International Research Journal of Engineering and Technology (IRJET) Volume: 09 Issue: 11 | Nov 2022

www.irjet.net

e-ISSN: 2395-0056 p-ISSN: 2395-0072

Meshing and Analysis of Vehicle Wheel Rim Ameya Malwadkar1, Pradnya Mungi2 1Student,

Department of Mechanical Engineering, Vishwakarma Institute of Information Technology, Pune-48, Maharashtra, India 2Student, Department of Mechanical Engineering, Vishwakarma Institute of Information Technology, Pune-48, Maharashtra, India ---------------------------------------------------------------------***---------------------------------------------------------------------

Abstract – In this study a basic analysis of the vehicle’s

conditions by having a combine of safety humps extending inside of the rim toward the opposite tire bead seat from associate in nursing outer contoured surface of the rim.

wheel rim is shown. The wheel rim is the affiliation between the hub & the tire. The tire is put in on the rim, & the rim is bolted to the hub. They play an important half within the handling of the vehicle and conjointly part in reducing the air drag of the vehicle. Developing such a wheel rim which will serve each purpose and conjointly are light-weight and form optimized plays a vital role in overall vehicle performance increase. Alloy wheel rims are employed in most of the vehicles. They're lightweight weight and also are simple to manufacture. The development of such components is an ongoing process. In this study, Solidworks software is used for designing purpose and for meshing and analyzing ANSYS software is used.

Heavy vehicles and some trucks may have a removable multi-piece rim assembly consisting of a base that mounts to the wheel and axle. They then have either a facet ring or a facet and lock ring combination. These elements square measure removable from one facet for tire mounting, whereas the other facet hooked up to the bottom encompasses a fastened projection. Low tire pressure applications such as off-roading and drag racing use a bead lock that clamps or physically attaches the bead of the tire to the rim of the wheel. This reduces the possibility of the tire separating from the rim inflicting a unforeseen deflation.

Key Words: Wheel Rims, Wheel Hub, Optimization, FEA, Analysis, Meshing, Factor of Safety, Ansys, Solidworks

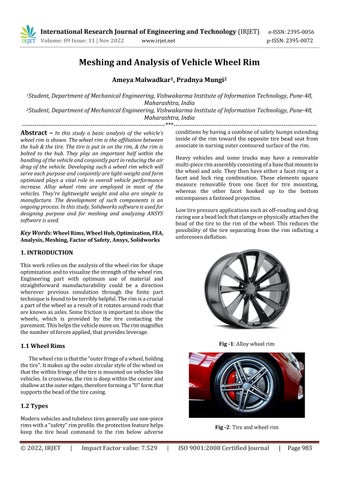

1. INTRODUCTION This work relies on the analysis of the wheel rim for shape optimization and to visualize the strength of the wheel rim. Engineering part with optimum use of material and straightforward manufacturability could be a direction wherever previous simulation through the finite part technique is found to be terribly helpful. The rim is a crucial a part of the wheel as a result of it rotates around rods that are known as axles. Some friction is important to show the wheels, which is provided by the tire contacting the pavement. This helps the vehicle move on. The rim magnifies the number of forces applied, that provides leverage. Fig -1: Alloy wheel rim

1.1 Wheel Rims The wheel rim is that the "outer fringe of a wheel, holding the tire". It makes up the outer circular style of the wheel on that the within fringe of the tire is mounted on vehicles like vehicles. In crosswise, the rim is deep within the center and shallow at the outer edges, therefore forming a "U" form that supports the bead of the tire casing.

1.2 Types Modern vehicles and tubeless tires generally use one-piece rims with a "safety" rim profile. the protection feature helps keep the tire bead command to the rim below adverse

© 2022, IRJET

|

Impact Factor value: 7.529

Fig -2: Tire and wheel rim

|

ISO 9001:2008 Certified Journal

|

Page 983