International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

1 Associate Professor, Division of Architecture and Civil Engineering, Ashikaga University, Japan

2 Assistant Professor, Division of Architecture and Civil Engineering, Ashikaga University, Japan ***

Abstract - The purpose of this study is to improve the practicality of paving blocks made of bamboo fiber taken from abandoned bamboo groves. The bamboo block composes of bamboo fiber and cement and water without any chemical additive. In some cases, bamboo powder finer than bamboo chip can be layered on the top of the block to smooth the surface for pedestrians. Pavement materials made of bamboo fiber have already been studied, and examples of the practical use can be seen. However, they are not pavement blocks. The bamboo fiber block developed in this study does not basically require the construction technique to pour pavement material and form the surface all over the ground. If some blocks break, anyone just replaces them. New bamboo pavement block is not only much lighter and replaceable but also low price compared to conventional concrete pavement blocks. Eventually, a circular plaza paved with the 340 bamboo pavement blocks was constructed at the vacant lot of the Ashikaga city’s land in November, 2021 as an exposure test.

Key Words: Bamboo Fiber, Concrete, Pavement Block, Exposure Test

Thispaper discussesthe background, productionmethod, and features of the bamboo fiber blocks used for pedestrianpavement.

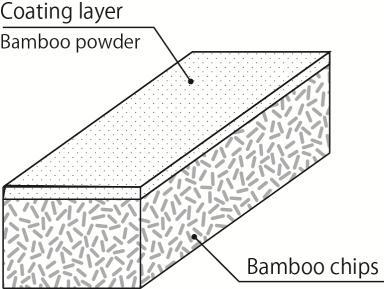

Abamboofiberblockisapavingblockmadebymixing cementwithpulverizedbamboochipsandpowder(Fig.1)

The blocks were created in a collaboration between university students and townspeople in the city of Ashikaga and financially supported by the government of TochigiPrefecture,Japansince2015.

TochigiPrefecture,surroundedbymountains,isfamous for its bamboo production [1]. There are many vast bamboogrovesinAshikagaCityandneighboringSanoCity. On the other hand, abandoned bamboo groves have recentlybecomeabiggerproblemduetothedeclineofthe forestry industry. The problem has been addressed from the viewpoint of the Sustainable Development Goals( SDGs).

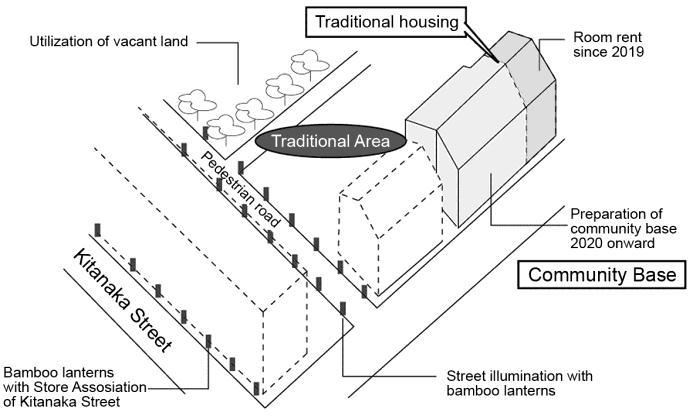

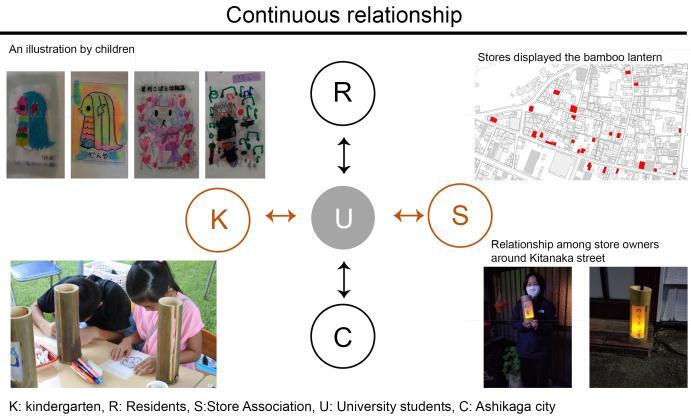

Thisprojectwasimplementedaspartofthe“Creatinga Lively Ashikaga City” plan that generated communication amongtownspeopleonthenightscapebybamboolanterns made by cutting down from abandoned bamboo groves (Figs.2and3).

The bamboo lantern events raised awareness in the region and achieved certain results. However, the large number of used bamboo cylinders for the lanterns was a major problem. Moreover, the bamboo cylinders decay in about a year and become unusable. Therefore, further action is necessary. Bamboo cylinders can be reused to create bamboo fiber blocks by pulverizing the bamboo cylinders.

This paper discusses the following procedure: firstly, the background of the development of the bamboo fiber block will be described indetail.Next,after describing the manufacturing method of bamboo fiber blocks, their features based on strength experiments are explained. Finally, it explains the result of the bamboo fiber blocks exhibition conducted in November 2021, which was implementedasanexposureexperiment.

There are some previous studies on pavement materialsusing bamboo fiber. Some ofthemaresimilarin material composition to the block in this research. For example, there is research on mixing bamboo fibers with cement to form pavement blocks abroad [2&3]. However, aggregates(gravel,etc.)aremixedintoensurestrength,so

e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

InJapan,soilpavingmaterialsmixedwithbamboofiber have been developed [4&5], but it is different from the developmentofpavingmaterialswithreplaceableblocksin thisresearch.Furthermore,thereisalsoabambooblockas abuildingmaterialindomesticpatents.Itsblockusesonly bamboo powder, which has a shorter fiber length than bamboo chips, and cement [6]. Compared to creating paving material with chips, it requires more than double theamountofbamboo,soitisnotaslightweight.

This study develops a very lightweight and reasonable pavement block for pedestrians using only bamboo chips andcement.Asaresult,itisexpectedthatitwillbeusedas acommunitydevelopmenttoolthatcanbereplacedeasily by residents if a paving block becomes damaged, and can beusedtoimprovethelocalenvironmentatanytime.

OF

2.1 Summary of the bamboo lantern and its event

Various events have been held using bamboo lanterns since 2015 [7&8]. In addition, instead of holding the bamboolanterneventasatemporaryevent,thebasefora regional collaboration project was set up in the Yukiwa area in Ashikaga City to study and practice a method for supportingactivitiesoflocalpeople(Fig.4).

Bamboolanternsarebamboocylinders25cminheight with a hole in the side andan LEDlight inside. Theyare a device for brightening the nightscape and are lined up on theroadsideandinthesquaretoilluminatetheground.

The bamboo lantern events consist of two approaches (Fig.3). Oneistosetup bamboo lanterns intownatnight and attract people to the lights. The other is to share the funandcreatelivelinessthroughmakingbamboolanterns with kindergarten children and holding on-site bamboo lantern-makingworkshopsforlocalchildrenandresidents.

Forexample,universitystudentscollaboratedwithfive kindergartens in the city to make approximately 500 bamboolanternstogetherin2020 [9].Universitystudents made bamboo cylinders in an abandoned bamboo grove and opened a window on the side of them. The children drew colorful illustrations on the tracing paper that covered the windows of the bamboo cylinders. These 500 bamboo lanterns were installed over a period of about a month from the base in the Yukiwa area to the dimly lit back alleys of the area. Bamboo lanterns illustrated with shops’ names were set in front of 30 shops’ eaves in the area. As a result, people had the opportunity to gather in the back alleys and shops in the area, which were not usuallycrowded(Figs.5and6).

Fig -2: Studentscuttingdownbambooinanabandoned bamboogroveinSanoCity(left)andMakingbamboo cylindersforbamboolanterns(right) Fig -3: Bamboolanterneventatthevacantlandinthecity (left)andBamboolanternmakingworkshopwithlocal children(right) Fig -4: Settingupthebaseandcontinuingactivities rootedinlocalcommunities Fig -5: Parentsandchildrengatheringinabackalley(left) andlong-termexhibitionusing500bamboolanterns madeincollaborationwithkindergartenchildren(right)International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

and gravel,so the blocks themselvesare heavy.Therefore, it is not easy to place a large number of blocks in a large area.

On the other hand, there is a prior art that aims to significantly reduce the weight of cement blocks by developing cement blocks that consist entirely of bamboo powder with short fiber lengths, without using sand or gravel [6]. Although this technology was not originally for paving blocks, it has sufficient strength to be adapted for thispurpose.

Asseeninthispriorart,bamboofibershaveanaverage fiberlengthofabout10mm,mostlypowderwitharangeof 1 to 30 mm. Powder is used because it is easy to manufactureconcretemoldingsthroughadjustmentwithin thisrange.

Fig -6: Akindergartenandastoreassociationthat collaboratedonbamboolanterns.Inadditiontothis, studentsfromAshikagatechnicalhighschooland elementaryschoolchildrenalsocollaboratedonbamboo fiberblocks.

The following two problems came to light when proceeding with the bamboo lantern events. 1) The bamboo cylinders used for the bamboo lanterns are damaged considerably in one year, and 2) in the case of long-term exhibitions, there are legal rules regarding the useofroads,andthebamboolanternsmustbefixedtothe ground. As a solution to these problems, the development of bamboo fiber blocks was started to create a pavement materialmadebypulverizingbamboocylindersandmixing themwithcementafterusingthemforbamboolanterns.

However,ifthebamboofibersarefine,theyaredensely packed without any gaps, so a very large amount of bamboo powder is required, and the weight increases accordingly. Moreover, simply increasing the length of the bamboo fiber reduces the adhesive surface between the bamboo and cement, weakening the bond and making it difficulttomaintainstrength.

Therefore, there has been a demand for a lightweight pavementblockthatcanmaintainsufficientstrengthwhile usinglongbamboofibers.

The manufactured bamboo fiber block consists of two layers: the upper layer is a coating made of powdered bamboo fibers that have a fiber length of 30 mm or less with cement. The lower layer is made of bamboo chips which have a fiber length of 30 mm or more and 100 mm orlesswithcement.(Fig.7).

Conventional pavement blocks, from the viewpoint of reducing environmental impact and improving walking performance, have already been improved. For example, there are cement blocks made by mixing bamboo fiber with sand and gravel to improve water retention and at thesametimegivethetextureofnaturalmaterials.

Improvementofworkability,however,isalsoimportant forpavingblocksthatmustbeusedinlargequantities.The major problem regarding workability is the weight of pavingblocks.

Commonly used pavement blocks are cement blocks, bricks,andstones,whicharecomposedof70to80%sand

Fig -7: Compositionofbamboofiberblock.

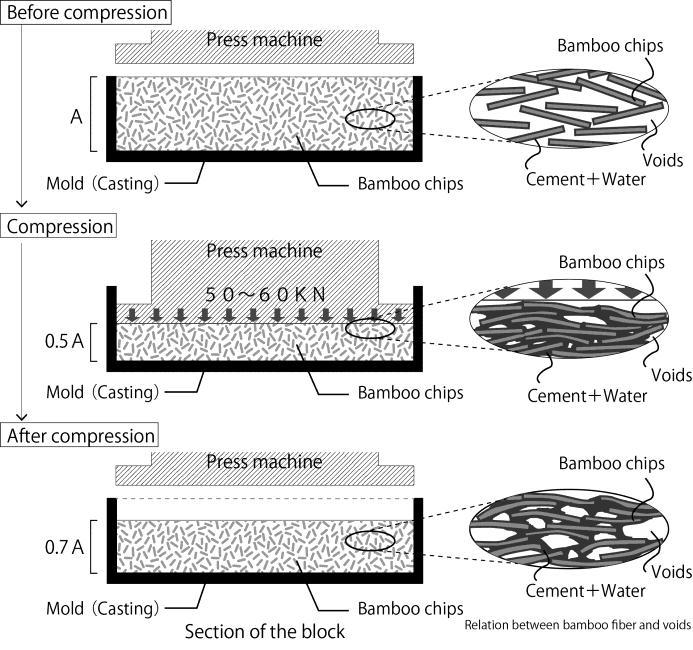

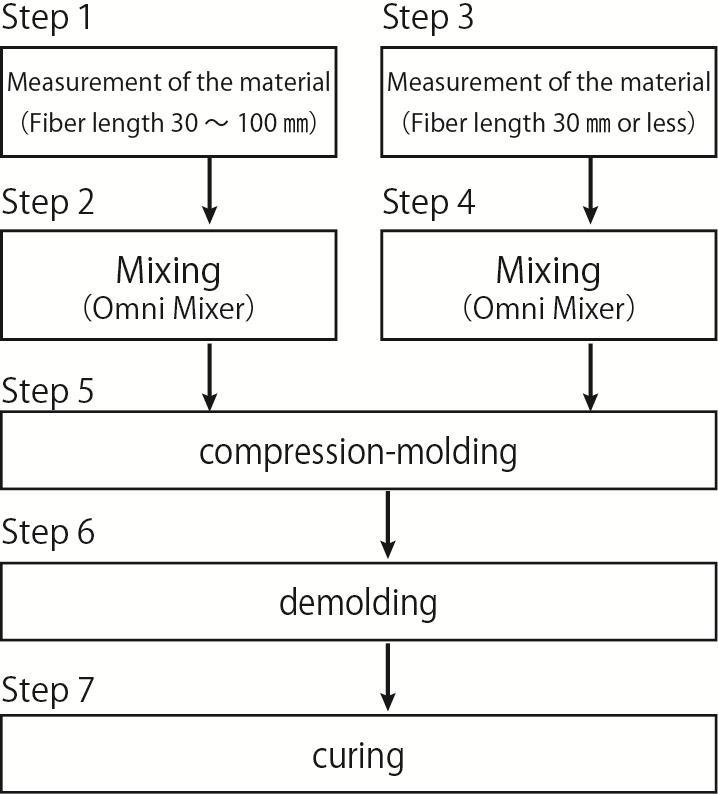

Theblockmanufacturingmethodisasfollows(Fig.8).

Step 1 is the measurement of the material to form the lowerlayeroftheblock.

The materials are bamboo chips, water, cement, and organic admixture. It is desirable that the water-cement

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

ratio is 0.40 and the admixture is added at 0.7% of the weightofthecement.Fineaggregatessuchassand,gravel, andresinarenotusedatall.

bamboochipswiththecement,becausewaterandcement willgatheratthebottomofthemixer.

The bamboo chips are Madake bamboo (Phyllostachys bambusoides)orMosobamboo(Phyllostachysheterocycla f. pubescens) which have been pulverized with a chopper and dried to a moderate degree. There is no need to consider the moisture inside the bamboo through drying and it does not affect the water-cement ratio. However, it doesnothavetobecompletelydry.

Regardingthefiberlengthofbamboochips,thereisan inverse relationship between the fiber length and the weight of the molded block. For example, bamboo chips composed of longer fibers are lighter. If the fibers with a length of 50 mm to 100 mm exceed 75%, the joining surface between the fibers is too small and the necessary strength cannot be achieved. 50-30 mm fiber length size should comprise 20-30% of the total quantity of bamboo chips. As a result, the number of joining surfaces between bamboofibersincreases,thebondstrengthbetweenfibers become stronger, and the inherent bending strength of bamboocanbeexhibited.

In step 2, the bamboochipsmeasured instep1,water, cement, and an organic admixture are uniformly mixed with an Omni Mixer, which is advanced mixing with a rotationspeedof100to480RPM.ByusinganOmniMixer formixing,thecementcanbethinlyandevenlydistributed acrossthesurfaceofthebamboochips.Evenifthisisdone withaconventionalPanmixer(rotationspeed20-30RPM), it is quite difficult to evenly cover the surface of the

Step 3 is the measurement of the material used in the upper coating layer. The materials are bamboo powder with a fiber length of 30 mm or less, water, and cement. Thewater-cementratiois0.30.Theorganicadmixturemay not be used. The weight of the bamboo powder should be about 50% of the total weight. The bamboo powder uses MadakeorMosobamboo.

It is also beneficial to use white cement for the upper layer. Thecolor of paving blocks made fromwhitecement canbeclosetowhite.Inaddition,pigmentscanbeaddedto white cement to create different-colored paving blocks. Thecolorofthepavementisanimportantfactortoattract pedestrians’attentionandinfluencestheatmosphereofthe place.

In step 4, the material measured in step 3 is uniformly mixed byan OmniMixer.Atthis time, itispossible tomix by Pan mixer. But, as bamboo powder has a low specific gravity, it is difficult to mixuniformly due to the tendency for lumps toformduringstirring. Inaddition, iflumpsare formed,itlosesthembeforeuse.

In step 5, 90 mm of the material produced in Steps 1 and2forthelowerlayerisputintoamoldwithaheightof 100 mm, then 10 mm of the material produced in Steps 3 and 4 is put on top of it. As the thickness of the coating layer increases, the weight increases. The materials inside of the mold are compression-molded by evenly applying compression of 50 to 60 KN with a press machine. The

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

upper coating layer is compressed and more densely compacted, but the thickness of the layer remains almost thesame.AsshowninFig.9,thelowerlayeriscompressed toabout60to70mm[10&11]

Compression molding makes it possible to mold bamboo chips with large fiber lengths. As a result, it is possible to produce a paving block that not only requires lessbamboofiberthanmoldingwithbamboopowderonly butalsohasaflexibleperformancethattakesadvantageof thebendingstrengthofbamboochips.Thisblock hashigh waterpermeabilityduetohavinghighporosity.

Thefinalstepisdemolding.Itleavesforabout24hours after compression molding and removal from the mold. Then, it cures and hardens for about 14 days. In addition, most of the strength comes out in about 14 days, but it is desirabletocurefor28days.

The composition and manufacturing method of the bamboo fiber block described here was submitted to the JapanPatentOfficeonOctober18,2021,andarequestwas submitted for examination of the application on February 15,2022[10]

4.1

4.1.1

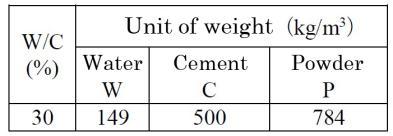

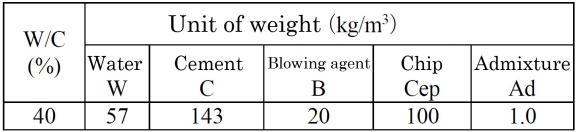

Twotypesofcement,ordinaryPortlandcementandwhite cement,wereused.Inaddition,bamboochipsandbamboo powder were used instead of fine and coarse aggregates (Fig. 1). Three types of admixtures were used: a highperformanceAEwater-reducingagent,alow-additiontype expansive agent for concrete, and a coating-type highperformance shrinkage reducing agent. In the case of bamboo powder, the water-cement ratio was 30%. In the case of bamboo chips, the water-cement ratio was 40%. Tables 1 and 2 show a combination of bamboo powder andbamboochips.

Table -1: Formulatedwithbamboopowder

Mixingwasconductedusingamortarmixerforbamboo powderandanOmnimixerforbamboochips.Amoldsized

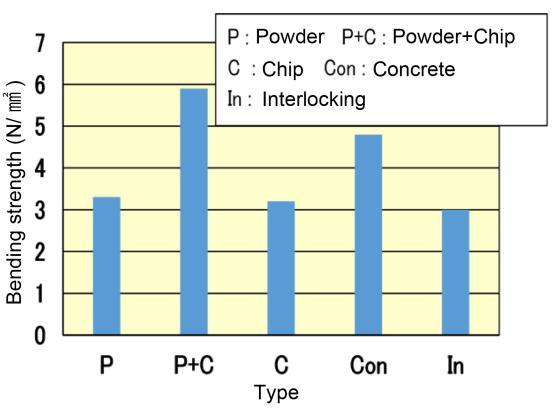

Chart -1:Relationshipbetweenbambootypeandbending strength

Table -2: Formulatedwithbamboochip

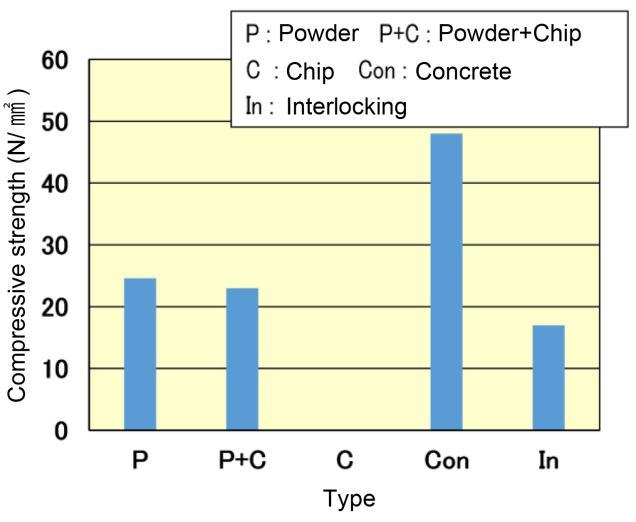

Chart -2:Relationshipbetweenbambootypeand compressivestrength

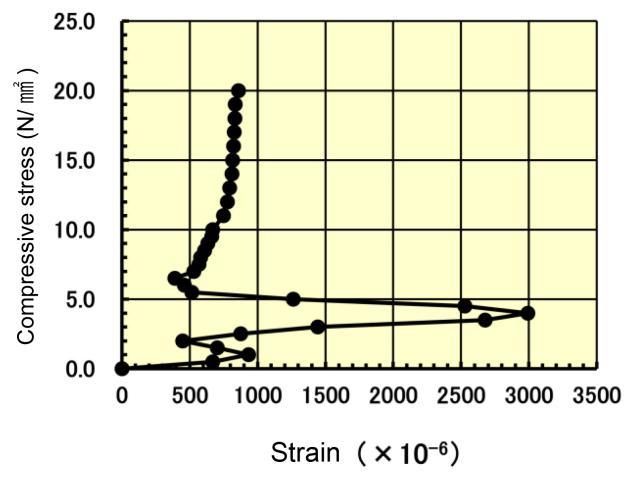

Chart -3:Stress-straincurveofthebamboofiberblock

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

100W×400L×100H mm was used to produce the sample pieces. Sample pieces consisted of three types: 1) bamboo chipblock(C)2)bamboopowderblock(P)and3)bamboo fiberblock(C+P).

The bamboo chip block (C) consists of bamboo chips only. The bamboo powder block (P) consists of bamboo powderonly.Thebamboofiberblock(P+C)iscomposedof two layers mentioned in section 3. The first layer was bamboo chips on the bottom of the mold and the second layerwasbamboopowderonthefirstlayer.

Byapplyingapressureofabout60KN,thetestpiecesof all types became approximately 100W× 400L×60H mm. After air-dried curing, bending strength and compressive strength were measured after 28 days according to JIS (Japan Industrial Standard) A 1106 and JIS A 1108. In addition, the strain was measured with a strain gauge whilemeasuringthecompressivestrength.

According to quality standards of interlocking blocks forpedestriansmentionedbytheJapanInterlockingBlock Pavement Engineering Association (JIPEA), the bending strength must be 3.0 N/mm2 or more. Chart 1 shows the bending strength of all bamboo block types, concrete, and interlocking blocks. It was confirmed that the bending strength of the bamboo chip block (C) generated by pulverizingwastebamboosatisfiesthequalitystandardof 3.0N/mm2 ormoreforinterlockingblocksforpedestrians (In)andwasalsoconfirmedtohavesufficientcompressive strength. In addition, it was found that the bending strengthofthebamboofiberblock(P+C)isabouttwiceas strong as the quality standard of the pedestrian interlockingblock(In).

Chart 2 shows the compressive strength. According to the qualitystandard mentioned by JIPEA, thecompressive strengthoftheinterlockingblockforpedestrians(In)must be 17.0 N/mm2 or more. The compressive strength of bamboo powder (P) is 24.6 N/mm2 and the bamboo fiber block (P+C) had a compressive strength of 23.0 N/mm2 . Both were confirmed to meet the quality standards of the pedestrian interlocking block (In). In addition, the compressive strength of the bamboo fiber block (P+C) is about the same as that of bamboo powder (P), so no differenceinstrengthisobserved.However,asthedensity of the bamboo chip is decreased due to many voids in it, the strength is also decreased. Bending strength is not affected.

Chart 3 shows the stress-strain curves of the bamboo fiber block. It was confirmed that the strain increased in the initial stage, then decreased,andthenincreasedagain. Thereasonwhythestrainwaslessenedisthatthebamboo fiber blocks have many voids, and when the voids apply pressure, the voids are clogged, and the strain becomes less.

Theresultsoftheexperimentarethefollowing:

(1)Thebendingstrengthofthebamboofiberblockwas5.9 N/mm2, so that was confirmed to be sufficient as paving blocks for pedestrians. This outcome is due largely to the two-layerstructure(bamboochipsandbamboopowder).

(2) The compressive strength of the bamboo fiber block was 23.0N/mm2, so that wasconfirmed tohave sufficient strength. Furthermore, no difference in compressive strength between the two-layer structure and the powder alonewasobserved.

Fig -10: Productionsceneryofbamboofiberblock.

Fig -11: Layingbamboofiberblock.

Fig -12: Squarepavedwithbamboofiberblock.

Fig -10: Productionsceneryofbamboofiberblock.

Fig -11: Layingbamboofiberblock.

Fig -12: Squarepavedwithbamboofiberblock.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

(3) The strain of the bamboo fiber block tended to be less at the initial stageand then increaseagain. The reason for this is that the voids were clogged, and the strain was reducedbyapplyingpressuretothevoidscontainedinthe

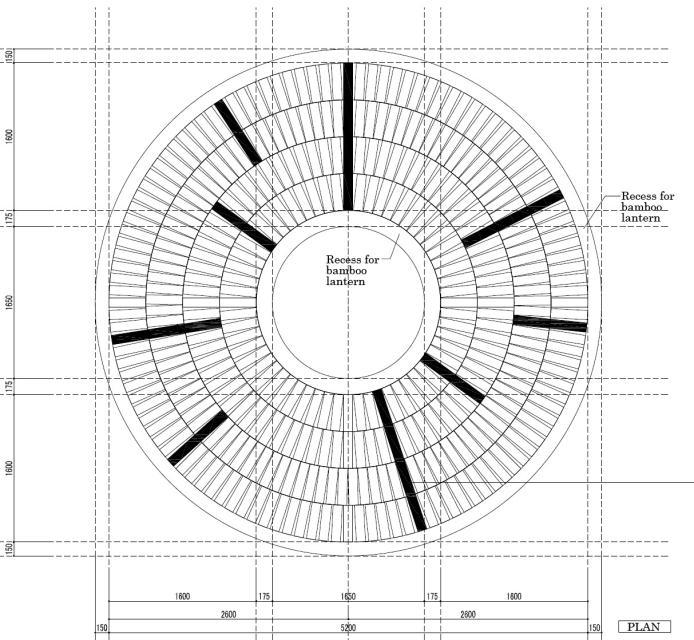

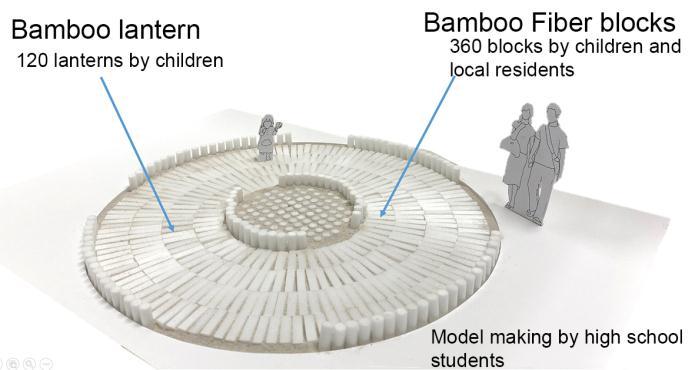

Firstly,thegroundwasexcavatedtoadepthofabout15 cm, the surface (10 cm of crushed stone was paved and rolled) was prepared, and about 340 bamboo fiber blocks werelaidout.Furthermore,120bamboolanternswereset around it. The bamboo lanterns were exhibited for two weeks. After that, the bamboo fiber blocks were continuously paved, and exposure tests were carried out forayear.

Problems such as cracks due to water permeability and drying shrinkage of bamboo fiber blocks and verification remain,andthisstudywillcontinuein2022.

Thisstudybeganwiththeproblemofabandonedbamboo groves, which has become a problem in the local community area. Then, the utilization of overlooked local resources considered. Abandoned bamboo groves were reusedintheformofbamboolanterns.Insuchasituation, bamboofiberblockswerealsoproduced.

Bamboo fiber blocks are more reasonable than conventionalcementpavingblocksandhavethetextureof natural resources and the flexibility of bamboo. The manufacturing method maximizes the flexibility of bamboo, applying bamboo fibers that are as long as possible. Long bamboo fibers are difficult to mold into blocks,butthiscanbeovercomebycompressionmolding. Thatiswhatmakestheblockevenstronger.Thefeaturesof theblockinthisresearcharesummarizedasfollows.

1) Very light, 2) high flexibility, suitable for pedestrian pavement,3)highwaterpermeabilityandwaterretention, excellent heat-island effect, 4) the color of blocks can be adjusted while retaining the texture of bamboo. The features and effectiveness of the block were proven throughexperiments.

Fig -13: Modelforcompositionplanofbamboofiberblock (upper)anditsdrawing(lower) Groundlightsare installedintheblack-paintedareasonthedrawing.

bamboofiberblock.

Bamboo fiber blocks were exhibited together with bamboo lanterns on vacant land in the Ietomi area, Ashikaga City, which was owned by the municipal cooperation of Ashikaga, from November 4th (Thursday) to13th(Saturday)in2021(Fig.10-13)[12]

This research has just taken the first step; further verification is still required. Exposure experiments are currently being conducted for one year. Through experiments,theblocksonthesitearebeinginspectedfor efficiency of water permeability and cracking due to the drying shrinkage of bamboo. Based on the experiment, efficiencycanbeimprovedfurther.

In addition, bamboo fiber blocks need to be replaced due to damage. However, they can be easily replaced by residentsbecausetheyarelightweightandeasytohandle. Moreover,damagedblockscanbeeasilybrokenintopieces and turned back into bamboo fibers and returned to nature. The eco-cycles of abandoned bamboo would also makeuseofacommunitydevelopmenttool.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

[1] Yoko T., HIkaru, A.: Bamboo woods and the environment, Annual Report of Researches in Environmental Education, Kyoto University of Education,Vol.15,pp.99-123、 2007[inJapanese].

[2] MudjanarkoSriW,MayestinoM,RasidiN,Indrawan, andSetiawanIkhsanM.,“BambooWasteasPartofThe AggregatePavementTheWayGreenInfrastructurein The Future”, MATEC Web of Conferences 138, 03013 (2017)

[3] Chaoming X, Chaofan W, Kefei L and Kang J.:“Study on the Durability of Bamboo Fiber Asphalt Mixture”, Materials2021,March2021.

[4] Hiroaki S., Yudai S., Yoshimi T., and Hiroshi T.,: Geotechnical properties of bamboo chips-soil mixture and its applicability as pedestrian pavement, Journal of Japan Society of Civil Engineers, Ser. C (Geosphere Engineering), Vol.73, No.3, 266-275,2017 [in Japanese]

[5] SatoK.:UtilizationofBambooforsoilpavement(Take no Dokeihosou heno Katuyouhou), New Technology presentation Meetings, Vol. 35, Issue.11, pp.1-12, 2018

[6] Hiroshi H.: Concrete molding and its manufacturing method, Japan patent 2003 104768, published in 2003

[7] Taiga M., Takashi O., Hirohide F. and Subaru S.: Creating Liveliness of the Community in Yukiwa, Ashikaga -As Student-Based Experimental Learning-, 、 Summaries of design works of annual meeting, ArchitecturalInstituteofJapan,2020

[8] Niito A., Motoki T: Creating liveliness in Ashikaga town -From abandoned bamboo groves to bamboo lanterns and bamboo fiber blocks-, Proceeding of ‘Research presentation of Students & Enterprise’, vol.18,pp.10-11,2021

[9] Ashikaga Univ. and Ashikaga Junior college: Annual report2021forgrantprojectofcollaborationbetween University and Region entitled “Creating liveliness in Ashikagatownbybamboolanterns-”,2021.3

[10] Takashi O. and Kimio M: Paving block and its manufacturing method, patent pending 2021 183745,JapanPatentOffice

[11] Nito A. and Masahiro K (Director: Kimio M.):Study on bamboo fiber block as pedestrian pavement, Batcher Thesis, Division of Architecture and Civil engineering,AshikagaUniversity,2022.2

[12] Ashikaga Univ. and Ashikaga Junior college: Annual report2022forgrantprojectofcollaborationbetween University and Region entitled “Creating liveliness in Ashikagatownbybamboolanterns-”,2022.3

Fig.1-13,chart1-3andtable1&2:Author