International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

1Professor, Faculty of Agril Engg & Tech, (C.S.A. Univ of Agri & Tech, Kanpur) Campus Etawah, U.P. 2Faculty, Department Civil Engineering, Kamla Nehru Institute of Technology, Sultanpur, U.P. ***

Abstract - Corn has been called the "Queen of Grains" and "King of Fodder" which is used for industrial products and for human and animal feed. Traditionally, corn shelling was done mechanically by small and marginal farmers in the corn-prone region of Uttar Pradesh in India, either by rubbing corn on each other or shelling the grains by using fingers. Sometimes cylindrical tools with wire mesh are used for shelling the corn grains. All these methods are tiresome and time consuming. Here in this paper power operated Corn-Sheller is developed and its performance is evaluated for its shelling capacity and shelling efficiency. The corn shelling machine consists of a hopper, cylinder and a concave with chain spikes that rotate inside the cylinder to separate the grain from the cob. The shelling capacity of machine is reported to be 973kg/h with a shelling efficiency of 97.37%. The output rate of the corn shelling machine was around 577 kg/h. This corn-sheller is robust, cost effective and can be easily made by local artisans.

Key Words: Corn,Corn-sheller,cornshellingefficiency.

Cornisarichsourceofstarch(60–80%),protein(8–12%), fat (3–5%) and minerals (1–2%) (Hosmani et al., 2000). India is the fifth largest producer of maize in the world contributing3%oftheglobalproduction.Withgenetically improved varieties and production/conservation technologiesthroughAllIndiaCoordinatedResearchProject (AICRP) since 1957, maize is now grown in India in all seasons i.e., Kharif, Rabi and Summer. The major maize producingstatesofIndia,whichcontributemorethan80% ofthetotalmaizeproduction,areAndhraPradesh(20.9%), Karnataka(16.5%),Rajasthan(9.9%),Maharashtra(9.1%), Bihar(8.9%,UttarPradesh(6.1%),MadhyaPradesh(5.7%), andHimachalPradesh(4.4%).

Maize yields for varieties like Hybrid (Navjot, Naveen, Shweta,AzadUttam,Kanchan,Gaurav)andHybrid(Prakash, JH3459,PusaAgateiHybridMaize,Deccan-115,MMH-133, Pro-4212,MalvianHybridMaize-2,HQPM-15)variesfrom 35-40Q/haforSankuland35-50Q/haforhybrids.(Source: AgricultureDepartment,UttarPradesh).DistrictKannaujin Uttar Pradesh is the leading district in corn production accountingfor9.75%ofIndia'scornproduction.Thetopfive other regions are Mainpuri, Bahraich, Bulandshahr, Farrukhabad and Etawah districts. (Source: Krishi Vigyan Kendra,Etawah,UttarPradesh)Mechanizationofthreshing is gaining more importance in recent times. Due to the

increasing importance of mechanized threshing, several typesofthresherswereintroducedandevaluatedacrossthe country. These include spike tooth type, chaff cutter type, syndicatortypeand beatertypecommonlyusedinIndian farmsforthreshingofspecificcrops.Electricpoweredcornshellers have been popularized to take care of corn crops grownbysmallandmarginalfarmerstoreducethecostof operationandtime.Cornkernelsaredifficulttobreakorcut fromthecobwhenmoistureismorethan25percent.With thismoisturecontent,thegrainseparationefficiencyisvery poor,withhighoperatingenergyandmechanicaldamageto thekernels.Whenthegrainhasamoisturecontentof13to 14%, more efficient shelling is achieved. In order to get better performance from shelling machine, a certain relationship exists between sheller speed, concave and cylinderclearancewithrespecttocroptype.Consideringthe abovefactors,astudywasconductedtosurveythevarious threshing/shellingmethodsusedbyfarmersforcornandthe suitability of various power operated corn-shellers in the contextoftheprevailingsocioeconomicconditionsinUttar Pradeshwasevaluated.Hereinthispaperthecornshelling machineisdesignedandmanufacturedwiththenecessary safeguardsforitsperformanceevaluationfollowingpower threshers – safety requirements (IS 9020:2002), Indian StandardTestcodeforpowermaize-shellers(IS:7052-1973 –reaffirmed2012)andRNAMTestcodes&proceduresfor farmmachinery.

Theshellingisaccomplishedbyshearingbyrotatingpegson thecylinder,whichliftthegrainoutofthecorncobsholding it.Differentgraincropsanddifferentvarietiesofthesame grain crop have different characteristics, which require differentspeedofthecylindertoachievethebestresultof shelling,sotheadjustmentofcylinderspeedandappropriate feeding of cob is necessary. For comparison of power operated corn-shellers, different shelling methods were adoptedsuchas hand-sheller, hand-held-shellerand pedal operated corn-sheller. The Power Operated Corn-Sheller consistedofahopperthatwasfabricatedintoatrapezoidal shape of mild steel sheet of 18-gauge thickness and had dimensionsof508mminlength,508mminwidthand228.6 mm in height. Hopper is a main important part of the machinewhichisprovidedinthemachinetofeedthecornto shelling. Main frame structures are generally used to overcome the large moments developed due to applied loading. The main frame is made of angle iron of 5mm thickness.Thedimensionsoftheframeare1000×541×767

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

mm.Theshellingtoolusedissixtosixchainspikesonboth sides of the main shaft as shown in Figure 1 for high productionratesanduniformshelling.Thechainspikeshave alengthofabout158mm.AsshowninFigure2,theflatsof cylinderandbearingsweremountedontherotorshaft.The standardsizeandlengthoftheshaftwasselectedbasedon thedesignoftheshaft.Apulleywasinstalledtogivedrive fromthemotortotheshaft.Twoballbearingsweremounted inthebearinghousingonthemachine.Theinnerdiameterof the bearing is 25.4 mm. It runs over a pulley having a Vshapedgroove.TheB62v-beltisselectedaccordingtothe sizeoftherequirement.Therequiredlength,width,heightis 1660mm(62inches’innercircumference),17mm,11mm. The1HPsinglephaseand1440rpmelectricmotorisusedto operatethemachine.Thecollectingtrayisthelowerpartof themachinewhichisusedtocollectthecorngrainsafterthe shellingprocess.ThisismadeofGIsheet.Safetyguardisthe upperrightpartofthemachinewhichismadebyfibersheet supportedonironframe.Thespecificationsofcorn-sheller are shown in Table 1 and Annexure A. The required important formulae and parametric relations are given at AnnexureB.

Serial No.

Particulars

1. Typeofmachine

2. OverallDimension

Specifications

CornSheller

Length(mm) 1368.00 Width(mm) 541.02 Height(mm) 769.20 Weight(Kg) 150.00

3. Powerunit

Powerunit ElectricMotor HorsePower(HP) 2 Revolutionperminute(rpm) 1440

4. Pulley

NumberofPulley(mm) 2 DiameterofdrivingPulley(mm) 90 DiameterofdrivenPulley(mm) 228.6

5. Perforatedconcave Length(mm) 635 Width(mm) 297 Clearanceb/wrods(mm) 22.6

6. Bearing

Typeofbearings BallBearing Numberofbearings 2 Diameterofbearings(mm) 22.86

7. Shaft

Numberofshafts 1(main transmission shaft)

Diameterofmainshaft(mm) 31.75

8. Belt Size(m) 1.6 9. Hopper Capacity(kg) 10-12

11. ShellingTool

Type

Locally available corn was taken and its moisture content was assessed in laboratory with ambient temperature on variable dates and corn-sheller was tested on various parameterssuchasfeedrate,productionrateandshelling efficiencyatvariablespeedofmotorasshowninTable2.It hasbeenobservedthatboththefeedrateandtheproduction rateincreaseasthemotorspeedincreases,buttheshelling efficiency is variable which is dependent on the ambient temperatureandmoisturecontent.

Cylindricalbar havingtwelve chainspikes

Lengthofchainspikes(mm) 157.48

12. Collectingtray Length(mm) 800

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

Observations Quantity of dry corn (k g) Speed of motor (rpm) Time taken (sec)

Threshed grains (kg) Weight of cobs (kg) Unbroken grains, kg Broken grains, kg Feed rate, kg/h Production rate, kg/h Unbroken efficiency, % Unthreshed grains, kg Shelling efficiency, %

Obs.1:with28% moisturecontentand 42.40C,dtd21.5.2019 0.5 1000 3 0.350 0.130 0.344 0.006 600 420.00 98.40 0.020 98.28

Obs.2:with31% moisturecontentand 39.20C,dtd22.5.2019 1.0 1100 5 0.720 0.240 0.708 0.012 720 518.40 98.11 0.040 97.50

Obs.3:with26% moisturecontentand 40.30C,dtd25.5.2019 1.5 1200 7 1.170 0.280 1.125 0.045 772 602.00 96.15 0.050 99.50

Obs.4:with34% moisturecontentand 380C,dtd28.5.2019 2.0 1300 8 1.416 0.460 1.358 0.058 900 637.20 95.90 0.124 95.40

Obs.5:with23% moisturecontentand 42.40C,dtd28.5.2019 1.0 1440 4 0.758 0.180 0.748 0.010 900 682.20 99.07 0.062 96.19

Averagevalue 973 571.96 97.53 0.059 97.37

Table -3: Performanceparametersundervarioustreatments

Treatments No. of Labor required Wages per day of 8 h Total a mo unt ( Rs) Shelling capacity kg/h Output capacity(Kg/h) Shellingefficiency (%) Moisture content (%) Visual damage(%) Unshelled cobs (%) Cost of operation(Rs/qtl)

T1 1 250 250 12.50 12.40 100.00 13 0.0 0.00 250.00 T2 1 250 250 18.30 17.90 100.00 13 0.1 0.00 168.92 T3 2 250 500 74.60 74.10 95.92 13 0.5 0.55 83.78 T4 2 250 500 973.00 576.91 97.37 13 1.0 0.12 06.42 T1-Handshelling,T2–Hand-held-sheller,T3-Pedaloperatedcorn-sheller,T4-Poweroperatedcorn-sheller

Trialswereconductedforfourdifferenttreatmentswith thesamesamplesizeasmentioned.Theresultsoftheeffect of treatment on shelling efficiency (%), output capacity (kg/h),visibledamage(%),unshelledcobsefficiency(%)and cost of operation (Rs/qtl) are presented in Table 3. Parametric observations reveal significant variations in parameters such as shelling capacity (feed rate), output capacity (production rate) and cost of operation under

different treatments. The power operated corn-sheller's shelling capacity is many times higher than that of other treatments.Althoughtheshellingefficiencyofhand-sheller and hand-held-sheller is 100%, it is drudgeries and time consumingcomparedtopoweroperatedcorn-shellerwhich hasanefficiencyof97.37%.Thecostofoperationofshelling cornhasbeengraduallyreducedfromRs250perquintalto Rs 6.42 per quintal while switching from hand-sheller to hand-held-sheller,pedaloperatedshellertopoweroperated corn-sheller ignoring other inputs like electricity consumptionchargeswhilegoingforeconomicanalysis.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page347

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

TheperformanceofPowerOperatedCorn-Shellerwasfound to be better during testing with the following findings as comparedtoconventionalhandshelling,handheld-shellers andpedaloperatedshellers:

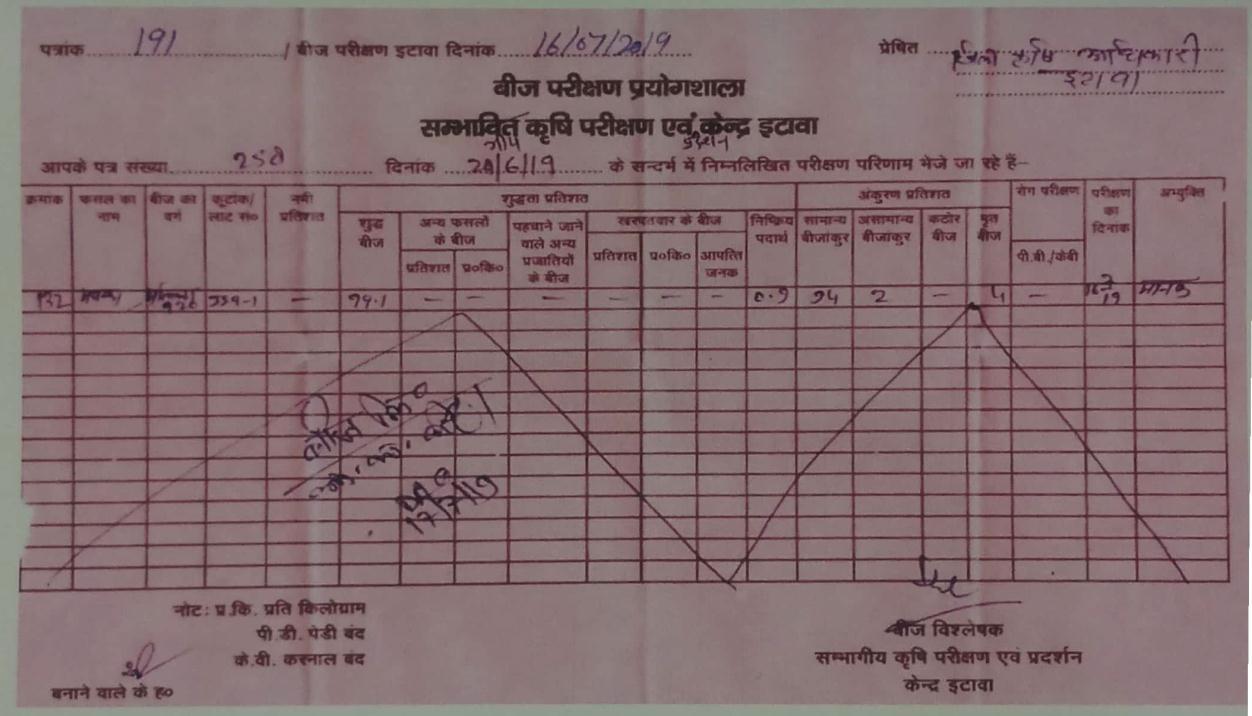

Thesampleofcorngrainshelledoutbythepoweroperated corn-shellerwassenttoSeedTestingLaboratory,Regional Agri-Testing and Breeding Centre, Etawah, India, for germinationtesting.Thetestreportisattachedbelowwith thepurityoftheseedbeing99.1%and0.9%impureseed.

ThegerminationtestbytheStateGovernmentSeed TestingLaboratoryshowsthepurityoftheseedas 99.1%and0.9%asimpureseed.

The performance of the power operated cornsheller was better than other traditional shelling

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

methods as the productivity increased with negligibletotalloss(damaged+unpeeledgrains).

The shelling efficiency of power operated cornshellerwas97.37%.

[7] Anonymous,1986,ConsolidatedFinalreport1975-1986 of Operational Research Project on Post-Harvest Technology(Coimbatorecentre):72-78.

[8] Anonymous,2005a,PAUProgressReportofAICRPon FIM.PAU,Ludhiana.

Thefeedrateofpoweroperatedcorn-shellerwas about973kg/h.

Theoutputrateofthecorn-shellerwasaround577 kg/h.

[9] Lee Sum-Ping. Mafu Li., 2008, Transactions of differential design of thresher Corn Seed [Papers]AgriculturalMachineryin(08).

Noun-shelledcobswereleftinthecorn-shellerasit isbestsuitedforlowmoisturecorns.

The use of chain spikes is beneficial for better removalofcorngrainsfromthecobs.

The author is thankful to Shri Sarvesh Tripathi, Lab Technician(welding)andB.Tech.students,viz.AjayKumar, Akanksha Upadhyay, C.P. Singh, Prashant Kumar, Gargi Awashthi and Akash Singh, for their contribution in designingandfabricationofprototypepoweroperatedcornshellerforitsperformanceevaluationundermysupervision. The author also gratefully acknowledges the UPCAR, Lucknow,forfinancialsupportunder"CentralofExcellence in Farm Machinery". We acknowledge Seed Testing Laboratory, Regional Agri-Testing and Breeding Centre, Etawah,India,fortheirkindsupportandhelpingermination testingofcornshelledsamples.

[1] Abdul Kadir Baba Hassan, et al., 2009, Design and ConstructionofMaizeThreshingMachineAUJ.T.12(3): 199-206.

[2] Agrawal.K.N.,2006,ErgonomicalEvaluationofPlastic covered Tabular Maize Sheller. Agro-Processing Division,Central Instituteof Agricultural Engineering, NabiBaghBerasiaRoadBhopal-462038.

[3] Ahmad Muhammad Danfulani., 2009, Design and construction of a maize Sheller. Nigerian defence academyKaduna7622.

[4] Ajav, E.A., and J. C. Igbeka., 1995, Performance evaluationofaNigeriancornSheller.

[5] Akubuo C O., 2002, Performance evaluation of a local maizeSheller[Papers]-BioSystemsEngineering.

[6] Alka Singh, U. S. Gautam, Surendra Pannase and Anju Singh., 2010, Ergonomic Evaluation of Farm Women duringMaizeShelling.IndianRes.J.Ext.Edu.Vol.10(3).

[10] Lee Sum-Ping. Mafu LI., 2009, Transactions of mechanical damage of the maize seed germination [Papers]-AgriculturalMechanizationResearch(03).

[11] Liao, K; M. R. Paulsen; and Reid J. F., 1994, Real- time detectionofcolourandsurfacedefectsofcornkernels using machine vision. J. Agril. Eng. Res. 59 (4): 263 –271.

[12] Mady, M. A., 2012, Development and evaluation of a poweroperatedcornSheller.SoilandWaterDept.,Fac. ofAgric.,SuezCanalUniversity,Ismaielia,Egypt.

[13] Pavasiya Uttam N., Patel Hardik., 2018 Design and Fabrication of a Motorized maize shelling machine. BabariyaInstituteofTechnology.

[14] Suzuki, M., 1990, Economic evaluation of appropriate agriculturalmachineryinIndonesia.Japanagricultural ResearchQuarterly2994):276-281.

[15] Singh, S.P, and Gite, L.P., 2007, Technical bulletin No. CIAE /128, Women friendly improved farm tools and equipment.PublishedbyCIAE,Bhopal.56p.

[16] Singh, SP.,2005, Ergonomical EvaluationofManually OperatedCleaner-Graders,FertilizerBroadcaster,Seed DrillandHandRidgerwithfarmWomen.FinalReport. NRCWA(BhopalSubcentre),CIAE,Bhopal:31p.

[17] Singh, S.P,Gite,L PandAgarwaL,N.,2006,Improved farm tools and equipment for women workers for increasedproductivityandreduceddrudgery.Gender, TechnologyandDevelopment.10(2):229-244.

[18] Singh,SandPandey,M.M.,2008,XPlanachievements (2002to2007).TechnicalBulletinNo.:CIAE/2008/137. AICRPonFIM,CIAE,Bhopal:38-39.

[19] Singh,S.,2008AfarmmechanizationscenarioinIndia. PaperPresentedinAllIndiaNationalSeminaronStatus of Farm Mechanization and Farm Equipment ManufacturingatCTAE,UdaipuronMarch15-16.

[20] SinghSP,andPratapSingh.,2010,HandOperatedMaize DehuskerShellerforFarmWomen.Vol.34(1):152-154.

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page349

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

[21] SolankiN.,RamtekerT.,andGitelP.,2006,Evaluationof HandOperatedMaizeShellers.J.AgriEngg.Vol.43(4): 125-128.

[22] Swapan K Roy, Mike Albu and Abdur Rob., 2007, BusinessRationaleforInvestmentonPowerOperated Maize Sheller in Bangladesh. Agricultural engineering international:CIGRJournal,volumeIX.

[23] Tajuddin, T and Karunanithi., 1996, Comparative performance evaluation of different hand operated maizeshellers.J.AgriculturalEngg.vol.20:(1-4).

[24] Tastra, I. K., 2009, Designing and testing of improved maizeSheller,AgriculturalMechanizationinAsia,Africa andLatinAmericaVol.40(1)pp.12-17,31.

[25] V.B.Bhandari,Designofmachineelements.

Annexure A

A. Specifications

1. Typeofmachine–Corn-sheller

2. Manufacturer'saddress–B.S.Dr.B.R.A.C.A.E.T., Etawah-206001

3. Market price – US$ (292.50) (Local currency 20,352) Year2018-19

4. Nameofcropsforwhichthemachineissuitable–Corn

5. Weight in kg. (i) Overall: 150 kg (ii) at transportation: 150kg

6. Powersource–Electricity

7. Powertransmissionsystem–Pulleysandbelt

8. Threshingdrumorcylinder

i. Type–Chainspikestype

ii. Diameterofdrum–457.20mm

iii. Lengthofdrum –635.00mm

iv. Ratedrevolutionspeedofdrum–560rpm

v. Number and size of wire loop – 12 chain spikes and 5 mm thickness &157.48 mm length.

9. Labourrequirementforfeeding,supplyofcropto feeder(s),collectingandbagginggrain,disposalof otheroutlets–1Persons(max.2persons).

10. Outputcapacity(announced)kg/hr.–577kg/h

PoweroperatedCorn-Sheller

Dateofverification:25May2019, Venue:Etawah,U.P.

Particulars Performancetests

Dateoftest 25May 2019 27May 2019

Locationoftest Etawah Etawah

A. Testconditions

I. Conditionofcorn Dry Dry (1) Nameofcorns Mallika Mallika (2) Varietyofcorns NMH920 NMH920 (3) Lengthofcorn (cm) 15-20 15-20 (4) Moisturecontent (%) 26 32

(5) Percentageof brokengrains 1.16% 3.02%

II. Conditionofmachine

(1) Revolutionspeed primemoverno load(rpm)

1440 1440 (2) Threshingdrum, noload(rpm) 560 560 (3) Peripheralspeed ofthreshingdrum (rpm)

520-530 520-530

III. Conditionofoperation

(1) Nameofprime moverandfuel Electric motor,& Electricity

Electric motor,& Electricity (2) Feedingmethod Manual feeding Manual feeding (3) Numberandrole oflabourers Two laboursfor feedingand collecting

IV. Conditionoflabour

Two laboursfor feedingand collecting

(1) Skilloflabour Lessskilled Lessskilled (2) Wagesoflabour (local currency/day)

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page350

Rs250-350 Rs250-350

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

V. Ambientconditions

(1) Temperature 40.10C 380C

(2) Relativehumidity (%) 45% 48%

(3) Windvelocity (m/s) 4m/s 4m/s

(4) Weather(sunny, cloudy,hot,cold, etc.)

Sunny Sunny

VI. Methodofmeasuring powerconsumption P= 2πNT/60 P= 2πNT/60

B. Performancetest

(1) Actualoperating time(min) 60min 60min (2) Timelostowingto a) Adjustments (min) 05min 05min b) Others(min) 05min 05min (3) Powerrequired a) Fornoload (kw) 0.5–0.6kw 0.5–0.6kw b)Forload(kw) 0.7-1.5kw 0.7-1.5kw

Discussion:

Machine aspect: The handling of machine is quite easy. It doesnotrequireanyeducationalskillsforitsoperation.

1. Cropaspect:Themachineissuitableforonlycorn shelling.

2. Field operation: The machine requires minimum one or maximum two labour at a time to do the operations. The working capacity of machine is approximately900kg/hour.Themachinerequires anelectricmotorof1hp.

3. Machine Cost: The total manufacturing cost of machineisRs20,352/-

4. Summaryandconclusions

a. Theperformanceofpoweroperatedcornshellerwasbetterthanmanuallyoperated Corn-Shellerbecausetheproductivityhas increasedandthetotallosses(damaged+ un-threshedgrains)haddecreased.

b. Thethreshing/shellingefficiencyofpower operatedcorn-shelleris97.37%.

c. The feed rate kg per hour of power operatedcorn-shellerisapproximately900 kg/h.

d. The un-threshed grain % by power operated corn-sheller was lower than manuallyoperatedcornshellingmachine.

1. Capacityofmachine,C=W/t,kg/h whereW=weightofcorncobfedinthehopper,kg;andt= timetakenforshelling,h

3. Percentageofunshelledgrain= 100(Quantityofunshelledgrainobtainedfromalloutlets inkg)/Totalgraininputsinkg

5. Energyconsumption, where =specificenergyforshelling,Wh/kg;Q= throughputofthemachine,kg/h, =wattmeter reading(average)atload,W; =efficiencyofprimemover atload(assume0.9); =wattmeterreading(average)at no-load,W;and =efficiencyofprimemoveratno-load (assume0.5)

7. Diameterofshaft,D3 =16/πSs[(Kb×Mb)2 +(Kt×Mt)2]1/2 Assuming,Kb,Ktas2andfactorofsafety2

9. Powerrequirementofmachine =T×ω

2. Shellingefficiency,ηt =[Wg/(Wg +Wu)]×100 whereWu=weightofunshelledcorn,kg;andWg =weight ofgrain,kg

4. Specificenergyrequirement,E=K/W, whereE=energyrequirementperkgofcorncobs, kWh/kg;K=energymeterreading,kWh;and W=weightofcornshelled,kg.

6. Volumeofshellingchamber

Determinationofspeedofdrivenpulley, Anglesoflap, α 1 =180 0 -2sin -1 [228.6-88.9)/2560]

Lengthofthebelt,L=2x+ Velocitiesofdrivinganddrivenpulley /60, /60

8. Powerrequiredtodrivethethreshingbar, =T×ω