International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

Sharma1

andAnuj Kumar Sharma2

1M.Tech. Final Year Student, Dept. of Civil Engineering, GNIOT, Greater Noida, U.P, India 2Assistant Professor, Dept. of Civil Engineering, GNIOT, Greater Noida, U.P, India ***

Abstract - Using cement, coarse aggregates, and fine aggregates raises construction costs. Leaving trash outside can cause environmental problems. Thus, recycling is encouraged. Many industries produce waste materials that, due to their nature, can be used to partially replace fundamental resources. Concrete producers are continually looking for solutions to reduce solid waste disposal. Steel fibres are employed because concrete is weak in stress. There are experimental reuse and recycling alternatives for this industrial by product. These wastes are disposed nearby, destroying the soil's natural fertility. We discuss wastes' physical, mechanical, and chemical qualities.

The research is done on M60 grade concrete with 0%, 15%, 30%, 45%, and 60% marble dust replacing sand and 0.8% steel fibres added to increase compressive, flexural, and split tensile strengths.

Based on feasibility, replacing up to 45% marble powder and 0.8% steel fibres in concrete is appropriate. After 15% replacement, compressive strength and spilt tensile started falling.

Afterfoodandwater,humansuseconcrete.Ithascement, fine, coarse, and water aggregates. River sand is fine aggregate. Cement dominates concrete. Cement, fly ash, and slag bind the aggregates. Aggregates include fine and coarse gravel, limestone, and granite. Many admixtures haveuniqueproperties.Watermakesthedrycombination firm and strong. Hydration strengthens and hardens. Water and cement combine to produce stone. Concrete needs reinforcements because it compresses well but stretchesbadly.

Concretecracksfromshrinkageandtension.Durable,fireresistant, and increasing strength with time, it's great for building. Admixtures make high-strength concrete costeffectiveandefficient.

Flexibleconcrete.Originallyconceivedasasteelcover,it's nowa structural part.Concreteisstrengthened byadding steel.Normalconcreteisweakerthansteel.High-strength concreteeliminatedthisproblem(HSC).

Modernadmixturesandconcretetechnologiescanachieve 50MPain12to18hoursand70MPain28days.

MPain12to18hours&70+MPain28days.

New technologies using artificial and waste materials minimise the load on natural resources. Replace concrete withsandtoincreaseitsmechanicalcharacteristics.Marble dust is utilised instead. Marble dust is a construction material. Marble cutting and shaping creates it. Dumping causes pollution. Utilizing garbage reduces environmental problems. This research investigates utilising marble dust tosubstitutesandinconcrete.

Marble dust has been utilised in construction since prehistorictimes.Everyyear,theglobeproduces7,000,000 tonnesofmarble,ofwhich25%istransformedintodustor powder, a large amount whose disposal is a worry. Using discarded marble dust to increase the strength and other attributes of concrete by adding steel fibres solves the disposalproblemandisbeneficial

Fibers-reinforced concrete is a mixture of four distinct systems, including cement, water, coarse particles, fine aggregates,andsteelfibredispersion.Itisalsopossibleto add admixture and pozzolans to the system of conservative concrete. Under ASTM guidelines, all admixtures suitable for usage in Steel Fiber-reinforced concreteareaddedtoconcrete(SFRC).

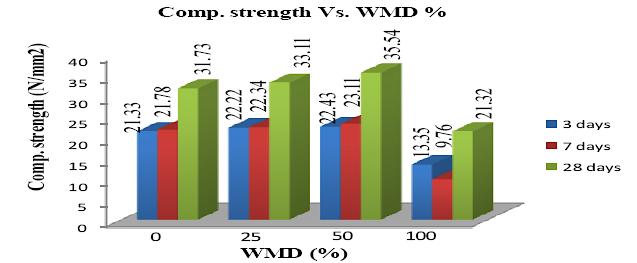

Dhawale et al. (2014) researched concrete compression.

These experiments were done using compression testingmachines(CTM)utilisingcubeswithvaried marbledust-to-sandratios.

50% marble dust to sand produces stronger compressivestrengththan100%.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

Table-1: CompressiveStrengthatdifferentproportions (Dhawale et al.,2014)

M25 Grades 3days (N/mm2) 7days (N/mm2) 28days (N/mm2)

MD0% 21.33 21.78 31.73

MD25% 22.22 22.34 33.11

MD50% 22.43 23.11 35.54

MD100% 13.35 9.76 21.32

Hashmi et al. (2014) investigated the concrete's split tensile strength. For different percentages of cement to marble powder, only three cylinders were produced. On substituting 10% of the cement with marble powder, the split tensile strength was shown to rise; however, the increaseinsplittensilestrengthisinhibitedbytheaddition of more marble dust. As indicated in Table 3, substituting 10%ofthecementwithmarbledustresultedina 19.61% improvementininitialsplittensilestrengthafter28days.

Table-3: Splittensilestrengthofconcrete(Hashmi et al., 2014)

Sr. No. Replacement of cement by MP (%)

Days of curing (days)

Split tensile strength (N/mm2)

1. 0 28 38.368

2. 5 28 41.093

3. 10 28 44.69 4. 15 28 36.769 5. 20 28 35.061

Chart -1:Compressivestrengthatdifferentcuringages (Dhawale et al.,2014)

Hameed et al. (2009) evaluated the concrete's compressivestrength.

For casting, the inside of the mould was properly oiledsothattheconcretewouldn'tsticktoit.

Before casting, all of the parts must be bolted togethercorrectly.

A150mmconcretecubeanda150mmdiameter, 300 mm tall concrete cylinder were utilised to evaluatecompressivestrength.

Topreventenvironmentaldamage,helabouredon thecreationofgreenconcrete.

Table-2: FlexuralstrengthatdifferentProportions (Dhawale et al.,2014)

M25 grade 3Days (N/mm2) 7Days (N/mm2) 28Days (N/mm2)

MD0% 2.94 3.30 4.43

MD25% 3.04 3.56 4.70

MD50% 3.15 3.74 5.10

MD100% 2.21 2.43 3.51

Care was taken with the batching, mixing, and casting.

Thecoarseandfineaggregateswereweighedfirst tomakesuretheywerecorrect.

For each mix, or batch, the right amount of cement, coarse aggregates (20 mm and 10 mm), fine aggregates, marble dust, steel fibres, and waterwereweighedandtested.

For casting, the inside of the mould was properly oiled so thattheconcretewouldn'tstick toit.Beforecasting,allof the parts must be bolted together correctly. Making batches,mixing,andpouringItisthemostcommonwayto figure out if something will work. The slump flow test needs to be done on High Strength Concrete. It is very

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

helpfultodotestson-sitetoseehowthematerialsthatgo intothemixeschangefromdaytoday.

Where, fst is measured split tensile strength, P is the maximumloadatfailure anddisthelengthanddiameter ofthecylinderinmm.

Fig. 1: SlumpFlowTest

The compressive strength is equal to the load written down from the CTM divided by the area. Then, take the average of the three values and compare it to IS: 5161959.”

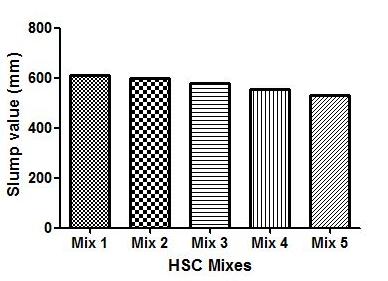

Theslumpflowtestisaverycommonwaytofindouthow easyitistoworkwithconcrete.Differentmixeshavebeen made and tested to see how they affect the properties of fresh concrete. The best results were achieved by using 1% SP and 0.31 w/c ratio. Table-4 shows how the slump flow value changes with the amount of marble dust and steel fibres. When making different batches, different amountsofmarbledustwereused,buttheamountofsteel fibreswaskeptthesame.TherangeofslumpflowforHSC is between 500 and 700. It was seen that the slump flow value went down as the percentage of marble dust went up. Due to its tendency to soak up water, marble dust made the material less easy to work with. Chart-2 shows howtheslumpflowchangeswhendifferentHSCmixesare used.

Table-4: SlumpflowvaluesforvariousHSCMixes

Fig. 2: Compressiontestingmachine(CTM)usedforstudy

4.3 Split Tensile Strength, IS: 5816-1999

Having recorded the highest load, the following formula wasapplied:

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

59.17 62.57

Mix2 60.64 62.15 67.93 66.23 62.09 65.84 63.72 64.92

Mix3 64.91 65.06 65.53 67.18 66.34 68.21 63.93 67.80

Mix4 67.24 66.29 70.15 69.38 65.71 68.45 65.92 69.54

Chart -2:Variationofslumpflowwithrespecttodifferent HSCmixes

To find out what would happen to the compressive strengthofconcreteifsandwasreplacedwithmarbleand steel fibres were added, concrete cubes were made and testedafter7and28days.Table5showstheresultsofthe compressive strength at 7 days and 28 days after curing. The test was done on a 2000 KN ASTM capacity. For the control mix, samples were made and compared to the %age replacements. For each age, three samples were used to make moulds. After 7 days and 28 days, the sampleswereputthroughtests.

All of the mixes were tested for compressive strength at different percentages of replacement. After 28 days, the compressivestrengthofMix4is8.10%higherthanthatof Mix 1 (the control mix). The curve and bar chart of compressivestrengthshow thatthecompressivestrength of concrete cubes at a water-to-cement ratio of 0.31 increased as the replacement percentage went up. The cubes were found to be the strongest when mix 4 (45% sand instead of marble dust and 0.8% fibres) was used. But as more cubes were added, the cubes' compressive strengthwentdown.

Table-5:

Mix5 60.78 58.92 64.76 63.18 56.86 63.10 59.12 61.68

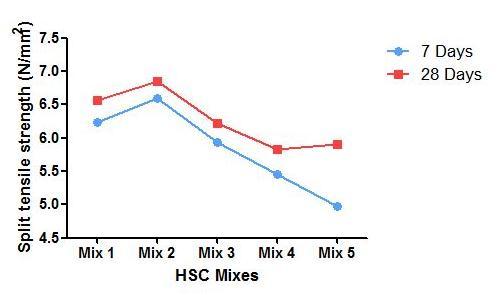

To find out what happened to the split tensile strength of concrete when sand was replaced with marble dust and steelfibreswereadded,concretecylindersweremadeand testedafter7and28days.Table6showstheresultsofthe split tensile strength test after 7 days and 28 days of curing. Split tensile strength kept going down as the amountofmarbledustwentup.

Table-6: SplitTensileStrengthsofvariousHSCmixes

HSC Mixes

7 Days 28 Days STS (N/mm2) Avg. STS (N/mm2) STS (N/mm2) Avg. STS (N/mm2)

Mix1 6.17 6.24 6.48 6.56 6.57 6.25 5.98 6.95 Mix2 6.53 6.60 7.04 6.84 6.40 6.83 6.87 6.65 Mix3 6.12 5.94 6.59 6.22 5.71 5.82 5.89 6.25

Mix4 5.32 5.46 5.63 5.83 5.65 6.09 5.41 5.77

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Mix5 4.78 4.98 5.80 5.91 5.34 5.73 4.82 6.20

Mix5 5.95 5.95 6.02 6.23 6.08 6.35 5.82 6.32

Chart -3:VariationofSplittensilestrengthswithrespect toages

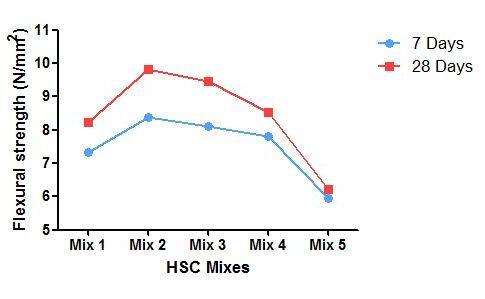

Tofindoutwhatwouldhappentotheflexural strength of concrete if sand was replaced with marble dust and steel fibres were added, concrete beams were poured and testedafter7daysand28days.Table 7showstheresults of the flexural strength test. As the percentage of marble dustwentup,thebendingstrengthkeptgoingdown.

Table-7: FlexuralStrengthsofvariousHSCmixes

HSC Mixes 7 Days 28 Days FS (N/mm2) Avg. FS (N/mm2) FS (N/mm2) Avg. FS (N/mm2)

Mix1 7.43 7.33 8.32 8.21 7.32 8.05 7.24 8.28 Mix2 8.4 8.38 9.84 9.82 8.52 9.76 8.22 9.86 Mix3 8.15 8.12 9.34 9.46 8.25 9.40 7.93 9.64 Mix4 8.05 7.82 8.66 8.53 7.86 8.37 7.55 8.56

Chart -4:VariationsofFlexuralstrengthofHSCmixes withrespecttoage

The goal of this study was to find out how the flexural strengths, split tensile strengths, and compressive strengths of concrete changed when different amounts of sandwerereplacedwithmarbledustandsteelfibreswere added. Sand was replaced in part by marble dust (0%, 15%,30%,45%,and60%),andsteelfibreswereaddedto all of the batches at a rate of 0.8%. All HSC mixes contained1%byweightofcementofthesuperplasticizer BASF-PCE BASE 50. Recent research shows that adding waste materials to concrete makes it stronger and more durable.

TheslumpflowoftheHSC mixesis between500and700 mm. As more things were thrown away, the slump got worse. The amount of marble powder in the concrete makes it harder to work with. But it's good to know that the needed workability of the concrete can be achieved bothwithandwithoutchemicaladditives.

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page774

The compressive strengths went up until it reached 45% replacement,andthenitstartedgoingdown.Withalower w/c ratio, marble dust worked better than sand when it was used to replace sand. At 28 days of curing, adding 0.8% of steel fibre made the most difference. This was when 45% of the marble dust was replaced with it. After

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

45% of the cement was replaced with marble dust, the compressive strength went down. This is because marble dust has a pozzolonic property that changes the way cementworks.

The curve and the bar chart of the split tensile strengths testshowthattheconcrete'ssplittensilestrengthwentup to15%,thenstartedgoingdown.Thew/cratiostayedthe sameforallmixes,whichis0.31.Duetothelowerfineness modulus of the marble dust, the material sticks together better, so the split tensile strength goes up. At 28 days of curing, the highest increase was at 15% marble dust and 0.8%steelfibre,whichwasalmost4%.

The curve and the bar chart of the flexural strength test showthattheconcrete'sflexuralstrengthwentupto15%, thenstartedgoingdown.Themostimprovementwasseen when 15% of the marble dust was replaced and 0.8% of steelfibrewasadded.After28days,theimprovementwas almost 20%. Concrete's flexural strength goes up because its fineness modulus is lower, which makes the material sticktogether.

Forfurtherresearch,ifweincreasetheamountof fibres in the concrete mix, the engineering properties of the concrete show that its strength hasincreasedsignificantly.

4) AmitRana.Somestudiesonsteelfibersreinforced concrete. International Journal of Emerging TechnologyandAdvancedEngineering,Volume3, Issue1

5) ASTM C1585 (2007) Standard test method for measurement of rate of absorption of water by hydraulic-cementconcretes

6) Baboo, Rai. Influence of marble powder/granules in concrete mix. International Journal of Civil & StructuralEngineering1.4:827-834

7) BiniciH.,KaplanH.,YilmazS.,(2007).Influenceof marble dust and limestone dusts as additives on somemechanicalpropertiesofconcrete.Scientific ResearchandEssayVol.2(9),pp.372-379

8) Chavhan P., Bhole S.D. (2014). To study the behavior of marble powder as supplement cementitious material in concrete. International JournalofEngineeringResearchandApplications, ISSN:2248-922,Volume4,Issue4,pp.371-381

9) Chunxiang., Qian., Indubhushan Patnaikuni. (1999). Properties of high- strength steel fiberreinforced concrete beams in bending. Cement andConcreteComposites21.1:73-81

10) Corinaldesi V., Moriconi G., Naik T.R., (2010). Characterization of marble powder for its use in mortar and concrete. Construction and Building MaterialsVolume24,pp.113-117

Infutureresearch,wethinkitwouldbehelpfulto look at how high temperatures affect the mechanical properties of concrete with marble dust.

11) Demirel, Bahar. (2010). The effect of using waste marble dust as fine sand on the mechanical properties of concrete. International Journal of thePhysicalSciences5.9:1372-1380.

Thereneedstoberesearchonthemicrostructure.

1) AliabdoAA,ElmoatyMA,AudaEM.(2014).Re-use ofwastemarbledustinthe productionofcement and concrete. Construction of Building Material, 50:28-41

2) Altun F, Haktanir T, Ari K. (2007). Effects of steel fibers addition on mechanical properties of concrete and RC beams. Construction and BuildingMaterials21:654e61

3) Alyamac, Aydin. (2015). Concrete properties containing fine aggregates marble powder. KSCE JournalofCivilEngineering.19(7),2208-2216

12) Gurumoorthy N. (2014). Influence marble dust as a partial replacement of cement in concrete. InternationalJournalofEngineeringResearchand TechnologyVol.3,Issue3

13) Hameed M., Sekar S. (2009). Properties of green concrete containing quarry rock dust and marble sludge powder as fine aggregates. India, ARPN JournalofEngineeringandAppliedSciences4(4) 83-89

14) Heboub H., Aoun H., Belacia M., Houari H., Gorbel E. (2010). Use of waste marble aggregates in concrete. Construction and Building Material 25: 1167-1171

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

15) IS: 383-1970: Specification for coarse and fine aggregates from natural sources for concrete, BureauofIndianstandard,NewDelhi(India)

16) IS: 4031 (Part 4, 5&6)-1988: Methods of Physical Tests for Hydraulic Cement, Bureau of Indian Standard,NewDelhi(India)

17) IS: 516 (1959) Indian standard code of practicemethods of tests for strength of concrete, Bureau ofIndianstandard,NewDelhi(India)

18) IS: 5816 (1999) Methods of test for splitting tensile strength of concrete, Bureau of Indian standard,NewDelhi(India)

19) Ishwar Chand. (2012). Engineering utilization of marble slurry. International Journal of Civil Engineering and Technology (IJCIET), Volume 3, Issue2,July-December,pp.01-06

20) KoksalFuat.,AltunFatih.,YigitLhami.,SahinYusa. (2008). Combined effect of silica fume and steel fiber on the mechanical properties of high strength concretes. Construction and Building Materials22:1874-1880

21) Mohamadien Hassan A. (2012). The effect of marble powder and silica fume as partial replacement for cement on mortar. International Journal of Civil and Structural Engineering Vol. 3, Issue2

22) Mohod Milind V. (2012). Performance of steel fiber reinforced concrete. International Journal of Engineering and Science Volume 1, Issue 12, pp01-04

23) NiliMahmoud.,AfroughsabetV.(2010).Combined effectofsilicafumeandsteelfibersontheimpact resistanceandmechanical properties ofconcrete. International Journal of Impact Engineering 37:879-886

24) Rodrigues R., Brito J. de., Sardinha M., (2015). Mechanical properties of structural concrete containing very fine aggregates from marble cutting sludge. Construction and Building Materials77,349-356

AshwaniSharma

M.Tech(Civil)Final YearStudent, GNIOT,GreaterNoida B.Tech in Civil from LPU, Punjab in2015.

Mr AnujKumarSharma

B.Tech, MTech (Structural Engineering)

5yearsofTeachingExperience Assistant Professor GNIOT, GreaterNoida