International Research Journal of Engineering and Technology (IRJET) Volume: 09 Issue: 11 | Nov 2022

www.irjet.net

e-ISSN: 2395-0056 p-ISSN: 2395-0072

Usage of Waste Materials in Concrete Pratibimb Bhatt1, Sanjeev Kumar Verma2 M.Tech Scholar, Civil Engineering Department, SAGE University, Bhopal, Madhya Pradesh, India 2 Professor, Civil Engineering Department, SAGE University, Bhopal, Madhya Pradesh, India ---------------------------------------------------------------------***--------------------------------------------------------------------decreases solid waste, greenhouse gas emissions, air and Abstract - Utilization of more environment-friendly 1

water pollution, and solid waste by conserving natural resources and saving energy. Comparing trash incineration and landfills, recycling, reusing, and composting are estimated to provide six to ten times as many employment. Even without factoring in the energy lost in burning materials, recycling, according to the Global Alliance for Incinerator Alternatives (GAIA) (2012), saves three to five times the energy produced by waste-to-energy facilities.

materials in any firm or industry or construction industry is of principal importance. Due to the release of a variety of greenhouse gases as a result of industrial operations, our planet's environment is highly polluted. Cement is utilised as a binding agent in creating concrete, which is being employed in large quantities by the building sector. More than 8% of CO2 is discharged into the atmosphere and a tremendous quantity of energy is required during cement production. Concrete becomes an unsustainable material as a result. In consideration these views, construction industry needs a alternate for cement, by replacing cement to some extent with waste products large amount of pollution can be avoided.

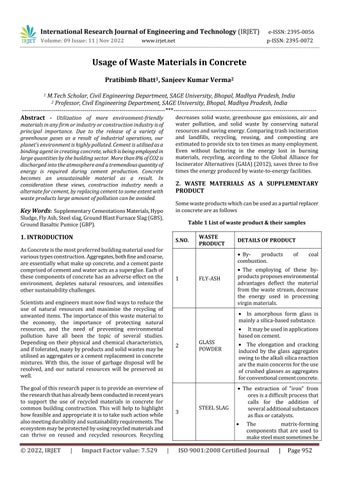

2. WASTE MATERIALS AS A SUPPLEMENTARY PRODUCT

Key Words: Supplementary Cementations Materials, Hypo

Some waste products which can be used as a partial replacer in concrete are as follows

Sludge, Fly Ash, Steel slag, Ground Blast Furnace Slag (GBS), Ground Basaltic Pumice (GBP).

Table 1 List of waste product & their samples

1. INTRODUCTION

S.NO.

As Concrete is the most preferred building material used for various types construction. Aggregates, both fine and coarse, are essentially what make up concrete, and a cement paste comprised of cement and water acts as a superglue. Each of these components of concrete has an adverse effect on the environment, depletes natural resources, and intensifies other sustainability challenges.

1

Impact Factor value: 7.529

FLY-ASH

of

coal

The employing of these byproducts proposes environmental advantages deflect the material from the waste stream, decrease the energy used in processing virgin materials. In amorphous form glass is mainly a silica-based substance.

2

The goal of this research paper is to provide an overview of the research that has already been conducted in recent years to support the use of recycled materials in concrete for common building construction. This will help to highlight how feasible and appropriate it is to take such action while also meeting durability and sustainability requirements. The ecosystem may be protected by using recycled materials and can thrive on reused and recycled resources. Recycling

|

DETAILS OF PRODUCT

Byproducts combustion.

Scientists and engineers must now find ways to reduce the use of natural resources and maximise the recycling of unwanted items. The importance of this waste material to the economy, the importance of protecting natural resources, and the need of preventing environmental pollution have all been the topic of several studies. Depending on their physical and chemical characteristics, and if tolerated, many by products and solid wastes may be utilised as aggregates or a cement replacement in concrete mixtures. With this, the issue of garbage disposal will be resolved, and our natural resources will be preserved as well.

© 2022, IRJET

WASTE PRODUCT

3

GLASS POWDER

STEEL SLAG

It may be used in applications based on cement. The elongation and cracking induced by the glass aggregates owing to the alkali silica reaction are the main concerns for the use of crushed glasses as aggregates for conventional cement concrete. The extraction of "iron" from ores is a difficult process that calls for the addition of several additional substances as flux or catalysts.

|

The matrix-forming components that are used to make steel must sometimes be

ISO 9001:2008 Certified Journal

|

Page 952