International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

1P.G student, Department of Mechanical, Annamacharya institute of technology & sciences, Tirupati, India 2Assistant Professor, Department of Mechanical, Annamacharya institute of technology & sciences, Tirupati, India 33Assistant Professor, Department of Mechanical, Annamacharya institute of technology & sciences, Tirupati, India ***

Abstract - Inthiswork,powdermetallurgy,compaction, sintering, and hot extrusion were used to create pure magnesium and magnesium matrix composite enhanced withtitaniumnitridenanoparticles.Thisstudymadeuseof magnesiumpowderandtitaniumnanoparticles.Mechanical and microstructural investigation of extruded specimens were performed using a universal testing machine, and scanningelectronmicroscopewithenergydispersiveX-ray spectroscopy(SEM–EDS).TheadditionofTiNnanoparticles to the magnesium matrix increased mass density and ultimate tensile strength., and maximum UTS were investigated in Mg0.97 vol% TiN nanocomposite. Further SEM micrographs and EDS data corroborated the distribution and existence of TiN nanoparticles in the magnesiummatrix.

Key Words: magnesiumcomposite,hotextrusion,scanning electron microscope, hardness magnesium composite, hot extrusion,scanningelectronmicroscope,hardness.

Magnesiumanditsalloysareusedaslightweightstructural materialsfordifferentapplicationsinautomobile,aerospace, telecommunicationandelectronicindustries.Magnesiumis potentialmaterialforlightweightproductionandishighly prepared for strength to weight applications without compromisingtheoverallstrength.Itissixthmostabundant element in the earth crust (~2.7% of weight). Further magnesium based material are recently attracted for bio medicalapplication.Amongthemetalsmagnesiumandpure iron have excellent bio compatibility without any local toxicity.Magnesiumhaveloweryoung’smoduluswhichis closetohumanboneandalsoeliminatessecondarysurgery inbioimplantapplications.Lowmodulus,limitedductility and poor corrosion resistant, wear resistant and poor surface property are some of the inherent properties of magnesiumbasedmaterial whichrestrictstheirextensive applications

Magnesiumisthedensestmetalusefulforcriticalstructural and bio-medical applications. Magnesium based materials due to the low density offer high specific strength, high

stiffness, high thermal conductivity and diffusivity, good castability,goodmachinability,gooddampingcapacityand bio compatibility. The density of magnesium(1.74g/cc) is two third of aluminium, one third of titanium, one fifth of steelandiron

Selectionofreinforcementcanbeclassifiedtheyare

Basedonthetype

1. Metallicreinforcement

2. Ceramicreinforcement

Basedonsize

1. Micron(1×10^-6m-100×10^-6m)

2. Submicron(0.1×10^-6m–1×10^-6m)

3. Nano(1×10^-9m–100×10^-9m)

Generallyceramicreinforcementcanbegroupedintooxides, carbides,nitridesandborides.Theselectionofreinforcement allows to make new magnesium-based composites by reinforcingwithhardandinexpensiveceramicsormetalsfor the purpose of tailoring the properties. Addition of inexpensive nanoparticles to enable improvements in strength and ductility of magnesium-based composites withoutcompromisingthegaininweight

Processingofmagnesiummatrixcompositescanbe classifiedintotwotypes:

1.PrimaryProcessing a. Liquidstateprocessing b. Solidstateprocessing

2.SecondaryProcessing a. Hotextrusion

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

b. Hotforging c. Hotrolling d. Hotdrawing

Liquid state processing-processed by addition of reinforcementintoliquidmetal.

Conventionalcasting

Liquidinfiltration

In-situprocesses

Spraydeposition

Disintegratedmeltdeposition(DMD)

Solidstateprocessing-processingatatemperaturebelowthe solidus temperature of metal matrix. Example powder metallurgy

Themechanicalpropertiesofmatrixmetalandalloyshave been enhancing the strength by decreasing reinforcement particle size of particulate reinforced metal matrix composites(Barekaretal.,2009).Thealuminiumreinforced metalmatrixcompositehasbeenenhancingthestrength1540%,stiffness30-100%withsuperiorwearresistancethan the unreinforced aluminium and its alloys. But the reinforcement particles contribute a negative effect on matrix phase properties such as tensile strength, ductility and fracture toughness (Srivatsan et al., 2003). The mechanical and physical properties of metal matrix composites are tailored based on the interface region formation,whichdependsonthemanufacturingmethods. The region shared between the matrix and reinforcement phase is called an interface region in MMC. The interface regionbehaviorinfluencesthepropertiesofcomposite,soit isalsocalledthecriticalregion.Thesoundnessinproperties ofcompositesisassociatedwiththeinterfaceregiondueto theinterfacialchemicalreaction,poorwettabilityofmatrix withreinforcementparticle,degradationofreinforcement, etc.(Rajanetal.,1998).

S.C. Cifuentes et al (2017) [1] studied the thermal behaviour and mechanical behaviour of PLLA/Mg compositessynthesisedbyhotextrusion.opticalmicroscope, XRD,FTIRandDSCwasusedtocharacterisetheextruded samples.Fromtheresultsmicrostructure,thermalstability, heatflow,absorbancepeaks,deformationbehaviourunder compressionandyoung’smoduluswereobserved.

Chen Q et al (2016) [2] synthesisedtheMg-Nd-Zn(ZM6) alloy matrix reinforced with SiC particles using semisolid

thermaltransformationroute(SSTT)andrecrystallization and partial melting route (RAT). Microstructural and thermal properties of extruded samples was examined by Optical microscope, SEM-EDS, XRD and DSC. From the results micrographs, partial remelting of composite elemental composition, solidification and liquid fraction temperaturewereobserved.

Ganesh kumar and manoj gupta et al (2015) [3] synthesised the Mg (0.58,0.97 and 1.98) vol % of TiC nanocompositeusingDMDprocessingtechniquefollowedby hot extrusion at 350℃ with an extrusion ratio of 20.25 :1 using150tonhydraulicpress.mgturnings>99.9%pureand TiCparticlesof>98%pureandapproximately30-50nmsize wasusedinthisstudy.Thephysical,optical,microstructural andmechanicalpropertieswereexaminedbypycnometer, TMA (Thermo mechanical analysis), Optical microscope, FESEM,XRDandmicrohardnesstesterandservohydraulic testingmachine.fromtheresultsitwasconcludedthat,and comparedtopureMgtheexperimentalresultsexhibitedthe finegrainsize,increaseinmicrohardness,increasein0.2% TYS,UTSandfracturestrainofMgmatrixwithanadditionof TiC particles further Mg 0.97 TiC composite exhibited the maximumof0.2%CYSandminimumTCAcomparedtothat ofothercompositesamples

Kumar et al. (2013) statedthatthepuremagnesiumwas enhanced by adding Si as an alloying element and proved that the wear resistance of Mg–Si alloys increased with higher amount of Si addition and reduced when higher normal loadwasapplied.Theadditionof Sicontentin Mg decreasedthespecificwearrate.

Srinivasan et al. (2012) studiedandcomparedtheAZ31B magnesium alloy and the nano-composite of magnesium alloy reinforced with alumina and calcium, which shows lower wear rates due to higher hardness improvement in nano-composite.

Sun & Ahlatci (2011) mentioned that the Al-12SixMg/Mg2Si composite was studied and enhanced the mechanicalpropertiesandwearbehavior.Theadditionof different amountofMg and Mg2Si reinforcementin the Al increases the bulk hardness, compressive strength and wearsresistance.

Shanthi et al. (2010) investigated the dry sliding wear behavior of AZ31B/Al2O3 and AZ31B/Al2O3 (1-3) wt % Calcium nano-composites at a range of 1-10 m/s sliding velocity under 10 N constant loads and reported that the compositereinforcedwithaluminaandcalciumparticulate, dominate the higher wear resistance than composite reinforced with alumina particle alone in either lower or higherslidingspeeds.Theyalsoobservedthatabrasionand adhesion wear are the dominant wear mechanisms to transitionforthermalsofteningwhenitisslidingathigher speeds.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

Mondal & Kumar (2009) conductedaweartestunderdry sliding condition with a constant sliding velocity and distanceof0.837m/sand2.5km,respectivelybyvarying the applied load from 10-40 N. They reported that AE42 magnesium alloy reinforced with SiC particles and saffil short fiber hybrid composite has a lower wear rate than magnesium alloy and saffil reinforced composite samples. They also concluded that the presence of SiC ceramic particlesinthemagnesiumalloymatriximprovesthewear resistanceofhybridcompositematerial.

• TodevelopthepureMg&Mg-TiNnanocomposite usingpowdermetallurgyfollowedbyhotextrusion.

• TostudytheMicrostructuralpropertiesofpureMg &Mg-TiNnanocomposite.

• TostudytheThermalpropertiesofpureMg&MgTiNnanocomposite.

• TostudythePhysicalpropertiesofpureMg&MgTiNnanocomposite.

Materials

andpropertiesof

nitridepowdersareshownintable

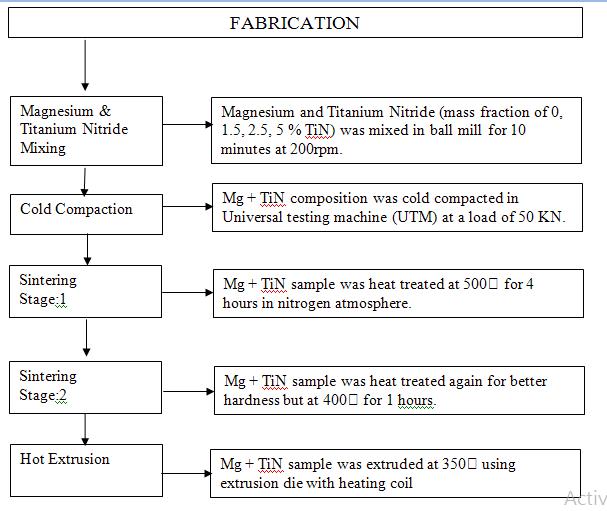

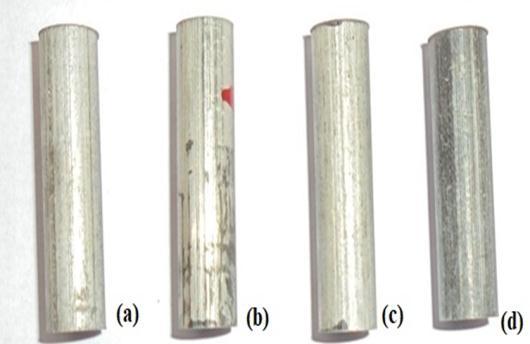

The synthesis of pure Mg and Mg matrix with differentproportionsof(1.5,2.5and5wt.%)nanosizedTiN ceramic reinforcement was done by powder metallurgy (solid state processing) incorporated with microwave sintering followed by hot extrusion. Finally, the 8mm extrudedsamplesarecutdowntorequiredlengthbyusing diamond saw for further characterisation studies. The sequenceofoperationinfabricationprocessandextruded samplesareshowninfig1.1(I)and(II).

Fig-1.(I) Extrudedsamples(a)PureMg,(b)Mg-1.5TiN,(c) Mg-2.5TiNand(d)Mg-5TiN

Fig-1. (II)SequenceofoperationinFabricationProcess

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

pressureof21psig(2.4611bar)forallsixcycles.usingrule of mixture principle, the theoretical density of Mg-TiN nanocompositesamplewascalculatedandcomparedtothat of true density (experimental density) values, The theoreticaldensityofpureMgandMg-TiNnanocomposite sampleswerecalculatedbyusingthefollowingequations. (1)

…….(Equation.1) Where, het isthetheoreticaldensitying/cm3 exp istheexperimentaldensitying/cm3 r isthedensityofreinforcement(TiN–5.22)ing/cm3 m isthedensityofmatrixmaterial(Mg-1.74)ing/cm3 rv isthevolumefractionofreinforcementincm3

FIELDEMISSIONSCANNING ELECTRONMICROSCOPE(FESEM)

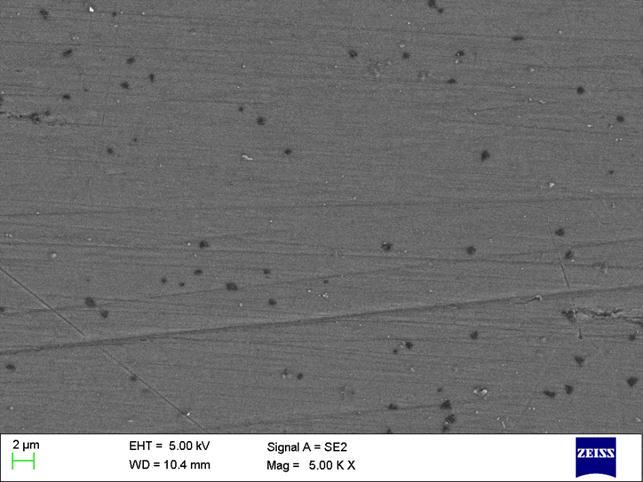

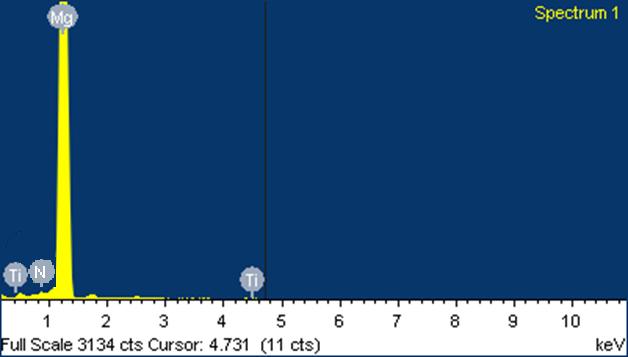

Sample for microstructure study was prepared using standard procedure for sample preparation, they were etchedusingacetic-picralagent.Microstructureexamination wascarriedoutusingaKARLZEISSUltra55fieldemission scanning electron microscope (FE-SEM). The microstructure of etched sample along with EDS spectrum presented in fig. 5 and fig.6 which shows that titanium nitrideparticlesdistributedinthematrix. Fig-5 FE-SEMofMg+2.5TiN

ThetruedensityMgalongsidehierarchicalMg-tin nanocompositemeasuredbyusingHeliumgaspycnometer. Each sample were run for six cycles to measure the true densitymoreprecisely.Pureheliumgaswaspurgedwitha

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

The goal of a compression test is to determine the behavior or response of a material while it experiences a compressiveloadbymeasuringfundamentalvariables,such as,strain,stress,anddeformation.Here,foursamplestaken inthenamesof1.5Mg,2.5Mg,5Mg,PUREMgforthissamples had been tested and based upon the stress-strain relationshipgraphvaluesarenoted.5Mghasbeenfoundthe bestcompressionvaluecomparewiththeothersamples

Table-3 TensileTest(N/mm2)Values

S.NO SAMPLE NO. TENSILE TEST(N/mm2) VALUES

EDSanalysisexposedthequantitativecomposition ofpureMg,Mg-1.5%TiN,Mg-2.5%,TiN,Mg-5%TiN.Further oxides(O)presencewasobservedin thePure magnesium. Thedistributionofmajorchemicalelements,includingMg, Ti,NandOwithinthemicrostructure,wastracedbyEDSto detectdifferencesinthechemistryofmicroregionsbetween thematrixandphase.Itisclearlyseenthatthecenterofthe Mg grain contains small traces of Ti, N and O. The compoundsarealmostthestoichiometricproportionofthe phase,whichcontainstheelementsofMg,TiandN COMPRESSION

1 1.5Mg 108 2 2.5Mg 85 3 5Mg 30 4 PUREMg 60

Acompressiontestisconductedinamannersimilartothe tensile test, except that the force is compressive and the specimen contracts along the direction of the stress. Here,foursamplestakeninthenamesof1.5Mg,2.5Mg,5Mg, PUREMgforthissampleshadbeentestedandbasedupon the stress-strain relationship graph values are noted.5Mg has been found the best compression value compare with theothersamples

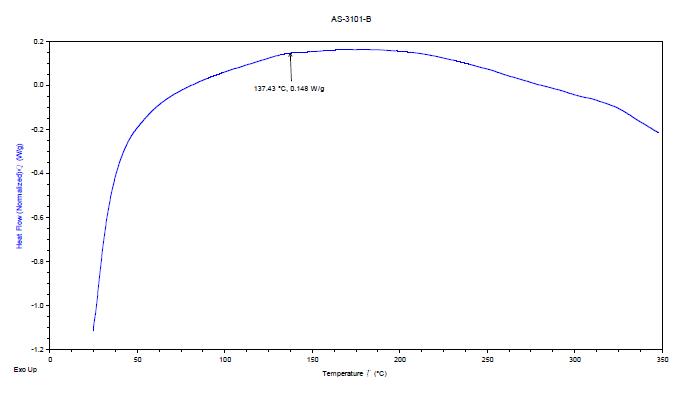

Graph-1 DSCgraphshowstheglasstransition temperatureofMg+5TiN

DSC graph shows the glass transition temperature, Tg at 137.430C and weight loss of (0.148w/g) was observed in Mg+5TiN.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

Pure Mg & Mg-TiN nanocomposite was successfully fabricatedbypowdermetallurgyfollowedbyhotextrusion and SEM results exposed the micrograph, distribution of TiNnanoparticlesinMgmatrix.InSEM resultsMg+2.5TiN hasfoundthebestvaluesforWeight% aswellasAtomic% comparedwithothersamples.InCompressiontest,among the four samples ‘5Mg’ will be the best compression value(N/mm2). In Tenslie test, among the four samples ‘1.5Mg’ will be the best tensile value(N/mm2). DSC graph showsthebest glasstransitiontemperature,Tg at137.430C andweightlossof(0.148w/g)wasobservedinMg+5TiN.

EDSresultsconfirmedthatTiNpresenceinMgmatrixand also quantitativecompositionalofMg-TiNnanocomposites was recorded and DSC results reveals that composite samples exhibits the weight loss values of 0.57, 0.49 and 0.148w/grespectively.

1. Cifuentes SC, Lieblich M, López FA, Benavente R, González-CarrascoJL.(2017)‘EffectofMgcontenton the thermal stability and mechanical behaviour of PLLA/Mg composites processed by hot extrusion’. MaterSciEngC,72:18–25

2. ChenQ,ChenG,HanL,HuN,HanF,ZhaoZ,etal. (2016) ‘Microstructure evolution of SiCp/ZM6 (MgNd-Zn)magnesiummatrixcompositeinthesemi-solid state’.JAlloysCompd,656:67–76.

3. MeenashisundaramGK,GuptaM.(2015)‘Synthesis andcharacterizationofhighperformancelowvolume fractionTiCreinforcedMgnanocompositestargeting biocompatible/structuralapplications’.MaterSciEng A,627:306–15.

4. Tekumalla S, Nandigam Y, Bibhanshu N, RajashekaraS,YangC,SuwasS,etal.(2018)‘Astrong and deformable in-situ magnesium nanocomposite ignitingabove1000°c’.Naturematerials,8(1):1–10.

5. MeenashisundaramGK,NaiMH,AlmajidA,Gupta M.(2016)‘Reinforcinglow-volumefractionnano-tin particulates to monolithical, pure MG for enhanced tensileandcompressiveresponse’.Materials(Basel), 9(3):1–21.

6. Manakari V, Parande G, Doddamani M, Kumar Meenashisundaram G, Gupta M. (2017) ‘Enhancing significantlythedampingresponseofMgusinghollow glass microspheres while simultaneously reducing weight’.AdvMaterLett,8(12):1171–7.

7. Kozak, K. P. Rajurkar and S. Z. Wang. (1994) “MaterialRemovalinWEDMofPCDBlanks”,Journalof EngineeringforIndustry,Vol.116,pp.363-369.

8. Y. S. Tarng, S. C. Ma and L. K. Chung, (1995) “DeterminationofOptimalCuttingParametersinWire ElectricalDischargeMachining”,InternationalJournal ofMachineTools&Manufacture,Vol.35,No.12,pp. 1693-1701.

9. M. T. Yan and Y. S. Liao, (1996) “Monitoring and Self-Learning Fuzzy Control for Wire Rupture Prevention in WEDM”, International Journal of MachineTools&Manufacture,Vol.36.No.3,pp.339353.

10. J. Prohaszka, A.G. Mamalisand N.M. Vaxevanidis, (1997) “The effect of electrode material on machinability in wire electro-discharge machining”, Journal of Materials Processing Technology, Vol. 69, pp.233-237.