International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

1College of Engineering and Technology, Construction Technology and Management, Wachemo University, Hossana, Ethiopia.

2Faculty of Civil and Water Resource Engineering, Bahir Dar Institute of Technology, Bahir Dar University, Bahir Dar, Ethiopia. ***

Currently there has been potential need of housing due to high rate of population in worldwide. Most of developing countries including Ethiopia, proceeding in the hopeful progress in construction methods in terms of addressing such a problem. The objective of this study was to develop the mortar-less masonry work by using interlocking hollow concrete blocks as alternative construction method to have affordable houses. Questionnaire survey was distributed and collected from respondents, and twenty seven (27) samples of the interlocking concrete blocks were used to conduct experimental works. From the analysis, HCB was ranked as the mostly used product for a masonry works of building construction in a Hossana town when compared to other materials, and currently, there has been not the experience of using interlocking concrete block for a masonry works of building construction in a town. According to the output of modeling, there are two basic models developed with the size of 200 x 200 x 400 mm, and 100 x 200x 400 mm. The maximum density achieved was 1222.73 Kg/m3 for an interlocking hollow concrete block after 28th day curing period, the maximum compressive strength achieved was 2.39 MPa (N/mm2) that the products can be categorized in the Class C according to ESC D3.301. The water absorption capacity of the product was 16.45% which is greater than the standard requirements for concrete masonry units that have to be less than 10%, which requires using a proper plastering to prevent the penetration of rain water. IHCB ranked the least cost and time required when compared to that of conventional Hollow Concrete Blocks

Keywords: IHCB, Mortar-less masonry, Alternative building construction method

Worldwide,towns and cities have grown atarapid rate and the dramaticproblemslinked to this include huge shelter needs; emergence of squatter settlements and slums; and deficient infrastructure in many low-income settlements [1,2]. Currently, millions of people worldwide live in substandard housing conditions and this problem is expected to get worse.By2025,itisestimatedthatthenumberofurbanhouseholdsoccupyinginadequate,unsafe,andcrowdedhousingwill risetoroughly440million[3].

The building sector has undergone a radical change in the type of building materials and methods used for urban dwellings over the past few decades in most countries. More and more often, alternative building materials are used in place of conventional and traditional building materials. The present rate of construction in developing countries including our countryEthiopiaisgenerallysufficienttomeettheneedsofonly10%ofthenetincreaseinpopulationperyear[4].

So, the impact of construction methods have on productivity, quality, and cost, their selection is a key decision for the successfulandsustainableconstructionprojects,andhasinfluenceontheproductivityandefficiencyofconstructionprojects [5, 6]. Therefore, achieving high productivity depends greatly on the selection of the construction methods to be employed throughout the execution of a construction [7]. Building using distinct units, frequently put in and connected by mortar, is knownasmasonry;theterm"masonry" can alsorefer tothemodulesthemselves. The mortarless masonry worksbyusing interlocking block configurations were first developed from compressed mixtures of Portland cement, dust from industries and water [8]. Researchers developed the compressed interlocking earth blocks in developing country which is reinforcedbydifferentnaturalfibers,andstabilizingwithcement[9,10].

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

Thestrengthisincreasedby40%comparedtothebrickandby20%comparedtotheconcretemasonryhollow.Furthermore, ascomparedtotheinterlockingcharacteristics,theincreaseincompressivestrengthisalsoseen.Incomparisontotheprism without interlocking mortar, interlocking mortar enhances strength by 30% [11]. Considering the structural behavior of interlocking blocks, they are commonly less economic, non-loadbearing constructions. An interlocking lightweight cement block was developed to use in load bearing masonry walls. It was found that the mix proportion of constituent materials to achievethetargetstrengthanddensitytobe1:1:2ofcement: sand:polystyrenebeads,withwatercementratioof0.35.The averageweightofanindividualblockwas20.4kg,whichisanacceptableweightforasinglepersontohandleWhencompared toconventionmasonryblockconstruction,interlockingblocks,whicharedry,assembled,saveagreatdealofmortar[12].

Obviously, currently there has been a potential need for housing due to high rate of population in worldwide. Most of developingcountriesincludingourcountryEthiopia,proceedinginthehopefulprogressinconstructionmethodsintermsof addressingsuchaproblem.But,inourlocalconstructionpracticestillthereislessproductivitywithgreatwastageespecially in concrete dependent works. And, it is longing to see either new creative ideas or modification of the existing method of statement that can minimize the cost and time with respective quality for building construction project nowadays in our country.So,itistherighttimetoassessthealternativeconstructionmethodsincludingthedevelopmentofinterlockingblocks formasonryworks,precastelementsofbuildingstructure,modularconstructionsystemandotheroptionsthatcanreducethe projectcostbyreducingthewastes,workforces,andperiodtoaccomplishitwithconfirmativestandardofquality.

The present study focused on developing better interlocking blocks that can reduce the mortar works to make the building masonry construction by a smaller number of semi-skilled labors with in short period of time comparatively to the existing practice of construction firms around Hossana town, SNNPR, Ethiopia. Furthermore, assessed the current practice of alternativeconstructionmethodsthatcouldbeusedinlocalfirms,anddeterminedthephysicalandmechanicalpropertiesof mostlyfeasibleproducts,

Dangote Ordinary Portland Cement (OPC) of grade 32.5R CEM I was used throughout this study in the preparation of the concrete mixes of the solid block according to IS 269. Based on result of experiment, the initial setting time and final setting timeofDangoteOPCofGrade32.5R Iwere128.75 min and244.5min respectively when manual Vicatapparatus used.Both resultsarenearesttothevaluepointedonthespecificationofmanufacturer.

Coarse and fine aggregate- Concrete disposal in Wachemo university that discharged due to floor maintenance Allphysical tests were done as per ASTM standardsandconformed to all necessary standard requirements. Table 1indicates physical propertiesgainedasaresultofcoarseaggregate.Themaximumsizeoftheaggregatewas12.5mm.

Table1;Physicalpropertiesofaggregates

2.2.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

So, the actual mix ratio of ingredients that researcher used for this research is cement to sand to gravel to scoria coarser aggregate was 1:5:1:1 that imply 1 part of cement with 5 parts of sand, 1 part of gravel, and 1 part of scoria. And water to cementratiowas0.64consideringtheabsorptionandmoisturecontentsoftheaggregates.

2.3.

In order to attain the relative output, qualitative approach of the research strategy through preparing questionnaires and interviews for local construction firms around Hossana town was required to assess the existing construction practice of masonryworks.And,thequantitativeapproachesofthestudywasconductedintermsofdeterminingthevariationofcostand timewhencomparedtothemasonryworksfromstone,brick,andHCBunits.

AmongthepublicbuildingsandrealstateshousesinHossanatown,twelve(12)construction site;andcontractor,consultant, andworkersonsitefocusedforthisstudy.ResearcherselectedasampleofquestionnairesandopeninterviewfromHosanna townconstructionprojectenvironmentcontractors,managers,engineers,supervisors,andotherlaborswhoworkedonsiteto assesshowhandleconcreteconstructionmaterialonsite.Theestimatedtotalpopulationsizeofthisstudywas1,480workers thoseinvolvedonvariousactivitiesofconstructionworksinthetown.

Thecollectionofsampleswasthroughastratifiedsampling.A stratified sampling is a technique which consist of dividing population under study into mini groups namely strata. Beforesampling,thestudypopulationwasdividedintofeaturesof significance for the study. In our case, given the stratum was based on various positions of works such as consultant, contractor,Dailylabors.

Thesamplesizeforthestudywasarrivedatusingstatisticalcalculation[13]

SS=N/((1+Ne^2)),ifthetotalpopulationis>30…………….....................................Equation[1]

Where:N=population,e=error,SS=samplesize

Now,Nisthepopulation=1486+9+0withinHosannatownlete=10%.

So,SS=1480/((1+1480〖*0.1〗^2))=94

The sampling technique regarding to experimental work of the product for this research was a non-probability sampling technique which is the purposive method. For material laboratory test, the samples was depending on the types of test requirement and standards. And, size of sample of all aggregates in this study determined by using chute-type mechanical samplesplittermethodwhichisdividingofsampleasdescribedandbeneaththeblanketinevenamount.

Basedontypesandsizeofmixmaterialsthattobeusedfortwomodelinterlockinghollowconcreteblockandtestcategories, twentyseven(27)samplesinthreedifferentspecimenswerecastedforeach7th,14th,21st,and28th daytest(Table2)

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

Table2:Totalsamplesizeused

SAMPLE CODE

Samples Code Number of cube samples Total

For 7th day For 14th day For 21th day For 28th day

M01IHCBc 03 03 03 03 12

M01IHCBu 03 03 03 03 12

M01IHCBw 03 03

Total 06 06 06 09 27

Where;M01IHCBc standsforModel 01InterlockingHollowConcreteBlock sample thatusedforCompressivestrengthtests, M01IHCBu is for Model 01 Interlocking Hollow Concrete Block sample that used for Unit weight determination, and M01IHCBwisforModel01interlockinghollowconcreteblocksamplethatusedforwaterabsorptiontests.

2.6.

ThetestsonhardenedconcretedweretakenasperthestandardsofASTMasmentionedintheTable3below.

Table3.StandardTestMethodusedtoconductthelaboratoryexperimentalworks.

No. Property Tests Standard Test Method 1 Unitweight ASTMC138M-17

2 Compressivestrength ASTMC469/ASTMC109M-16

3 Waterabsorption ASTM C140-03

3.1.

Amultiplesetoofquestionnaires survey weredistributedforboth publicandprivatebuildingconstructionprojects inorder toreviewtheexistingdifferentmaterialsthatusedasmasonryunits Accordingtotherespondents’ rate(Table4),HCBwas rankedasthemostlyusedproductforamasonryworksofbuildingconstructioninaHossanatownwithaPercentage=100. As shown in the figure, a dressed stone and timber has been used as masonry units with highest percentage with value of 47.67% and 18.60% respectively. But unfortunately, there was current experience of using interlocking concrete block for a masonryworksofbuildingconstructionina referredtown withavalueof2.31% Inaddition, thestabilizedinterlockingsoil blockyieldedaminimumranktobeusedasmasonryunitswitha9.30%inabuildingconstructionpracticeofHossanatown.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

Table4:MasonryunitsofbuildingconstructionusedinHossanaTown

No. Types of Material Number of Respondent % of Usage

1 Hollowconcreteblocks 8 100.00 2 Mixed 86 44.19 3 Dressedstone 26 30.23 4 Timber 7 11.63 5 Brick 5 9.30 6 Agro-stone 10 8.14 7 Soilstabilizedinterlockingblocks 2 5.81 8 InterlockingConcreteblocks 38 2.31

3.2. The factor affects the current practice of using mortar - less (Interlocking) blocks in Hossana Town

Thispartofthestudywasperformedbyconsideringtherategivenbytherespondentsforthefive(05)Likertscalesonfactors affectingonthecurrentuseofinterlockingblockforamortar-lessmasonryworksasalternativebuildingconstruction,andRII (RelativeImportanceindex)wascalculated.BasedontheresponseoftheparticipantsasshowninTable5below,absenceofa product supply in a local market like other brick, HCB, Stone, etc. was a factor ranked as the most critical factor affected the use of IHCB with RII= 0.97. Lack of knowledge in using such a product due to more people follows a traditional masonry works for building construction, and the sustainability and applicability for load bearing masonry is not determined are the following factors of affecting the use of IHCB with RII = 0.95 and RII = 0.79 respectively. Based on the respondent rate, perception on qualityof a product will be poortouseasmasonry unitsconsidered asa factorfor not experiencing ofuseof suchaproductwithaleastRII=0.58.

Table5:FactoraffectsthecurrentPracticeofusingInterlockinghollowconcreteblocksinHossanaTown

No. Factors affected the use of Interlocking blocks as masonry units RII

1 Lackofknowledgeinusingsucha productduetomorepeoplefollowsatraditional masonryworksforbuilding construction 0.95

2 Absenceofaproductsupplyinalocalmarketlikeotherbrick,HCB,Stone,etc. 0.97

3 Difficultiestogetskilledpersontoworkthemasonrybyusinginterlockingconcreteblocks 0.77

4 Perceptiononqualityofaproductwillbepoortouseasmasonryunits 0.58

5 Duetoitshighpricewhencomparedtootherlocalmasonryunitslikeburntbricks,HCB,Stone,etc. 0.63

6 Thesustainabilityandapplicabilityforloadbearingmasonryisnotdetermined 0.79

AutoCAD 2012 was used to develop a model of interlocking blocks that can be produced from concrete in order to enable mortar - less masonry works as better alternatives of building construction method. According to the output of modeling, therearetwobasicmodelsdevelopedasdescribedbelow.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

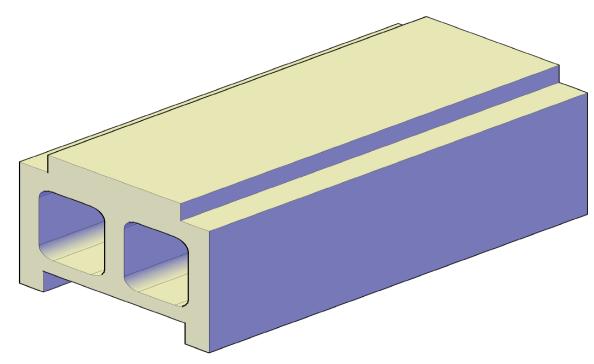

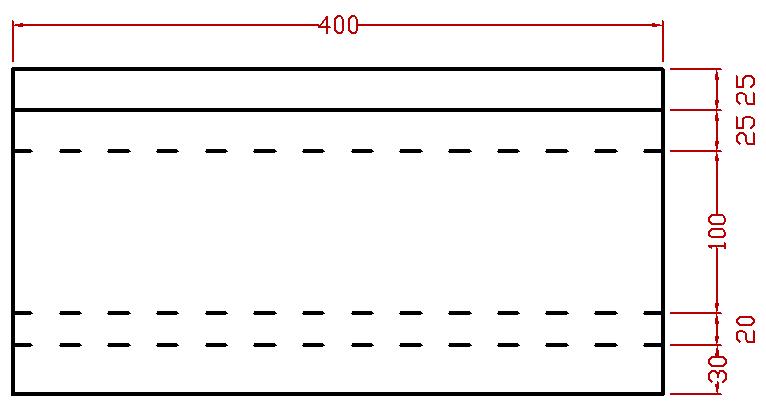

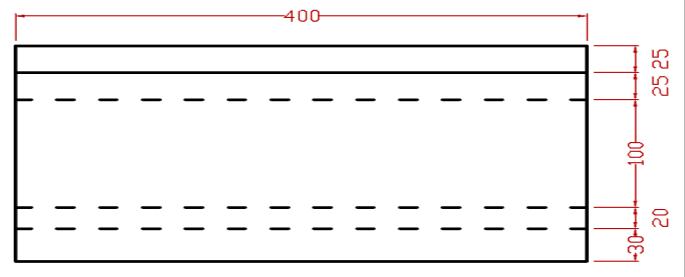

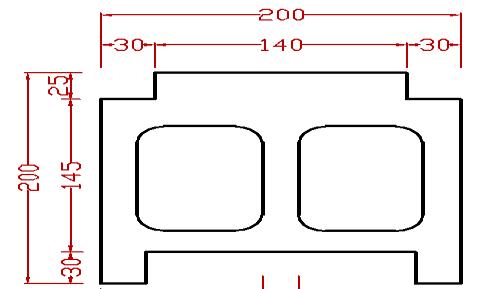

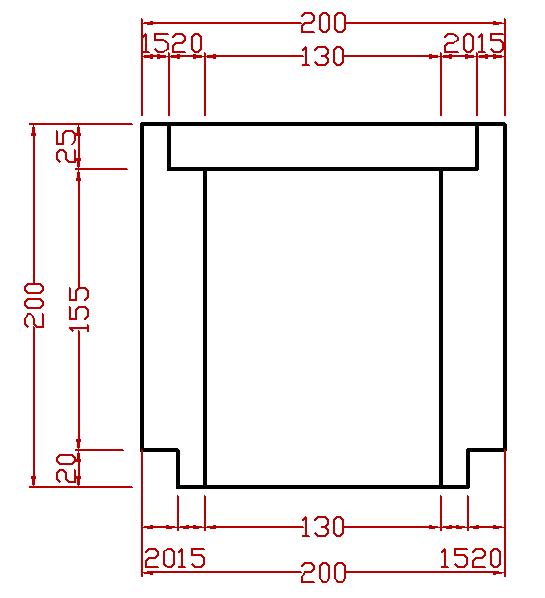

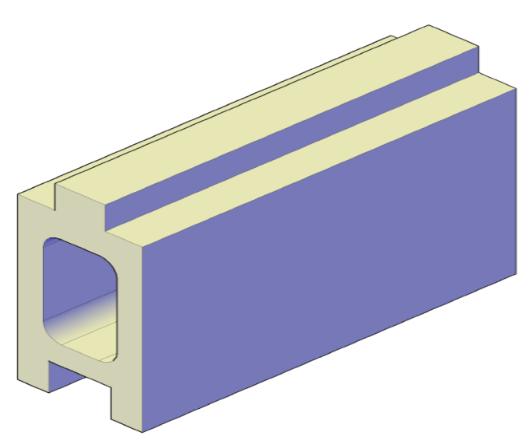

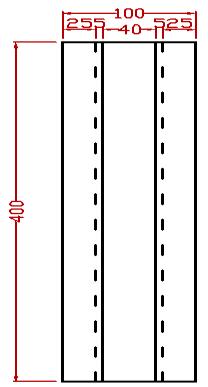

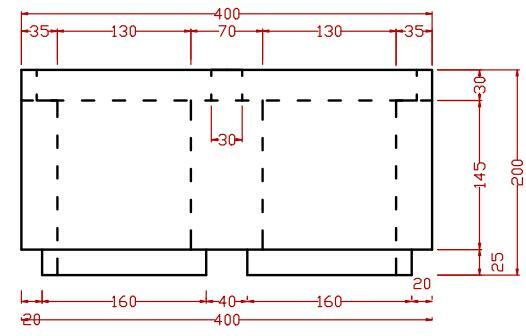

A hollow along the horizontal axis with the size of 200 x 200 x 400 mm, and 100 x 200x 400 mm was mould was used to establish this model. Figure 1 and Figure 2 shows that the top view from outer part of the product it acts as a key and the bottomasalock.

FrontView LeftsideView

TopView 3D(SoutheastIsometricView)

Figure1:Model01(200*200*400mm)ofinterlockinghollowconcreteblock

FrontView LeftsideView

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

TopView 3D(SoutheastIsometricView)

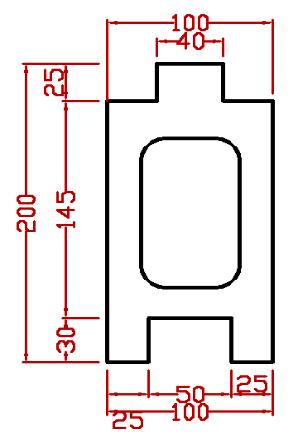

Figure2:Model01(100*200*400mm)ofinterlockinghollowconcreteblock

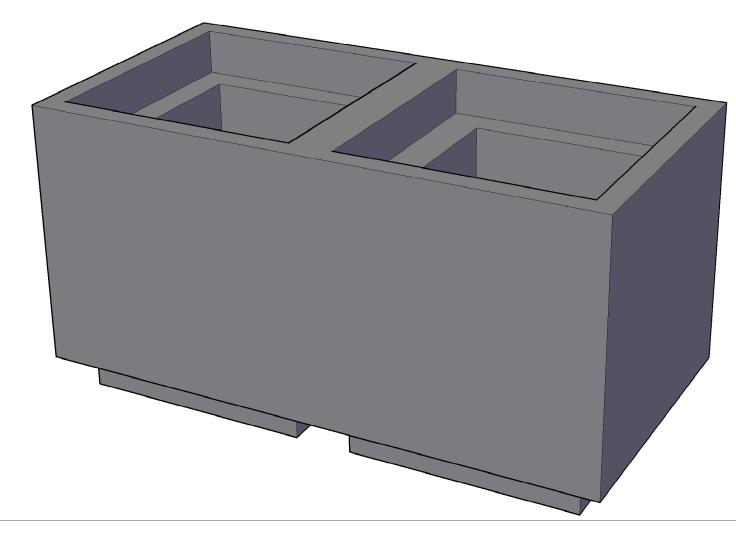

b) Model – 02

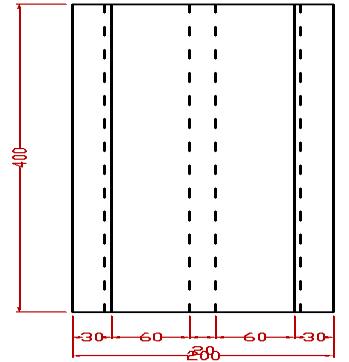

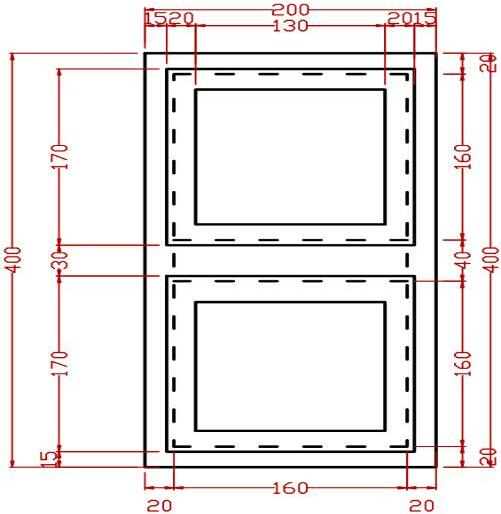

Accordingtothismodel,ahollowisalongtheverticalaxiswiththesizeof200x200x400mm.Asshowninthetopviewfrom outerpartoftheproductitactsasalockandthebottomasakeytomakeitinterlock-abletouseasmasonryunitsthatcanbe coursedwithoutmortar(Figure3).

FrontView LeftsideView

3.4.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

TopView 3D(SoutheastIsometricView)

Figure3:Model02(200*200*400mm)ofinterlockingHollowconcreteblock

As the result from laboratory, the slump of mix of Interlocking Hollow Concrete Block was very dry mix. Based on the Laboratoryrecord,theslumpoffreshmixofIHCByieldedto8mm.

3.5. Properties of hardened interlocking hollow concrete block

Toanalyzethedrydensityofeachspecimenofconcrete(IHCB)sampleswerepreparedwithsizeof100x200x400mmand curedfor7,14,21and28th days.Accordingtopreviousliterature,thedensityofhollowconcreteblockshouldnotbelessthan 1200Kg/m3 Thedryunitweightmeasured resultindicatesthataverageweightthatrecodedwithineachcuringagemetthe requirement (Figure 4). The maximum density achieved was 1222.73 Kg/m3 for an interlocking hollow concrete block after 28th daycuringperiod.While,theminimumdensitybeen1211.11Kg/m3 forasampleat7th day.Astheresultindicateswhen thecuringageofthesampleincreasesthedensityofIHCBalsoincreasesslightly.Generally,theunitweightofsolidconcrete blockmeetstherequirementofASTMstandardspractically.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

DryDensity

Dry Density (Kg/m 3 )

1220

1216

1212

1224 1211.11

1222.22 1215.66

1222.73

1208

7days 14days 21days 28days

CuringAge(Days)

Figure4:Unitweightofinterlockinghollowconcreteblock

The test was focused to check the compression resistance of a product before recommending it for application of masonry works.Theresultwasanalyzedintermsofspecimenswithasizeof100x200x400mmforeachcuringperiodofinterlocking hollowconcrete block asshown in Figure5 below. The 7th dayage ofcuredresultofinterlockinghollow concrete block was potentiallylesstoresistthecompressionstressanditisabout0.45 MPawhichis18.92%whencomparedtothatofthesame productat28th daycuringage. Furthermore,curingperiodincreasesthecompressivestrengthincreasesinthesamemanner. Sample at 14th day was 1.84 MPa. Meanwhile, compressive strength of IHCB for curing period of 21 days after the cube was 2.01 MPa which achieved about 84.26% in terms of 28th day aged. As the result shows most of the time in our local construction industry basically for masonry work the contractors use the either of hollow or solid concrete block products with in this curing period even if it not achieves its relevant required strength. Additionally, the maximum compressive strength achieved for this sample of interlocking hollow concrete block product was 2.39 MPa (N/mm2). Based on the experimentalresultsofthisinvestigationrecordedat28thdaycuringperiod,theseproductscanbecategorizedintheClassC accordingtoESCD3.301thatwillbeusedfornon-loadbearingwalls.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

Compressive Strength (N/mm 2 )

90

80

70

60

50

40

30

20

100 18.05

10

73.53

80.39

95.41

7days 14days 21days 28days

Figure5:CompressiveStrengthofIHCB

Three full sizes of IHCB products were completely immersed in clean water that prepared on curing tank at a room temperaturefor24hours.Fromtheexaminedtestresults,thepreparedsampleyielded8.07kgafterimmersedinwaterfor24 hours,andbeenmeasuredabout6.93Kgwhendriedinovenwiththesametimeextents.

Absorption,percent=(8.07–6.93)/6.93*100=16.45% Where,A=wetmass=8.07kg. B=drymassofunit=6.93kg.

As displays in the figure, the water absorption capacity of the product was 16.45% which is greater than the standard requirements for concrete masonry units that have to be less than 10%. This result show that product is sensitive for absorption of water due to either using of scoria as one of mix material and/or porous in the hardened product resulted by lesscompaction.So,itistheresearcher’srecommendationtousesuchaproductininternalwallsofbuildingconstruction, and touseaproperplasteringtopreventthepenetrationofrainwateriftheproductusedforexternalmasonryworks.

IHCB with other commonly used materials

in this part, the cost of masonry works that will be made from Interlocking Hollow Concrete Blocks were evaluated comparatively with the other materials basically, nominal HCB, stone, and brick works. Considering the mix ratio, dry shrinkageandwastageduringtheactualwork,thequantityofeachmaterialperunitsdetermined.Then,thepurchasepriceof material basedonthecurrentlocal marketsurveyedandconvertedtounitprice.Basedoncurrentmaterial priceofsomeof materialstobeusedforthisstudylistedbelowunderTable6.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

Table showsthedetailedunitcostcomparisonstoproduce1m2 wallhaving20cmthickwhichmadefrom HCB,IHCB,stone, and bricks, and the percentage difference in cost with respect to the IHCB. As seen from the table, there was almost similar costsforbothlaborandequipmentforeitherproductofIHCBandHCB,onlytheshapeoftheproductsandtheirnumberthat would be required for a 1m2 varies. So, due to similarity in the production method, type and amount material used, it was consideredtheequivalentthecostofIHCBtothatofnominalHCBwiththesamesize. Itwasfocusedtocomparetheunitcost ofa20cmthickmasonrywallin1m2 duetouseofIHCBwithothermasonryunits(HCB,Bricks,andStone)thatpracticedby highratesinHossana town. Consideringthecurrentmarketpriceoftheproductsandmaterialsto beusedfor a 20cmthick wall including 15% of overhead cost and 10% profit by neglecting the cost of equipments/tools, the total unit cost of 1 m2 buildingmasonrywallcomputedandexplainedintermsofHCB,IHCB,stone,andbrickunits.Thetableshowstheunitcostofa 1 m2 20cm thick works from IHCB ranked the least cost which is equals to 386.89 ETB/m2 that saves a 30.69 % when comparedtothatofconventionalHollowConcreteBlocks,130.36%thanstonemasonry,319.9%thanbrick.Duetothecostof material required per a square meter, and the minimum labor hourly output, brick wall ranked a highest unit cost when comparedtoanothermaterialbasedwallwhichisequalsto1624.57Birr/m2

Table7:Unitcostof1m2 20cmthickwallfromHCB,IHCB,stone,andbricks

Materials used for Masonry Unit Cost Manpower Unit Cost Overhead Cost Profit Cost Total Unit Cost % of differences in cost with respect to IHCB classC,HCB 305.69 98.82 60.68 40.45 505.63 30.69 classC,IHCB 295.98 13.53 46.43 30.95 386.89 0.00 Stone 282.35 430.65 106.95 71.30 891.26 130.36 Fullsizebrickwall 1311.88 138.63 101.54 72.53 1624.57 319.90

Inordertocompare the construction timetaken betweentheIHCBandtheother masonryunits,theactual timerequired to builda1m2 ofbolckworksfromIHCBwererecordedafterpreapringthesampleproductsandcomparedtothetimerequired fro the same area of block works. For the rest of the masonry units, the datas’ were taken by interbiewing masons’ from constructionsites,andthecomparsionoftheresultisshowninTable.Accordingtotheobservationresultsoftimerecoded,it required an average of 7.5 min per 1 m2 of block. According to the collected dat’s, brick and dressed stone was the highest bolckworksthatrequiredmoretimescomparedtotheotherswith75.00and72.69minutes,respectively;whiletobuild 1m2 agro stone masonry works were the second least working time next to IHCB which was equals to 15 min even if it is not

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

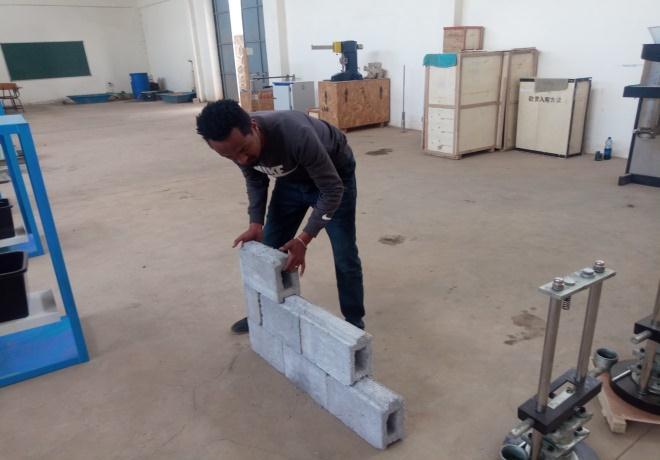

commonly used around the Hossana town. The table indicates that the time required to accomplish a square meter block works from bricks was 75 min, HCB taken 45.74 min, and a dressed stone wall takes 72.69 minutes. Using of IHCB for a masonry work fasters five times than the wall construction from nominal HCB, nine times faster when compared with a building wall constructionfrom brick andstone construction This enhancesfastconstruction of masonry worksthatwill be resulted due to deducting the need of the mortar, and the setting out to adjust the horizontal and vertical alignment of a specificwall.Figure demonstratesthetheconnectionofinterlockingmortar–lessmasonryunitswithIHCB.

Figure6:CoursingamasonryusingIHCB(Mortar-less)units

Table6:AtimelimitstobuildawallfromHCB,IHCB,stone,andothermaterials

Materials

Indexed Time that will be required (min) Percentage of the differences in a time

Brick 75.00 900.00 HCB 45.74 509.88 DressedStone 72.69 869.23 Agro-Stone 15.00 100.00 Soilstabilizedinterlockingblocks 23.00 206.67 Timber 56.00 646.67 IHCB 7.50 0.00

The main aims of this study were to identify the current masonry units that used in Hossana town, develop interlocking mortar-less concrete blocks for masonry works, assess their physical properties, to compare the cost and time required to buildmasonryunits.Accordingtoinvestigatedanalysis,thefollowinglistedconclusionsaremade;

HCBwasthewidelyusedproductforamasonryworksofbuildingconstructioninaHossanatownwhencomparedto bricks,adressedstone,stabilizedinterlockingsoilblockandtimber.

Therehasbeennoexperienceofusinginterlockingconcreteblockforamasonryworksofbuildingconstructionina town.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

The absence of a product supply in a local market like other brick, HCB, Stone, etc. was a factor ranked as the most criticalfactorresultedonthenegligenceontheuseofIHCB.However,lackofknowledgeinusingsucha productdue tomorepeoplefollowsatraditionalmasonryworksforbuildingconstruction,andthesustainabilityandapplicability forloadbearingmasonrywerenotdeterminedthefactorsofaffectingtheuseofIHCB.

Therecouldbetwobasicmodelsdevelopedbysettingahollowalongthehorizontalaxiswiththesizeof200x200x 400mm,and100x200x400mm

The maximum density achieved was 1222.73 Kg/m3 for an interlocking hollow concrete block after 28th day curing period that meets the requirement of ASTM standards, and the maximum compressive strength achieved for the interlockinghollowconcreteblockproductwas2.39MPa(N/mm2).

Thewaterabsorptioncapacityoftheproductwas16.45%whichgreaterthanthestandardrequirementsforconcrete masonryunitsthathaveto belessthan10%,whichrequiresusingaproperplasteringtopreventthepenetrationof rainwateriftheproductusedforexternalmasonryworks.

comparedtoothermasonryunits,theunitcostandtherequiredtimetobuildamasonryblockworksfromIHCBwas lowerandsavesabouta30.69%to319.9%costoftheothers.

No conflict of interest among the Authors

1. RoserM.FuturePopulationGrowth.OurWorldinData.2013.

2. AigbavboaC,Thwala,W.PredictionofResidentialSatisfactioninSouthAfricanLow-IncomeHousing:RoleofBeneficiaries. JournalofArchitecturalEngineering.2018;24(01).

3. A Holistic Approach to Affordable Housing [Internet]. 2019. Available from: https://digitalcommons.wpi.edu/cgi/ view content.cgi?article=7861&context=mqp–all

4. KrishnaiahSRPS.EffectsofClayonSoilCementBlock. The12thInternationalConferenceofInternationalAssociationfor ComputerMethodsandAdvancesinGeomechanics(IACMAG);Goa,India.2008.

5. Alzahrani J, Emsley M. The impact of contractors’ attributes on construction project success: A post construction evaluation.InternationalJournalofProjectManagement.2013;31:313–322.

6. BarnesR.BoostingaffordablehousinginAfricanusingABTs.Construction2015September18.

7. RodriguesH,ŠipošTK.MasonryBuildings:ResearchandPractice.Buildings.2019.

8. Etherington AB. Interlocking Soil-Cement Bricks- A Modified Cinva Ram Brick Making Machine. Asian Institute of Technology-HumanSettlementDevelopmentDivision(AIT-HSD);Bankok1983.

9. Eires R, Sturm T, Camões A, Ramos LF. STUDY OF A NEW INTERLOCKING STABILISED COMPRESSED EARTH MASONRY BLOCK.2012.

10. Davis L, Maïni S, Royo Olid J. Feasibility report for compressed stabilised earth block (CSEB) production and use in the northandeastofSriLankaPublicationsOfficeoftheEuropeanUnion;2018.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

11. AhmadS,Sadam,Hussain.,Awais,M.,Asif,Mohd.,Muzamil,H.,Ahmad,Rafiq., Ahmad,S..TheBehaviorofInterlockingOf MasonryUnits/Blocks.JournalofEngineering.2014;04(03):39-47.

12. Sayanthan R, Ilamaran, S., Rifdy, M., Nanayakkara, S.M.A. DEVELOPMENT OF INTERLOCKING LIGHTWEIGHT CEMENT BLOCKS. InternationalConferenceonKandy;SriLanka:StructuralEngineeringandConstructionManagement;2013.

13. Yamane,T.Statistics,anIntroductoryAnalysis,2ndEd.,NewYork:HarperandRow.1967.

14. Jablonski N. Mix designs for concrete block by Proportioning using the fineness modulus method. Milwaukee: J960363; 1996.