International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

1Senior Scientist Officer, Rural Energy & Infrastructure Div., MGIRI, Wardha.

2 Professor, Civil Engineering Dept, BDCOE, Wardha.

3 Anil Gupta, Retd. Scientist Incharge, CGCRI, Khurja

4 Shubham Chaudhary, Technical Associate, RE&I Div., MGIRI, Wardha.

***

Abstract:

Indian red clay-based pottery or terracotta has become a significant cottage industry in the past few decades. And it is one of the rural industrial sectors in our nation, thusmany rural families rely on the sale of pottery as a source of income. For several generations. Potters are still using traditional processes for producing pottery. Due to the traditional age-old method, the manufacturing cost of pottery is also high as well as the potters are unable to maintain the same standard of quality, and to ensure productivity. As a result, this pottery is unable to compete with potteries available in the market due quality of the product. Accounting the demerits of Traditional age- old methods led to study the Techno-economical Up-gradation Strategies of Traditional Terracotta up-draught kilns. These kilns suffer higher fuel consumption, poor ware strength and extensive breakage. Smokes produced during firing will serious health problems to pottery workers and their family. Therefore, thermal studies onkilns are required to advise necessary modifications. This modification issuggesting for the new design of improved pottery kiln, which will be able to achieve uniform temperatures inside the kiln,decrease fuel consumption through better heat distribution and thermal insulation ofkiln walls.

Key words : Red clay, Techno economical upgradation, ware strength, fuelconsumption

The Techno economical Up-gradation of rural industrial sector is the key to the development of our rural masses and for this, technical inputs are essential for reducing costs, increasing productivity, and raising the quality of output. The pottery industry uses a lot of energy, and mostofthetraditional kilnsusedin rural areastofirethe pottery are relatively inefficient. The Pottery Cottage industrycannotaffordthehighefficiencywhiteclaybased pottery kilns utilized in the organized ceramic sector because of their high cost. The burning process in

conventional kilns must be optimized to raise product qualitywhileloweringproductioncosts.

The main objective for this study is to overcome the limitation in the traditional kiln and improved pottery kilnbyconstructinganenergyefficientkilnwhichhelpsto improvetemperaturedistributioninsidethekiln.Thenew, improvedpottery kilnuseslessfuelandmaintainsamore consistent temperature than older kilns. Itoffers potters a better working environment and fewer tendencies for spots on pots. Improved fire control results from longer gas residence times inside the kiln. Also contributes to reducing production costs and the construction of kiln is affordabletothevillagers

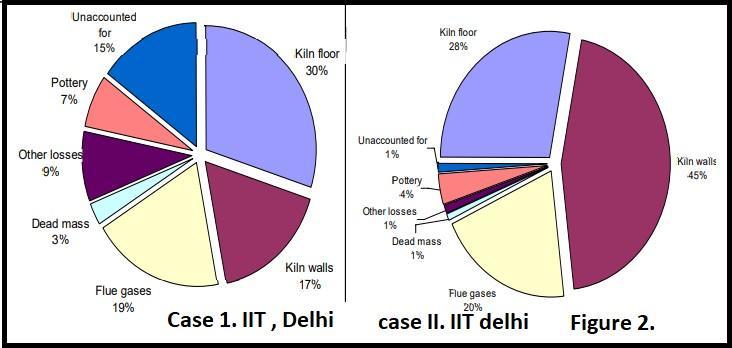

The unit of production of Indian red clay pottery industryisofhomescalelevel.

Maximum older people whose age is above 45 years are continuing in the occupation. None of the respondents is willing that their children should learn this age-old traditional occupation.

This occupation is not providing adequate employment for the respondents who are completely dependent on this occupation. On an average only 40 per cent families arecontinuing in this occupation, and the rest are engaged in other professions as an unskilled Labour. Some families who do not themselves produce pots prefer to purchase pottery products from other villages for the purpose of selling in their own villagestocontinuetheircastetradition.

Around 70 percent products are traditional, 20 percent is moderate and hardly 10 percent contemporary products are produced by the potters and they are either staying in the cityor closetocity.

International Research Journal

Engineering

Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

No modern technology and new techniques of productionhavebeenintroduced.

Villages nearer to forest are usingfirewood and others are using cow- dung cake as fuel for bakingofproduct.

v) Without any controls devices in the traditional kilns, they are difficult to operate for controlled rise of temperature,resultinghighrejectionofgoods.

vi) Finally, these kilns cannot be operated in rainy seasons.

Potters still using traditional technique of firing which is not suitable for high production and notsuitableforqualityofproduct.

If potters have access to affordable scientific technology,theycanmaximizetheirprofitswhile maintainingproductquality.

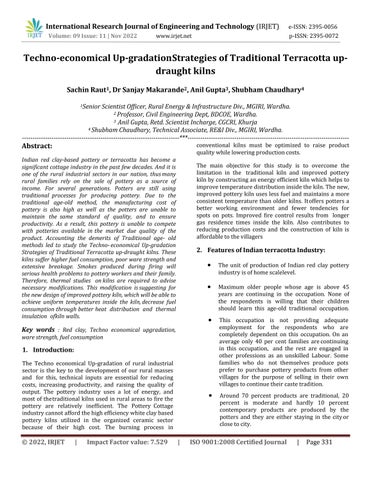

In a Traditional Kiln, The energy released by the combustion of fuel in a pottery kiln gets distributed with only a small fraction getting absorbed by the pottery. In traditional kilns, the walls are made very thick, which absorb a large part of the energy, which is essentially a loss. Also, the fuel is burnt directly on the floor, causing veryhighlossestotheground.Alargepartoftheenergyis lost due to high temperature of the flue gases exiting the kiln. Figure 2 gives the breakup of energy consumed in a traditional updraught kiln used at Kumharpara in Kondagaon,districtBastar,Chhattisgarh.Herehighestloss is to the ground followed by the loss due to the energy stored in the kiln wall, which is 18” thick. Figure 2 gives the energy budget of another updraught kiln used in GramodaySanghatBhadrawati,Maharashtra.Thiskilnhad even thicker walls which stored 45% of the energy released during the operation of the kiln. The losses through the flue gases are nearly the same in both. Other lossesincludetheconvectionandradiationlossesfromthe wallexteriorandtheflames

Fig 1: Critical scenario potter’s community in India.

i) The kilns are open without any wallsexcept few with walls of small height ( `2’ ) resulting problem in loading of wares and non-uniformity in temperature due tomovement of winds through kiln (through the cracks developedduringfiringinmudplaster).

ii) Plenty of heat energy is wasted, resulting lower thermalefficiency.

iii) Difficult to load the articles, being no regular platform as a result the articlesare loaded generally in waywhicharresttheentryofadequateair-supply.

iv) Due to inadequate supply of air and irregular circulationofgasesinsidethekiln,thewaresaregenerally produced non-uniform in colour and occasionally with blackpatches.

The energy absorbed by the floor and the kiln walls is many folds higher than that absorbed by the pottery, because the wallsandfloorareseveraltimesheavierthan the payload of pottery: The traditionalKondagaon kiln, for example, fires about 1000 kg of payload in a single firing, whilethemassofthewallsalonewouldbearound7500kg ofbrickwork. Acomparablemass ofsoiland bricksbelow thefloorarealsogettingheated.

e-ISSN:2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

Most of the potters in different regions are using the traditional kilns. In this kiln there is no provision to control the temperatureand percentage of breakage is around 10 to 40 percent, which enhance the cost of finished product and reduces the profitmargin. The fuel efficiencyofthesekilnsisverypoor.

The Mattikala board, Gujarat, has modified the traditional awa kiln and this has saved around 40 percent of fuel. But thesurveywithpottershasrevealedtobegoodonlyforbig pots like water pots. MGIRI, Wardha, has modified the updraft kiln and reduced the fuel consumption around 33 percent. MGIRI, Wardha, had developed another energy efficient low-cost Cross- draught lgas kiln (1 cubic feet loading size) for value added terracotta products. But the size is good for studio potters. Still there is a need to develop different size of energy efficient, low-cost kilns. Lotsofkilnsareavailablein themarketbutthesekilnsare notaffordable forsmall potters therefore there isneed for developmentofenergyefficientkiln.

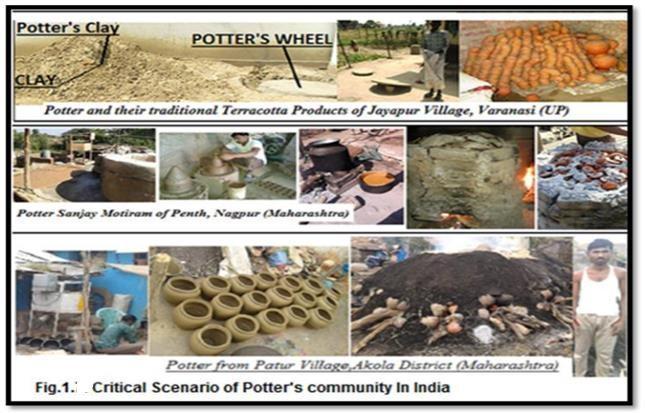

In this study, further modification of the MGIRI’s updraught kiln is taken into consideration. The new, improved pottery kiln uses less fuel and maintains a more consistent temperature than older kilns. Itoffers potters a better working environment. Improved fire control results from longer gas residence times inside the kiln. Also contributes to reducing production costs and the constructionofkilnisaffordabletothevillagers.

I. Materials for construction are to be adopted, which are readily available with village potters andsize/capacityofthekilncanbechangedtosuit therequirements.

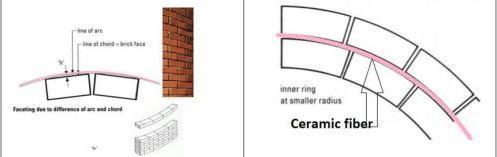

II. The bottom ground, side walls and the top are insulatedwithamaterial,whichiseasilyavailable andcanbeappliedtokiln–CeramicFiber.

III. The kiln is to be an enclosed cylindrical shape with chimney at thetop resulting better retention ofheatinsidethekiln.

Where, intermixing of gases generating from the bottom loading floor is provide so that the chimney can equalize the suction pressure from all the corners,middleofthekiln.

(ref. JP 5492340 B1- JP2006266638A *2005-03252006-1005ShiníyuHokushin:KkSmokelessceíamicaítkiln.

e-ISSN:2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

IV. Separate one or more fuel-feeding hole are to be provided, so that the entry of fuel can closely be regulated

V. Due to provision for separate fire grate with separate entries for air supply from bottom, the combustion efficiency of wood fuel is enhanced, resulting more efficient than traditional kilns and a temperaturearound1050oCcanbeattained.

VI. A Top loading and regular platform are to be provided for easy loadingofarticles.

VII. Operation of kiln is to be designed very simple in view of the controls provided and the same can be operatedbysemi-skilledworkers.

VIII. Thekilnistobefreefromthreatsofthefireaccident andcanbeoperatedinrainyseasons.

IX. TemperatureUniformityinsidethekilnistobegood andthusreproduciblequalityisassured.

7. Modifications in Energy efficient kiln

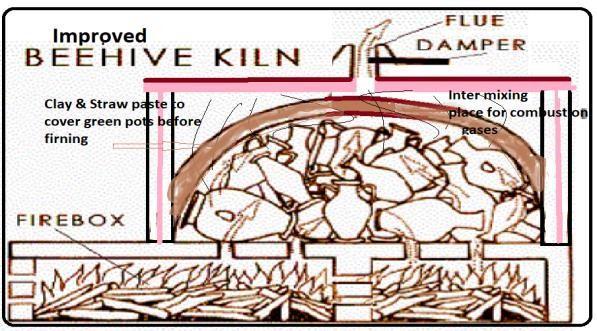

Thekilniscylindricalorrectangular inshapeconsistingof

(i)Firegrates.

(ii)

Holesforairentry(3Nos.)

(iii) FireBox/FireChamber

(iv) Fuelentryholes(3Nos.)

(v) Loadingplatformwithholesforheatcirculation.

(vi) Loadingchamber

(vii)Crownand,

(viii)Chimneycentrallyplacedatthetopofthekiln.

(ix) Air holes in side walls to control the secondary air, if required.

The combustion chamber provided separately with provision for supply of preheated air facilities for proper combustion of fuel. The top of the kiln is covered with a permanent dome with a centrally located Chimney. The dome helpsto conserve the heat inside the kiln chamber and also ensures temperatures uniformity in different zonesofthekiln.

The Chimney provided centrally at the top of the kiln is also fitted with a damper at the bottom and helps to improvedraftinkiln.Thedraftisregulatedwiththehelpof damper.Thedomeisalsoprovided withfourfluegasholes toincreasethetemperatureaswellasforrapidcooling.

The entry of fuel is regulated through fuelholesprovided at equal distance apart. Thereare also 3 Nos. air – entry holes placed at equal distance apart beneath the fire grates. The platform provided for loading of articles has numberofholesfortheentryofhotgasesandflamesinside the kiln. Thenumber of holes on the kiln floor/platform depends on the size and capacity of the kiln. Articles are loaded in the kiln 5from top astraditionally. The kiln wall is tied up at twoplaces, (top and bottom) with the help of flatironstrip.

The kiln was loaded with terracotta wares and covered with an Iron sheet dully fitted with Ceramic Fiber and a ceramic coating the kiln was lighted up with leaves and straws.Thefiringwas slow (60oC/hr.forabout 6 hours) at the initial stage to allow

thewarestodryupslowlyto avoid drying cracks. The slow firing was attained by regulating the air entry to the lower side as well as the fuel (viewing the length of flame on lower side). After attaining 360oC the firing was slightly speeded up by increasingtheentryoffuelandair.Thefuelentryholeswere closed immediately after charging of firewood to avoid theentryofcoldairaswellastocutdowntheheatlossesby radiation from the fire-boxes. The air entry was provided from bottom of the fire grate it got pre-heated before reachingtothecombustionefficiencyoffuel.

Thetemperaturewasmeasuredwiththehelpof charomalAlumel thermo-couple at different interval of time. The rateofriseoftemperaturewasascertainedbyplottingthe time and temperature curve. During the firing the kiln was closed on completion of firing after 15 hours. All the holes in the kilnwere properly closed and the kiln was allowed to cool under natural condition for24 hrs. It was observed later on that the holes may bekept open for better colourdevelopment of terracottawares.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

The above study provides a solution to the drawbacks of traditional kiln. These kilns suffer from higher fuel consumption, poor ware strength and extensive breakages.Thispaperhelpstoaccountingthedemeritsof traditional kilns and upgrade the traditional kiln by technically and economically for small potters which led to the development of an energy efficient pottery kiln by modifying the parameters of traditional kiln and provide suitable insulated boundary to reduce the extensive breakagesofkiln.

traditional pottery kiln for terracota wares Volume: 09 Issue:08|Aug2022irjet