International Research Journal of Engineering and Technology (IRJET)

e-ISSN:2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

International Research Journal of Engineering and Technology (IRJET)

e-ISSN:2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

1M.tech (T.E) student at Desh Bhagat University Mandi Gobindgarh 2Asst. Professor in deptt of Civil Engg. At Desh Bhagat University Punjab ,India

Abstract - The road network has been continuously deteriorating due to the ongoing rise in traffic and the insufficient level of maintenance caused by a lack of funding. Various sorts of actions, such as obtaining finances for maintenance, improving route design, using higher quality materials, and using more efficient building methods are believed to be useful in easing this process. In the wake of the rise in usage, it had been demonstrated that improving the quality of the materials used in road building might improve road service performance. Asphalt concrete can benefit from various different modifications to the bituminous binder that are made with polymer additives, as demonstrated by practical experience over the past 40 years. The country has seen a significant increase in the usage of polythene materials for clean water sachets because to its plentiful availability and good resistance to insects, fungus, animals, moulds, mildew, rot, and many chemicals. However, it has been difficult to dispose of the waste polythene materials in huge numbers across the nation. Therefore, the purpose of this investigation was to ascertain the impact of polythene as it was present in pure water sachets on the characteristics of asphalt and concrete. As a binder modification, grinded polythene was added. By melting it inthe bitumen usedto prepare the combination, it was added.

Key Words: Bitumen,Aggregates,polythene,PlasticetcBituminousbinders,whicharesubstantiallyutilisedinthe paving business, have several uses in civil engineering. The pavement is made up of numerous layers. Aggregate and bitumen are the two major factors of bituminous concrete( BC) blend. In general, Flexible Pavement and Rigid Pavement are the two classes into which all hard surfacedpavementsfall.Plasticsisamaterialthatcontains one orfurtherorganicpolymer oflarge molecularweight, solid in its finished stated and it also can flow under specific state. It's durable and has veritably slow process ofdeclination.Plasticcanbedividedintotwomajororders which are thermoses and thermoplastics. Thermos is a fettleofplasticwhenit'sinsolidform.Thistypeofplastic isveritablyusefulintheircontinuityandstrength.

Currently, the use of the plastic bag with several of sizes has been growing day by day. This development led to an increaseinthequantumofwaste.Thisdangerouswasteis disposed by land stuffing or incineration. Waste plastic doesn't suffer bio-decomposition. thus, whether it's land filled or incinerated, it still pollutes the land and the atmosphere. still, the discovery of the list property of plasticinitsmoltenstatewhichcanbeusedinroadlaying hashelptowellmanagethiswasteplastic.Roadpavement thatusesplasticwasteasoneofitmaterialiscalledplastic road.Plastic bag isnon-biodegradable but utmost of it's recyclable. The recycled products are more environmentally dangerous than the first time manufactured bones ,because every time plastic is reclaimed it's subject to high intenseness heat.This can make it to deteriorate and lead to environmental pollution.That's why, it's necessary to determine the effectivewaytodealwiththisnon-biodegradablewaste

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

Bitumen grade of 60- 70 was used in this exploration. Physical tests for the density, penetration and also softening points for both unmodified and modified bitumen of 60- 70 penetration grades were included in this study. In addition, the rheological parcels of modified binders will suitable to help for the identification of the significance of using the modifiers in pavement diligence. ThetestforrheologicalwillbeconductedbyusingaDirect Shear Rheometer( DSR) outfit grounded on the abecedarian of dynamic mechanical analysis. All the procedures used for the laboratory workshop are appertained to Indian standard Testing and Material( IS ) specifications

● When the composites were put through performance testing including Marshall Stability, tensile strength, compressive strength tests, and tri-axial tests, Bindu and Beena( 2010) delved how Waste plastic functions as a stabilizing addition in Stone Mastic Asphalt. The findings showed that 10 tattered plastic may give flexible pavementwithgreatperformanceandcontinuity.

● Using the thermoplastic elastomer styrene butadiene styrene( SBS), Fernandez etal.( 2008) explored the rheological assessment of polymer modified asphalt binders. To increase their comity,theyestimatedthechangedbinder'srates by adding oil painting shale and sweet oil painting.Inadynamicshearrheometer(DSR),the rheological parcels of the SBS PMBs were examined, and luminescence optic microscopy was used to pierce the morphology. The findings showed that the goods of sweet and shale canvases on the microstructure, storehouse stability, and viscoelastic geste of the PMBs were similar. Shale oil painting might thus effectively serve as a compatibilizer agent without immolating rates or indeed take the place of sweetoilpainting.

● According to Awwad and Shbeeb's 2007 exploration, the changed admixture has a lesser stability and VMA chance than thenon-modified composites, which appreciatively affects the fusions' resistance to rutting. They claim that adding HDPE polyethylene to asphalt admixture improvestheadmixture'scharacteristicsfarmore thanaddingLDPEpolyethylenedoes.

● According to Khan and Gundaliya (2012),the process of modifying bitumen with waste polythene improves the overall performance of roads over a long period of time by adding softening point, hardness, and reducing stripping due to water. This improves resistance to cracking,potholeconformation,andrutting.They

claim that the used waste polythene fleeces the admixture's summations, reducing porosity and humidityimmersionwhilealsoenhancingbinding parcels.

● Jainetal.(2011)studiedthemitigationofrutting in bituminous roads by use of waste polymeric packaging materials and came to the conclusion that adding the right amount of polyethylene to bituminous mix for road construction can reduce ruttingofbituminousmixto3.6mmfromavalue of 16.2 mm after application of 20,000 cycles, ultimately improving pavement performance and alleviating disposal issues of WPPM for a clean andsafeenvironment.

Thebasicmaterialsusedareasfollows:

● Aggregates

● FlyAsh

● Slag

● BituminousBinder

● Polyethylene

Bitumen (80/100), aggregates, and waste polythene nylons were thematerialsemployed forthisstudy. Waste polythene nylons are gathered, cleaned, sorted, and dried in the sun for a few days until all the samples are dry. To maximise its surface area of contact with the bitumen duringblending,theshreddingmachinewasusedtoshred the dried samples of the waste polythene into pieces ranging from 0.6mm to 2.36mm. In asphalt concrete, polymers are often used as aggregate or as a binder modifier. As a binder modifier for this study, polythene materialwasemployed.Byheatingbitumenwithshredsof polythene ranging in size from 0.6mm to 2.36mm, modified bitumen was created. Six polythene content ratios by bitumen weight (2.5, 5, 7.5, 10, 12.5 and 15%) were takenintoconsideration. Whenthemixturereached 265°C, it was blended uniformly after constant steering. Graduation criteria are oftensufficientlyflexiblethat they allow the use of paving mixes with varying degrees of stability, from coarse to fine. To manage certain grading ranges, various combinations of sieve sizes are provided, whichcomplicatesthesituationfurther.

This experimental works carried out in this present investigation.Itinvolvesmainly2processes.i.e.

● PreparationofMarshallsamples

● Testsonsamples

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

The specific gravity, tensile strength, and softening point ofpolythene werecalculated

Specific gravity of polyethylene was found out by followingtheguidelinesofASTMD792Theprocedureadoptedisgivenbelow;

The weight of the polyethylene in air was measured by a balance.Letitbedenotedby“a”.

An immersion vessel full of water was kept below the balance.

An iron wire was attached to the balance so that it is suspendedabout25mmabovethesupport.

The polyethylene was then tied with a sink by the iron wireandallowedtosubmergeinthevesselandtheweight wasmeasured.Letitbedenotedas“b”.

Then polyethylene was extracted and the weight of the wire , sink was measured by soaking them inside water. Letitbedenotedas“w”.

Thespecificgravityisgivenby s=a/(a+w-b)Where: a=Apparentmassofspecimen,withoutwireorsinker, inair

b = Apparent mass of specimen and of sinker completely immersed and of the wire partially immersed inliquid w = Apparent mass of totally immersed sinker and of partially immersed wire. From the experiment, it was foundthat a=19gm.b=24gm.w=26gm. =>s=19/(19+26-24)=19/21=0.90476

Takespecificgravityofpolyethylene=0.905.

● Methods

1.Sieveanalysis

2.Marshalstabilitytest

Mechanical shakers were used to conduct the sieve analysis. The diameters of the sieves range from 0.075 to 19mm. Each sieve's weight retention was measured and noted. It was determined what percentage of each size

passed. To determine if the chosen aggregates fall inside the designated envelop, a graph of percentage weight passing against sieve size was generated. To get an all-in combination grade that satisfies the standard, test mixes combiningthecoarseandfineaggregateswerecreated.

Itisrequiredtoconductmixdesigntoidentifytheideal bitumencontentforthemix usingunmodifiedbitumenas thebinderinordertoassesstheimpactofmodifiedbinder onthecharacteristicsofasphaltconcrete.

Retained Stability measures streaking in the blend causedbyhumidityandtheconsequentlossofstabilityas a result of the weaker link between the summations and binder. The test was run on the Marshall machine using the standard Marshall samples after STP 204- 22. After putting the samples in a water bath at 60 °C for 30 twinklesand24hours,thestabilitywasassessed.

The Marshall stability value improves with an increase in bitumenattentionuptoa specific bitumencontentbefore itstartstodecline.Theidealbindercontentisthatspecific bitumen content( OBC). The OBC in the current disquisitionwasdecidedtobe6,4.5,and4.5fortraditional SMA,BC,andDBMmixes,and4formodifiedSMA,BC,and DBM mixes with polyethylene at colorful attention. The graphs show that the stability value improves with the addition of polyethylene up to a point and also declines with fresh addition. This may be because there's too important polyethylene present and it can not duly mix with the asphalt. The quantum of polyethylene in the admixture is known as optimum polyethylene content( OPC)whichissetupas2forSMAandDBMand1.5forBC mixes.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

For SMA, BC, and DBM fusions, retained stability is reckonedbothwithandwithoutpolyethylene.Ithasbeen shown that when polyethylene is added to the admixture, the conserved stability value rises. Following DBM with polyethylene and SMA with polyethylene, analysis shows that BC with polyethylene produces the maximum maintainedstability..

Typesofmix Avg.stability after 1hourin waterat260°c

Avg.stabilityafter 24hoursinwater at60°c

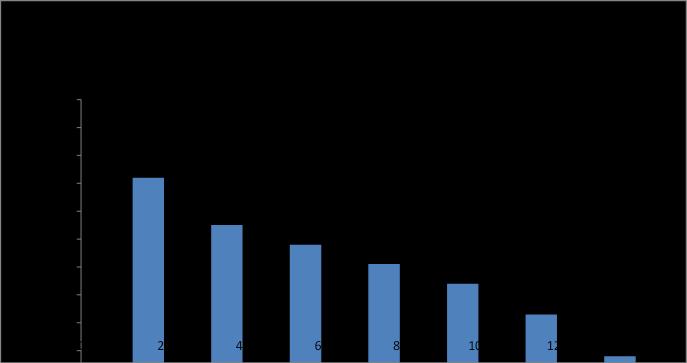

% Plastic waste by weight Penetration Index (PI)

0 -0.02

1.5 -0.23 3.0 -0.39 4.5 -0.10 6.0 -1.31

Chart -1:Nameofthechart

Avg.retained Stabilityin%

SMAwithout polyethylene 10.93 8.49 73.2

SMAwith polyethylene 10.87 8.49 78.13

DBMwithout polyethylene 12.76 9.96 74.04

DBMwith polyethylene 14.96 12.01 80.2

BCwithout polyethylene 17.58 14.13 76.38

BCwithout polyethylene 17.44 14.21 81.46

After conducting several studies, I have come to the conclusion that waste polythene may be utilized for good as it might cause problems if not handled properly. As a result, it is essential that various waste plastics be gatheredandaddedtobituminousmix.

Inthisstudy,VG30gradebitumenisemployedasabinder to create three different types of mixtures, namely SMA, DBM, and BC. By adjusting polyethylene concentrations from 0% to 2.5% at an increment of 0.5%, the effect of addingwastepolyethyleneintheformoflocallyaccessible imitation milk with brand OMFED packages in the bituminousmixeshasbeenexplored.

The ideal bitumen content (OBC) and ideal polyethylene content(OPC)forvarioustypesofmixeshave been found using the Marshall Method of mix design. When using stone dust as a filler, it has been shown that adding 2% polyethylene for SMA and DBM mixes and 1.5% polyethylene for BC mixes yields the best Marshall Properties. The best Marshall Properties for all types of mixes,however,areobtainedwithonlya1.5%additionof polyethylene when a tiny portion of fine aggregates are replaced by granulated blast furnace slag and filler is replaced by fly ash. The OBCs in modified SMA, BC, and DBMmixesthatcontainstonedustasa filleraredetected at4%,andtheOBCsinmodifiedSMA,BC,andDBMmixes that using fly ash and slag are found to be 5% and 4% respectively.

Penetration indicator( PI) The penetration indicator( PI) represents the quantitative measure of the reaction of bitumen to variation in temperature. The information of penetrationindicatorofparticularbitumencanbeusedto prognosticate its gusted in an application. Therefore, bitumenwithhighpenetrationfiguresthatcanbecalledas soft are used for cold climates while asphalt binders with low penetration figures that known as hard are used for warmclimates.

Using just VG 30 penetration grade bitumen and polyethylene, several attributes of SMA, BC, and DBM mixes, including Marshall Properties, drain down characteristics, static tensile strength, and static creep characteristics, have been examined in this experiment. However,itwasnecessarytolookatsomeofthequalities, including dynamic creep behaviour, dynamic indirect tensile strength characteristics, and dynamic fatigue properties

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

In the current investigation, dry mixing is used to add polyethylenetothemixture.Polyethylenemaylikewisebe used to modify bitumen by wet mixing, and similarities canbedrawn.

To determine the degree of homogeneity, the microstructureofthemodifiedbituminousmixtureshould beexaminedusingthepropertechnique.

In order to adequately investigate the possibilities of locating appropriate materials for paving mixes in the event of the current challenging circumstances, a combination of paving mixes formed with other types of plastic wastes that are widely available, wastes to replace conventionalfineaggregatesandfiller,anddifferenttypes ofbindersincludingmodifiedbinders,shouldbetried.

● González U. O. 2008. Rheological property of bitumen modified with polyethylene and polyethylenebasedblends

● MohammadT.A.,AwabandLinaS.2007.Theuse of Polyethylene in Hot Asphalt Mixture’s. AmericanJournalofAppliedSciences.

● Qi X, Sebaly P E & Epps J A, J Mater Civil Eng, 7 (1995)7627. polyethylene T. Baghae Moghadam, M. R. Karimm and T. Syamaun, (2012), Dynamic properties of stone mastic asphalt mixtures containingwasteplasticbottles,Constructionand BuildingMaterials34,236-242.

● T.BaghaeMoghadam,M.SoltaniandM.R.Kariim, (2014), Evaluation of permanent deformation characteristics of unmodified and terephthalate modified asphalt mixtures using dynamic creep test,Materials&Design53,317-324.

● B. Moghadamm T, Soltani M, Kariim MR, (2014), Experimental characterization of rutting performance of polyethylene terephthalate modifiedasphaltmixturesunder

● GayleandKingEt.al,“polymermodifiedBitumen”, Third International Road Federation, Middle East Regional Meeting, Riyadh, Saudi Arabia, February 1998.

● “Sinan Hinislioglu Et.al, “Use of High Density Waste Polyethylene as a bitumen modifier.” Materials Letters 58(2004)267-271, Science Direct.

● “R. Vasudevan Et.al,” Proceedings of the International Conference on Sustainable Solid Waste Management, 5 - 7 September 2007, Chennai,India.Pp.105-111

● Y.Adnan.,H.Arshad.,I.Muhammad.,A.Anwaar.,2014. Performance Evaluation of AsphalticMixtures Using Bakelite .Life Science Journal2014; 11(7s).[6] Dwivedi. A., Mattoo.M., Prabhu.J., Dwivedi.A., Jain.P.,2014.A Survey on Cost Comparison ofSustainable Plastic Road with Regular BitumenRoad,IJIRSET.2017,p.0602011.[7]