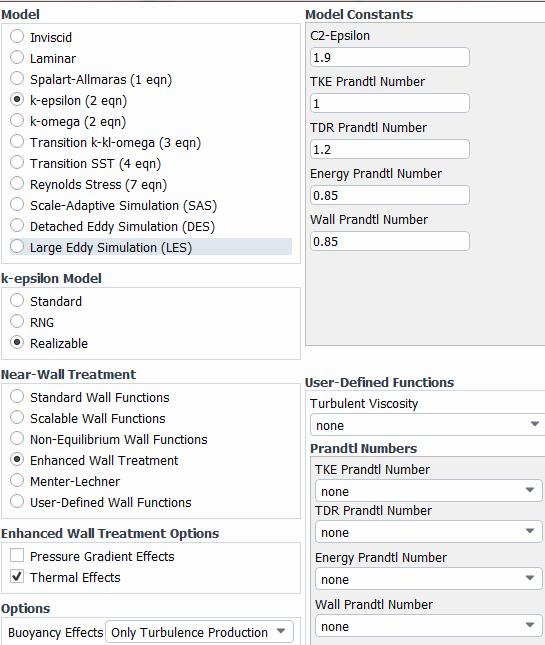

a. Aftermeshing&namedselection3rdprocessissetup, which means setting up the problem for defined boundary conditions.Thisprocesscontainsseveralscopeswhichneedsto be set up before solving it. following are the configuration or boundaryconditionappliedwhilesolving.

i. Checkingformesh

ii. Turningonenergyequation

iii. Describingtypeofflow

Figure8Viscosmodel

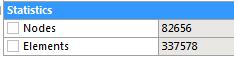

2.1.4 Radiation model

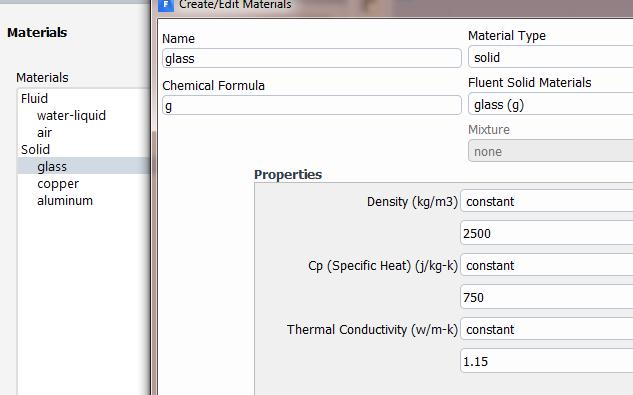

Figure9radiationmodel 2.1.5 Material Creation

Figure10material

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

1. inlet=0.05kg/secmassflowinlet

2. inletwatertemperature=25degreeCelsius

3. absorber plate = copper material addition + solar tracingturningon

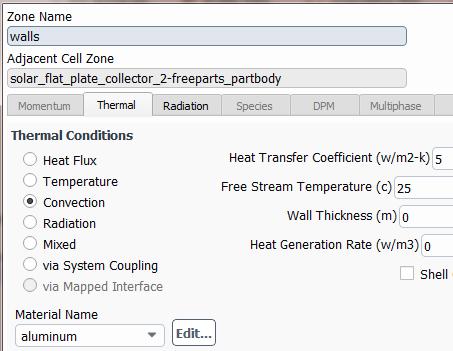

4. walls

Figure11wallscoping

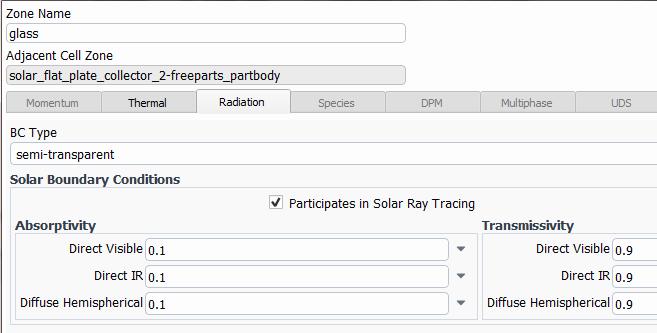

2.1.7 glass

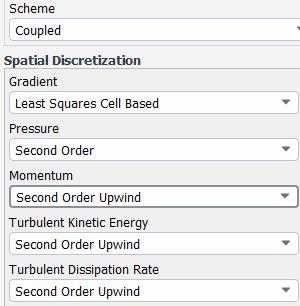

2.1.8 Method for solution

Figure13solutionType

viii.initialization–Hybridinitialization

ix.solutioncalculation50iterationorsteps.

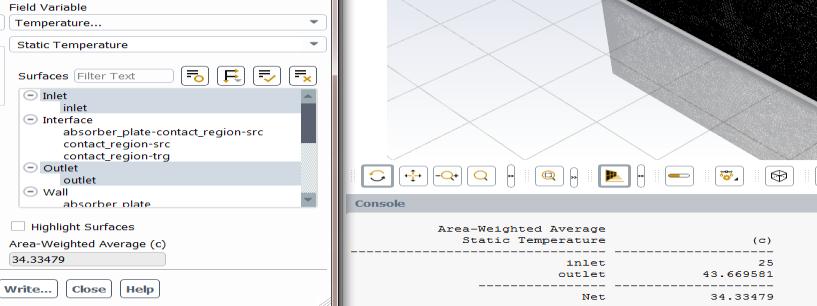

2.1.9 Results

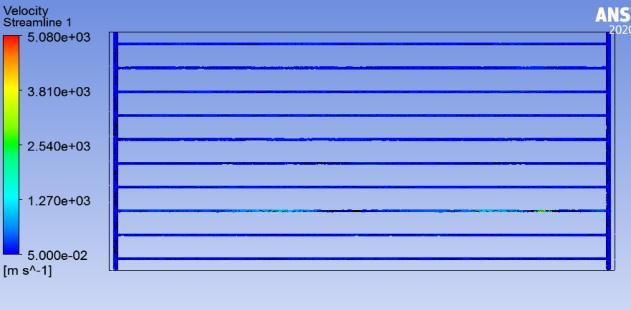

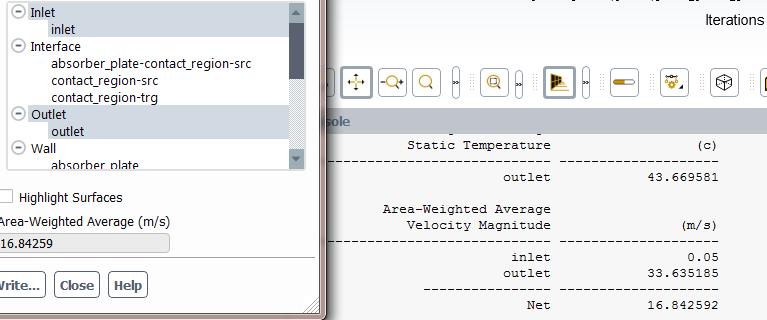

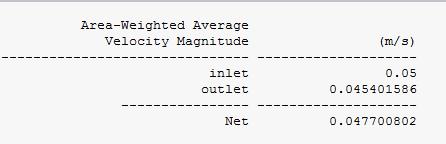

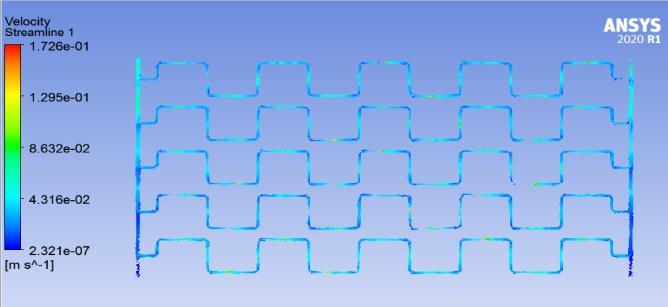

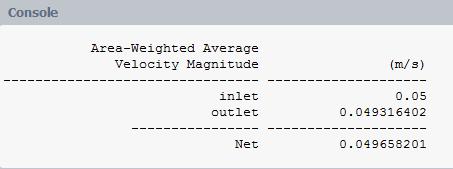

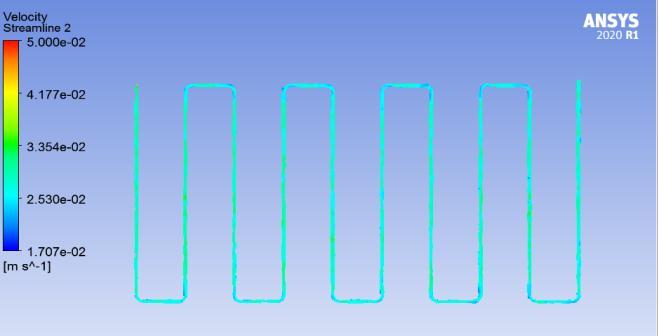

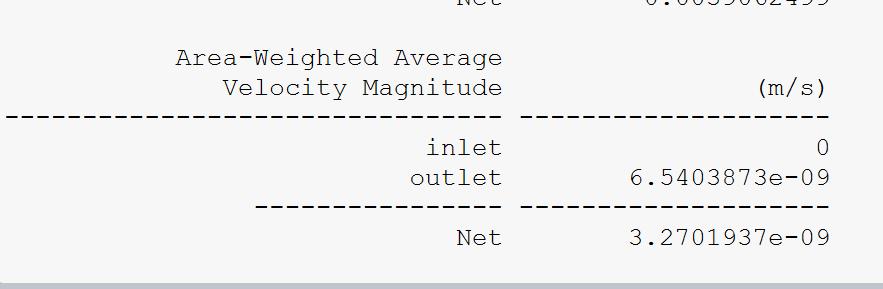

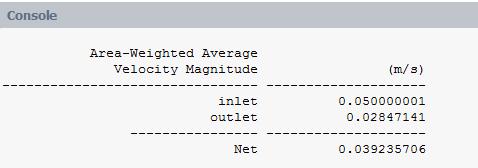

Velocityflowratioat0.05k/secinletflow

Figure14geometryinresultmode

Figure12glassscoping

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

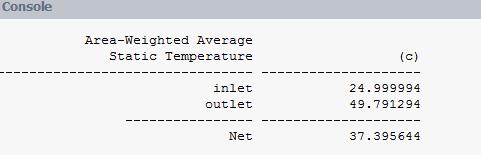

Figure15resultinlet&outletvelocity

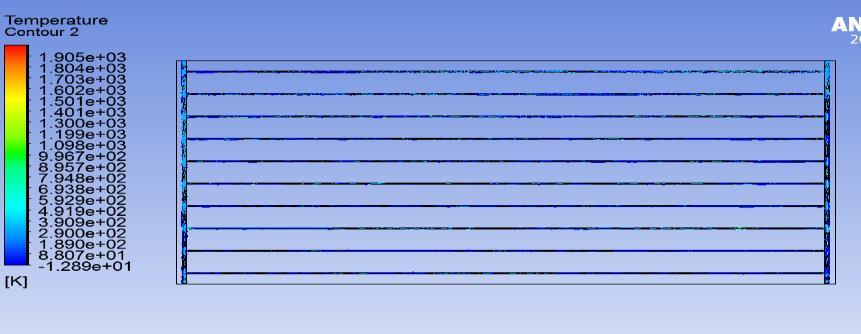

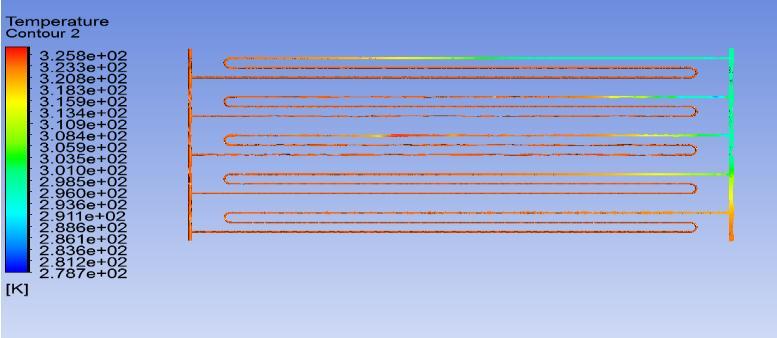

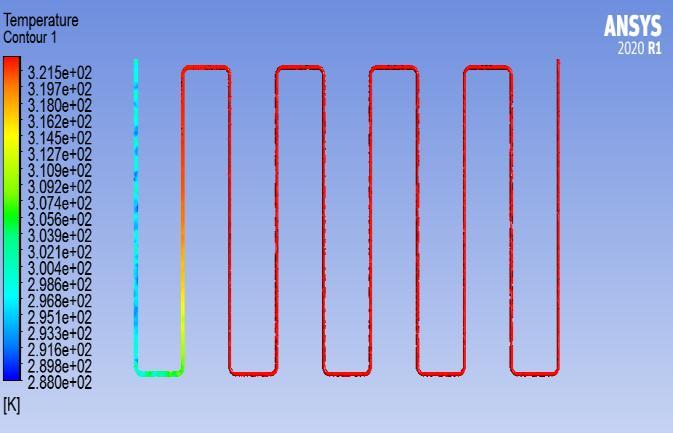

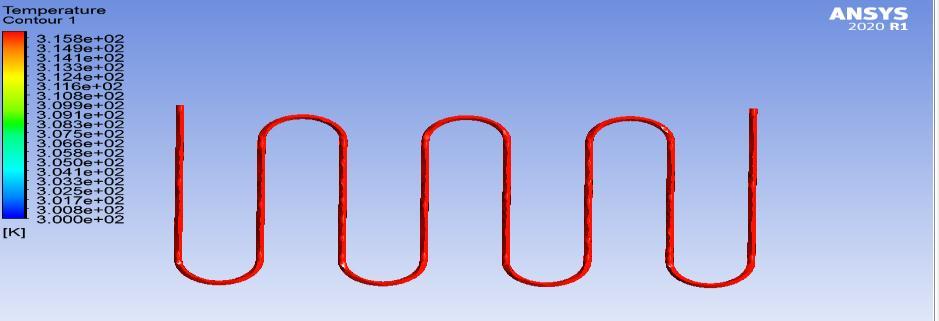

Figure19temperaturecontour

2.1.10 Discussion

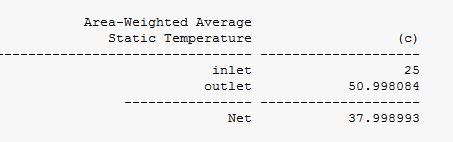

In this iteration parallel tube are considered and radiation is appliedontopoftheglass.Thewaterflowinginsidethetubehas a temperatureof 25degree Celsius andatoutlet43.66 degree Celsiushasbeenmeasured.

In next iteration we will calculate the outlet temperature by changingitspathfromparalleltoU-bent.

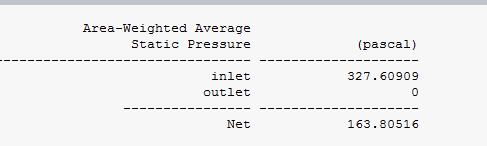

2.2 Iteration 2

Figure16Velocity

2.2.1 In this iteration

1. boundaryconditions

2. materialconstants

3. solarmodule

4. energyequationsand

5. Numberofstepsiterations

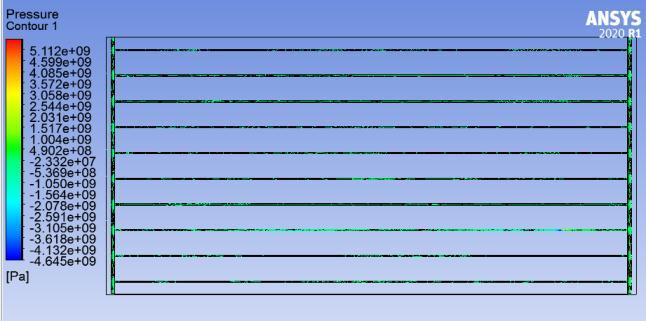

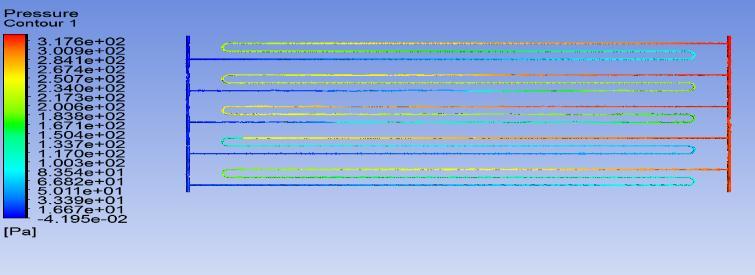

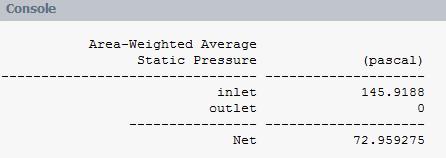

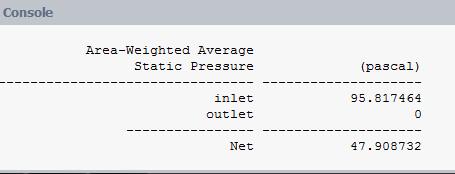

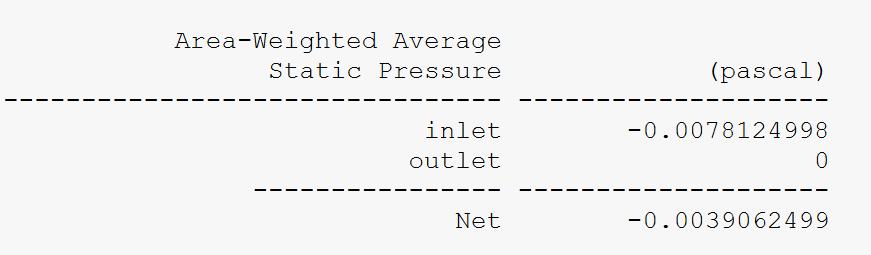

Figure17pressureinpascal

Havebeenkeptsameastothepreviousproblem

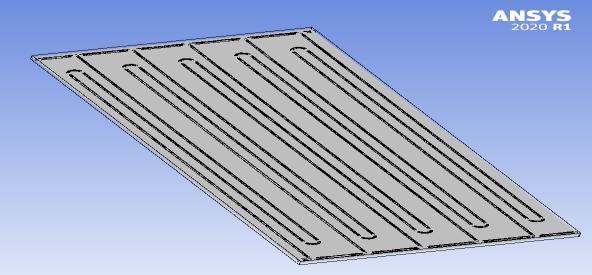

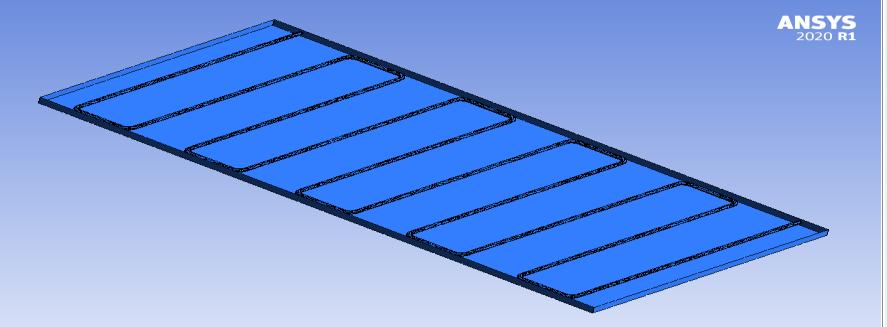

Onlytubepathhasbeenchangedfromstraightorparalleltoubent. Aswecanseeinthebelowfigure.

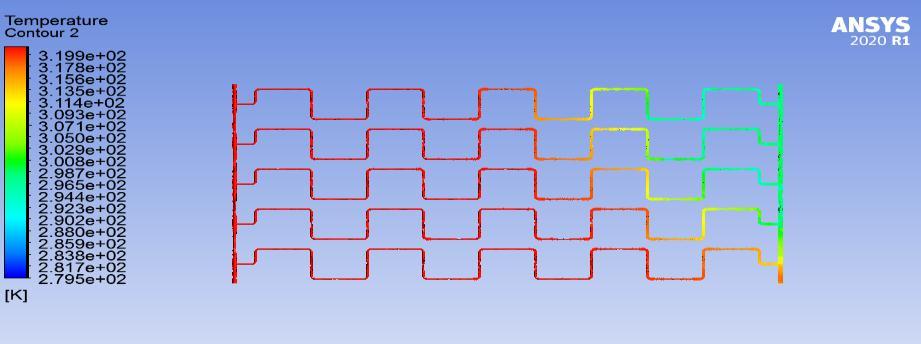

Figure18temperaturecontours

Figure20solarflatplatecollectorwithU-Benttubes

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056 Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

1. Velocity

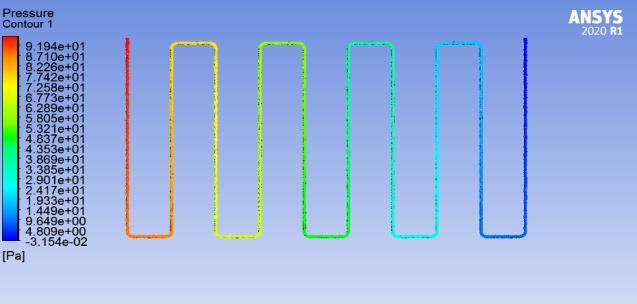

2.4 Iteration 4

Figure28velocity

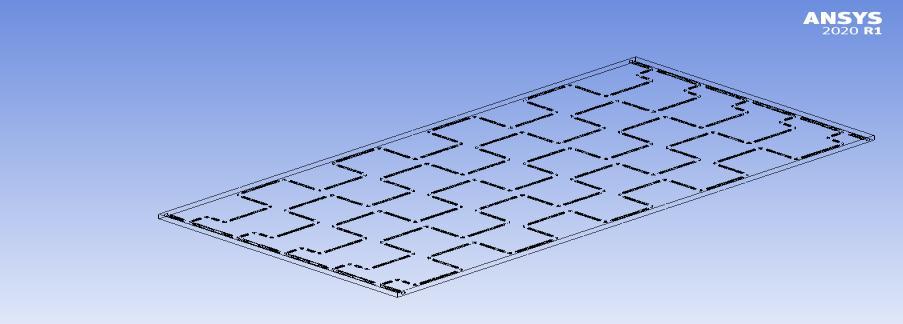

Figure32Zig-Zagwithsingletubing

• Gapbetweentubes = 200mm

• Nooftubes = 10X

1. Temperature Results.

Figure29Velocitydistributioninthetubing

2. Pressure

Figure33temperatureresults

Figure30pressure

Figure34temperatureresultplotonsingletubeZig-zagPath

Figure31temperaturecontourofZig-Zagtubing

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

2. Pressure Results

• MaterialComparisonforexperimentalmodal

• Material

• Tube

SteelCollector

Copperalloy

Figure34Pressure

Figure38temperaturecontour

Figure35pressuredropatoutlet

3. Velocity

figure39temperature

Figure36velocity

Figure40Pressure

Figure37velocityvaluesatdefinedoutlet

Figure41Velocity

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

LCD screen About35.7x16.8mm/1.4x0.66''

Wire length 1.5m/4.9ft

TableSpecificationoftemperaturesensor

3.3 Water motor

Figure42ExperimentalModalSolarflatplatecollectorsingle coppertubewithsteelcollector&FigureWatermotor

3.1 Parameters

Collector750*400*30mm

Glass750*400*2mm

Coppertubediameter = 10mm Watermotor = 6vpowers

Temperaturesensor Blackpaint = forabsorption

3.2 Digital result

Temperaturesensorisusedtomeasuretheoutletflowofthe waterflowinginsideasteelcollectorviacoppertube.

R3856-12VDCDiaphragmBasedMiniAquariumWater Pumpisanidealnonsubmersiblepumpforvarietyofliquid movement application. It has enough pressure to be used with nozzle to make spray system. The pump can handle heated liquids up to a temperature of 80°C and when suitablypoweredcansuckwaterthroughthetubefromup to2mandpumpwaterverticallyforupto3m.

1. Model:R385

2. RatedVoltage:DC6Vto12V(1amps)

3. Workingcurrent:0.5Ato0.7A(Max)

4. Power:4W-7W

5. MaxLift:3m

6. MaxSuction:2m

7. MaxWaterTemp:80°C

8. PumpSize:90mm*40mm*35mmapprox.

9. Fluid:0-100°C

10. Input/outputtubediameter:outer8.5mm,inner6mm approx.

11. MaxCurrent:Upto2Ampswhilestartingup

12. Life:upto2500Hours

13. Themaximumflowrateofupto1–3L/min.

Figure43LCDtemperaturesensor

Weight 50g

Battery 2LR44buttonbatteries(Included)

Size About 48x28.5x15.2mm/1.88x1.12x0.59''

Figure44diaphragmMiniMotor

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

Outlettemperatureofwaterafter–minute

Figure45temperatureofwateratoutletafter75min

Experimental results in tabular form

Sr. No Time in hours Temperature T1 in 0C Temperature T2 in Degree Celsius

1. 55 min 24 0C 50.6 0C

2. 75min 24 0C 59.5 0C Software AnsysCFD

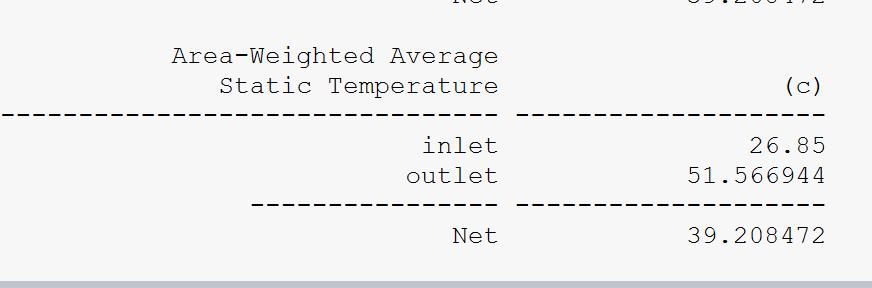

1. 50 Iterations 26.85 51.566 0C

Table1Analytical&experimentalanalysis

• Hencethevalueoftemperatureat55minmatchingthe simulationresultwhichwassolvedfor50iterations.

• Hencetheprojectisvalidatedaswecanseetheabove readingsobtainedarematchingwiththeexperimental solution.

• Thefabricatedparthasanefficiencytorisethewater with an average increment in the temperature radiationofsunenergy.

• Futurescope

• Onecanchangetubeandcollectormaterialtoknowthe thermalaspectofproperties.

Thisprojecthelpsindeterminingthedesignparameter requiredtoenhancethethermalheattransferbetween the flat plate solar collector and the working medium passinginsideacoppertube.

3D model was prepared using Catia v5 3D experience software, & FEA simulation is done using Ansys workbench.

UntilnowFEMfordifferentiterationshavebeensolved, basedonthedesigncriteria&resultswerenotedoutas wecanseeintheresulttabularcolumnforbelowpath flowoftubingsection.

• Paralleltubeflow

• U-benttubeflow

• Zig-zagwith5Xtubing&

• Zig-Zagwith1Xtubing

Zig-Zag with steel material process, temperature of waterbetterthananyotherpath,becauseofzig-zaglike structure, water inside the tube rests longer than any othercross-section,butonlydisadvantageispressure.

Hencefromallaspect

Steelisbetterinstrength,asitpossessesgoodthermal& electricalenergy,lowerincost.Collectorwillbemade usingSS.Tubecopperandathermalglasswithabsorber plate.

To validate the project, experimental modal will be prepared by procuring standard materials and fabricationprocessandwillbevalidatedwiththeFem solution

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

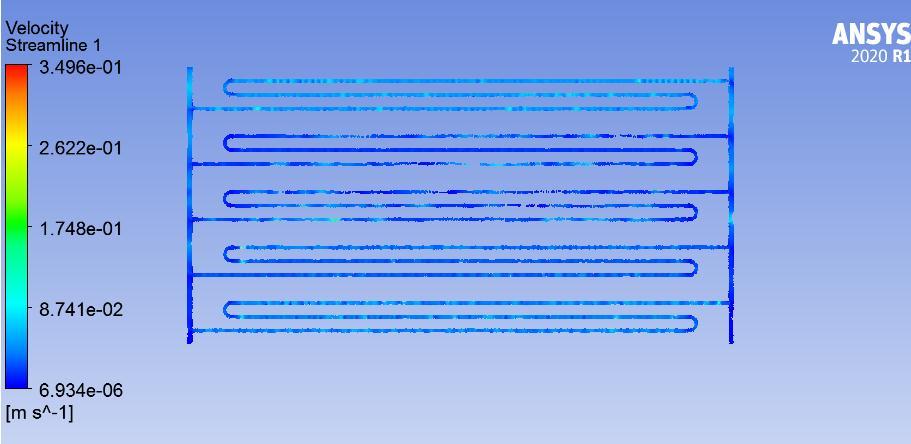

Type Boundary Conditions

1. Parallel tube

2. U-Bent tube

Inlettemperature

Result Result: Temperature In 0c

Pressure Outletin

3. Zig-zag

Outlet Velocity 0.05m/sec

T1=250C

Inlettemperature

T1=250C

P1=418 temperature T2=43.660C

Outlet Velocity 0.05m/sec

Inlettemperature 5Xtube

4. Zig-zag

T1=250C

Inlettemperature 1Xtube

5. Zig-Zag with steel collector

Outlet Velocity 0.05m/sec

InM/Sec

Result Velocity Pascal

V2=33.635 P2=0

P1=327.6 temperature T2=50.990C

V2=0.0454 P2=0

P1=145 temperature T2=48.98 0C

V2=0.0493 P2=0

Sr.No Components Specs Cost

1. WaterMotor 1X 6V 345/-

2. Coppertube 1x 1meter 785/-

3. Collector Double angleplate 1meter

345/-

4. Sheetplates 1-2mm thickness 645/-

5. Transparent tube 1meter 165/-

6. Glass 2mm thickness 1200/-

7. Temperature Sensor 1X 263/Components Total 3748/Fabrication& transportation 3500/Total 6748/-

Outlet temperature Velocity 0.05m/sec

T1=250C

P1=95 T2=49.79 0C

V2=0.0284 P2=0

T2=51.566oC P10 T1=250C

V2= 2.481e8 P2=-0.078

Table2Billofmaterial

[1] "Solar Energy Perspectives: Executive Summary". InternationalEnergyAgency.2011.Archivedfromthe original(PDF)on3December2011.

[2]Jumpup^"Energy".rsc.org.

Table3resultstable

Hencetheanalysisdoneforexperimentmodal has a temperature of 51.566944 degree Celsiusat50SubIteration.

In next phase, modal of solar flat plate collector will be prepared with additive manufacturingProcess.

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page502

[3] International Journal of Emerging Technology and AdvancedEngineeringWebsite:www.ijetae.com(ISSN 2250-2459,ISO9001:2008CertifiedJournal,Volume3, [4] U.S. Department of Energy - Energy Efficiency and RenewableEnergySolarEnergyTechnologiesProgram. http://www1.eere.energy.gov/solar

[5] “Handbook of Heat Transfer” by Warren M.Rohsenow,JamesP.Hartnett,YoungI.Cho,MCGRAWHILL,3rdEdition,ISBN0-07-053555-8.

[6]MohammedAbdulJunaid&S.IrfanSadaq“Design& OptimizationofFinsinSolarFlatPlateCollectorUsing CFD”. International Journal of Science & Research Website:www.ijsr.net(ISSN2319-7064)Volume6Issue 1,January2017

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056 Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

[7]SatelliteImageofLocation,www.google.com/map

[8] https://www.internationaljournalssrg.org/IJME/paper -details?Id=313

[9] C. Eaton and H. A. Blum, “The use of moderate vacuum environments as a means of increasing the collection efficienciesandoperating temperatures of flat-platesolarcollectors,”SolarEnergy,vol.17,no.3, pp.151–158,1975.

[10] N. Benz and T. Beikircher, “High efficiency evacuatedflatplatesolarcollectorforprocesssteam production,”SolarEnergy,vol.65,no.2,pp.111–118, 1999.

[11]C.Benvenuti,“Evacuableflatpanelsolarcollector,” PCT/EP2004/000503,CERN,2005.

[12]R.MossandS.Shire,“Designandperformanceof evacuated solar collector microchannel plates,” in EuroSunConference,Aix-les-Bains,France,2014.

[13]G.S.F.Shire,R.W.Moss,P.Henshall,F.Arya,P.C. Eames,andT.Hyde,“Developmentofanefficientlowand medium temperature vacuum flat-plate solar thermalcollector,”inRenewableEnergyintheService ofMankind,vol.2,pp.859–866,SpringerInternational Publishing,Switzerland,2016.

[14]Y.Fang,T.Hyde,P.C.Eames,P.C.Eames,andN. Hewitt, “Theoretical and experiment analysis of the vacuum pressure in a vacuum glazing after extreme thermalcycling,”SolarEnergy,vol.83,no.9,pp.1723–1730,2009.

[15] M. M. Koebel, H. Manz, K. E. Mayerhofer, and B. Keller, “Service-life limitations in vacuum glazing: a transient pressure balance model,” Solar Energy MaterialsandSolarCells,vol.94,no.6,pp.1015–1024, 2010

Mr.VipulSudhirMahajan

MEMechanicalDesignEngineering studentfromDYCOEAkurdi.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page503