International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

1Final year students, Department of Mechanical Engineering, Sathyabama Institute of Science and Technology, Chennai, India.

2 Professor, Head of Department, Department of Mechanical Engineering, Sathyabama Institute of Science and Technology, Chennai, India. ***

The purpose of this study is to create an automated hydraulic jack system. A jack is a mechanical lifting device used to apply greater force to lift heavy loads. A mechanical jack employs a screw thread for lifting heavy equipment. A hydraulic jack uses hydraulic power. It is a tool that raises and lowers the automotive vehicle. The automated hydraulic jack will be useful to elderly people and women who find it extremely difficult to physically operate the jack during any car breakdown. Whenever the tire failure was occurred in the automotive vehicle, lifting the vehicle from ground surface is very difficult, it also involves intense human effort and it is a more time taking process. For rectifying, this kind of problem an automated hydraulic jack system helps to lift the vehicle automatically from the ground instead of conventional mechanical jack, which can save the time and excess effort. The motive behind this work is instead of using an automated jack system which is the more power produced and simple in design as compared to a conventional design. When compared to a pneumatic system, which runs on compressible air, hydraulic systems have a greater lifting capacity since the hydraulic oil is incompressible. Major components of this work include hydraulic jack, DC motor, hydraulic oil.

Key Words: Hydraulic jack, Automotive vehicles, motor, Automated operation, hydraulic oil, pascal law, ground clearance.

In this work we are replacing normal conventional jack as automated hydraulic jack for lifting purpose in automotive vehicle.Inhydraulicdevice,poweristransmittedbypushingtheconfinedliquid.Itisamechanicalfunctionthatoperated throughforceorliquidpressure.Itisbasedontheprincipleofpascal’slaw.Theapplicationofhydraulicsystemisusually usedinvariousfieldslikefoodindustry,beverageindustry, machineryindustry,automotiveindustry,roboticarms,itcan withstandandliftheavyloads.

Normallyweusebottlehydraulicjack,scissorjackforliftingvehicles.Thegroundclearanceofacarshouldbeconsidered mainlyduringthisoperation.In thissystem theyhave replaced conventional hydraulicjack asinbuilthydraulicjack and theyhaveintegratedinthevehicle[1] Followingstudiescanalsoanalysestheadvantagesofanintegratedhydraulicjack systemoveraconventionalmechanicaljacksystem.Byexaminingthedesignoftheprototype,itispossibletoseethatthe designofthebuilt-inhydraulicjacksandalsoautomatedhydraulicjackisalsoinvestigatedandadjustedtothenecessary extent[2].Thebuilt-inself-jackingcomponentisstartedbypressingthedesignatedbuttononthedashboard.Thebuilt-in hydraulic jack will be helpful to elderly people and ladies who find it extremely difficult to physically operate the jack duringanycarbreakdown.Thishydraulicjackwillhavetheabilitytoliftthewheelsinaccordancewithourrequirements; forexample,ifwejustneedtolifttwowheels,thecylinderwillbemovedasnecessaryontherackwiththehelpoftheDC motor[3]

Thiskindofconceptwill be veryusefulinsociety,soourteam interactedandquestionedsometypesofpeoplestoknow whataretheproblems that theyarefacing while theirtyregetspunctured incertaincircumstances.Aladystated that,if my car gets punctured, I face many difficulties and inconvenience. Also, she said that it is very difficult to operate lever bottlehydraulicjack orsomeanykindof mechanicaljack.Wealsointeracted withonecardriver.Hestatedthat “ weare usingcarsforcommercialpurpose.sothatthetyrequalitywill getdepreciatedaybyday.Becauseofthatmanytimescar will getpuncture atoutofcitylimitareas and remoteareas,onthattime,itisvery difficulttofindworkshops, mechanic shops.Manytimes,wechangedthetyresindarkplaces.Itwillbeveryeasyifanyproductisthereforustoreplacetyres in afasterandautomatedmanner” Ourteamvisitedsomecargaragesand workshopstodiscussthatiftheyarehavingany

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

devices,instrumentsoranyideastorectifytheaboveproblem.Throughthisfieldsurveyourprojectteamgotsomeuseful inputsforprojectideas.

Ahydraulicjackisamechanicaldeviceusedtoliftheavyloads.Itisadevicethatusesspecificfluidstopushagainstpiston. Itworksontheprincipleofpascal’slaw.Itstatesthatthepressureappliesonclosedfluidistransmittedandundiminished in every direction and acts with equal force and same area. In this system the use of oil act as a power transmission. Hydraulic system is a good choice for lifting heavy machineries, it is more efficient compared to pneumatic set up machines.Usageofhydraulicmachineriesinindustriescanachievemassproductionandmoreefficiency.Therearemany types of jacks like scissor jack, floor jack, highlight jack, hydraulic bottle jack. Among these hydraulic bottle jacks is portable,cheaper,easytouse.Theincorporatedhydrauliccarjackthatisintegratedwiththeautomobile'scurrentbraking systemandcanhelpinovercomingthedrawbacksofthepresentmechanicaljackofferedinthevehicle.Withthebuilt-in hydraulicjack,wecannowliftthepuncturedside(tyre)ofthecarusingpistoncylinderarrangementsthatareweldedto thevehicle'schassisbyapplyingpressurefromthebrakingfluid,whichwaspreviouslyusedjustforbraking [4].Themost typicaltypeofjackusedforliftingisthehydraulicjack.Withdiverseelectronicgadgets,thehydraulicjackhasundergonea numberofchanges.Safety,luxury,andcomfortareprioritizedwiththeaidoftechnology[5].

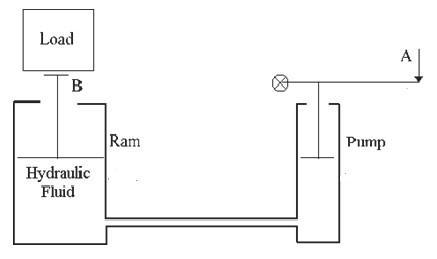

Pascal'slawisthefoundationforthehydraulicjack.Thetimeandeffortrequiredtousethejacksthatarecurrentlyonthe market make using jacks exceedingly challenging. Given below figure 1 and figure 2 represents the working of a simple hydraulicjack.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

P1=P2(bypascal’slawwhichispressurewillbesameatentryandexit)

F1/A1=F2/A2

F2=F1*A2/A1

F2=F1*πR22 /πR21

F2=F1*R22 /R21

Whereas,

P1=P2=Pressure

F1=Forceoninputpistonpump

F2=LiftingForceonoutputpiston

A1=Cross-sectionalareaofpistonpump

A2=Cross-sectionalareaofpistonvalveinoutletpump

R1=Radiusofinputpiston

R2=Radiusofoutputpiston

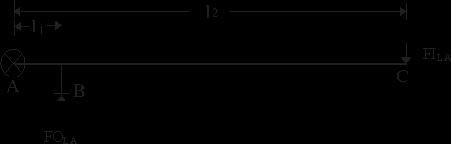

Whereas,

FILA →Forceappliedbyinputleverarm

FOLA→ Outputforceproducedinthepiston

SummingmomentsaboutPoint A;

ΣMA =0=(FOLA *l1)–(FILA *l2) or (FOLA *l1)=(FILA *l2) or

FOLA /FILA =l2 /l1

International

e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

Therearemanytypesofjacksavailableinthemarkettoliftheavyload,jackslikefloorjack,bottlejack,farmjack,scissor jack,pneumatic jack and strandjack.But mostly many ofthe mentioned jacksrequired manual power, most of domestic purposejacksusedmanpoweronlytooperate.Ifanyofthistypeofjackthatcanbeworkuponbyautomatedmannerfor domesticpurposeitwillbeveryuseful.

pneumatic based jacks which will use the pressurised air to generate mechanical motion. A model pneumatic jack was createdandmountedonafour-wheelertoaddresstheissuethatexistedwiththetraditionaljack.Thisconstructedmodel consists of a small reciprocating air compressor that is powered by a battery used in a four-wheeler, an air tank that is usedtostorecompressedair,apneumaticcontrolvalvethatregulatesairflow,andadoubleactingcylinderthatservesas ajackforlifting[6]

Withthedevelopmentoftechnology,wenowmakesurethatanyelectronicsequipmentneedslessspacewhen inuse.We can"rotate"afour-wheeledvehicle,particularlyonethatresemblesacar,toanydegreeutilisingahydraulicjacksupport thatiskeptinthemiddleofthevehicle.Thisstrategycanbeutilisedwhenthereisn'tenoughroomforthecartomakea "u"turnandwhentheroadorpathistoonarrowtochangedirections[7].

Toggle or scissor jacks are straightforward devices used to lift and move heavy weights over short distances. A typical togglejack'spowerscrewdesignlessenstheforceneededbytheusertodrivethemechanism.Toliftthebigloadsatthe stable state under some special circumstances, a Toggle jack with a distinctive design is used. A nut is a stationary part whereas a screw is a moving part The market available car jacks have some drawbacks, including the need for greater energy to operate, unsuitability for usage by women, and inability to be employed on uneven surfaces. As a result, this designhasbeenalteredforthepracticalityandhumanfactorconsiderationsoftheexistingautomobilejacks[8]

Innormalconventionalhydraulicjack,theintensityofpressureistransformeduniformlyinalldirectionsthroughamass of fluid. In this study, Pascal's Law Concept is used to examine the lift force. Also, this study analyses hydraulic system components or hydraulic telescopic capabilities to better the hydraulic jack's capability. The simple automation work of jackcanbedonewiththemotordrivemechanism [9].Thegoalofthisresearchistodesignthehydraulicportablegadget tofacilitatethemechanicsincarmaintenanceandrepairnotablyacomponentofthebottommachine.Thedatacollection can be done by directly assessing the performance test of the portable automated hydraulic jack in automobiles and comparedwiththeoriginal jack [10] Also,someofthe systemscanbework byintegratingthehydraulicprincipletothe scissor-basedjack,thiswill work bytransferringthehydraulicpressurewiththehelpofhydrauliccylindertothescissor jack mechanism, this will be useful forlifting the light weight automobilesfor servicing or repairkind purpose, itcan be handled indoor as well as outdoor [11]. In order to assist the elderly and physically disabled, this project's automatic hydraulic jack mechanism is more beneficial. So, they made an effort to seize the chance. This system can also be integratedwithwipermotorasadrivingmechanismforoperatinghydraulicjack[12]

Automatedjacksystemisasimpleandcompactabledesign,someofthemcanproposeminiatureinbuiltjackmodels,and some of them can propose automated jack models. the reason why inbuilt jack system doesn’t have the tendency to performwellisduetoitsadditionalweightinautomobileandalsogroundclearanceissues.Theseproblemscanbesimply rectifiedbyinstallingaautomatedsysteminconventionalhydraulicjack.Atypicallocomotivemechanismthatcanbeable to convert the output into reciprocating motion that will able to drive the jack into automated manner. Since it takes power from car battery itself, so no any additional power source is required. it reduces man power, time saving, easy to operate and able to lift the vehicle. By altering and improving the design modification and testing in future we can integratethissystemtopowerbrakesalso,sothehydraulicfluidwillcirculateforcarbrakesandalsoforpowerlifting.

[1] Dr.Ramachandra CG, Krishna pavana, Shivraj Shet, Venugopal Reddy,Virupaxappa B(2013).Designandfabrication ofautomotivehydraulicjacksystemformvehicles.

[2] Mayank Agarwal, Minti Geholt Thakur, Deepanshu Mahajan, Tejveer Singh Chahar (2018). Inbuilt hydraulic jack systemforfourwheelers.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

[3] Shivangi Patidar, Shivam Patel, Naman Mehta, Vikas Ojha, Suveer Chandra Dubey (2021). Mechanism of inbuilt automatichydraulicjackusedforlightandheavyvehicles.

[4] Aditya Masiwal, Aman Kanungo,Ishan Rawlley, Devendra Jha, Ashutosh Singh, Dhruv Kumar, Ram Jatan Yadav (2018).Designandfabricationofhydraulicjacksystemforfourwheelers.

[5] ParthMPatel,ParthSpatel,VaibhavHShah,SurilRShah(2016).Automatichydraulicjackinbuitinafour-wheeler.

[6] AtulADhawale,RohitkumarRGupta,ShubhamAGawande,YogeshDBate,V.S.Nikam(2017).Designandfabrication automaticpneumaticinbuiltjacksystembyusingfifthwheelparkingsystem.

[7] D.Bhattacharya(2018).Hydraulicjackmechatronicsforanyanglerotationinfourwheelers.

[8] DhamakC.S.,BajajD.S.,V.S.Aher,G.S.Nikam(2015).DesignandStandardizationoftogglejack

[9] RinasaAgistyaAnugrah,PutriRachmawati(2021).Analysisofhydraulicsystemonportableelectrichydraulicjack.

[10]PRachmawati,IRKurniawan(2019).Designofportableelectrichydraulicjackforimprovingtheproductivity.

[11]Charlie J. Cano, Warlito M. Galita, Elmer I. Samoranos, Aloy Alino De Leon, (2022). Design and Fabrication of a hydraulicmotorcyclelifter.

[12]Durvesh Rohidas More, Aditya Arun Patil, Adesh Ananta Thakare, Nishank Rajesh Vartak, Md Saqib Ansari (2022). Designandfabricationofmotorizedhydraulicjacksystem.

[13]ParameshwarDurge,NiteshThakur,AbhishekGhawalkar,SunilS.Patil(2019).Inbuiltmotoroperatedscrewjackand automatictyreinflationsystem.

[14]Shinde, Aishwarya B, Daphal, Pranitaa B, Nilange, Pratiksha S. Nanwatkar, R.K. (2016). Design and fabrication of mechanicalliftfortransportation.

[15]Dhiraj P.Bhuwad, Roshan S. Kodare, Prathamesh R.Shetye, Priyanka P.Pawaskar (2016). Design and fabrication of brakepedaloperatedhydraulicjack.

[16]RakeshY.Suryawanshi,PranayS.Ramteke,NirajPatil,DeepakKumar,A.V.Vanalkar(2015).Designandfabricationof hydraulicbearingpullerandpusher.

[17]DRamesh,AThirumoorthy,KKandasamy,SSuresh(2019).Hydrauliccomportmentpuller.