International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

1Research Scholar, Department of Mechanical Engineering, Harcourt Butler Technical University, Kanpur, India 2 Associate Professor, Department of Mechanical Engineering, Harcourt Butler Technical University, Kanpur, India ***

Abstract - During the development of 3D printing technology, the researcher was very interested in the application of 3D printing in the medical field. If we apply 3D printing technology to the medical sector, it will help us to solve very complex problems that arise during and before surgery. The Adam process in additive manufacturing will be of great help in solving complexity in the medical industry. With the help of this process, we can create many medical devices that will help us during and before surgery. Some examples are making a surgical guide for dental implants for surgery, and there are many other non-invasive devices that can be used for ADAM that can be developed with the help of metal 3D printing. This technique can be used in various medical fields like dentistry, rheumatology, surgery, etc. Important items like medical sector equipment and natural objects that must first be developed using 3D software are made utilising 3D printing technology. Once the 3D model is accessible, you can see distributed three-dimensional images of patient scans using specialised tools and software.

Key Words: 3D Printing, Additive, Fusion, Microscopic, Thermal Stress, Hardness, etc.

The market for 3D printing was worth roughly $1 per 1000 in 2018, and it is anticipated to increase to $3.7 billion by 2026. The use of 3D printing in medicine is enormousandisalmostcertainlyheretostay.Theuseof 3D printing in medicine will be among the most significant. Here, the use of 3D printing has already beguntosignificantlyalterthemedicalindustry.Priorto using 3D printing technology, we were unable to rehearseanylists.Wewillbeabletoemploy3Dprinting technology in the future by using a 3D model of the operation on which we planned the surgery so that the doctor needed less time and was able to cut Shirdi correctly[1-3].

Allourmedicalindustryhopeswillbedashedbyadevice that will be employed. Several businesses are now able to benefit from this fantastic choice because to the advancements made in 3D printing technology over the years. In the past, 3D printing was mostly employed by powerful politicians who could afford pricey machines and materials. Medical professionals have been utilizing 3D printing technology to enhance their workflow,

particularly to give patients more individualized and reasonably priced healthcare solutions. New sentence There is a function to healthcare that has a long-term impact.

The first time that 3D printing technology was applied wasin1980.DoctorKodamainitiallytriedtopatentthis technology but was unable to finish the process. Chuck Hull was the recipient of the first stereolithography apparatus patent, which was granted to him later in 1986. He is a 3D Systems Corporation co-founder. Carl Deckard was given a wait typing method for selective legendry in the US in 1989, which was followed by the FDMmethod.Wearegoingtograduallyintroducealotof improvements to the 3D printing sector. There are numerous options for 3D printing now that we are familiarwithhowitisdoneusingthismethodandunder Matter3DPrinting.

Therearealreadymorethanadozenvarious3Dprinting methods, three or four of which have been developed specifically for metal 3D printing. This is a separate procedurethatmakesuseofnumerousmaterials,aswell as various printer speeds, restrictions, and techniques. Almost any geometry specified in a computer-aided design(CAD)filecanbetranslatedintoa3Dobjectusing thistechnique[4-6].

Following the directions in the 3D files before 3D printing new ones for the object is the fundamental setup. Printed materials must be carried with codes created after slicing-rays, MRIs, and CT scans are examples of two-dimensional (2D) radiographic images thatcanbeconvertedintodigital3Dprintfiles,enabling the production of complex physical and medical structures.PrintedmaterialscanbecarriedalongtheXY planeastheprintercontinuestofollowtheinstructions.

Importantitemslikemedicalequipmentandnaturalobjects areproducedusing3Dprinting.Withtheaidof3Dsoftware, the objects are first developed, and after that, the model is madebytravellingthere.Tomake3Dprintingeasierforus, wedivideditintolayersandprepareditforprintingusingthe test3Dprinter.Youcanviewthismaterialandworkwiththe

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

designer to ensure that it is ideal for your underprivileged applicationbeforespendingmoneyonit[6-7].Eventhough they want to upgrade their 3D software, medical professionals still utilise it. Software for 3D modelling is available in a huge range. There isn't a fix that works for everyone. You must be aware of yourmost pressing needs. Whichdoyourequire?Youonlyneedtoprintit.Softwarethat providesamoredistributedviewiswhatyou'relookingfor. Perhaps you require both at once. There is no correct response, therefore it's crucial that you take your time and consider theadvantages of eachpiece of software. Andyou maynowchoosewhichisbestforyourpractisebeyond3D printing table dioramas for children. Important items like medical equipment and natural objects are produced using 3Dprinting.Withtheaidof3Dsoftware,theobjectsarefirst developed, and after that, the model is made by travelling there.Tomake3D printing easier forus, we divided itinto layersandprepareditforprintingusingthetest3Dprinter. You can view this material and work with the designer to ensure that it is ideal for your underprivileged application beforespendingmoneyonit[6-7].Eventhoughtheywantto upgradetheir3Dsoftware,medicalprofessionalsstillutilise it. Software for 3D modelling is available in a huge range. Thereisn'tafixthatworksforeveryone.Youmustbeaware ofyourmostpressingneeds.Whichdoyourequire?Youonly need to print it. Software that provides a more distributed viewiswhatyou'relookingfor.Perhapsyourequirebothat once.Thereisnocorrectresponse,thereforeit'scrucialthat youtakeyourtimeandconsidertheadvantagesofeachpiece ofsoftware.Andyoumaynowchoosewhichisbestforyour practisebeyond3Dprintingtabledioramasforchildren.[8]

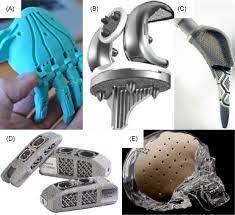

Although medical equipment is made to be as adaptable aspossible,itmightoccasionallybeusefultohavealittle customization. The equipment you require can be expensivetoorderandtakeawhiletoarrive.3Dprinting YoumayquicklydesignyourownuniqueutilityusingCT Scan [10–11]. For additional jobs, you can even design yourowncustomisedtool.UsingCTscansofthepatient, medical practitioners design the precise surgical tools neededforeachpatientandtreatment.Knowingthatthe item will work in the situation can help you to be more preparedand effectiveinyourjob.Accordingto studies, using a 3D printer in the medical area can speed up processes and save costs. surgery can increase ticks, especiallyintheoralandmaxillofacialareas[12]

Figure 3: 3DPrintedSurgicalTool.

Despitethefactthatmedicalequipmentisdesignedtobe as versatile as feasible, a little customisation could occasionallybeadvantageous.Orderingandshippingthe

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

necessary equipment can be expensive and timeconsuming. 3D modelling Using a CT scan, you can quicklycreateyourownspecialutility[10–11].Youmay evencreateyourownuniquetooltoperformmoretasks. Medical professionals create the precise surgical tools required for each patient and treatment using CT scans of the patient. Being more organised and productive at work can be facilitated by knowing that the item will function in the circumstance. Studies show that employinga3Dprinterinthemedicalfieldcanexpedite proceduresandreduceexpenses.

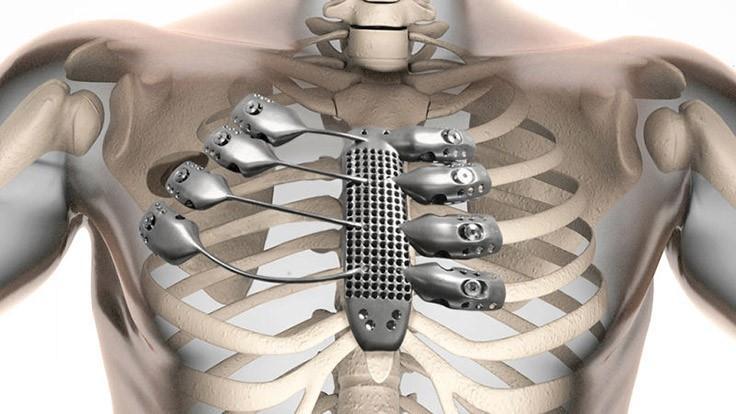

Medical 3D printing can be used to assist repair the entire bone and joint structure, much like a prosthetic. You can utilize additive manufacturing to build specialized in-plants rather than employing a one-sizefits-all plant that frequently doesn't fit all [18]. Healthcare professionals can get started with 3D printing, which can be used for joint and body part reconstructioninadditiontopre-formingbone.Hereare afewofthemainusesthat3Dprintingmaybeputto. JawReplacement

hipsubstitute breastreconstructionafterakneereplacement Reconstructionoftheface

Thisisbynomeansa shortlist.Medical applicationsfor 3D printing may be possible, and we are investigating this.

Dentistry

Orthodontists and Dentists need customized solutions to help their patients because if they were the same, they would have to use different moulds on each mouth, so instead of making these companions with old technology [19], we 3D printed thembasedonX-rayandCTscanimagesofthepatients' mouths. Instead of taking the time to make new moulds andcustom-madeTaxoranyotherthingthatisrequired, this whole process from scanning the 3d printing to creating a 3D model to painting is done by one person. This process saves time, money, and labor. And this kid can be authorized to make custard if someone's jaw is broken, and with the help of a 3D printer, we can also add fights, and in dental[20], we can make many such tools that only email 3D printing can make possible. It can only be possible; otherwise, we cannot get them fromanyoneelse.Intoday'stime.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

Detailed visualizations using 3D printing forthemedicalindustry

Make specialized 3D-printed medical industry prostheses tools Customized for Patients

JointandBoneReplacement

reconstructedjaw

replacementhips

Kneeprostheses

Breastaugmentation

Reconstructionoftheface

While planning complex or uncommon treatments, medical personnel mayconsultchartsorscans,butthey don't often receive much actual experience beforehand. Thankstomedical3Dprinting,theycannow[21]

2016 saw a difficult kidney transplant from a father tohis2yearolddaughterbeingcarriedoutbysurgeons in Ireland. They developed 3D-printed replicas of an adult kidney and a child's torso to help surgeons rehearse difficult procedures and plan. The procedure wentwell.

Surgeonscangaintheskillsandexpertisenecessary to carry out the trickiest operations by practicing on 3D printedorgansandmodels.Withthehelpofthistraining, the surgeon will be more confident and have a better probabilityofsuccess[22]

1. BioprintingArtificialOrgansandTissue 2. 3DMedicalPrintingforDentalApplications. 3. MedicalTrainingforComplicatedProcedures

[1] H. Arun, Healthcare 3D Printing Market 2018 Prominent Players-Aprecia Pharmaceuticals, Aspect Biosystems, Bio 3D Technologies, Biobots, Cyfuse Biomedical, Digilab, 3 Dynamics Systems, Envision Tec, Luxexcel, Materialise NV, Nano 3D Biosciences, Oceanz, Organovo Ho, http://www.openpr.com.

[2] C.L.Ventola,“Medicalapplicationsfor3Dprinting: current and projected uses,” Pharmacy and Therapeutics,vol.39,no.10,pp.704–711,2014.

[3] D.B.Jones,R.Sung,C.Weinberg,T.Korelitz,andR. Andrews, “Three-dimensional modeling may improve surgical education and clinical practice,” Surgical Innovation, vol. 23, no. 2, pp. 189–195, 2016.Viewat:PublisherSite|GoogleScholar

[4] D.C.Ackland,D.Robinson, M.Redhead,P. Vee Sin Lee, A. Moskaljuk, and G. Dimitoulis, “A personalized 3D-printed prosthetic joint replacement for the human temporomandibular joint: From implant design to implantation,” Journal of the Mechanical Behavior of Biomedical Materials, vol. 69, pp. 404–411, 2017.View at: PublisherSite|GoogleScholar

[5] K.Phan,A.Sgro,M.M.Maharaj,P.D’Urso,andR.J. Mobbs, “Application of a 3D custom printed patient specific spinal implant for C1/2 arthrodesis,”JournalofSpineSurgery,vol.2,no.4, pp.314–318,2016.Viewat:PublisherSite|Google Scholar

Future Applications of Metal 3D Printing in the Medical Sector are covered in this paper. The following outcome hasbeenconcluded:

[6] L. E. Diment, M. S. Thompson, and J. H. M. Bergmann, “Clinical efficacy and effectiveness of 3D printing: a systematic review,” BMJ Open, vol. 7, no. 12, Article ID e016891, 2017. View at: PublisherSite|GoogleScholar

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

[7] J.Garcia,Z.Yang,R.Mongrain,R.L.Leask,andK. Lachapelle,“3Dprintingmaterialsandtheirusein medicaleducation:a reviewofcurrenttechnology and trends for the future,” BMJ Simulation and Technology Enhanced Learning, vol. 4, no. 1, pp. 27–40, 2017. View at: Publisher Site | Google Scholar

[8] R. J.Mondschein, A. Kanitkar,C. B. Williams,S. S. Verbridge, and T. E. Long, “Polymer structureproperty requirements for stereolithographic 3D printing of soft tissue engineering scaffolds,” Biomaterials,vol.140,pp.170–188,2017.Viewat: PublisherSite|GoogleScholar

[9] W. Zhu, X. Ma, M. Gou, D. Mei, K. Zhang, and S. Chen, “3D printing of functional biomaterials for tissue engineering,” Current opinion in biotechnology,vol.40,pp.103–112,2016.Viewat: PublisherSite|GoogleScholar

[10] ASTM, Standard Technology for Additive Manufacturing-General Principles/Terminology, ASTM ISO/ASTM 52900:2015 (E), West Conshohocken,PA,USA,2015.

[11] H.J.ChenandM.Gariel,AroadmapfromIdeato Implementation–3D Printing for Pre-Surgical Applications, CreateSpace Independent Publishing Platform,ScottsValley,CA,USA,1stedition,2012.

[12] A. Cohen, A. Laviv, P. Berman, R. Nashef, and J. Abu-Tair, “Mandibular reconstruction using stereolithographic 3-dimensional printing modeling technology,” Oral Surgery, Oral Medicine, Oral Pathology, Oral Radiology, and Endodontology,vol.108,no.5,pp.661–666,2009. Viewat:PublisherSite|GoogleScholar

[13] D. Whitley, R. S. Eidson, I. Rudek, and S. Bencharit, “In-office fabrication of dental implant surgical guides using desktop stereolithographic printingandimplanttreatmentplanningsoftware: a clinical report,” Journal of Prosthetic Dentistry, vol. 118, no. 3, pp. 256–263, 2017 View at: PublisherSite|GoogleScholar

[14] H. Dodziuk, “Application of 3D printing in healthcare,” Kardiochirurgia i Torakochirurgia Polska,vol.13,no.3,pp.283–293,2017.

[15] D.Ibrahim,T.L.Broilo,C.Heitzetal.,“Dimensional error of selective laser sintering, threedimensional printing and PolyJet models in the reproduction of mandibular anatomy,” Journal of Cranio-Maxillofacial Surgery, vol. 37, no. 3, pp. 167–173, 2009.View at: Publisher Site | Google

Scholar https://www.sys-uk.com/news/3dprinted-surgical-guides-and-dental-implants/.

[16] J. S. Matsumoto, J. M. Morris, T. A. Foley et al., “Three-dimensional physical modelling: applications and experience at mayo clinic,” RadioGraphics, vol. 35, no. 7, pp. 1989–2006, 2015.Viewat:PublisherSite|GoogleScholar

[17] Medtronic case study, Custom surgical instruments becoming working prototypes using FDM3Dprintingtechnology.

[18] K. S. Tanaka and N. Lightdale-Miric, “Advances in 3d-printed pediatric prostheses for upper extremity differences,” Journal of Bone and Joint Surgery, vol. 98, no. 15, pp. 1320–1326, 2016. Viewat:PublisherSite|GoogleScholar

[19] S.L.Sing,J.An,W.Y.Teong,andF.E.Wiria,“Laser and electron beam powder-bed additive manufacturing of metallic implants: a review on processes, materials and designs,” Journal of Orthopaedic Research,vol. 34,no.3, pp.369–385. Viewat:GoogleScholar

[20] F. Auricchio and S. Marconi, “3D printing: clinical applications in orthopaedics and traumatology,” EFORT Open Reviews, vol. 1, no. 5, pp. 121–127, 2016.Viewat:PublisherSite|GoogleScholar

[21] C. G. Helguero, V. M. Mustahsan, S. Parmar et al., “Biomechanical properties of 3D-printed bone scaffolds are improved by treatment by CRFP,” JournalofOrthopaedicSurgeryandReasearch,vol. 12, no. 1, p. 195, 2017. View at: Publisher Site | GoogleScholar

[22] M. Asadi-Edyvand, M. Solati-Hasjin, A. Farzad, and N. A. A. Osman, “Effect of technical parameters on porous structure and strength of 3D printed calcium sulfate prototypes,” Robotics and Computer-Integrated Manufacturing, vol. 37, pp. 57–67, 2015. View at: Google Scholar 2014. 54: p. 207-211.

© 2022, IRJET | ImpactFactorvalue: 7.529 | ISO 9001:2008 Certified Journal | Page265