International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056 Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056 Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

1 Assistant Professor, Department of Civil Engineering, Krishna Institute of Technology, Kanpur, UP, India 2,3,4 UG Student, Department of Civil Engineering, Krishna Institute of Technology, Kanpur, UP, India ***

Abstract - Thisexperimentwasundertakentoknowabout thepropertiesofconcreteusingBananaLeafash.Concreteis oneoftheextremelygoodmaterialsthatareextensivelyused inconstructioneverywhereinthecompleteglobal.Concreteis extensively used because it has many benefits such as durability,energyefficiency,lowmaintenance,fireresistance, superthermalmass,andversatility.Theworldisnowfocusing on alternative physical sources that are eco-friendly and biodegradable in nature. Banana Leaf Ash is an agricultural waste that has the potential to replace one of the building materials which is cement. Banana Leaf Ash undergoes a pozzolanic reaction that typically takes place in Portland cement. Asopposedto developingabananatree handiest for fruit consumptionand discarding the trunks, the use ofbanana leaf must be explored after the fruit has been harvested.

Thisundertaking is conductedto determine the energy of concretethe use ofBanana leaf Ash to providesuitable cementitious material.ThesourceofBanana Leaf Ash is found in banana plants and is readily available, eco-friendly, and inexpensive. further, Banana Leaf Ash has anincrediblecapacitytoimprovetheperformanceofconcrete. The banana stem ashturned into constituted ofthetechniqueof burning the dried banana stem andaccumulating itsstays. The Banana Leaf Ash might beusedto updateapproximately0%,10%&20%respectively in cement. Mechanical properties such as compressive, split tensile, and flexural strength were determined by casting cubes,cylinders,andbeamsrespectively.

Key Words: Banana Leaf Ash, Coarse Aggregate, Fine Aggregate, Cement.

Concreteismostwidelyusedasabuildingmaterialduetoits good compressive strength & durability. It is the material thatisusedforconstructionworkmorethananyothermanmade material on the earth. The main factor which determinesthestrengthofconcreteistheamountofcement usedinthemixandthewater/cementratio.Dependingon the nature of the work the cement, fine aggregate, coarse aggregate&wateraremixedinspecificproportionstomake concrete.Plainconcreterequiresasuitableenvironmentby providingmoistureforaminimumtimeframeof28daysfor betterhydration&forjoiningtothedesiredstrength.Aswe

knowthatthehydrationprocessrequiresconcretetocure. Anydeficiencyincuringwillseverelyaffectthestrength& durabilityoftheconcreteTheuseofalternativematerialsin constructionisincreasingdaybyday.Theprojectdealswith thecomparativestudyofthepropertiesofconcretebyusing BananaLeafAshascementingmaterialintheconcretemix. Theashgeneratedfromvarioustypesofagriculturalwaste canbeeffectivelyusedasapartialreplacementforcement. Many researchers evaluated the presence of pozzolanic activity in the derived ash of Banana Leaf. The total productionofbananasinIndiaisabout16.71millionTonnes from491thousandHectares,withanationalaverageof34 Tonnes/Ha.Maharashtraisthenumberoneproducerwith 60tonnesperhectare.Aftercuttingoffthebananatreethe outstanding part of the tree which is the stem and leaf is directlydumpedorburnedafterdryingit.Itcanbeusedas analternativematerialforthepartialreplacementofcement. The banana tree contains approximately 80% fluid; after drying,itsweightisreducedtoabout80%.Afterburningdry leafs,itgives21%ashbyitsdryweight.Thatis,ifyoudry 1000kgoffreshleafsandstemsofa bananatreesee,you will get 210 kg of dry leaf’s and 21 kg of leaf ash. Bananaleafsare mainlysourcedfrom variousbanana growers.Leafsaredriedfromthesunforatimeframeof30 days&open-airburningisaccomplished.Theremainderof leafsaftertheburningiscollectedandknownasBananaLeaf Ash.Ifrequired,thisashismadefinebyusingaballmillfor 30minutes.Thefinalproductobtainedinisfinerenoughto mixwiththecement.

This research is carried out to overcome the problem of disposal of farming waste Banana Leafs Ash.

TheresearchmotiveistoevaluatethefeasibilityofBanana LeafsAshasanalternativeforthefractionalreplacementof cement.

1. Knowledge on using banana leaf ashin concretemixestoimprovetheperformanceof concreteinconstruction.

2. Knowingtheoptimalpercentageofbananaleaf ashinconcrete.

3. Toknowabouttheworkabilityofconcretewith BananaLeafAsh.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

4. To know about the strength of concrete like compressive, split & flexural while using BananaLeafsAshusing0%,10%,and20%.

5. Knowledgeoftheeconomicsofconcretemixed withbananaleafashandordinaryconcrete.

Ogenyi Ikenna Ndubuisi (2020) said that the mass strength and density of the specimens decreased as the cementlevelswerereplacedwithbananaleafashes,butthe concreteremainsofitsplasticnature.Thereasonisthatit maintains its workability, so it needs to be increased, practicalitybyadequateutilizationofsuitabilitysothatwork efficiency is improved and in turn, its high power is maintained.Concretewith15%bananaleafashcontentfor cementreplacementof15–20%byweightcanbeusedfor works requiring medium-strength concrete as it exhibits sufficient compressive strength. Replacingcement with bananaleafashisbeneficialtolow-incomecommunitiesdue toitsavailabilityandeaseofprocurement.

K. Madhu prasad et.al. (2019) According to their investigation the strength value decreases slightly by increasing the amount of ash in the banana compared to controlling the banana. Whenever the strength achieved exceeds the target strength of 30 N / mm2. Pozzolanic reactionsalsoincreasestrengthwithage. Thus,theuse of BLAinconcretehelpsconvertenvironmentalconcernsintoa useful resource for the production of highly effective alternativecementitiousmaterials.Theprocessemployedto producebananaleafashcanbeimprovedasthisresearch has employed banana leaf ash derived from agricultural wastes.

Jugal R. Pawar et.al. (2018) They have conducted experimentalinvestigationsonthepropertiesofconcreteby partial replacement of cement with banana leaves. The partial replacement of cement with BLA results in compression, flexural, and split tensile changes in the concrete according to their investigation. They analyzed properties such as compressive, partition tensile, and flexural strength were determined by casting cubes, cylinders, and beams. The BLA will be used in cement to replaceapproximately0%,15%,and25%respectively. As thepercentageofBLAinconcreteincreases,thecompressive strengthisjoinedtothedesiredstrengththatdecreaseswith 28 days for 15% replacement with cement and 25% for replacement.Theflexibleandsplittensilestrengthincreases forreplacementby15%anddecreasesby25%,respectively, compared to normal mixtures. It concludes that a 15% replacement of cement with BLA increases compressive, flexural,andsplittensilestrength.

S. Sakthivel et.al. (2019)conductedexperimentalresearch forconcretewithpartialreplacementofcementbybanana leafash(2%,4%,and6%)andtestedinadditiontobanana

fiber with 0.2%, test results show that the strength of concreteincreases.Concretemixturesdifferinworkability comparedtoconventionalmixtures.Theadditionofbanana leafashincreasedthecompressivestrengthofconcreteby 2%and6%.Asaresult,itwasclarifiedthatashsubstitution can fully satisfytheproperties of cement. Adding banana fiber to the conventional mixture by 0.2% increases the tensilestrengthoftheconcrete.

DuringtheexperimentusedUltratechCement53gradeOPC confirmingtoIS:12269-1987forthepresentresearch.The propertiesofcementaregivenbelow.

Fineness

2939cm2/gm

Normalconsistency 28%

Vicat’sinitialsettingtime(min.) 64 Vicat’sfinalsettingtime(min.) 192

Specificgravity 3.1 Compressivestrengthat7days 36.01Mpa Compressivestrengthat28days 45.20Mpa

Lime(CaO) 60-64 Silica(SiO2) 17-23 Alumina(Al2O3) 3.5-8.5

FerrousOxide(Fe2O3) 0.4-6.0

MagnesiumOxide(MgO) 0.2-4.0 Alkalis(K2Na2O) 0.5-1.2 Sulphurdioxide(SO2) 1.2-3.0

TheBananaleafswithstemsusedforthisstudyareobtained fromlocalbananafarms.Inthisprocess,theavailableleafs aredriedforaperiodof30days(min),afterwhichthedried banana leafs are burned in a controlled atmosphere and residualashoftheleafsiscollectedalongthestem.Thisash issievedthrougha90micronsievetoobtainafinepowderof Banana Leafs Ash. This ash is used to partially replace cementinthepercentagecalculatedinourstudy.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

Parameter Composition of Banana Leaves Ash (%)

SiliconDioxide(Si02) 48.2

IronOxide(Fe2O3) 1.25

AluminiumOxide(Al203) 2.62

SodiumOxide(Na2O) 0.25

SodiumOxide(Na2O) 5.12

Thecoarseaggregateusedwasanormal-weightaggregate with a maximum size of 20mm and was got from a local supplier.

Usinggoodqualityfineaggregatesthatareavailablelocally.

Experimental study concrete mix design of M25 grade is designed as per IS 10262-2009. This code represents the method for the selection of mixed proportions. The quantities of materials used in this experiment are given below.

Banan a Leaf Ash Replac ement( %)

Mix Prop ortio n

Cem ent (kg)

BLA (kg) F. Agg (kg )

C. Agg (kg)

Thetotalspecimensusedforare36whichincludes6cubes,3 beams&3cylindersforeachcastingof0%,10 %&20%. The cubes of size 150x150x150 mm, beams of size 700x150x150mm&cylindersofsize300mmheightx150 mm diameter. The concrete is mixed, compacted using a tablevibrator&finishedasperthestandardspecificationof castingthespecimens.

Allcastedelementsarecuredfor7&28daysfromthetime ofcastinginthecuringtankatnormaltemperature.

All casted elements are tested at 7 & 28 days for Compressive,Flexural&Splittensilestrength.Thecubes& cylinders specimens are tested by using (CTM) of their capacity is 2000 KN in the site laboratory. The beams are testedon(UTM)theircapacityis1000KN.

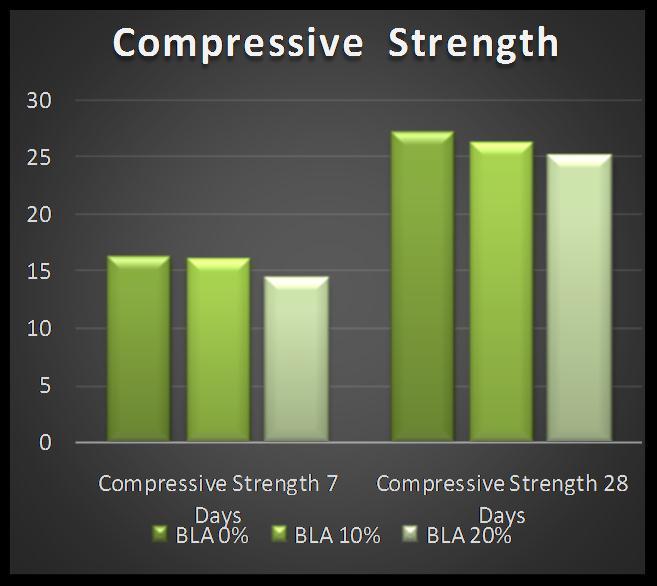

4.9.1 Compressive Strength testing [As per IS:516]

Thecompressivestrengthtestisperformedonthecubesat7 & 28 days. to determine compressive strength. Concrete cubesizeis150x150x150mm.Thespecimensarestep-bysteploadedinCTMtillthespecimenfails.

Wat er(l iter s)

Adm ixtur e kg/ M3

0 1:12: 21 355 0 670 1201 160 34 10 1:12: 21 319. 5 355 670 1201 160 34

20 1:12: 2.1 284 71 670 1201 163 35

Themixingofmaterialiscompletedbyweightbatching.This method is used for that mixing manual. The cement is fractionalreplacedbyBananaLeafAshinpercentagesof0, 10&20 respectively.Theadmixtureisused with different quantitiesinthisexperimentforgettingworkability.

Banana Leaf Ash Replacement (%)

Curing time (Days) Compressive Strength (N/mm2) 0 7 1630 28 2720 10 7 1610 28 2640 20 7 1455 28 25.30

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

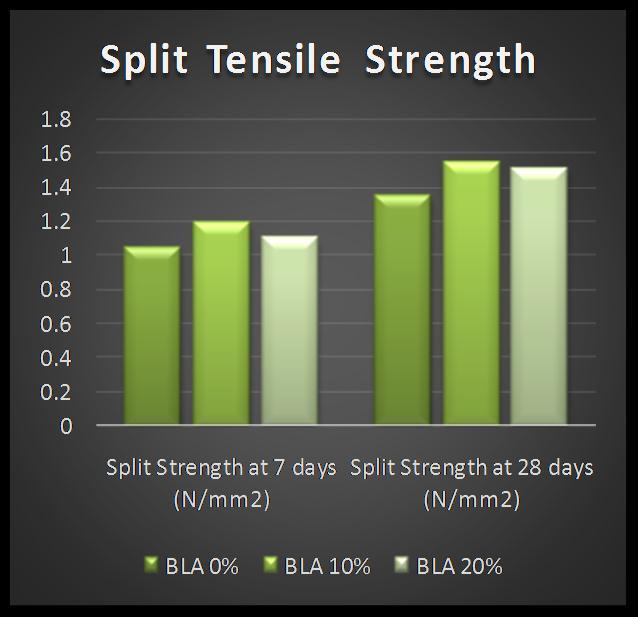

TheSplitTensiletestisperformedonthecylindersat7&28 days to determine tensile strength. The concrete cylinder sizeis300heightx150diametermm.

Banana Leaf Ash Replacement (%) Curing time (Days) Compressive Strength (N/mm2) 0 7 1.05 28 1.35 10 7 1.20 28 1.55 20 7 1.11 28 1.52

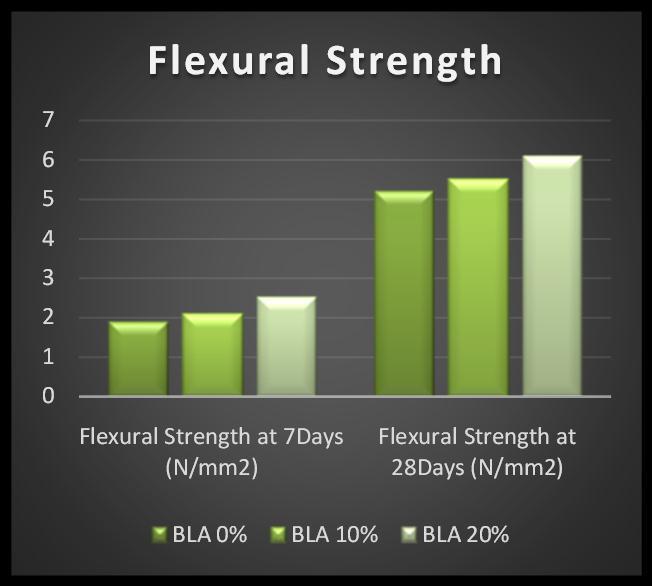

4.9.2 Flexural Strength Testing [As per IS:9399]

Theflexuralstrengthtestisperformedonthebeamsat7& 28days to determine flexural strength. Beam size is 700 x 150 x 150 mm. The elements are tested on UTM at the standardloadingsystem.

Banana Leaf Ash Replacement (%) Curing time (Days) Compressive Strength (N/mm2) 0 7 1.90 28 5.20 10 7 2.10 28 5.50 20 7 2.50 28 6.10

The study leads to the following conclusions: - Partial replacement of cement that changes the Compressive, Flexural & Split tensile strength of concrete. Increasingtheproportionofbanana leaf ashin concretereduces itscompressive strength compared toordinary cement. Combined use ofthe above partialreplacementscanreduceconcretecostsandimprove concretestrength.So,thecombinationofthetwomaterials canbeusedtogetbetterStrengthpropertiesatmincost.As per the presence of pozzolanic essential compound as requiredbystandards,thepresenceoffinerparticles,anda larger surface area per particle make Banana Leafs Ash pozzolanic material. The strengthparameter decreasesslightlywithincreasingbananaleafashcontentin theconcretecomparedtonormalconcrete.Also,thestrength increaseswithagewithpozzolanicreactions.Thus,theuse ofBananaLeafsAshinconcretehelpstotransformitfroman

environmental concern to a useful resource for the production of a highly effective alternative cementing material. Using banana leaf ashas acement substituteforconcreteresultsinamoredurableandstronger concrete.

[1]OgenyiIkennaNdubuisi,“Potentialsofbananaleafasan admixtureintheproductionofconcrete",ajournaloncivil andenvironmentalengineering,2020

[2]K.MadhuPrasad,P.Eswanth,"MechanicalandDurability propertiesofconcretebypartialreplacementofcementwith BananaLeavesAsh",JAC:AJournalofcompositionVolume XIIIssueXII(DECEMBER2019)

[3] Jugal R. Pawar, Aman S. Khaire, Experimental Investigation on Properties of Concrete by Partial Replacement of Cement with Banana Leaves Ash", International Journal for Research in Engineering Application&Management(IJREAM)SpecialIssue-ICRTET2018

[4] S. Sakthivel, R. Parameswari, M. Gomathi, S. Sangeeth,"Experimental Investigation on Concrete with Banana fiber and Partial Replacement of Cement with Banana Leaf Ash", International Research Journal of Engineering and Technology (IRJET), Volume:06 Issue:03, MARCH2019.

[5] Priyanka Selvi, “Comparative Study of GBFS & Banana Fibre Reinforced Concrete with Normal Concrete”, International Research Journal of Engineering and Technology(IRJET),vol.6(11),2019,pp.2351-2354.

[6]RamyaM,MercyShanthiR,SujiD,“StrengthEvaluation ofSustainableConcretewithPartialReplacementofCement byCombination of Banana Leaf Powder and Cattle Bone Powder”, International Journal of Innovative Technology andExploringEngineering,vol.8(6S4),2019,pp.884-886.

[7]AyyappaRA,SandeepReddyB,G.SwamyYadav,Dara SwethaSudarshan, “Partial Replacement of Cement and CoarseAggregatebyEggShellPowderandCoconutShells”, International Journal of Innovative Technology and ExploringEngineering (IJITEE), vol.9(4),2020, pp. 12421246.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056 Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page442