International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

MINI STEAM GENERATOR

1 Dr. Jonny Carmona Reyes, 2 Cruz Norberto González Morales, 3 Luis Ángel Juárez Cerón,

1,2,3, Universidad Tecnológica de Tlaxcala, El Carmen Xalpatlahuaya, Huamantla, Tlaxcala, México, 90500 ***

Abstract - This document presents the invasion of a mini steam generator that will be programmed by means of pressure, temperature and water level sensors. The mini generator will be portable, thus innovating the sizesince most boilers or industrial steam generators are large, and heavy. It has a digital controller that will controlthesensorsandwillbe shown in a digital screen. It is required an appropriatelevelof water so that the boiler continuously generates steam. The temperature that the water must contain when filling the boiler and the generator will reduce accidents due to poor control of temperature, level and pressure

Key Words: Temperature, pressure, programming, generator, sensors.

1. INTRODUCTION

Preventivemaintenanceistheactofperformingregularly scheduledmaintenanceactivitiestohelppreventunexpected failuresinthefuture.Inotherwords,it'saboutfixingthings beforetheybreak.Thebenefitsthatmaintenancegivesusis the increase in the life of the assets, reduce maintenance, boost activity, reduce downtime in addition to reducing failures,preventingcatastrophesandsavingeconomy.Inthe industry, the figure for a steam generator to explode is 35949.0%duetopoormaintenanceandsupervisionofthe level.(Machines,2019).

Theproblemthatregularlyarisesinsteamgeneratorsisthe poor supervision of water level and its installation, this causesexplosionsandthereforehumanandmateriallosses. For this reason, it is proposed the implementation of temperature sensors, water level sensors, and pressure sensorsbesidesthis,theywillbeprogramedwithArduinoin order to reduce the number of accidents due to poor supervisionofsteamgenerator

Thesteamgeneratoritselfisaclosedvesselthatgenerates water vapor at pressures higher than atmospheric. The temperature of the liquid increases until it reaches the vaporizationtemperatureand remainsconstant whilethe liquid becomes vapor, once the boiling temperature is reached,theoperatingpressurecontinuestheheatsupply andvaporizationbeginswithouttemperaturevariation.The steamgeneratorismadewithastainlesssteeltubularwitha heightof50cm,adiameterof33cm,anelectricalresistance forheating,aswellasalayeroffiberglassforprotection,a sheetcap,withtemperatureandpressuremeters.

2. METHODOLOGY

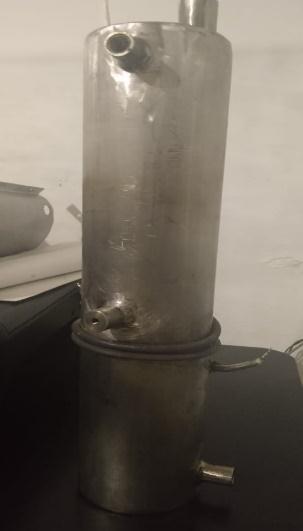

For the development of this project, a container was first manufactured with a 316 stainless steel schedule 20 tube with a length of 500mm and a diameter of 101.6mm. Therefore,thecontainerhas2lidsonbothsideswithaplate ofthesamematerialwithathicknessof3mm,forthat316 weldingof1/8indiameterwasapplied,whichalsoallows thecorrectfusionofthematerials,Figure1.

Fig- 1 Container

33/8connectionswereadopted,and2wereplacedinthe lowerpartofthecontainerforthewatersupplyandtoplace the temperature sensors, likewise, 1 was installed in the upperpartfortheadaptationofthepressuresensor.

Therefore,2thermowellswereplacedfortheadaptationof typeKthermocouplesintwodifferentareasofthecontainer to detect the temperature of the liquid, 2 stainless steel nipples 1, ¼” were also placed where they will be set the waterlevelsensorstocontrolthelevelfromtheinside.Inany case,allthesevariableswillbecontrolledsemi-automatically bytheATMEGA328Pmicrocontroller,Figure2.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

6.6mmandalengthof255mmwasinstalledwitha120VAC powersupplyfor180°C(350°F),Figure4.

Fig- 2 Placementofthermowells.

Likewise,forthesteamoutlet,anoutletwasadaptedatthe topofthecontainer.Inthesameway,itwillbecontrolledby ametalballvalvethatallowsmanualcontrolofthesteam outlet However, it also has a check valve brass relief that opensat1.23MPaforsafetyincasetheinternalpressureof thecontainerisexceeded,Figure3.

Fig-4

Placementofresistance

.

Itshouldbeconsideredthatitisveryimportanttomeasure thetemperatureofthesteamgenerator,whichiswhy2type KthermocoupleswereusedwiththeirrespectiveMAX6675 transmittertomaketemperaturemeasurementsinawide rangefrom0°to1024°Csothattheirsupplyisfrom3.3-5V, itsworkingcurrentis50mA,thetemperaturerangeisfrom200°Cto1024°Canditstemperatureresolutionis0.25°C; therefore,the2thermocoupleswillbeprogrammedwiththe ATMEGA328Pmicrocontroller,Figure5and6.

Fig- 3 Placementofreliefvalve.

Later testswerecarriedouttoverifyleaksinsidethesteam generatorsincetherearepartsthatwere welded.Forthis reason,itwasdecidedtotestthecontainerinweldingjoints, soitwassubjectedtocompressedairtestsinadditiontoa water test was carried out to rule out leaks between the weldedpieces,insuchawaythattheresultwasnegativeand noleakwasfound,laterallthesensorswereplacedintheir respectiveplacestocarryoutsaidteststoverifythatitdid not exist any leak once the sensors are placed in their respectiveplace.

Inthisway,togenerateheatinthecontainer,a65W/inlowdensitycartridge-typetubularresistancewithadiameterof

Fig- 5 Rod-typethermometer

Fig- 6 TypeKthermocoupleandMAX6675module.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

To measure the pressure, an analog sensor HK3022 was used, which works at a range of 0 to 0.5MPa for constant pressure systems such as water, air, and oil. The sensor outputhasananalogvoltagethatvarieslinearlyfrom0.5V equivalentto0MPaand4.0Vequivalentto0.8MPa,forthis reason, its analog outputs are compatible with the analog inputs(ADC)oftheATMEGA328Pmicrocontroller,Figure7.

Fig- 9 12Vwaterpump.

Fig- 10 Hose

Figure 7 Analogpressuresensor.

Inthisway,tomeasurethewaterlevelfrominsidethesteam generator,2stainlesssteelanglelevelsensorswereusedfor thefillingandemptyingoperation, isbasedonamagnetic ReedSwitchtypeswitchthatishermeticallysealedinside the stem of our sensor and activated by moving the foam floatthatcontainsapermanentmagnetsoitsvoltagerange is0–250V,Max.0.5-120VAC,Opencircuitresistance100 MO,Closed-circuitresistance0.4O,Power10W,Operating temperature -30° ~ 125° C, Thread diameter 28 mm, Nut diameter1/8´NPT,Figure8.

Onceallthesensorswereplacedintheirrespectiveplaces, testswerecarriedoutwiththetemperaturesensorssothat the steam generator was filled with water, later the resistancewasconnectedtoheatthewaterandbeableto carry out the temperature tests and verify from ATMEGA 328P,sotheresultwaspositivesincethe2thermocouples markedtheirtemperature,Figure11.

Fig- 8 Switch-type

waterlevelsensor.

Forfillingthesteamgeneratorwithwater,a12VDCMini electric water pump was used, with a power of 6W, operatingcurrent0.5-0.7A,Traffic:1300mL/min100ml,Lift 1.5m, life up to 2500H, water temperature is 5-40, outlet diameter:6.72mm,size98x35mm,so6metersof6.72mm transparenthosewasusedtofillthesteamgenerator,Figure 9and10.

Fig- 11 Test

In the same way, pressure tests were carried out, which weredonewithhotwater,allowingittoreachatemperature of90°Ctogeneratesteampressure,sothepressuresensor marked the data in ATMEGA 328P so that a second test wherethesteamgeneratorwasemptiedandcompressedair wasputinsidethecontainersothatthe2formsthesensor markeditspressure.

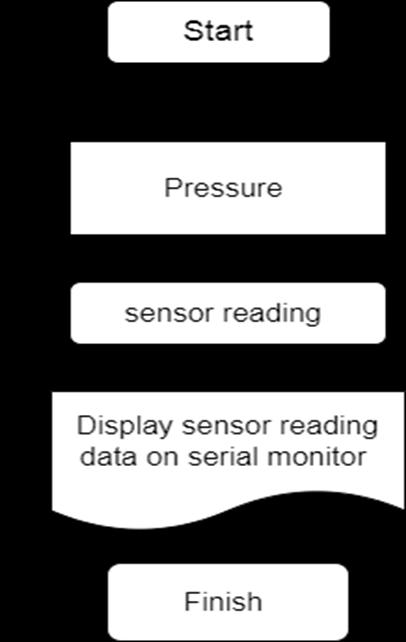

To better understand the operation of the process, the followingflowchartofthepressuresensorisshown(Figure 12) in which the functionality of the pressure sensor is represented,saidsensorwillcollectthedataofthepressure that is inside the generator, a once the sensor checks the

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

measurement, the data will be sent to the ATMEGA 328P serial monitor where the data will be displayed. Said measurements will be repeated during the time that the steamgeneratorisinoperation.

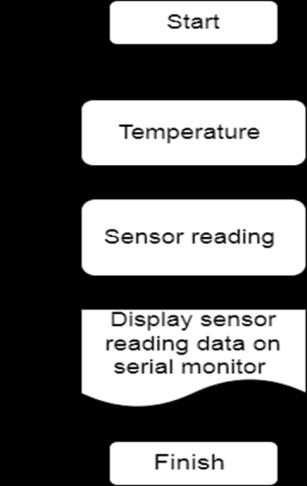

So that theslackdiagramofthetemperaturesensorwillbe explained(Figure14),whichrepresentstheoperationofthe thermocouple. Its purpose is to keep the temperature in ATMEGA328Pmonitoredsothatitwillavoidanyaccidents andwillallowitnottoexceedthetemperatureatwhichit shouldbemaintained.

Fig- 12 Diagramoftheoperationofthepressuresensor.

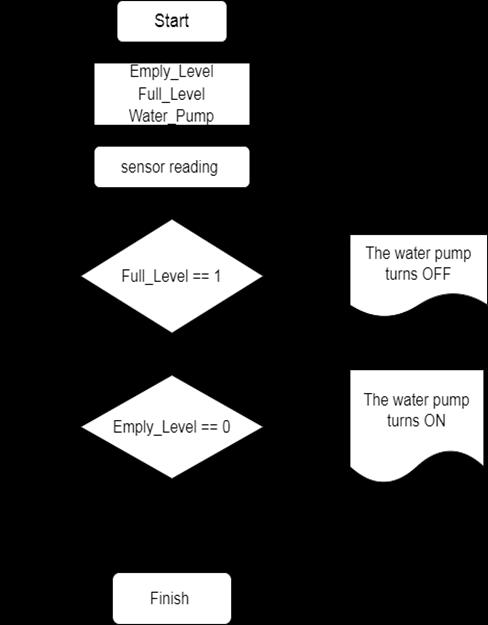

Thefollowingdiagramoftheoperationofthelevelsensor willbeexplained(Figure13),itsmainfunctionistoactivate and deactivate the pump that supplies water to the generator.Theaforementionedsensorhasasimilarfunction toaswitch,therefore,whenthecontainerisatitsmaximum waterlevel,thesensorwillmaintainthefunctionofanNC switch, consequently, due to the production of steam, the water level will decrease. and the sensor will take the functionofaNAswitch.

Figure14Temperaturesensorflowchart

3. CONCLUSIONS

Basedonthisresearch,theefficiencyofthesteamgenerator dependsonitsdesign.Thesensorsandthewaterpumpthat feeds the generator were correctly installed. Through ATMEGA328P they will have pressure, temperature and levelreadings.

Filling tests were performed on the generator and it was observed that the level switches correctly deactivate the generatorfeedpump.

With the help of a display of the ATMEGA328P microcontroller,thereadingsaredisplayedthatallowusto keepabreastoftheinternaltemperatureofthecontainer, so that thewaterthatenterstheboilerthroughthepumpwill have a temperature of 40 ° C by means of the feed water preheating system, to have a constant evaporation. It is worthmentioningthatthesafetyvalveneveropeneddueto some excess internal pressure. Thus, verifying that the pressureandtemperatureindicatorsimplementedfulfilled theirfunction Somepossiblecausesoffailurewouldbethat ifyoudonothavewaterataminimumtemperatureof40°C, a thermal shock can be caused, and the resistance would havealowerqualityoflife.Ifthesteamgeneratorreachesan overpressure,itcangenerateanexplosion,andifthepump fails, it would run out of liquid and the generator would explode.

Itisimportanttolookforanidealtypeofwaterthatdoes notaffectordamagethecontainerbecausewhenthewater getsveryhot,itcangeneratescalethatstickstothewater

Fig- 13 Levelsensorflowchart

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

level sensors. Finally, the generator must contain a foil coatingforgreaterpersonalsafety.

REFERENCES

E. J. Alzate Rodríguez, J. W. Montes Ocampo, y C. A. Silva Ortega, «Medición de temperatura: sensores termoeléctricos»,Sci.tech,vol.1,n.º34,may2007.

Sepúlveda, D. L., & Ramírez, J. (2011). Condiciones de seguridadencalderasdevapordeempresasafiliadasauna administradoraderiesgosprofesionalesenAntioquia,2009. RevistaFacultadNacionaldeSaludPública,29(2),145-152.

Gonzalez,M.A.(1999).Análisisderiesgosdeltratamiento delaguaparacalderas.PlazayValdes.

Varetto,R.H.(2012).Conduccióndegeneradoresdevapor. TECNIBOOKEDICIONES.

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page55