International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

Er. Gaurav Bhougal1 , Er. Prabhjot Singh2 , Dr. H.S Rai3

1 PG Scholar Er. Gaurav Bhougal Department of civil Engineering G.N.D.E.C. Ludhiana, India 2 Assistant Professor. Er. Prabhjot Singh Department of civil Engineering G.N.D.E.C. Ludhiana, India 3 Professor Dr. H.S Rai Department of civil Engineering G.N.D.E.C. Ludhiana, India ***

Abstract - In this research, an experimental program has been proposed to study the strength behavior of fly-ash slag basedgeopolymerconcretepreparedwithwastebrickpowder by replacing natural sand. For the geo-polymerization reaction to take place, the fly ash and GGBFS utilized as the binderwerebeingactivatedbythealkalisolutionmadewitha fixed molar concentration of sodium hydroxide and solution binder ratio for trial mixes also ratio of concentration for sodium hydroxide to sodium silicate is kept constant. Tests wereconductedtoassessphysicalpropertiesofmaterialsand MechanicalpropertiesanddurabilityofpreparedGPconcrete. Test reveals solution binder ratio has a strong impact over every sample where the strength also varies with the replacement of waste brick powder with natural sand at different proportions.

Key Words: S/b, GP, GPC, Geo-polymerization, Alkali solution,WBP,NSandNSWBP

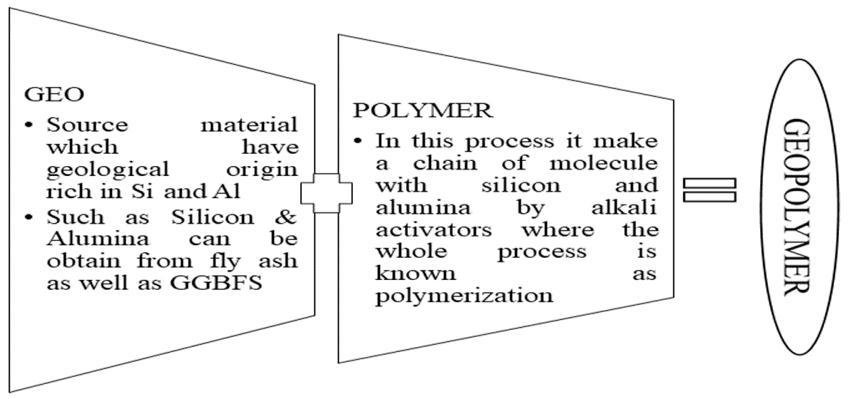

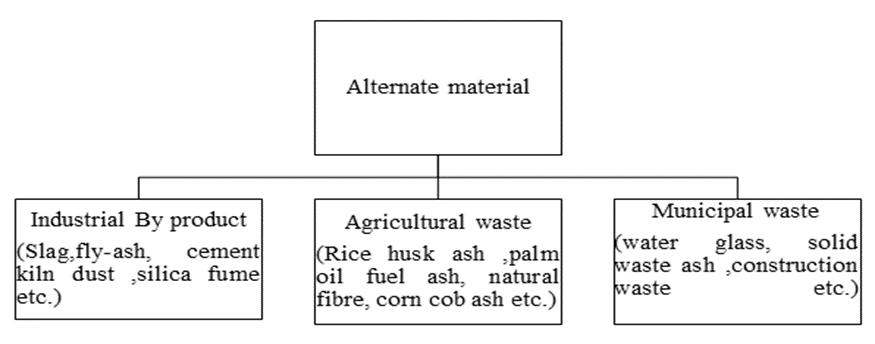

In the construction sector, concrete is the most powerful material.Engineersandmanufacturersarechallengedbythe steadily rising demand for concrete to improve its dependabilityandsuitabilityregardingtheenvironmentand naturalresources.OrdinaryPortlandcementisproducedby calcining limestone (calcium carbonate) and silicoaluminous material at extremely high temperatures, resultingin1metrictonneofcementisproducedforevery1 metric tonne of CO2. The degradation of the atmosphere occurs when cement consumption rises. The cement industry is one of the greatest industrial pollutants of the environment.Toovercomeandlimitthedemandofnatural resources many came with idea of replacing natural resources with artificial resources which can be obtained fromalmosteveryindustrialsectorandallareacceptingto preservenatureforourfuturegenerationandmakeeartha betterplacetolive.Asaresult,theneedofgeo -polymer,an alternativematerialrepresentedinFigure1.,emergedasan eco-friendly alternative material with low carbon dioxide emissions,evolved.Reusingsuchwastematerialcanlowers thecostofbuildingandreducesenvironmentalharm.

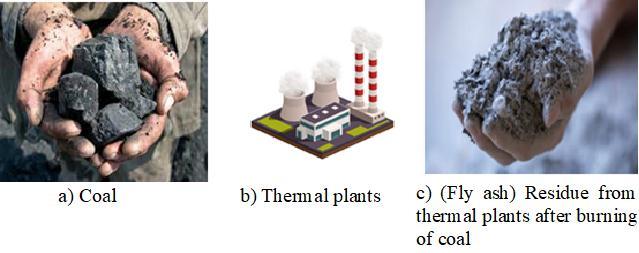

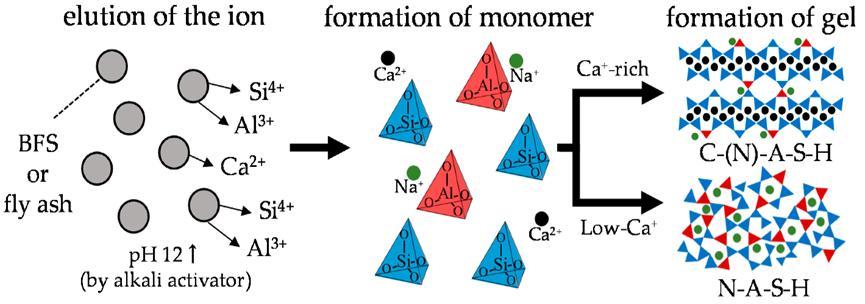

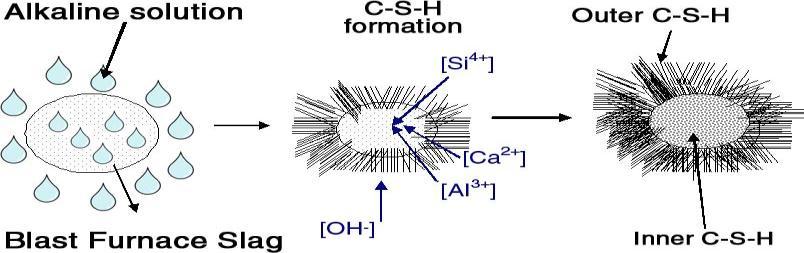

TheJosephDavidovitsusedtheterm"geopolymer"in1978to describepolymerswithaninorganiccomposition.Utilizing wasteproductslikefly-ash(trashfromthermalpower-plants) and(GGBFS)GroundGranulated-Blast-Furnace-Slag(waste fromironmanufacturing)asafullreplacementforcement, geopolymercementiscreatedasshownaboveinFigure1.1 followingthechainofgeo-polymerizationgelbelowinFigure 1.2. Geopolymer cement has a large amount of potential because of its enhanced durability, chemical and thermal resistance to heat, and early age strength. To increase the dependability and durability of geopolymer concrete, researchersareconductingseveralstudiesonitsworkability.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

TheGlobal-ChangeInstituteattheuniversityofQueensland hasbuiltthefirstbuildingevermadeofgeopolymerconcrete (GCI).It isa four-storystructurewhere 33%of the panels usedintheGCI’sfloorplatesisthelargestapplicationusedin world.

utilized to produce coarse aggregates, which are used in construction. These ground deposits include, for instance, river gravel, crushed stone from rock quarries and old concrete.Sand,gravel,orcrushedstoneareexampleofinert granularmaterialsthatareusedincombinationasabinding agent, such as water, bitumen, Portland cement, lime, etc. mixtogethertocreatecompoundmaterials.

Wastebrickpowder/Surkhiisthattypeofwastethat, when dumped, not only occupies space but also causes environmentalissues.Thiswastewillbetakenfrombrickkilns (where the bricks are produced). So, to reduce the wastematerialbyreusingwastebrickpowderasanartificial fineaggregate.

Fig-1.2 Chainofgeo-polymerizationgel

Cementworksasthebinderofconcreteusedinbuilding construction.Variousbindermaterialthatcanbeusedare fly-ash, GGBFS, metakaolin, rice husk ash, corn cob ash, Bagasseash,andUltrafineSlag.ThemajorityofGGBSisused asapartialreplacementforcement,whereasmostoftheflyash is used as additive in the cement industry, for the construction of roads and embankments, and for the manufacture of bricks. The potential for using these industrial by-products as stabilizing agents is quite high. AbundantcontentofSiandAlcanbeusedasraw=material for*manufacturinggeopolymerconcretewheremetakaolin, fly/ash,andcrushedgranulated/blast slagareamongthe principal sources of raw materials for production of geopolymerconcretethatareusingtoday.

Over the past ten year or so there has emerged a large amountofinterestinalkali-activatedbinders,especiallythe substancesknownas"geo-polymers."Thegeo-polymersare producedbyreactinganalkalineactivator,whichisgenerally a concentration solution of alkaline hydroxide, silicon, calcium, or sulphate., using an aluminosilicate, which is frequentlyavailableinpowderasanindustrialby-productor otherlow-costmaterial.ReportofProvis[11]explainedthe behaviourofalkali-activatedbindersorgeopolymerbinders as hardened compounds which acquire their strength and other properties by chemical reaction such as geopolymerization between an alkaline soluble source and aluminaterichrawmaterialsasshowninfigure1.4below:

Fig-1.4 Reactionmechanisminanalkali-activatedslag particle

Geopolymer concrete based on industrial byproducts with high early strength, minimal shrinkage, dehydration resistance,sulfateresistance,andresistancetocorrosionare categorized[3]inTable1below:

Coarse aggregates and fine aggregates are the main constituentofgeo-polymerconcretethatwouldbeusedin naturalaswellasartificialformwithappropriatequantityto obtainmaximumstrength.Rockdugfromnaturaldepositsis

Table 1: CategoriesofgeopolymerbyJosephdavidovits

1.Slagbasedgeopolymerconcrete.

2.Rockbasedgeopolymerconcrete.

3.Fly/ashslagbasedgeo-polymerconcrete.

4.Ferro-silicatebasedgeo-polymerconcrete

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

Thefollowinggoalsarepursuedwiththisresearchproject:-

1. To study the workability of geopolymer concrete containingwastebrickpowder/surkhi.

2. To study the mechanical properties such as compressive strength, flexural strength, and split tensile strength of prepared geopolymer concrete incorporatedWBP.

3. To study the influence of carbonation on geopolymerconcreteincorporatedwastebrickpowder /surkhi.

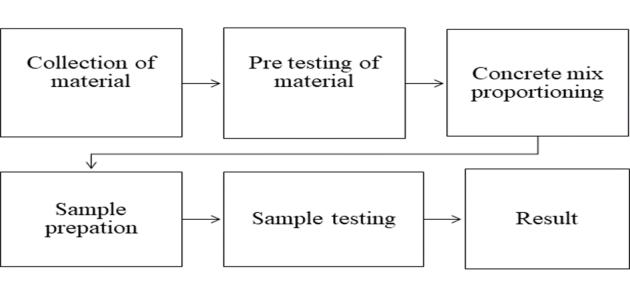

Aflowchartdepictingahigh-leveloverviewoftheprogram givenbelowinFigure3:

GGBFS FlyashClassF Specificgravity

30% 70% 2.79

Inthisexperiment,coarseaggregateconsistsofamixture ofmaterialwithnominalsizesof20mmand10mm.Both types of coarse aggregate came from nearby sources. The techniques described in the Bureau of Indian Standards criteria,as indicatedin Tables below. Bothtypes ofcoarse aggregate's specific gravities were determined using the waterbasketmethod.

Table 3.1: PhysicalpropertiesofCoarseaggregate

FinenessModulus Specificgravity Waterabsorption 6.8 2.13 1.07%

Table 3.2: Sieveanalysis

ISSieves Weight Retained [gm]

Weight Retained (%)

Cumulative Percentage Retained

Fig- 3: Flow-Chartofwork

TheGGBFS.andflyashwasusedinthecurrentstudyas thealuminasilicatesourcematerialtocreatethegeopolymer specimens.Bindercontained70percentofhighclass'F'fly ashand30percentofGGBFSmanufacturedbyAkarshearth power solution and JSW Cement Ltd. Their physical propertiesshowninFigure3.1andTable3 suchasspecific gravityareassessedusingprocessesoutlinedinBureauof IndianStandard8112-2013.

a) 70%flyash30%GGBFS b)specificgravity

Fig-3.1: Flyashandgroundgranulatedblastfurnace slagasBinder

Passing Percentage [%]

Limits asper IS 3832016 [%]

40mm 0 0 0 100 100

20mm 52 1.04 1.04 98.96 85100

10mm 4367 87.34 88.38 11.62 0-20

4.75mm 546 10.92 99.3 0.7 0-5

Pan 35 0.7 - - -

Total 5000 grams Σ188.72

Thephysicalcharacteristicsofnaturalsandareexamined usingtheproceduresindicated in Bureau ofIndianNorms standards,suchassieveanalysisatTable3.3,specificgravity, water absorption, and silt content as results are shown in Table3.4.InaccordancewithBIS2386(Part1):1988,natural sandwas passedthrough aseries ofsieves toobtain sieve analysis,whichwasthencomparedtoBIS383:1970criteria. InaccordancewithBIS383:1970,thefinenessmoduluswas calculated,thesandzonewasidentified,andtheresultswere providedinTable3.4.Theprocessdescribedinemployedthe pycnometer method to calculate the specific gravity of naturalsandanditscapacitytoabsorbwater.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

Table 3.3: PhysicalpropertiesofNaturalSand

Fineness Modulus Specific Gravity Water absorption Silt content Grading Zone 2.11 2.51 1.9% 5% III

Table 3.4: SieveAnalysis

ISSieves Weight, Retained [gm]

Weight, Retained [%]

Cumulative [%Age], Retained

Passing Percentage, [%]

Limits asper IS3832016 [%] 10mm 0 0 0 100 100 4.75mm 18 1.8 1.8 98.2 90-100 2.36mm 42 4.2 6 94 85-100 1.18mm 120 12 18 82 75-100 600μ 55 5.5 23.5 76.5 60-79 300μ 429 42.9 66.4 33.6 12-40 150μ 242 24.2 90.6 9.4 0-10 Pan 94 9.4 4.7 -Total 1000 Σ211

Fig-3.3:

Table 3.5: PropertiesofWastebrickpowder

Fineness Modulus Specific Gravity Water absorption Silt content Grading Zone

2.63 2.35 2.8% 6% IV

Table 3 6:

3.1.4.

a)Specificgravity b)Siltcontent

Fig-3.2: NaturalSand

Surkhi other name of waste brick powder which is a collectedwastefromthebrickkilnsandhasnofurtheruse.It isobtainedduringtheprocessofmakingbrick,alayerofsand and clayey soil was used over unburned brick to make a cover in the mold. Same procedure has been followed to checkthephysicalpropertiesofwastebrickpowderasfor naturalsandshowninTable3.5and3.6.

IS Sieves Weight Retained [gm]

Weight Retained [%]

Cumulative %Age Retained

Passing Percentage [%]

Limitsas perIS 383-2016 [%] 4.75 mm 0 0 -2.36 mm 14 4.2 10 80 85-100 1.18 mm 40 12 25 82 75-100

600μ 20 5.5 24.5 76.5 60-79 300μ 48 42.9 69.4 33.6 12-40 150μ 172 24.2 100 10 0-10 Pan 206 9.4 - - -

Total 500 Σ263

Forthemixingofconcrete,waterisrequired.Inaddition towater,thealkalisolutionwasmadewithit.Potablewater was procured from GNDEC, Ludhiana, and was used throughouttheresearch.

The alkaline activator for Fly-Ash and GGBS activation wasasolutionofNaOHandsodiumNa2SiO3.Inthepresence ofNaOH,moresilicateandaluminatemonomersdevelop,and Sodium-basedactivatorswerechosenbecausetheyareless expensive than potassium-based activators. The sodium

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

hydroxideusedwasintheformofflakes.Intheprocessof makingthesodiumhydroxidesolution,theflakesorpellets weredissolvedinwater.Themolarityof12wereusedinthis study.ShivasChemicals,Ludhiana,providedthematerialfor the alkali activator solution, which was 97 percent pure. Accordingtothepreviousliterature,theratioofNa2SiO3 to NaOHiskept2.5[1].

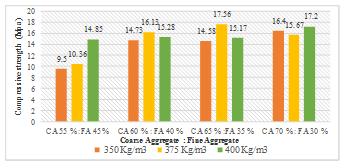

Inthebeginningf-orthepro-ductionofgeopolymerconcrete solutiont-obinderratioistakenasaconstant0.48inallthe mixestocheckthe3-daybehaviorofcompressivestrength, thefollowingassumptionsareusedtoperformtrialmixfor achievingmaximumstrength.

1. Different binder content from 350 to 400 kg per meter cube, where the binder content with a combinationof70%fly-ashand30%GGBFS was keptsameforallmixes.

2. Ratioofsodiumsilicatetosodiumhydroxideiskept 2.5withamolarityof12Molar.

3. Wastebrickpowderwasusedasfullyreplacedfine aggregate.

4. Varying ratio of coarse and fine aggregate from 55:45(%)to70:30(%)atanintervaloffive.

The proposed mixes were used to attain maximum compressivestrengthat3-daywithallthesuppositionwas further carried as shown in Table 37. Where total 36 are castedandtestedforthreeMix1,Mix2,andMix3.

Table 3.7: CoarsetoFineaggregateratioforvarying bindercontent

Fig-3.4: Variationincompressivestrengthat3-day ambientcuringfor0.48s/b.

Table 3.8: Compressivestrengthat3-dayfortrialmix

Binder (Kg/m3)

(CA55%: FA 45%) (CA60%: FA40%) (CA 65 %: FA 35 %) (CA 70%: FA 30 %) (MPa) (MPa) (MPa) (MPa) 350

9.42 14.94 14.96 16.69 9.6 14.7 14.8 16.4 9.5 14.5 14 16.12 Avg. 9.5 14.73 14.58 16.4 375

10.4 16.11 17.7 15.71 10.37 16 17.6 15.5 10.33 16.3 17.4 15.8 Avg. 10.36 16.13 17.56 15.67

14.93 15.04 15.42 17.52 14.8 15.6 15 17.2 14.75 15.2 15.1 17.1 Avg. 14.85 15.28 15.17 17.2

400

MIX Binder Content (Kg/m3)

CA: FA (%)

CA: FA (%)

CA: FA (%)

CA: FA (%) S/B MIX 1 350 55:45 60:40 65:35 70:30 0.48 MIX 2 375 MIX 3 400 3.2.2.

Fromtheabove-mentionedtrialmixes,mixwhichachieved themaximumcompressivestrengthat3-daywereselected forfulfilmentofobjectives.Resultfortrailmixpresentedin Table3.8andfigure3.4.

Consideringthebehaviorfor0.48solutionbinderratiois found good as shown in Figure 3.6. than it proceeds for furtherexaminationofstrengthwithfixed0.48solution,375 kg/m3 bindercontent,65%coarseaggregateand35%fine aggregates.

Based on the above mix assumptions, an all-in aggregate percentage of coarse and fine aggregate was determined, with a maximum compressive strength of 3 days, to be utilizedincalculatingcoarseandfineaggregateamountsat thetimeofmixdesignwheretheparticlepackingtheory[17]. Thequantityofaggregatewasestimatedbasedonweightof aggregateinconcreteandtheproportionwasselectedfrom trialmixasrepresentedinTable3.9and3.10.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

TheSSDconditionwasusedtocomputecoarseandfine aggregate quantities. As a result, the adequate water corrections are made based on the aggregate's moisture content during casting. Geopolymer concrete blends with wastebrickpowderproportionsmixeswithreplacementof naturalsandfrom0%,50%and100%wherewastebrick powder was designated as WBP0, WBP50 and WBP100, respectively.

Table 3.9: Proportioningofmaterials

MIX CA: FA (%) WBP (%) NS (%) S/B MIX2 65:35

0 100 0.48 50 50 100 0

Table 3.10: Mixproportion Binder Content (Kg/m3)

It is final stage of mixing where alkali solution is then added to dry mixing as the whole process is done in the electricallyoperatedmixershownbelowinFigure4.2.

Coarse Aggregate (Kg/m3)

Fine Aggregate (Kg/m3)

Alkali Solution (Kg/m3) Extra water 375 1020.612 647.60 180 5%of Alkali solution 1:1.72:2.72

In dry mixing material containing coarse and fine aggregateasintheformofSSDconditionweremixedwith binderforacalculatedquantity.

Alkali solution was prepared with NaOH and sodium silicate Na2SiO3 as shown below in Figure 4.1 Where 12 molar concentration of sodium hydroxide is mixed with sodium silicate i.e., 2.5 times of sodium hydroxide for exampleifwehavetoprepare12molarperlitersolutionfor NaOHthen12x40=480gmandNa2SiO31480x2.5=3700 gm,representsitsweightwithconcentrationof12molarity, duringthepreparationofsolutionitmustbepreparedprior toitsusagewhenmixedinwetmixingduetoitsexothermic reaction during mixing of chemicals together. Precautions should be taken such as before collection or touching of chemicals.

Aftermixingofmaterials,concreteisfilledtolubricated mold.Castingofthepreparedgeopolymerconcretewouldbe doneincubesize100mmx100mmx100mm,150x150x 150mm,cylinderofsize150mmx300mmandprism100 mmx100mmx500mmfromtheabovecombinationsthe total“63”numbersofsamplearecastedasno.ofspecimen presentedinTable4.1.andFigure4.3.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

Table 4.1: No.ofspecimen

Molarity (M)

Solution/ binder S/B

Fly ash: GGBFS (%)

12 0.48 70:30

NS (%) WBP (%) No. of specimen

100 0 (100x100x100) mm 3 50 50 3 0 100 3

Testingof18cubesbyCTmachineat7-dayand28-dayas per IS 516-1959. The blocks were placed under bearing platespreventinganydamageandgraduallyloadwasapplied untilcrackappeared.Figure5.1showsthetestingofcubes.

12 0.48 70:30

100 0 (150x150x150) mm 6 50 50 6 0 100 6

12 0.48 70:30

100 0 (100x100x500) mm 6 50 50 6 0 100 6

12 0.48 70:30

100 0 (150x300) mm 6 50 50 6 0 100 6

Testing of geopolymer concrete is followed as per Indian standardscodeprovisionfollowedbyASTMandACI.

AccordingtoIS1199(Part2):2018,theslumpconetest wasusedtoassessworkability.Threelayersofmaterialwere pouredintothehollowcone-shapedmold,whichhadinternal dimensionsof200mmatthebase,100mmatthetop,and 300mminheight.Eachlayertampedwith25strokesofthe tampingrod.Afterlevellingthe surface with the toplayer, remove the mold by lifting it vertically upward. The gap betweentheheightofthemoldandthehighestpointofthe slumpingconcretewasmeasuredinmillimetersjustafterthe moldwasremoved.TheslumpconetestisshowninFigure5

Fig-5 1 : DigitalCTMachine

Testingof18beamswascarriedoutonUTmachineafter7 dayand28-dayofambientcuring.Testingofconcretewas carriedoutasperACI318andIS516:1959(Methodoftests forstrengthofconcrete.

Fig-5.2 : DigitalUTMachine

It is an indirect method of determining tensile strength of concrete using cylinder which split across the vertical diameterwherethetestwascarriedoutaftercuringof7-day and28-day Testingofconcrete wascarriedoutas perACI 318 and IS 516:1959 (Method of tests for strength of concrete)representedinFigure5.3.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

NSWBPandWBP)forwhichcomparisonisproducedforits qualityproduction.

6.1.

To see the effect of replacement of natural sand with waste brick powder on workability of concrete and the observationsaregiveninTable6

Fig-5 3 : AutomatedCTM

Carbonation is a test to check the inflow of carbon through accelerated carbonation chamber in which the excess amount of carbon flow is present. Criteria for CarbonationwasfollowedasperIS1902-12.Soas9no.’sof specimen(100mmx100mmx100mm)wascasted.Tocheck the inflow of carbon, the specimens were waxed from the outerfourfacesforaperiodof28-dayopenaircuring,after the curingit was placedina chambershowninFigure 5.4 whereexcessamountofcarbonrequiredforanotherperiod of28days. Whenallthecubesweretakenoutofchamber thenitwasplacedforopenaircuringforsomeduration

Fig-5.4

Thisresearchhasbeencarriedouttopreparegeo-polymer concrete with available literature. In this chapter result obtained from the experimental program are discussed. There are three cases of geo-polymer concrete mix (NS,

Mix Designation Slump (mm)

NS 140 NSWBP 110 WBP 90

The slump for NS and NSWBP concrete mixtures is considerablyhighotherthanWBPwhichismediumbecause waste brick powder prepared concrete contains harsh substanceofburnedsandandclayeysoilwhichledtoabsorb morewaterevenafteritwassaturatedsurfacedriedbefore usinginmix.AccordingtoWongetal.[18]withanincreasein waste brick powder, the mixture flowability decreased linearly.

6.2. Effect of Strength Over NS, NSWBP AND WBP

6.2.1.

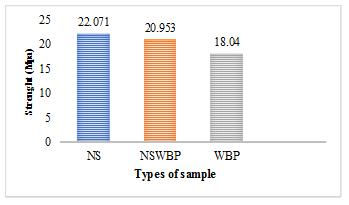

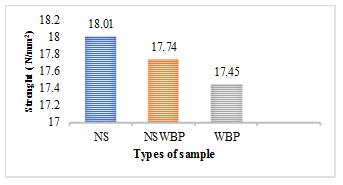

Total number of 18 cubes were tested on a digital CT machineofcapacity2000KNafteropenaircuringperiodof7 dayand28dayswhere3pairofcubesdenotedasNS,NSWBP andWBPcontainsetof6cubes.Thetestresultisshownin Table6.21and62withgraphicalrepresentationinFigure6 and61

Table 6.1: 7-daycompressivestrengthofambientcured specimensfor0.48s/b

Series NS (N/mm2) NSWBP (N/mm2) WBP (N/mm2)

1. 18.61 17.86 17.58 2. 17.37 18.35 17 3. 18.04 17 17.7

Average 18.01 17.74 17.45

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

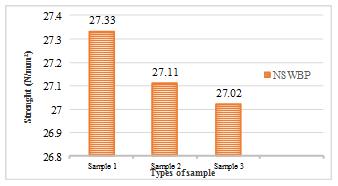

In Meantime 3 cube were casted with same quantity of material but increaseds/b i.e., 0.55and then compression wastested.Table6.3andFigure6.2representsresult.

Table 6.3: Variationincompressivestrengthat28-day ambientcuringfor0.55s/b

Fig-6 Variationincompressivestrengthat7-dayambient curingfor0.48s/b

Table 6.2: 28-daycompressivestrengthofambientcured specimensfor0.48s/b

Series NS (N/mm2) NSWBP (N/mm2) WBP (N/mm2) 1. 22.63 21.83 18.04 2. 2168 2054 18 3. 2189 2048 1808

Sample NSWBP (N/mm2) 1. 27.33 2. 27.11 3. 27.02 Average 27.15

Fig-6.1 Variationincompressivestrengthat28-day ambientcuringfor0.48s/b

After7-dayofopen-aircuringcompressiontestshowedthe behavior thatthe rate ofhardening isfastfor 7day which increasesstrengthupto18MPa.Butafter28daysofopen-air curing,wherethecompressiontestshowedbehaviorintheir rate of hardening which is slowed after 7 day and compressivestrengthisupto22MPa.

Rate of percentage in compression for fully natural sand increased by 22.55 % of 18.01 MPa after 7day till 28 days whileforNSWBPitwas18.11%of17.74MPaafter7daystill 28dayandforWBP,3.38%of17.45MPaafter3daytill28daywhereafter7dayratetill28daywas1.92%of17.7MPa.

Fig-6 2 Variationincompressivestrengthfor0.55s/bat 28-dayambientcuring

After testing result has been compared with result of geopolymerconcretepreparedbymixingnaturalsand50% andwastebrickpowder50%for0.48solutionbinderat28 dayandfoundthatstrengthalsoattherateof22.83%with the14.28%increaseinsolutionbinderratio.Accordingto Dingetal[6]withariseinalkalicontentcompressionpeak loadintestsofspecimenallincrease.

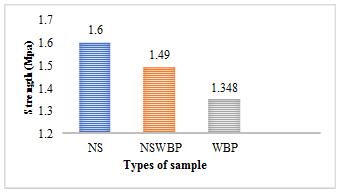

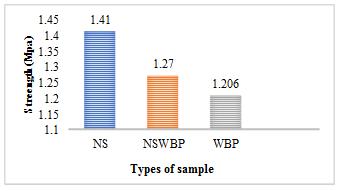

18cylindersweretestedovertheperiodof7and28day onautomatedCTMwithacapacityof2000KNassuchas3 pairofcylinderNS,NSWBP,andWBPrepresentseachsetof6 cylinder.Table64and65,togetherwithFigure63and64, showthetestresults.

Table 6.4: 7-daySplittensilestrengthofambientcured specimensfor0.48s/b

Sample NS (MPa) NSWBP (MPa) WBP (MPa) 1. 1.41 1.27 1.13 2. 1.41 1.23 1.25 3. 1.41 1.32 1.23 Average 1.41 1.27 1.20

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

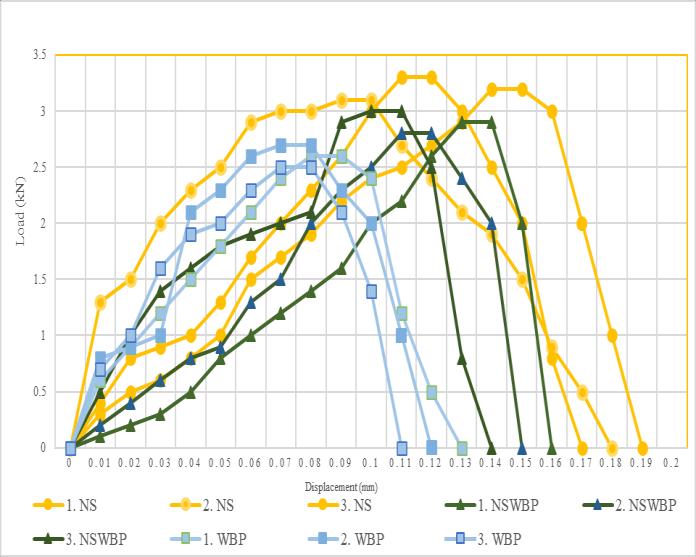

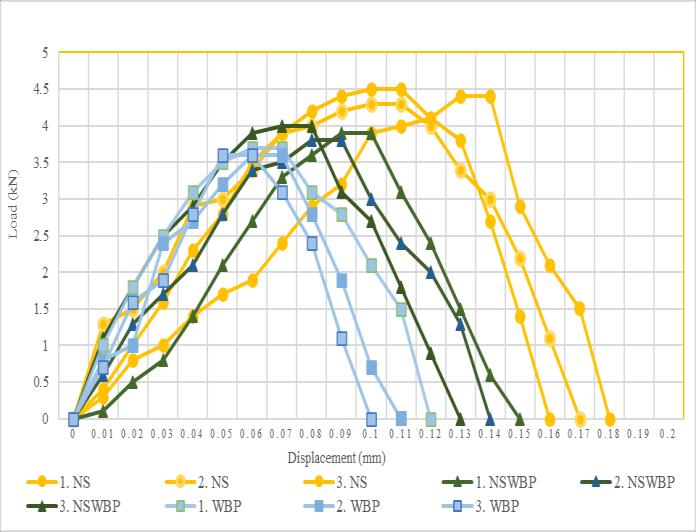

Overtheperiodof7and28days,atotalof18beamswere evaluatedonadigitalUTM,with3pairsofbeamNS,NSWBP, andWBPeachhavingasetof6beams.Thetestfindingsare displayedinTable66,67andFigure65,66

Table 6.6: 7-dayFlexuralstrengthofambientcuredbeam for0.48s/b

Sample NS (kN) NSWBP (kN) WBP (kN)

1. 3.1 2.9 2.7

Fig-6.3 Variationinsplittensilestrengthat7-dayambient curingfor0.48s/b

ThesplittensilestrengthofNSincreasesby7.8%and14.28 %whencomparewithNSWBPandWBPat7-day.Withthe increaseofquantityofwastebrickpowder,thestrengthofGP concretegetsdecreased.

Table 6.5: 28-daySplittensilestrengthofambientcured specimensfor0.48s/b

Sample NS (MPa) NSWBP (MPa) WBP (MPa)

1. 1.6 1.54 1.37

2. 1.58 1.41 1.32 3. 1.61 1.51 1.34

Average 1.60 1.49 1.34

2. 3.2 3 2.5 3. 3.3 2.8 2.6 Average 3.2 2.9 2.6

Fig-6.4 Variationinsplittensilestrengthat28-day ambientcuringfor0.48s/b

ThesplittensilestrengthofNSincreasesby6.25%and18.75 %whencomparewithNSWBPandWBPat28-day.Withthe increaseofquantityofwastebrickpowder,thestrengthofGP concretegetsdecreased.ItissafeaccordingtoChowdhury [2]wheresplittensilestrengthwillachieve8%to12%of compressivestrength.

Fig-6.5 VariationinFlexuralstrengthat7-dayambient curingfor0.48s/b

Table 6.7: 28-dayFlexuralstrengthofambientcured beamfor0.48s/b

Sample NS (kN) NSWBP (kN) WBP (kN)

1. 4.4 3.9 3.8

2. 4.3 3.8 3.6 3. 4.5 4 3.7

Average 4.4 3.9 3.7

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

S.No. Series Sample

Based on the load displacement curve of NS which shows maximumloadupto4.4kN,forNSWBPitwas3.9kNandfor fullyreplacedwastebrickpowderitwas3.7kN.

Flexuralstrengthat7daywas1.91MPaforNS,1.7MPafor NSWBPand1.56MPawhileat28dayitwas2.64MPawhich is comparatively higher from Natural sand waste brick powder(2.34MPa)andWastebrickpowder(2.22MPa).

Rateofstrengthinpercentat7-dayforNSwas10.99%when comparedtoNSWBPand18%whencomparedtoWBPwhile at28-dayforNSwas15.9%withrespecttoWBPand11.36 %forNSWBP.

Aftercuringofcubes,itwasexposedtoairforsomeduration andthencutintotwopiecesforapplyingofphenolphthalein solutionoveritthenleftfor1hour±10minutes.Thepieces appeared to purple color after applying solution which indicating non-carbonated region as the colorless region indicatescarbonatedzone.Colorless region was measured withverniercalipertocheckthedepthofcarbon.Table6.8 andfigure67representtheresultofCarbonationdepth.In following reaction (3), which is known as carbonation, calciumhydroxideandcarbondioxidecombinetogenerate insolublecalciumcarbonate(CaCO3),whichcausesconcrete to carbonate and result in a lower pH value. According to Pasupathy[12]thedurabilityperformanceofthegeopolymer containing70%flyashand30%GGBFSwascomparableto OPCconcrete.

Ca(OH)2 +CO2 CaCO3 +H2O………………….(3)

1. NS

Carbonation depth (mm) Average (mm)

1 10.9 10.86 2 11.2 3 10.5

2. NSWBP

3. WBP

1 8.7 8.73 2 8.5 3 9

1 7.3 7.06 2 7.1 3 6.8

Testrevealsthatwiththeincreasedamountofwastebrick powderthecarbonationdepthstartsdecreasingascompared toNSandNSWBP.ReportofZhuguo[19]representedthat thealkalineactivator,whichismadeofsodiumsilicateand NaOH,hasahighercarbonationresistanceifmoretheNaOH content.GPconcretebasedonFA&BFSarealsosignificantly influencedbycuringtemperature.Comparedtoheatcuring andambientcuring, atroomtemperaturecuringoffersless carbonationresistance.

The compressive strength of GP concrete influences as indirectlyrelatedtocarbonationashigherthecarbonation depth is typically associated with stronger concrete. However,othercharacteristics,suchasthetypeofalkaline activator,mayhaveanimpactonthecarbonationresistance ofGPconcrete.

Bindercontentwith70%offlyashand30%ofslagfor375 kg/m3 showed better result with solution binder ratio i.e., 0.48wherecoarsetofineaggregateratiosettledat65%to 35%soastoachievemaximumstrength.Duetohighwater absorption and silt content of waste brick powder results came out less. Also curing condition can impact in geopolymerization reaction as our study is done at open air

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

curing. For complete geo-polymerization reactions, curing needs to be done at elevated temperatures for minimum solution.

Inadditiontoabovestatementsfollowingaresomepoints observedfromtheexperimentalprogram:-

1. Freshlymixedconcretepreparedwith0%WBPis far better and flowable when prepared with designatedalkalisolutionbutinthecaseof50%to 100%wastebrickpowdermixgetsharshuntilextra addition of water to get completely mix. Water additionupto7%incaseof100%WBPwhilein caseofNSwateradditionisupto5%whichshows concreteisflowableandworkableforcasting.

2. Split tensile strength of GPC prepared with fully waste brick powder came out lower than those prepared with replacement of natural sand. As flexural strength of GP concrete prepared with 100%and50%ofwastebrickpowderwaslower whilespecimenpreparedwith100%naturalsand hashigherstrength.

3. Effect ofcarbon depthhasadverse reflection over compressive strength that larger the depth of carbonationhigherthecompressivestrength.While traces of carbonation depth in GPC concrete for wastebrickpowderwaslowerbutasonincreasing naturalsanditstartsincreasing.

[1] Aliabdo,A.A.,AbdElmoaty,M.,andSalem,H.A.(2016). Effectofwateraddition,plasticizerandalkalinesolution constitution on fly ash based geopolymer concrete performance. Construction and BIS,IS456(2000)Plain and reinforced concrete-Code of Practice. Bureau of Indian Standards, New Delhi, India

[2] Chowdhury,S.,Mohapatra,S.,Gaur,A.,Dwivedi,G.,and Soni, A. (2021). Study of various properties of geopolymer concrete–A review. Materials Today: Proceedings, 46,5687-5695.

[3] Davidovits, J. (1989). Geopolymers and geopolymeric materials. Journal of thermal analysis, 35(2),429-441

[4] Davidovits,J.(1994).GeopolymerInstitutePropertiesof geopolymer cements. Proceeding First International conferenceonalkalinecementandconcreteScientifics Research Institute on Binder and Material. Kiev State TechnicalUniversityUkraine1994pp.131-149.

[5] Davidovits, J. (2013). Geopolymer cement. A review. Geopolymer Institute, Technical papers, 21,1-11.

[6] Ding,Y.,Shi,C.J.,&Li,N.(2018).Fracturepropertiesof slag/fly ash-based geopolymer concrete cured in

ambient temperature. Construction and Building Materials, 190,787-795.

[7] El-Naggar, K. A. M., Amin, S. K., El-Sherbiny, S. A., and Abadir, M. F. (2019). Preparation of geopolymer insulatingbricksfromwasterawmaterials. Construction and Building Materials, 222,699-705.

[8] Hwang,C.L.,Yehualaw,M.D.,Vo,D.H.,&Huynh,T.P. (2019).Developmentof high-strengthalkali-activated pastes containing high volumes of waste brick and ceramic powders. Construction and Building Materials, 218,519-529.

[9] Okoye, F. N., Durgaprasad, J., and Singh, N. B. (2015). Mechanicalpropertiesofalkaliactivatedflyash/Kaolin basedgeopolymerconcrete. Construction and Building Materials, 98,685-691.

[10] Part, W. K., Ramli, M., and Cheah, C. B. (2015). An overview on the influence of various factors on the properties of geopolymer concrete derived from industrial by-products. Construction and Building Materials, 77,370-395.

[11] Provis, J. L. (2014). Geopolymers and other alkali activatedmaterials:why,how,andwhat. Materials and structures, 47(1),11-25.

[12] Pasupathy, K., Berndt, M., Castel, A., Sanjayan, J., & Pathmanathan,R.(2016).Carbonationofablendedslagflyashgeopolymerconcreteinfieldconditionsafter8 years. ConstructionandBuildingMaterials, 125,661-669

[13] Patil,A.A.,Chore,H.S.,andDode,P.A.(2014).Effectof curing condition on strength of geopolymer concrete. Advances in concrete construction, 2(1),029.

[14] Rameshwaran,P.M.,andMadhavi,T.C.(2021).Flexural behaviour of fly ash based geopolymer concrete. Materials Today: Proceedings, 46,3423-3425.

[15] Singh,B.,Ishwarya,G.,Gupta,M.,andBhattacharyya,S. K. (2015). Geopolymer concrete: A review of some recent developments. Construction and building materials, 85,78-90.

[16] Thunuguntla,C.S.,andRao,T.G.(2018).Effectofmix design parameters on mechanical and durability propertiesofalkaliactivatedslagconcrete. Construction and Building Materials, 193,173-188.

[17] Thunuguntla,C.S.,&GunneswaraRao,T.D.(2018).Mix designprocedureforalkali-activatedslagconcreteusing particle packing theory. Journal of Materials in Civil Engineering, 30(6),04018113.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056 Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

[18] Wong, C. L., Mo, K. H., Alengaram, U. J., & Yap, S. P. (2020).Mechanicalstrengthandpermeationproperties of high calcium fly ash-based geopolymer containing recycled brick powder. Journal of Building Engineering, 32,101655.

[19] Zhuguo,L.I.,&Sha,L.I.(2018).Carbonationresistance of fly ash and blast furnace slag based geopolymer concrete. ConstructionandBuildingMaterials, 163,668680.