International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN: 2395-0072

1M.Tech Scholar, Bhilai Institute of Technology, Raipur, Chhattisgarh

2Assistant Professor, Dept. of Mech. Engg., Bhilai Institute of Technology, Raipur, Chhattisgarh

3Associate Professor, Dept. of Civil Engg., Bhilai Institute of Technology, Raipur , Chhattisgarh ***

Abstract – The construction industry is one of the riskiest industry in all over the world. It is recognized to be highly risk prone, very complex and competitive where uncertainties emerge from a different source. Under-construction sites are loaded with numerous risks that possibly lead to countless accidents and a large number of deaths. Implementation of occupational health and safety standards at any working site is necessary to minimize such dangers. Health and safety risk and lack of protection of the workers are the major problems in the construction industry. Like many countries, health and safety risks and lack of protection of the workers are considered to be an important problem also in India. Therefore, the goal of this research work is to devise preemptive strategy for health and safety by identifying the risk factors which may affect the safety of the construction workers in India. To achieve the objectives, critical literature review was performed to identify the health and safety risk factors. All the identified factors in this research are significantly occurring and have significant impact. Thestudy has achieved a mile stone in development of health and safety framework in construction industry that will help the project managers to analyze the project risk more e_ciently at an early stage. Based upon these analysis, proper remedial measures would be possible for incorporationatplanningand strategy level to improve and manage these barriers.

Theconstructionindustryisoneoftheriskiestindustryinall overtheworld.Itisrecognizedtobeextremelyriskprone anddistinguishedasverycomplex,competitiveandspecial where uncertainties emerge from a different source [1]. According to Pinto et el. [2], occupational accidents and hazardshadaseriousimpactonhealthandsafetyaswellas economyduetohighcostsassociatedwithworkinjuries.In thebackgroundofconstructionprojects,accidentsaccount for7.9-15%ofthecostsofnon-residentialprojects.Raheem and Hinze [3] stated that small building construction industriesdonothaveasafetypolicysuchthat dangerous conditions occur at their worksites and workers are vulnerable to toxic conditions at construction sites. Construction-based OHS discernment of countries and causes for occupational accidents do not change substantially, considering the fact that certain global and habitualsignsexistinworkers.Pintoetel.[2]identifiedthat

the health and safety management is looking forward to takingintoaccountallaccidentsandhazardsthatarelikely toplaceprojectworkersatrisk.Therefore,advancedhealth andsafetyplanningseemsinevitabletoaddressthesafety concerns. Compliance with safety requires key health and safety measures which must be carried out by workers in ordertoensureaminimumlevelofsafetyattheworkplace.

According to Amin bakhsh et al. [1] modelling technique (AHP) is a methodology for forecasting health and safety measuresinconstructionprojects.Thismodellingtechnique (AHP)hasgainedmoreimportanceandattractionduetothe accurate and quick prediction that customize the falsified method of forecasting modelling techniques. Due to these forecastingmodellingtechniques,thehazardsandrisksmisassessment and time-consuming method with cheap predictivetechniquesandtoolsareeliminatedforaccurate prediction. Wu and Chau [7], stated that modelling techniquescommonlyusedduetotheirhighversatilityand broadapplicabilityandthesemodellingtechniquescanbe minimized by 17%. Most of the India's construction industriesfollowresponsivestrategiesandpoliciesinstead ofpre-emptivestrategies.AccordingtoWangandthan.[6] analysisofcasestudyofconstructionprojectswiththeassist ofmodelling technique (AHP)ensuresthat the healthand safetypoliciesarecorrectlymeasured.

To the best of author knowledge, study to investigate the assessment of safety management practices by using modellingtechniqueAnalyticHierarchyProcess

Ahmad et al. [10]; Raheem et al. [9], reported that the constructionindustriesin Indiadonotcomplywithhealth andsafetystandardsfortheirworkerswhichcontainsmany factors.ThepresentpositionofconstructionindustryinIndia isfailingtoachieveitstruepotentialduetonumberoffactors whichmakeitoneofthereasonsarethelackofhealthand safety standards. Accidents occurred because of worker's incompetency,workatheight,runningtoolsandmachinery withoutsafetygears,poorsitemanagementandinabilityto usepersonalprotectiveequipment(PPE).Theconstruction industryhires7.3%oftheoveralllaborforceofIndia[11], butitsaccidentsandinjuriesrateis17.3%whichishigher than that of other industries [12]. The majority of

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN: 2395-0072

construction industry's injuries are caused by a fall from heightaccompaniedbyliftingactivityandelectrocution[13]. Insufficientsupplyoffallsafetyequipment,lackoftraining, unrealistic construction time, and lack of availability of suitableanchorages pointsat constructionsiteshave been foundascausesoffallfromheight[14].

Unsafeactsandbehaviouralongwithunsafeconditionslead to 98% ofconstructionaccidents. Occupational health and safety(OHS)rulesandregulationareveryunsatisfactoryin India's construction industry. Even certain construction industrieshavenohealthandsafetystandardsandpolicies regulations [15]. The financial standing of an organization remains one of the grey aspects in health and safety arrangements of construction sector. Keeping in view this aspect,itisveryimportanttoexploreviablesolutionsthat wouldhelptoadoptedhealthandsafetyfactorsbythestake holderskeepinginviewtheirownfinancialconstraints.

Theobjectivesofthestudyareto:

Identifyandanalyzemajorriskfactorsforhealthand safetyinconstructionindustryofIndia

Assessthesehealthandsafetymajorconcerns.factor.

Developaframeworktodeterminetheseverityofrisk factorsforhealthandsafety.pa

Adoptmulticriteriadecisionmakingtechniqueto highlightmajorconcernsandproposeahierarchical safetymanagementmodel.

Thetheoryforthisresearchisbasedonadetailedliterature reviewwhichdescribesthehealthandsafetyproblemsinthe construction industry of the India. This study has been outlined to highlight the health and safety risk factors impacting construction projects in order to meet the objectivesoftheOSHAguidelinesrelatedtohealthandsafety atconstructionsites.Aliteraturereviewwasundertakento study the relevant areas of current research work and to identifytheriskfactorsofhealthandsafety.Bothsurveyand descriptive designs are used in this research. The survey methodology has been used to collect the information through questionnaire from site manager, construction professionals and construction workers at site. This study was conducted with descriptive research that assisted in evaluatingtheexecutionofhealthandsafetyrulesandlaws atconstructionsites.TheDelphimethodwasusedtoshort listtheimportanthealthandsafetyfactorsandtodevelopa questionnaire.Statisticalmethodhasbeenusedtoexamine theinformationobtained.Afterthedataanalysis,resultsand conclusionswerederived.

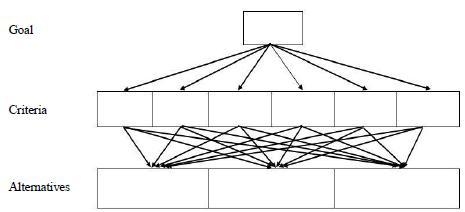

TheanalytichierarchyprocesswasfirstintroducedbySaaty (1980). AHP is anapproachfor resolving thecomplexand ambiguousissues.AHPisanimportanttoolfordealingwith complicated decision making that can help in determining and weighing criteria, assessing the data gathered and advancingthedecision-makingapproach,[1]:

ThefirststepintheAHPistoconstructthedecisionproblem hierarchy.Thereisnospecificrulethatcanbefollowedto constructahierarchy.AHPenablesthecomplexdecisionto beorganizedintoahierarchyandisstructuredtoaddressthe complicatedproblemsatmultiplehierarchylevelswithatop priorityasgoalwhereasmediumlevelsarecriteriaandthe lowestlevelasalternative[73].

139 questionnaires were distributed and out of 139 questionnaires,107questionnaireswerereceivedback.This representsthe77%responseratewhichisdeemedtobevery strongtomakeconclusionsforastudy.Ifthepopulationsize is unspecified any sample size greater than 96 can be consideredasreasonableandappropriate[116].According toAshleyandBoyd[117],50%responserateissatisfactory,

60%goodandabove70%ratedreallygood.Accordingtothis statement,the77%responseratewasverygood

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN: 2395-0072

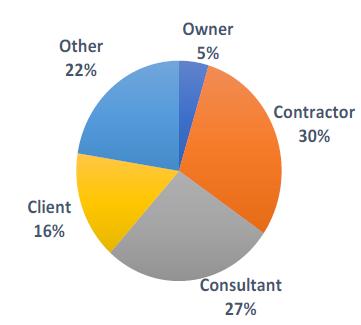

Figure 2 reveals that the respondents who filled the questionnaire,5%werefromowner,30%fromcontractors, 27%fromconsultants,16%fromclientsand22%fromother. The demographic statistics data indicates that majority of individualsareprofessionalwhofilledthequestionnaire.

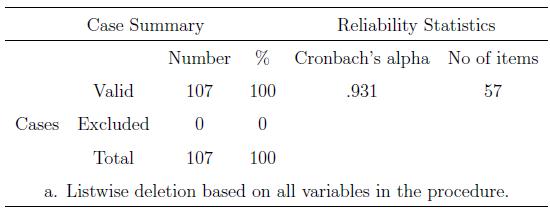

knownasCronbach'salpha test.Cronbach'salpha testisa valuable analysis used to assess the reliability or internal consistencyofanygivendatasetsStatisticsisusedtoassess thereliabilitytestofinteritemconsistency.Ahighervalue shows a strong relationship between the test items and a lowervalueshowsaweakerrelationshipbetweentestitems. Reliabilityisacceptableifthealphaiswithin.70and.99.If alphavalueisgreaterthan.70itmeansthedataisconsistent forfurtheranalysisInourcasestudy,Cronbach'salpha.931 isacquiredwhichverifytheconsistencyofdataachieved.It means according to this statement; result of reliability analysis data is reliable and further analysis can be proceeded.

Table1 Reliabilityvalue(Cronbach'salpha)ofimpact

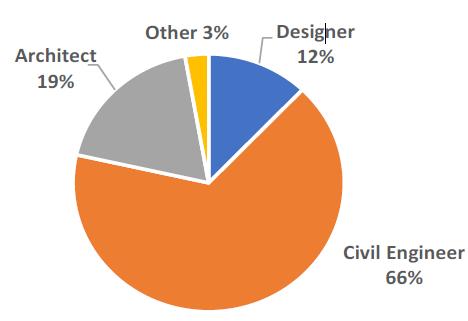

Fig 3. indicates that the major contribution was obtained fromthecivilengineers.Thedemographicresponserevealed thatmajorityofindividualsareprofessionalcivilengineers witharesponserateof66%and12%werefromdesigner, 19%fromarchitectand3%fromothers.

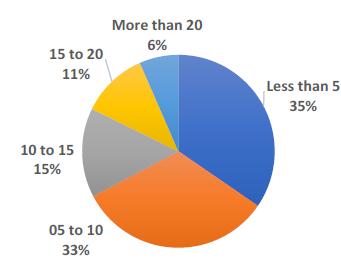

Theexperiencelevelplaysanimportantroleinenablingthe professionals.Plentyoftherespondentshadexperienceof building construction projects. Figure manifests that 35% respondentshaveanexperiencelessthan5years,33%have 05t010years,15%have10to15years,11%have15to20 years and 6% have an experience more than 20 years. respondentshaveanexperiencelessthan5years,33%have 05t010years,15%have10to15years,11%have15to20 yearsand6%

Thereliabilitytestisoneofthefundamentaltestsconducted to verify the reliability of the data. Reliability test is also

Coding is a process of defining and detecting a connection between concepts. Coding is a means of indexing or categorizing the data in order to develop a framework of thematicideas.Thisresearchcomprises5healthandsafety risksfactors.FortheeaseofriskevaluationcodingC=(C1,C2, C3,C4,C5)arereferredtoeachriskrespectivelyandallthe5 healthandsafetyrisksfactorscontain57sub-factorsandall ofthemisreferredS=(S1,S2,S3,.......,S57)respectively.

ThenormalitytestgenerallycalledasShapiro-Wilktestwas usedtoobservethedistributionpatternofthegathereddata in SPSS statistical tool to determine whether the gathered databelongstothenormallydistributedornot[97],Kimand Park.[100],haveconfirmedthatnon-parametrictestisused wheredatadoesnotobserveasnormaldistributed.Thetest rejectsthenormalityhypothesisifthep-valueissmalleror equalto0.05.Itwasobservedthatthesignificancevaluefor magnitudeofimpactof0.000wereobtained.

After normality test it was necessary to verify the level of perceptionoftherespondents.Normality'shypothesishad manifestedthatdatarelatestonon-parametricdata.Hence, theKruskalWallistestwasthenconductedtoevaluatethe level of perception of the respondents. Kruskal and Wallis [102], reported that this test investigated whether respondents have same or different perception regarding eachidentifiedfactor.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN: 2395-0072

Multi criteria decision approach is basically the analytic hierarchyprocess(AHP).TheAHPapproachfordetermining alternativesisrelativelysimplebuttechnicallyeffectivemulti criteriadecisionmakingapproach.Ithelpsdecisionmakers touseabasicformofhierarchyinordertosolveacomplex issueandtoanalyzebothquantitativedataandqualitative datainastructuredmulticriteriadecisionmakingapproach.

Thefive-pointLikertscalewasusedinquestionnairesurvey togatherdata.Itconsistsof5partsasmentionedaboveand these5partshavebeenfurtherclassifiedinto57sub-factors. Firstly, the relative importance index (RII) values of each subfactorwereassessedonebyoneandthenRIIofallthe5 factorsweredeterminedrespectivelybytakingaverageofall thesubfactorsofeachpartinordertoassesstheimpactlevel andranks.

After attaining the (RII) values of all the factors and subfactors,establishedthepair-wisecomparisonmatrixbyusing the Saaty's scale for pair-wise comparison matrix and obtainedthelocalweightofeachfactorandsub-factor.Factor withmaximumweighthashighimpactatconstructionsite thanotherfactors.

Theresultsanddiscussionhavebeendetailedinthischapter. The response rate and demographic characteristic of the respondents were summarized. Three tests for statistical data reliability test, normality test and non-parametric Kruskal Wallis test was applied in this research work to obtainandassessthereliabilitylevel,natureandperception leveloftherespondentsrespectively.Alltheidentifiedfactors werereferredwiththecodefortheeaseofunderstanding.In this chapter, health and safety problem in construction industry was structured as a hierarchy in the analytic hierarchyprocesstoassesstheweightofeachfactortosolve the major problem. Risk assessment was impossible only with quantitativeapproachbecause risk assessmentis the combinationofquantitativeandqualitativeevaluation.So,by using AHP-FCE method project risk grade level was evaluated.Thishelpedtoachievetheframeworkforapreempitiveriskmanagementstrategy.

Themainobjectiveofthisresearchworkwaslimitedtothe developmentofhealthandsafetyframeworkkeepinginview theconcernsandproblemsinconstructionindustryofIndia. Riskfactorswerefurthercategorizedtofindoutthepotential impactofhealthandsafetyproblemsinconstructionindustry ofIndia.AdetailedDelphitechniquewasappliedtoshortlist theidentifiedfactors.107filledquestionnaireswerereceived back,whichwasacceptableassupportedbyOsborn

1.Thestatisticofreliabilityanalysisimpactdatawas0.931, meansvaluesgreaterthan0.7.Thisresultjustifiedthatthe impactdatawasreliable.

2.AsperKruskal-Wallistest,accordingtotherespondent’s, poormaintenanceofequipment(0.028),inappropriatelifting ofheavyweight(0.040),pandemicandviral situation(e.g. Covid-19,inuenza,dengue,fever)(0.045),frequent

3.Baseduponthefrequencydata,RIIvaluesofallthe57subfactorsinindexlayerandtheir5mainfactorsincriterialayer werecalculatedonebyone.

4. Relative importance index values of the 5 main factors accidents and hazards (0.709), unsafe acts (0.643), unsafe conditions (0.682), management system and social groups (0.625)andnaturalfactors(0.598)werecalculated.

5.Localweightsofall57sub-factorsandtheir5factorswere calculated.Localweightofthe5factorsincriterialayerwere accidents and hazards (0.150), unsafe acts (0.191), unsafe conditions (0.168), management system and social groups (0.226)andnaturalfactors(0.274)werecalculated.contact withpeople(0.008)havenosignificantimpact.

[1]S.Aminbakhsh,M.Gunduz,andR.Sonmez, \Safetyrisk assessment using analytic hierarchy process (ahp) during planningandbudgetingofconstructionprojects,"Journalof safetyresearch,vol.46,pp.99{105,2013.

[2]A.Pinto,I.L.Nunes,andR.A.Ribeiro,\Occupationalrisk assessmentinconstructionindustry{overviewandreection," Safetyscience,vol.49,no.5,pp.616{624,2011.

[3]A.RaheemandJ.Hinze,\Understandingthesafetyculture ofconstructioncompaniesinIndiabyanalyzingsafetypolicy manuals,"inProceedingsoftheInternationalConferenceon Safety,ConstructionEngineeringandProjectManagement, Islamabad,August19,vol.21,2013.

[4] A. Darko, A. P. C. Chan, E. E. Ameyaw, E. K. Owusu, E. P• arn,andD.J.Edwards,\Reviewofapplicationofanalytic hierarchy process (ahp) in construction," International Journal of construction Management, vol. 19, no. 5, pp. 436{452,2019.

[5]E.S.BakhoumandD.C.Brown,\Ahybridapproachusing ahp{topsis{entropy methods for sustainable ranking of structural materials," International Journal of Sustainable Engineering,vol.6,no.3,pp.212{224,2013.

[6] X. Wang and H. K. Chan, \A hierarchical fuzzy topsis approachtoassessimprovementareaswhenimplementing green supply chain initiatives," International Journal of ProductionResearch,vol.51,no.10,pp.3117{3130,2013.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056 Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN: 2395-0072

[7] C. Wu and K. Chau, \Rainfall{runo_ modeling using arti_cial neural network coupled with singular spectrum analysis,"JournalofHydrology,vol.399,no.3-4,pp.394{409, 2011.

[8] H. Lingard, \Occupational health and safety in the construction industry," Construction management and economics,vol.31,no.6,pp.505{514,2013.

[9] A. A. Raheem and R. R. Issa, \Safety implementation frameworkforIndiaiconstructionindustry,"Safetyscience, vol.82,pp.301{314,2016.

[10]I.Ahmed,M.Z.Shaukat,A.Usman,M.M.Nawaz,andM.S. Nazir,\Occupationalhealthandsafetyissuesintheinformal economicsegmentofIndia:asurveyofconstructionsites," Internationaljournalofoccupationalsafetyandergonomics, vol.24,no.2,pp.240{250,2018.

[13] H. Zahoor, A. P. Chan, W. P. Utama, and R. Gao, \A research framework for investigating the relationship between safety climate and safety performance in the construction of multi-storey buildings in India," Procedia engineering,vol.118,pp.581{589,2015.

[14] R. M. Choudhry, B. Tariq, and H. F. Gabriel, \Insvestigationoffallprotectionpracticesintheconstruction industryofIndia,"AchievingSustainableConstructionHealth andSafety,2014.

[15] A. H. Memon, M. A. Soomro, N. A. Memon, and M. N. Abassi, \Factors causing health and safety hazards in constructionprojectsinIndia,"MehranUniversityResearch Journal of Engineering and Technology, vol. 36, no. 3, pp. 559{568,2017.

[16]H.Zahoor,A.P.Chan,R.Masood,R.M.Choudhry,A.A. Javed, and W. P. Utama, \Occupational safety and health performance in the Indiai construction industry: stakeholders' perspective," International Journal of ConstructionManagement,vol.16,no.3,pp.209{219,2016.

[17] Y. Khosravi, H. Asilian-Mahabadi, E. Hajizadeh, N. Hassanzadeh-Rangi,H.Bastani,andA.H.Behzadan,\Factors inuencing unsafe behaviors and accidents on construction sites:areview,"Internationaljournalofoccupationalsafety andergonomics,vol.20,no.1,pp.111{125,2014.

[18] S. A. Memon, M. Zain, D. Zhang, S. K. U. Rehman, M. Usman, and D. Lee\Emerging trends in the growth of structural systems for tall buildings, Journal of Structural IntegrityandMaintenance,vol.5,no.3,pp.155{170,2020.

[19] H. Zahoor, A. P. Chan, R. Gao, and W. P. Utama, \The factorscontributingtoconstructionaccidentsinpakistan," Engineering,constructionandarchitecturalmanagement,vol. 24(3),463-485,2017.

[20]J.-M.Kim,K.Son,S.-G.Yum,andS.Ahn,\Analyzingthe riskofsafetyaccidents:Therelativerisksofmigrantworkers in construction industry," Sustainability, vol. 12, no. 13, p. 5430,2020.

[21] Y. Le, M. Shan, A. P. Chan, and Y. Hu, \Overview of corruptionresearchinconstruction,"Journalofmanagement inengineering,vol.30,no.4,p.02514001,2014.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page696