International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

1 Department of Mechanical Engineering of ENSET, Systems Technology Research Laboratory, 210 Avenue des Grandes Écoles, 3989 Libreville, Gabon ***

Abstract - Currently, the machining of recycled aluminum alloys is developing. It is therefore time to have the necessary resources to master the machinability of these alloys. When machining any alloy, knowledge of certain characteristics to guarantee the quality of mechanical parts is very important. To continue the research on the machining of these alloys, we focused this study on the dry drilling machinability ofrecycled aluminum alloys. The focus is on two types of aluminum alloys from beverage cans. For the machinability of these alloys, three characteristics are taken into account, namely, the cutting force, the morphology of the chips and the concentration of metal particles that can be influenced by the feed and cutting speed. In this study, the results that show the link between machinability characteristics and cutting parameters are presented. Models have also been established for the evaluation of machinability.

Key Words : machinability,drydrilling,cuttingforce,chip morphology,metalparticles

Therecyclingofaluminumalloyshasseenagrowth ininterestandapplicationsoverthepastfortyyearsandhas becomeanothereffectivewaytoproducealuminumparts. Among many recycled aluminum products, there are beveragecans.Thesebeveragecansareusuallyrecycledto produce other cans or other objects. Everything that is producedonthebasisofrecycledcansremainsuntilnowon themarginsoftheproductionofmechanicalpartsthatcan beobtainedbymachining.Someindustrialsectorsalready userecycledaluminumparts(shapedbydeformation),not frombeveragecans.Whilethereareotherpartsthatneedto be shaped by material removal, such as drilling. To use recycled aluminum, it is necessary that a study be carried out. This study must globalize recycling methods and treatment. With theaimofimproving aluminumrecycling techniques,A.RKhoeiaandal[1]developedarobustdesign method, which consisted of experimentally analyzing the effectsofprocessparameters.Theysuggestedthattohavea goodrecoveryofthematerial,itisnecessarythatthehigh level ofthetemperatureofthefurnaceiscontrolled. They alsoobservedthatfurnacetemperatureandloadedquantity haveamajorinfluenceonthetotalvariationinrecovery. M. Samuel[2],presentedanewdirecttechniqueforrecycling

aluminum waste with low energy consumption and costs withoutinvolvingmetallurgicalprocesses.Theexperimental resultsobtainedshowthatthedirecttechniqueforrecycled aluminum allows high productivity and about 80% green density before sintering. From existing processes, Eulogio Velasc and Jose Nino [3] in their work, showed the need, during the transformation of the alloy, to control, remove impuritiesandinclusionshydrogenandexcessmagnesium.

All machining always generates cutting forces, whicharetheresultoftheshearandfrictionforcesexerted by the tool on the part. Knowledge of cutting forces is necessaryforthecontrolofthepowerrequiredforcutting, the mechanical efficiency of the machine tool, the dimensioningofmachinecomponents,thepredictionofthe deformation of parts. Cutting forces are involved in machiningprecision,intheformationofthesurfacefinish,in the process of chip formation. Finally, the cutting forces beingrelatedtothemechanicalpropertiesofthematerial, arelikelytoprovideinformationonthemachinabilityofthe machinedmaterial.Severalparametersinfluencethecutting forces during machining, including: feed per revolution, cutting speed, cutting depth, geometry and coating of the tool.

Manyexperimentaltechniqueshavebeenexploited to examine the cutting force. Thus, we note the implementationofcertainanalyticalmodels,suchasthatof Merchant[4]and[5]. Itisamodelinwhichthreephysical phenomena are considered. The first concerns the law of conduct. It uses a Bridgman [6] model from 1952, which does not take into account temperature and strain speed. The second, considers a constant friction at the interface between the tool and the chip. The third concerns the formation of the chip along the shear plane. Taking into account the importance of parameters and cutting conditions,inthephenomenonofcuttingforces,M.C.Shaw [7]showedthattheverylowcuttingspeed,oftheorderofa fewhundredm/minorless,hasnoinfluenceonthecutting forces.ThisisconfirmedbyE.Morinandal[8],specifying thatthenodalforce(Fn)andthemoment(M)areafunction oftheadvanceperturn.Duringdrillingofaluminumalloy,E. J.AArmarego[9]hadproposedamethodforthestudyofthe nodal force with the consideration of the geometry of the drill.AccordingtoJ.Masounaveandal[10]drymachining

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

causesanincreaseintemperatureinthecuttingarea,and caninfluencethenodalforce.Similarly,Moufki andal[11] hypothesized that constant friction increases the temperature and proposed taking into account the temperature at the interface to vary the coefficient of friction. Zemzemiandal[12]showedthatthecoefficientof frictiondecreasesstronglywiththespeedof slidingofthe chiponthecuttingface.

Theformationofthechipisalsoacharacteristicfor theevaluationofmachinability,becausethephenomenonof chipformationinvolvesalargenumberofparameters,such asthedifferentmachiningparameters,thenatureofthetoolmaterialcontactandtherheologyofthemachinedmaterial. AccordingtoG.CarroCaoandal[13]theunderstandingof the various phenomena during machining needs to be observed, for example, by microcinematography, as was donebyG.Warneckeandal[14].Theformationofthechip dependsonitsmorphology,anditisalsoveryimportantfor the evaluation of machinability, the mastery of which remainsachallengeduringmachiningforeconomicreasons relatedtochipmanagement.Thesechipsareclassifiedinto three categories by G. List [15], continuouschips, chips withedgesanddiscontinuous,segmentedorscallopedchips. Thegenerationofsurfacesbymachiningsystematicallyleads totheproductionofchipsthathaveshapesaccordingtothe cutting parameters. From a macrographic point of view, according to ISO DIS 3685, the shape of chips varies and depends on machining conditions and tool/material pair. KrishnamandIrusa[16]studied6063-T6aluminumchips obtained under dry cutting conditions, with abundant lubrication and MQL. Depending on the cutting speed J. Kouamandal[17] studiedaluminumchipsA319T0andT6, A356-T0.

In general, machining generates very high temperatures, sometimes forcing the use of R. Khettabi lubricants[18].Exceptthattheuseoflubricantsincreases machiningcostsandpresentsdifficultiesforchiprecycling. Toavoidthesedifficulties,drymachiningisthereforeused. Butdrymachiningproducesmetalparticlesofmicronand nanometricsizesthatoxidizeinairandremainsuspended for a long time depending on the concentrations. The presence of these metal particles in the air endangers the healthofmachinists.B. Levresqueandal[19]specifiedthat the machinist spends on average 90% of his time in his workplace,whichcontainsmanysubstanceslikelytoharm his health confirmed by W. G. Kreylingandal [20], and theirconcentrationisvariableinspaceaccordingtoX.Yang andal[21],C.Ostiguyandal[22].B.Baloutandal[23]have shown that the amount of fine particles produced is influenced by the material and the heat treatment it has undergone,thetemperatureandtheformationofthechip.V. Songmeneandal[24]showedthatthedepthofcuthasan influence on the particulate emissions in drilling of alloy 6061 – T6 and A356. The production of these particles is veryimportantatthebeginningofmachininganddecreases

whenthedepthsarealittlegreater.Theyalsoshowedthat particulate emissions during the cutting process are a functionofthematerial.Ductilematerialsgeneratemorefine and ultrafine particles than brittle materials, as there is a correlation between chip formation and particulate emissions.

Thisstudywasthereforecarriedout,withtheaimof providinga partialsolution,relatedtotheproblemonthe machinabilityofthevariousrecycledaluminumalloys.Two recycled aluminum alloys named 3003-R and 5052-R, respectivelyfromthebodiesandlidsofbeveragecans,were usedtodefinetheirmachinabilityindrydrilling.Thisstudy gave a certain amount of information on the dry drilling machinabilityofthesetworecycledaluminumalloys.This information will allow a safe realization of parts made of theserecycledalloysinthesamewayasothermaterials.The studythereforeconsistedinstudyingtheinfluenceofcutting parameters(feedandcuttingspeed)oncuttingforces,chip morphologyandmassconcentrationofmetalparticles.For this, relationships were established between cutting force and cutting parameters as a function of feed and cutting speed, cutting force and chip morphology as a function of feed per revolution, metal particles, chip morphology and feed.

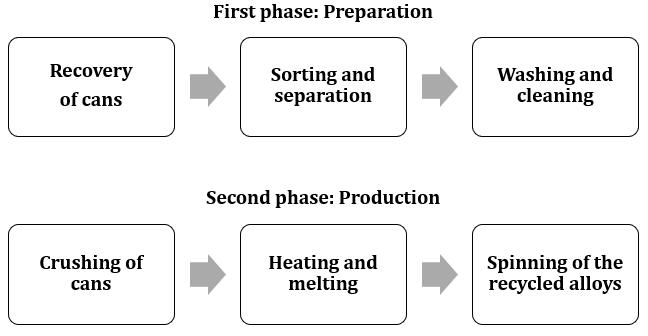

Figure1showstheprocessofobtainingtherecycled aluminum bars that were used to perform the tests. The process consists of two phases. The first phase is that of preparation (recovery of cans, sorting and separation, washing and cleaning). The second phase is production (grinding,heatingandmelting,andspinning). Thepointon separation consisted in separating the body of the can (aluminum + Manganese) from its lid (aluminum + Magnesium). Each was fed into the mill to obtain crushed material (Figure 1). The crushed metal is poured into a devicetoperformspinning.Onthedevicearemountedfour heating rings (200 ° C, 450 ° C, 550 ° C and 650 ° C). The groundmetal,heatedsuccessivelyuntilmelting,ispushed automaticallyandslowlybyapistonataconstantspeed.The barobtainedfromthebodyiscalled"alloy3003-R",andthe lid"alloy5052-R".

Fig-1:Processforobtainingrecycledaluminumbars

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

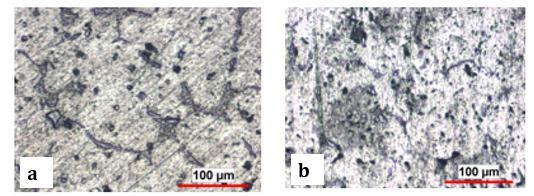

Figure 2 shows the microstructure of each alloy, observedwiththeScanningElectronMicroscope(SEM)in figure3. Thenon-homogeneousdistributionofprecipitates inthetwoalloysisobserved.Similarly,theobservationof the presence of pores of different dimensions and shapes and,ofnon-homogeneouslocalizationismade.Thisporosity remainspermissiblebecauseitisspecifictoN.Royfoundry alloys[25]

of30m/min,apowerof40kw,atorqueof50Nm,anaxis acceleration of 6m/s2 and a resolution of 1μm. The operationcarriedoutwasadrillingofdiameter8mmand depth 12 mm, with a HSS BLACK OXIDE fort with conventional gouges,tipangleof118°,propellerangleof 35°andcorediameterof2mm.

Fig-2: Microstructureofrecycledalloys:a)Alloy3003-R, b)Alloy5052-R

The same microscope was used for observation, analysis and segmentation of chips, and also to define the chemicalcompositionofeachalloy(Table1).

Table-1 : Chemicalcompositionofeachalloy(%)

alloys Al Cr Si Fe Cu Mn Mg Zn 3003-R 97 - 0.3 0.2 0.25 1.5 0.5 0.25 5052-R 94.85 0.1 0.3 0.4 0.1 0.3 3.8 0.15

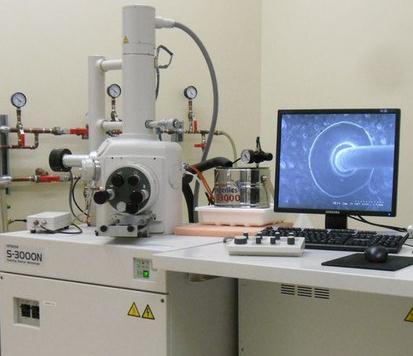

Fig-4 : CNCmillingmachineHuronK2x10

Several input parameters are used to study the cuttingforce,themassconcentrationofmetalparticlesand themorphologyofchipsasamachinabilitycriterion.Inthis study,twoparameterswereconsideredadvanceandcutting speedtostudycuttingforce.Theadvanceisconsideredfor the morphology of chips and the mass concentration of metalparticles.

Theresponsesurfacetypeexperimentaldesignwas used to investigate the influence of these parameters on cuttingforce.TableIIshowstheexperimentmatrix.

Table-2 : Experiencematrix f (mm/rev) Vc (m/min) Haut 0.03 100 Centre 0.115 155 Bas 0.2 210

The round bars obtained from the production process set up, were premachined to obtain prisms that servedassamplesformachinabilitytests.

ThedrillingoperationswereperformedonaHuron K2x10Graffenstaden3-axisCNCmillingmachine(Figure4), havingarotationfrequencyof28000rpmandacuttingfeed

Initially,themultifactorialmethodmadeitpossible toorganizeandexecutetheexperimentsinanoptimalway inordertoobtaintheinputparametersmostinfluencingthe cuttingforce.Theseexperimentaldesignsprovidedgraphsof directactionsandANOVAfordeterminingtheinfluenceof eachparameter.

In a second step, and in view of the results of the analysis from direct action graphs and ANOVA, the unifactorial method was used. This method consisted in definingtheeffectsoftheparametermostinfluencingon,the

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

cutting force, the morphology of the chips and the mass concentrationofthemetalparticles.

Thecuttingforcesweremeasured,thedataobtained was converted to be read by the Matlab software. This acquisitionwasmadeforbothrecycledalloys,andforeach machinability test, according to the experimental design fromtheanalysisofalltheimagesobtained,onlythecutting force Fz was retained. The other cutting forces Fx and Fy beingveryweak,werenottakenintoaccount.

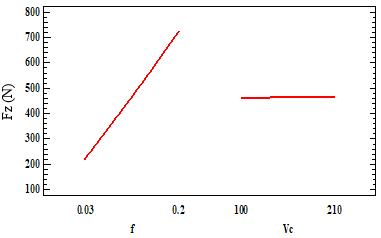

Withregardtothedirecteffects,foralloy3003-R,of chart1,oneobservesthedifferencebetweentheeffectsof the advance with respect to the cutting forces, and the cuttingspeedwithrespecttothecuttingforce. Theeffectof advance on cutting force for both alloys is remarkable. Indeed,thecuttingforceishighwhentheadvanceperturn increases.Thisisnotthecaseforthecuttingspeed,whose effectisalmostineffective.

Whatisobservedforalloy3003-Risthesamefor alloy5052-R.

Source DDL Sum of squares Average quadratic Rapport F Proba

ANOVA Fz 3003-R R2= 99.99%

f 1 366449 366449 445681.59 0.0000

Vc 1 3.84 3.84 4.67 0.074 f-f 1 8482.56 8482.56 10316.63 0.0000

ANOVA Fz 5052-R R2= 99.99% f 1 473923 473923 566733.92 0.0000 Vc 1 3.87207 3.87207 4.63 0.0749 f-f 1 21769.5 21769.5 26032.76 0.0000

The machinability tests made it possible to understand,forthecuttingforceFzofrecycledalloys3003-R and5052-R,thattheadvancehasasignificant,positiveand highereffect.Theeffectofadvanceisfollowedbythatofthe interaction advance - advance. Cutting speed and other interactionsoncuttingforceFzhavenosignificanteffects. The results of this analysis led to the conclusion that the cutting force is influenced by the advance. By keeping the cuttingspeedfixedat100m/min,theresultsshowedthat thecuttingforcealsodependsonthenatureofthealloy.To express the cutting force, Armarego and al [9] used the parametersoftherelation(1),andJ.Masounaveetal[10] thoseoftherelation(2).

Chart-1: Graphofdirecteffectsofalloy3003-R

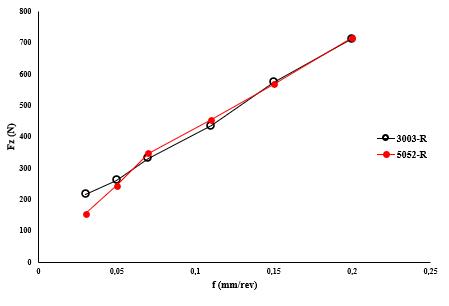

The analysis of the results, made it possible to observeforthetworecycledalloys,thatthecuttingforceFz increaseswhenthefeedchangesfrom0.03to0.2mm/rev. The cutting speed of 100 to 210 m/min shows almost no change. The ANOVA analysis in Table 3 showed that the cuttingforceFzcanbeevaluatedasafunctionofadvancefor recycled alloys 3003-R and 5052-R, and as a function of advance. Statistics R 2 explain 99.99 % variability in the cuttingforceFzofthetworecycledalloys3003-Rand5052R.Thereisthereforeaverystrongrelationshipbetweenthe advanceandthecuttingforceofrecycledalloys.

With:Fn(nodalforce),A(constant),f(feed),α,β,γ,n,m,k,l (influence coefficients), D (drill diameter), 2w (Drill core length),2P(drilltipangle),(δoPropellerangle),ψ(Central edgeangle),T(Macroscopicparttemperature),Tsu(Solidus temperatureinmaterialmachining).

In this study, some parameters considered by Armaregoandal[9]andJ.Masounaveandal[10](β,γ,n,m, k,l,D,2w,2P,δo,ψ,T,Tsu),werenotconsidered.Onlythe coefficientα,whichisacoefficientofinfluencerelativeto thenatureofthematerial.LikeMandatsyMoungomoandal [27,28],thecuttingforceFzwasexpressedas:

Keepingthecuttingspeedconstantat100m/min, further tests were performed on the same samples. The values of the cutting force measured (Table 4), made it

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

possibletoobservetheevolutionofthecuttingforcesFzasa functionoftheadvance. Theresultsobtainedareinlinewith thoseofMr.CShaw[7],bythefactthatthecuttingspeeds usedarelow.Acomparisonbetweenthecuttingforcesofthe twoalloys wasmade. Atoneadvance perturn off =0.03 mm/rev,thereisaslightdifferenceincuttingforce.Thedata obtainedareshowninTable4.

Table 4 : ThecuttingforcedataobtainedatVc=100m/min

Force de coupe Fz (N)

f 3003-R 5052-R 0.03 218.2 154.8 0.05 262.6 245 0.07 331.9 348 0.11 436.6 456 0.15 575.9 568.5 0.2 714 718

Chart2showstheevolutionofthecuttingforcesFzforthe machiningofthetworecycledalloys.

0.79 (5052) 2626.5* R Fzf (5)

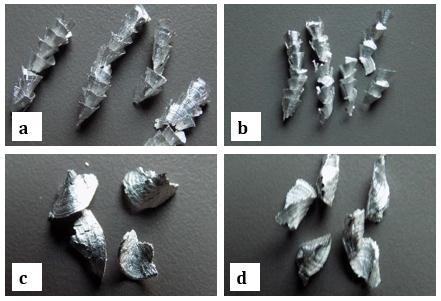

Thisanalysisconsistedinobservingthemorphology of the chips, produced during the dry drilling of recycled alloys 3003-R, 5052-R. The input parameter taken into accountisthefeed(rangingfrom0.03to0.2mm/rev)and theconstantcuttingspeedat100m/min.Theoutputdata arethechipstakenandobserved.Figure5showsanextract of the chips obtained during the drilling of these recycled alloys.Theresultsshowthatthemorphologyofthechipsis almostidenticalforbothrecycledalloys(Figure5aforalloy 3003-Rand5bforalloy5052-R).From0.03to0.07mm/rev, thechipsareshortandcomparabletoastackofcylindersof different diameters. Beyond 0.07 mm/rev, up to 0.2 mm/rev,thechipsarefragmented(Figure5cforalloy3003Rand5dforalloy5052-R).Theresultsshowadifferencein theevolutionofchipmorphologyasafunctionofadvance. Overall,thechipsofalloys3003-Rand5052-Rarelongand helical when the feeds are very low. As the advances increase,allthechipsbecomefragile.

Chart-2: Evolutionofthecuttingforceofalloy3003-Rand 5052-RasafunctionoftheadvanceatVc=100m/min.

The results of the analysis of this evolution have showntheexistenceofstrongandsignificantrelationships betweencuttingforceandadvance.Models4and5forthe evaluationofthecuttingforceFzhavebeendeducted.Bythe value of the coefficient α, and the constant A, it is clearly observedthatthenatureofthealloyalsohasaninfluenceon thecuttingforce.

0.639 (3003) 1893.3* R Fzf (4)

Fig-5: Morphologyofalloychips:a,b)Chipsofalloys3003-R and 5052-R, f = 0.03 to 0.2 mm/rev; c, d) Chips of alloys 3003-Rand5052-R,f=0. 7to0.2mm/rev

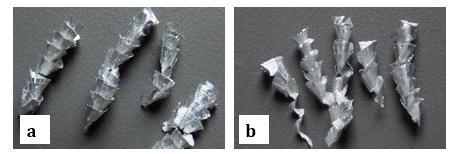

When comparing these chips with those of alloy A356-T0,whichwasmachinedunderthesameconditions andwiththesameparameters,nodifferenceinmorphology wasfound(Figure6).Theseresultsconfirmonceagainthat foundry alloys are generally brittle, and this brittleness promoteschipfragmentation.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

Table 5

concentrationdataofmetalparticlesobtained atVc=100m/min

Mass concentration of metal particles (mg/m3)

f 3000 R 5000 R

Fig-6: Alloy chip morphology, f=0.03 mm/rev (a) Alloy 3003-Rchips;(b)ChipsofalloyA356-T0

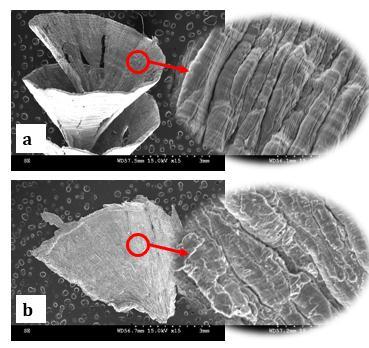

At a constant cutting rate of 100 m/min, chip segmentation was made and observed under a scanning electron microscope. Figure 8 shows an extract of the segmentation of the alloy chips, for the advance 0.03 mm/rev(Figure7a),fortheadvance0.2(Figure7b). The morphologyofchipsanditssegmentationdependsonthe properties of the alloys, but also on the parameters and cuttingconditions.Therefore,foragivenalloy,achangein thesedatacanmodifythemorphologyandsegmentationof thechips,Xieandal[26].Inthisfigure,theimageontheleft showsthechipsampledandmagnified15times.Theimage on the right, a selected part of the chip, shows the segmentationofthechip,magnifiedto500times.

0,03 57900 59500 0,05 51240 52916 0,07 45111 43111 0,11 24800 22400 0,15 20750 21250 0,2 19000 18000

Thestudyofmetalparticleshasshownthatforany alloymachined,theconcentrationofparticlesishigheratthe beginningofmachining,andlowattheendofmachining,as indicated by V. Songmene and al [24]. The analysis of the datamadeitpossibletoestablish,foreachalloy,correlations between:

Fig-7: Segmentationofalloychips:a)atf=0.03mm/rev; b)Af=0.2mm/rev

Theanalysisshowsthatwhenthefeedsarelow,f= 0.03 mm/rev for example, the segmentation of chips is almost the same for recycled alloys 300 3-R and 5052-R. Althoughthemorphologyofthechipsisalmostidentical,a difference was observed between the segmentation of recycledalloys3003-R,5052-R.

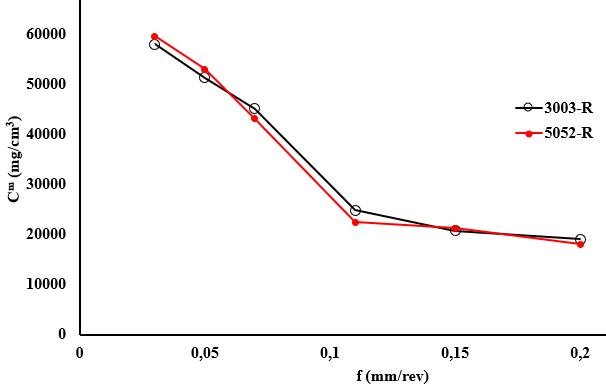

Machiningbyvaryingthefeed(0.03to0.2mm/rev) was done, at a constant cutting speed (100 m/min), to measurethemassconcentrationofmetalparticles(Table5).

Theemissionofmetalparticlesandthemorphology ofchips.

Theemissionofmetalparticlesandtheadvance.

The emission of metal particles and the cutting force.

Theanalysisshowsthatwhenthechipsarelongand helical, the mass concentration of metal particles is high. When chips are short and fragmented, the mass concentration of metal particles is low. The change in segmentationbetweenrecycledalloysshowsitsrelationship withthemassconcentrationofmetalparticles.Ananalysis wasmadetoshowtheexistenceofarelationshipbetween the mass concentration of the metal particles and the morphologyofthechips.Becauseofthefrictionofthechips onthecuttingtool,whichcauseswear,theirmorphologycan beinfluenced.Nowearofthecuttingtoolwasfound

Chart 3 shows the evolution of the mass concentrationofmetalparticles.Metalparticlesarehigher when advances are smaller. These results also show the existenceofarelationshipbetweenthemassconcentration ofmetalparticlesandtheadvance.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

the influence of the feed, the cutting speed on the machinabilityofeachrecycledalloy.

The cutting speed has no influence on the cutting forceforallrecycledalloys.Theadvancehasaninfluenceon thecuttingforce.Ataconstantcuttingspeedof100m/min, thecuttingforceincreaseswiththeincreaseinthefeed.

Thechipsofrecycledalloys,obtainedaccordingto the advance, at a cutting speed of 100 m/min, have similarities.Theyarelongandhelicalwithlowfeeds(less than0.1mm/rpm),shortandfragmentedwithstrongfeeds (greater than 0.1 mm/rpm). Like virgin aluminum alloys, recycled alloys 300 3-R and 5052-R exhibit good machinabilityperformanceindrydrilling.

Chart-3: Evolutionofsmetalparticlesofalloy3003-Rand 5052-RasafunctionoftheadvanceatVc=100m/min

Formulas6and 7 represent experimental models thatfollowalogarithmicformwithanR2statisticof0.94. These formulae could be used to evaluate the mass concentrationofmetalparticles,dependingontheadvance inmachiningrecycledalloys3003-Rand5052-R.

(3003) 23265ln()21213 m R Cf (6) (5052) 24605ln()24804 m R Cf (7)

The analysis of the curves of figures 7, 8 and 9, showedtheexistenceofalinkbetweenthemorphologyof thechipsandtheconcentrationofmetalparticles.Duringthe analysisofchips,itwasfoundthatshortchipswereobtained at feeds per turn ranging from 0.03 mm/rpm to 0.07 mm/rpm,andfragmentedchipsfrom0.11mm/rpmto0.2 mm/rpm.Thisledtotheconclusionthattheconcentrationof metal particles is higher when the advances per turn are small.Therefore,toreducetheemissionofmetalparticles, during dry drilling of these two alloys, there is a need to increasethefeedsperrevolution.

Thecorrelationbetweenthecuttingforceandthe metal particles is given by relations 8 and 9. From these relationships,itisunderstoodthatthemassconcentration ofmetalparticlesishigherwhenthecuttingforceislowand smallerwhenthecuttingforceishigh (3003) 35898ln()250458

This study provided some information on the influenceofcuttingparametersonthedrillingmachinability ofrecycledaluminumalloys.Theresultsobtainedshowed

This study also made it possible to understand that machinabilityindrydrillingisalsoafunctionofthenatureof thematerial.

[1] A.R Khoeia, I. Mastersb, D.T. Gethinb. (2002). Disign optimisation of aluminium recycling processus using Taguchi technique, journal of materials processing technology,12796-106

[2] M. Samuel. (2003). A new technique for recycling aluminium scrap, Journal of Materials Processing Technology135117-124.

[3] Eulogio Velasc et Jose Nino (2011), Recycling of aluminium scrap for secondary Al–Si alloys, Waste ManagementandResearch29(7),pp686–693

[4] M.E.Merchant(1945):Mechanicsofthe metal cutting process,orthogonalcuttingandatype2chip.Journalof AppliedPhysics,16(5),pp267–275.

[5] M.E.Merchant(1945):Mechanicsofthemetalcutting process, plasticity conditions in orthogonal cutting. JournalofAppliedPhysics,16(6),pp318–324.

[6] P.W.Bridgman(1952):StudiesinLargePlasticFlowand Fracture with Special Emphasis on the Effects of HydrostaticPressure.McGraw-Hill.

[7] M.CShaw(1957),Principleofcutting,ASME;vol.77,pp 103–114.

[8] E. Morin, J. Masounave, Laufer (1995), Effect of drill wear on cutting forces in drilling of metal – matrix composites,Wear,N°184,pp11–16.

[9] E.J.AArmarego(1984) Predictivemodelsfordrilling thrust and torque a comparison of three flank configurations,AnnalsoftheCIRPvol.33,pp5–10.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 09 Issue: 11 | Nov 2022 www.irjet.net p-ISSN:2395-0072

[10] J.Masounave,S.Maugendre,L.Scheed(1998),Preaching MetalDrillingEfforts,MaterialsandTechniquesN°9-10, pp7–16.

[11] AMoufki,AMolinarietD.Dudzinski(1998):Modelling of orthogonal cutting with temperature dependent frictionlaw.JournalofMechanicalPhysicsofSolids,46.

[12] F.Zemzemi,J.Rech,W.BenSalem,A.DoguietP.Kapsa (2008): Identification of a friction model at tool/chip/workpiece interfaces in dry machining of aisi4142treatedsteels.JournalofMaterialsProcessing Technology,InPress,CorrectedProof.

[13] G.CarroCao,M.Santochi,laformationducopeauetdela surfaceusinée,INSAdeLyon,1979,pp.367-476

[14] G. Warnecke, G. Hummel, Chip removal on metallic materials, Chip formation - cutting in microstructure, filmc1246,Inst.Dufilmscientifique,Gottingen,1977

[15] G. List (2004), Etude des mécanismes d’endommagement des outils carbure WC-CO par la caractérisationdel’interfaceoutil-copeau.Applicationà l’usinage { sec de l’alliage d’aluminium aéronautique AA2024 T351, PhD thesis, Bordeaux, Ecole Nationale Supérieured’ArtsetMétiers,156pages.

[16] S. M Krishnam, G. R Irusa (2012), Prediction and analysis of multiple quality characteristics in drilling under minimum quality lubrification, Journal of EngineeringManufacture,226(6),pp1061–1072.

[17] J. Kouam, V. Songmene, Y. Zedan, A. Djebera and R. Khettabi (2013), On chip formation during drilling of cast aluminum alloys Machining Science and Technology,17pp228–245

[18] R. Khettabi (2009), modélisation des émissions des particulesmicrométriquesetnanométriquesenusinage, ThèsesETS,210pages.

[19] LevresqueB,P.LAuger,J.Boourbeau,J.FDuchesne,P. Lajoie,D.Menzies(2003),Qualitédel’air{l’intérieur, Environnement et santé publique: Fondement et pratiques,Vol12,pp317–332.

[20] W.GKreyling,M.Semmler,W.Moller(2004),Disimetry andtoxicologyofultrafineparticles,J.AerosolMedecine, 17,pp140–152.

[21] X. Yang, Q. Chen (2001), A coupled airflow and source/sinkmodelforsimulationindoorvocexposures, IndoorAir,Vol11,N°4,pp257–269.

[22] OstiguyC,G.Lapointe,M.Trottier,L.Menard,L.Cloutier, Y. Boutin, M. Antoun (2006), Health effects of

nanoparticles,Normand,ChristianStudiesandResearch Projects/RapportR-469,Montreal,IRSST,55pages.

[23] Balout B, V. Songmene, J. Masounave (2007), An experimental study of dust generation durind dry drilling of pre-cooled and pre-heated workpiece materials,JournalofmanufacturingProcessvol9,N°1.

[24] V. Songmene, B. Balout, J. Masounave (2008), Clean machining experimental investigation on dust formation:Influenceofmachiningparametersandchip formation, International Journal of Environmentally Conscious Design and manufacturing (ECDM), vol 14, N°1,pp1–16.

[25] N. Roy (1994), Parametric study of the evolution of porosityinthesystemAl-9%Si-3%Cu,M.Ingthesis, Université du Québec à Chicoutimie, Chicoutimie, Canada(infrench).

[26] Xie, JQ, AE Bayoumi and HM Zbib. 1996. « A study on shear banding in chip formation of orthogonal machining».InternationalJournalofMachineToolsand Manufacture,vol.36,no7,p.835-847.

[27] MandatsyMoungomoJ.B.Nganga-Kouya,D.Songmene, V.Kouam,J.;Kenné,J.P.MachinabilityStudyofRecycled Aluminum Cans and Machining Chips. Adv. Manuf. Technol. 2016.

[28] MandatsyMoungomoJ.B.Nganga-Kouya,D.;Songmene, V. Tourning and Drilling Machinability of Recycled AluminumAlloys. Key Eng. Mater. 2016, 710,77–82.

Dr. Jean Brice Mandatsy Moungomo isa teacher researcher at ENSET. He is AssistantProfessoratCAMES.Memberof the Systems Technology Research Laboratory (LARTESY), he focuses his researchonthecontinuousoptimizationof productionprocesses,therecompositionof materialsandtheircharacterizations.

Dr. Guy Richard Kibouka is a teacherresearcherattheENSET.HeisAssistant Professor at CAMES. Member of the Systems Technology Research Laboratory (LARTESY), he focuses his research on the continuous optimizationofproductionprocesses,the reliability and maintenance of productionequipment.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page