International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

Lins Paul Kuriakose1 , Aravind K Sunil2 , Jerin Varghese3 , Nidhin Pradeep4 , Nijin Varghese5

1Assistant Professor, Department of Civil Engineering, Viswajyothi college of Engineering and Technology, Vazhakulam, Kerala, India 2, 3, 4, 5, UG Scholars Department of Civil Engineering, Viswajyothi college of engineering and technology, Vazhakulam, India ***

Abstract – The fundamental goal of this project is to diminish the dumping of waste in the environment by using waste plastic as a filler in bituminous mixes. This in-hand resource is being used as an asphalt modifier to promote the poor performance of walkways on streets due to brutal climate and high traffic loads, to increase the stability of the asphalt mix, and to diminish the amount of bitumen utilized A large amount of plastic is being dumbed day by day and only 9.1% is recycled and 75% is being dumped in the environment. Polymers can be added to the bituminous mix to some percentage, which can alter the properties of the conventional mix. Various experiments have been completed on whether waste plastic can reuse productively. The polymers which we are using in this current experimental study are LDPE plastic

The filler also plays a major role in the bituminous mix design. The filler used here in this study is M sand.

Key Words: Design,LDPE

For accomplishing this project, it is necessary to acquire knowledge about the different tests conducted for aggregatesandbitumenforcheckingwhethertheaggregate andbitumenaregoodstandards.TheMarshallstabilitytest isthemaintestrequiredtoconductandthevarioustestto beconductedforasphaltmixisMarshallstability,Marshall flowvalue,andBulkdensity

To use waste plastic in the bituminous pavement.

Toevaluatetheoptimumreplacementof%of fillerwithplasticat10%,20%,30%,and40%in thebituminouspavement.

To limit global warming, greenhouse gases, and pollution.

Thelifeexpectancyofthestreetscanbeexpanded.

Toeradicatepotholes

Eco-friendlyinnature.

To yield better-enhanced waste management and bettercityhygieneandenvironment

The methodology adopted for the study includes the followingstages.

a) Literature reviews:Referencesandjournalsare collected related to the subject. It helps to understandthevariousaspectsoftheprojectand therebyleadstotheprogressoftheproject.

b) Collection of materials: Aggregates, bitumen, andpolymerarecollectedforthestudytoconduct varioustests.

c) Test on aggregates and bitumen: Different testsonaggregateandbitumenwerecarriedoutto checkthestandardsofmaterials

d) Preparation of ordinary bituminous concrete specimen: Normal conventional mix waspreparedtochecktheefficiencyofthenormal mix.

e) Preparation of modified bituminous concrete specimen: Modified bituminous mix was prepared to check the efficiency of LDPE modifiedmix

Toconductdifferenttestsandcomparethem.

To compare Marshall stability parameters of bituminouspavement.

f) Analysis: Normal conventional mix and LDPE modifiedbituminousmixaretestedandcompared

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

Penetration Test on Bitumen:Penetrationisa measurement of the consistency or hardness of bituminousmaterial.

Softening point of bitumen: The softening pointofbitumenisthetemperatureatwhichthe substance accomplishes a special degree of softening.

Ductility Test: The ductility test gives the bitumenadhesivequalityandabilitytostretch.

Specificgravityofbitumen:Thespecificgravity ischaracterizedastheproportionofthemassofa given volume of a substance to the mass of an equivalentvolumeofwater,thetemperaturebeing specifiedat270C±0.10C

Aggregate Crushing Value Test: The "aggregate crushing value" gives the relative magnitudeofthetotalresistancetocrushingunder thecompressiveloadappliedgradually.

Aggregate impact value: Thecharacteristicofa material to resist sudden impact is known as toughness.

Specific gravity of aggregate: Specificgravityis theratiobetweenthetotalweightandtheweightof anequivalentamountofwater.

Los Angeles Abrasion Value: The surface of highway sidewalks is subject to wear due to the overalltrafficmovementused.

Mix design aims to have an economical mix of the right gradient ofaggregatesand a sufficient ratioof bitumen to meet the necessary properties of the mix. Bituminous concreteorasphaltisoneofthemostexpensiveandflexible pavement layers used on concrete surfaces. The desirable properties of a good bituminous mixture are stability, durability,flexibility,skidresistance,andperformance.

1. Selection of aggregates: Aggregates with sufficient strength, toughness, toughness, and toughness are selected based on availability and financial considerations. Crushed aggregates and sharp sand give higher stability to the mixture comparedtogravelandroundsand.

2. Gradation of aggregates: The properties of bituminous mixtures, including density and stability, depend largely on the overall size and distributionoftheirgrainsize.

Sieve size(mm) Weight(g) 12.5-10 120 10-4.75 360 4.75-2.36 240 2.36-0.600 216 0.600-0.300 48 0.300-0.150 96 0.150-0.075 48

Shape test for aggregates: Flakinessindexand Elongationindex.

The filler is used to fill small voids in the SMA mix and to make it denser. By performing laboratory tests, the propertiesofthefillercanbedetermined.

This test procedure is used to design and evaluate bituminouspavingmixesandiswidelyusedinroutinetest programsforpavingjobs Here,wearefocusingtoanalyse; Marshallstability,Marshallflowvalue,andBulkdensity.

3. Modified bituminous mix: The filler is 10%, 20%, 30%, and 40% polymer modified. The experimentalprocedureisperformedusingafiller ofthissize.Theresultingvalueisthencomparedto normalandmodifiedmixtures.

Marshallstability

Correctedload=Dialgaugereading*correction factor*coefficientfactorofprovingring

Marshallflowvalue

Bulkdensity

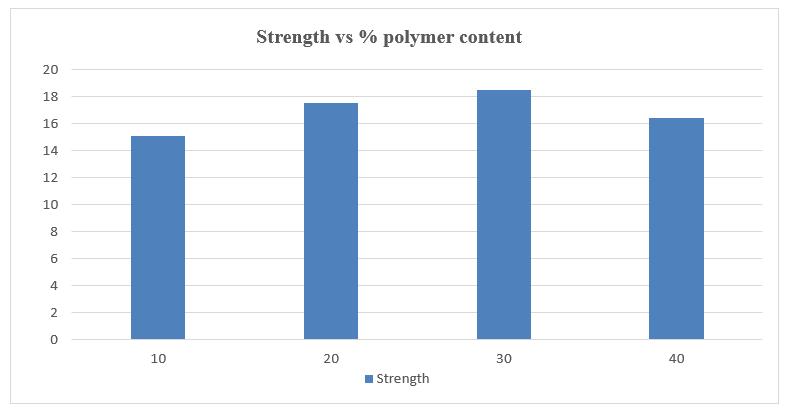

Strengthvs%polymercontent

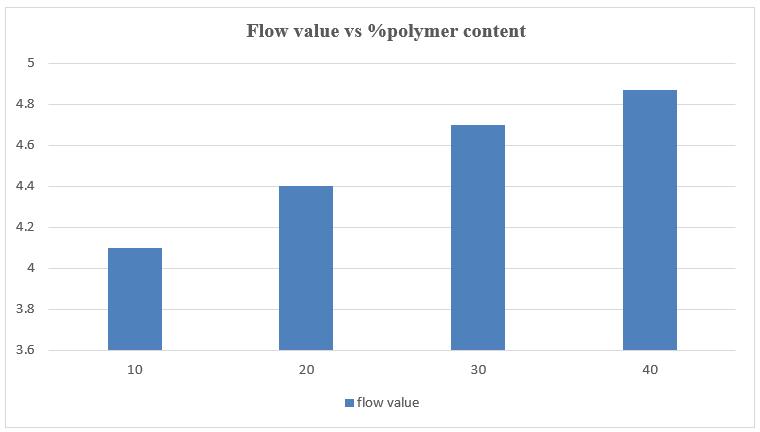

Marshallflowvs%polymercontent

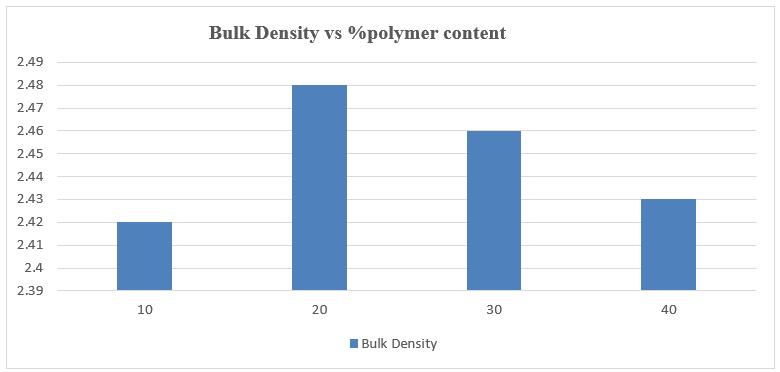

Bulkspecificgravityvs%polymercontent

Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page390

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

Sl No Property Test Result Remarks

1 Aggregateimpact value 24.70% satisfactory

2 Specificgravityof Coarseaggregate 2.62 satisfactory

3 Specifcgravityof fineaggregate 2.61 satisfactory

4 AggregateCrushing Value 23.5% satisfactory

5 LosAngeles AbrasionValue 37.52% satisfactory

6 Elongationindex 9.54% satisfactory

7 FlakinessIndex 14.47% satisfactory

Discussionsofthetestresultsfollow:

Aggregate Impact Value: The total impact value obtainedfromthistestis24.70%,whichisintherange of20-30%.Itissubdividedintogoodforroughsurface ofpavement,whichcanbeusedforbituminousconcrete surface dressing and carpet, bituminous concrete surfaceandcementconcretesurfacerough.

givenis14.47%&9.54%,itcanbeusedforpavement construction.

Specific Gravity of Coarse Aggregate: Thespecific gravity of the rough aggregate was found to be 2.62 between2.6-2.8.Sofolkaggregateisofgoodqualityand canbeusedforroadconstruction.

Specific Gravity of Fine Aggregate: The specific gravityofthefineaggregatewasfoundtobe2.61,which is2.6-2.8.Therefore,goodaggregateisofgoodquality andcanbeusedforroadconstruction.

Aggregate Crushing Value Test: Thetotalcrushing value acquired from this test is 23.5%. So, the given amountcanbeusedforconstruction.

Los Angeles Abrasion Value Test:TheLosAngeles abortion value acquired is 37.52%, which is less than 40%andmorethan35%.Therefore,itcanbeusedfor wetmixmacadam,water-boundmacadam,bituminous macadam,bituminouscarpet,andsurfacedressingasa whole.

Shape Test: AccordingtoSKEyeCEGJusto'Highway Engineering', the total flaccinus index & elongation indexusedinroadconstructionshouldnotbelessthan 15%¬morethan25%.Sincethetotalsamplesize

1

PenetrationTest 61.34 Satisfactory 2 SofteningPoint 48.9 Satisfactory 3 Ductility 75 Satisfactory 4 Specific Gravity of Bitumen 1.013 Satisfactory

Discussionsofthetestresultsfollows:

Penetration test: The penetration value of a given bitumenis56.ThebitumenprovidedunderIS73:2006 is50/70.So,itcanbeusedforpavementconstruction.

Softening Point: The bitumen softening point is obtainedas48.9:c.AccordingtoIS334.1982,thegiven bitumencanbeusedforpavementconstruction

Ductility: Theductilityvalueobtainedfromthetestwas 75 cm. The minimum ductility value specified for bitumen in pavement construction is 50 to 75 cm. Therefore,thegivenbitumenissuitableforpavement construction

Specific gravity of Bitumen: Thespecificgravityof bitumen was found to be 1.013, ranging from 0.97 to 1.02.Giventhatbitumenisfreefromimpuritiesitcanbe usedforpavementconstruction.

The optimal bitumen content is calculated as 5% as a standardresultforconductingmartialstabilitytests.

Sl. No. % of polymer Strength (KN) Flow Value(mm) Bulk Density

1 0 15.122 3.7 2.38 2 10 15.816 4.1 2.42 3 20 17.545 4.4 2.48 4 30 18.534 4.7 2.46 5 40 16.453 4.87 2.43

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

Sampleswerepreparedusingdifferentpolymercontentsof 10%,20%,30%,and40%.Thiswasdonetofindtheeffectof replacingthefillercontentattheconsistencyvalue.Thisplot helpsustofindtheoptimalpolymercontentforthismix.The plotaboveindicatesthatthestabilityvalueinitiallyincreases andthengraduallydecreasesasthefiller(Msand)contentis replaced.Thisisduetothefactthatwiththeinitialincrease inthepolymercontent,theoverallbitumenbondgradually strengthens, but with a further increase in the polymer content,thestabilitydecreases.

Flow is a variation in which the specimen performs at maximumloadatthepointoffailure.Thevalueoftheflow increases as the M sand content is replaced. Initially, the increase was small, but then the rate increased as the polymercontentincreased.

Itis seenthattheBulk density incrementsatfirst with an expansion in polymer rate and afterward it steadily diminishes This is because the density of bitumen is low compared to the total density and influences the overall mixedbulkdensity.

ThisprojectdealswiththereuseofLDPEwasteisbeneficial in improving the vital properties of the mixture With the initialincreaseinthepolymercontent,theoverallbitumen bond gradually strengthens, but as the polymer content increases further the stability decreases. As the polymer content increases, the flow value of the LDPE modified asphaltmixtureincreases.Ingeneral,wasteLDPEmodified asphalt mix improves the mechanical quality of road pavements to the utmost extent. The waste can be used effectively in LDPE pavement construction. This increases the effective disposal of municipal waste. Now the availabilityofwasteplasticisnotaproblemastheamountof wastedumpedisincreasingdaybyday.

1. ArjitaBiswasa, AmitGoela ,SandeepPotnis (2020), ‘Performancecomparisonofwasteplasticmodified versus conventional bituminous roads in Pune city:Acasestudy’, 2020,e00411

2. Shrikant dombe, Anand B Tapase, Y.M.Ghugal, B.A.Konnur,PatelAkshay(2020),‘Investigationon the use of e-waste and waste plastic in road construction’ , Recent Developments in Pavement Engineering, 2020,pp.85-99.

3. ‘All The Cities in India That Use Plastic Waste to Construct Roads - Lucknow, Chennai, Pune and More’, News18 , 23October2019.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

4. Tapase Anand, Kadam Digvijay, Mujawar Sahil (2015), ‘Utilization of e-waste and polymer modified bitumen in flexible pavemen’, Journal of Environmental Research and Development, Vol.9,3A.

Lins Paul Kuriakose

AssistantProfessor Deptofcivilengineering

Viswajyothicollegeofengineering andtechnology,Kerala

Aravind K Sunil

4thyearstudent,Civilengineering

Viswajyothicollegeofengineering andtechnology,Kerala Jerin Varghese

4thyearstudent,Civilengineering Viswajyothicollegeofengineering andtechnology,Kerala

Nidhin Pradeep

4thyearstudent,Civilengineering

Viswajyothicollegeofengineering andtechnology,Kerala

Nijin Varghese

4thyearstudent,Civilengineering

Viswajyothicollegeofengineering andtechnology,Kerala