International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

Madhu A S1 , T raghavendra2

1P G Student, Department of civil Engineering, R .V college Bengaluru, Visvesvaraya Technological University, Karnataka, India

2Associate professor, Department of civil Engineering, R.V college Bengaluru, Visvesvaraya Technological University Karnataka, India ***

Abstract - In the present study, an attempt is made to understand the Performance of warm dense bituminous mixes by conducting, indirect tensile strength and tensile strength ratio.VG-30 is used as binder and Sasobit as WMA. DBM -IImix is selectedfor the present study. The recycled pavement material (RAP) was added at different percentages to the conventional DBM-II mixes. Integrating WMA, and RAP inbituminousmixesoptimizestheadvantages towards durableandsustainablepavements.

Key Words: Recycled pavement materials, DBM, Sasobit.

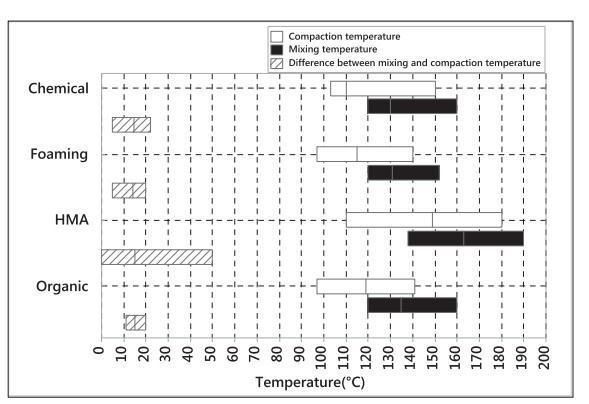

An asphalt mix method that is environmentally friendly, inexpensive,economical,andprotectiveofpeople'shealth and safety is necessary for sustainable road construction practises. Hot Mix Asphalt (HMA) technique is used in India and many other nations to buildasphalt roads. HMA hasanumberofdrawbacks,includinghighmanufacturing temperatures (155°C to 165°C), which raise GHG emissions.These gasescontribute toglobal warming and have a negative impact on paving crew members' respiratory systems. When compared toHMA, Warm Mix Asphalt technology can lower the temperature of mixing and compaction by about 30°C. WMA provides various benefits over HMA, including decreased emissions, better site visibility, and more use of reclaimed asphalt pavement[1].

Bitumen, fine and coarse mineral filler, and continuously graded aggregates make up dense grade asphalt. When hot, it is laid and compressed. In order to account for the greater traffic loading, highways, major, industrial, and distributorroadstypicallyutilizeastiffer,denser gradeof asphalt. Dense-graded mixes that have been properly planned and built are largely impermeable, making them appropriate for all types of traffic and pavement layers. The size of the majority of the aggregate particles in the mix distinguishes the two types of dense-graded mixes fine-graded and coarse-graded. Both surfaces and asphalt repairs can be made with these mixtures. Mixtures of

dense graded airport asphalt developed by Marshall typicallycomprise5.4to 5.8%ofbitumenand4to 6% of aggregatesthatpassthroughsievesizeof75µ.

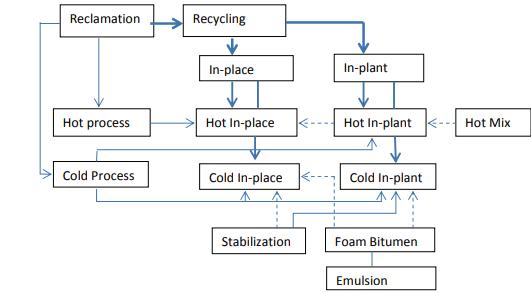

A technique that is currently under research but has shown to be very promising from an economic and environmentalstandpointis warmmixrecycled[1]asphalt with bitumen emulsion. By increasing the amount of recovered materials and enabling recycling at lower temperatures,thistechniqueconservesenergyandlowers CO2 emissions.Itmakesitpossibletomakeuseofthebasic materials already present on the worn-out pavement and touselessenergytocreatethenewcombination[2].

Thereareseveraladvantagestorecyclingextensivelyused binders of asphalt into fresh asphalt pavements. The production of recycled asphalt mixtures using RAP and recycled asphalt shingles (RAS) along with manufactured waste asphalt shingles (MWAS) and tear-off asphalt shingles (TOAS), can be cost effective, maintain depleting natural resources, save priceless landfill space &benefit the environment. While retaining acceptable pavement durability, it is difficult to mix the materials in significant amounts obtained from RAS and RAP into new asphalt pavements[4].

Heat between 150°C and 190°C is used to mix and compact conventional HMA.The main objectivesof using

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

the WMA are to conserve fossil fuels and reduce energy demand and GHG emissions. As a result, the researchers havecreatednewWMAtechnologiesforasphaltmaterials that require lower production temperatures. The same goals lower binder viscosity, increased workability, and decreasedemissionsaresharedbyWMAsolutionsdespite therelativelywiderangeof options availabletothemand the variety of ways in which they can function[6]. When compared to HMA, which must be mixed and compacted at temperatures ranging from 140 &160 degrees Celsius, WMA is a mixture whose performance attributes are not considerablyaffectedbythelowertemperatureatwhichit can be done. The effectiveness of WMA technologies in reducing energyuseandemissionsduringproductionhas been demonstrated. WMA is currently produced using a variety of additives and foaming techniques. A scientific classification is important because WMA technologies come in so many different forms. WMA technologies are now categorized in a variety of ways, and one popular system among them is on the basis of classification of additives. And this methodology allows for the classification of WMA technologies into three groups: organic additive technology, foamed bituminous technologies,andchemical additivetechnologies[7].

Foamex a foam based additive wasdeveloped by Mobil of Australia, where steam was substituted with 1-2% freezingwaterintohotasphaltin1968.Toavoidstripping problems, sufficient water needs to be added during process of foaming. Shell Bitumen filed a patent in 1995 for a two-component binder system known as WAMFoam, which made use a soft binder and a hard foamed binder at varying stages of plant production. Aspha-min, Advera, WAM -Foam, Terex, Gencor, Ultrafoam GX, Stansteel,andAquablackTMarefewofthe water-foaming WMAtechnologies[16].

The additives here are mixed with the binder or directly added to the asphalt mixture. Generally, organic additives meltbetween80° to120°C andtheymodifytheviscositytemperature interaction of the asphalt binder chemically. They are a long chained synthetic wax formed in the presence of a catalyst using the Fischer- Tropsch paraffin waxprocessbytreatinghotcoalwithsteam.Theviscosity ofthebinderisreducedby paraffinwaxanditalsoallows mixing at lower temperature. Selection of suitable additives must be carefully done such that the melting point of the additive is greater than the in-service mix temperature and also care should be taken that at low temperatures, brittlementof asphalt mixtures is reduced.

lists organic based additives such as Evotherm, Sasobit, EcoflexAsphaltan-B,andfattyacidsamides[16].

Conventional Aggregate: Basic physical examinations wereperformedinaccordancewithIS:2386-1963-PartIII & Part IV [18-19], 2386-1963-Part I [17]. Granite aggregates using thicknesses that range from 26.5 mm to 4.75 mm, according to MORTH, 2013[22], are utilized in the asphalt mixtures. Sieve analysis is performed in accordancewithIS:383-1978[21].

Binder : Bitumen VG30 grade (60/70) was used for the investigation and its fundamental characteristics were examinedinaccordancewithIS73:2013[22].

Recycled materials: Itwasretainedona26.5mmfilter was employed. Basic physical testing was done using IS: 2386-1963-Part I [17], IS: 2386-1963-Part III& Part IV [19][20]. The MORTH-V revision,2013 [21] states that the coarse particles used in asphalt mixes range in size from26.5mmto4.75mm

Sasobit was used as an organic WMA addition and was purchased from Sasobit Industries India. The bituminous mix for this investigation had 3 percent of these additives addedto it perthesupplier's instructions. Sasobit is a synthetic hard wax which is ideal for the production of warm mix asphalt plus it enhances workability,reducesruttingandextendsservicelife.[16]

The RAP materials were subjected to solvent (benzene) extraction method by centrifuge extractor as per IRCSP11:1988

According to IS:2386-1963-PART VI (mechanical propertiesofaggregateandIS:2386-1963-PARTI(partical size and shape ),the properties of aggregate are listed below.

Table 1 : Mechanical properties of aggregate

Properties (%)

Limits as per MORTH (V) revision

Impactvalue 27 Crushingvalue 24

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

Specificgravity (a) Coarse (b) fine 2.5-3

Combinedindex 30

Bitumen VG30 grade (60/70) was used for the investigation and its fundamental characteristics were examinedinaccordancewithIS73:2013.

Table 2: properties of bitumen

properties Limits as per MORTH Test method

Penetration in mm 60-70 IS-1203:1978

Softening pt in degree Celsius 45-50 IS-1205:1978

Ductilityincm 75 IS-1208:1978 Specificgravity 0.99 IS-1202:1978

Superpave, Marshall and Hveem mix design procedures are commonly used around the world. Almost all WMA studies have used a mix design protocols comparable to traditional HMA, but also, minor changes to HMA plant mayberequiredforWMA.Asphaltmixdesignmethodsfor WMAincludefivemajorchoices-a)selectionofmaterials, bindergrade&typeofaggregates,b)additionaladditives, c) gradation of aggregates, d) curing and conditioning of WMA mixing and e) mixing & compaction temperature. Following this, volumetric analysis, optimum binder content determination, and workability assessment are performed. Range of production temperature of HMA and WMAtechniqueareshowninfig2[23].

Table 3 : Specification of aggregate gradation for DBM Grade II as per MoRTH-V revision

IS sieve (mm)

FIG. 2 Range of production temperature of WMA technique

% Passing for middle limit (ML) 37.5 100 100 26.5 90-100 95 19 71-95 83 13.2 56-80 68 4.75 38-54 46 2.36 28-42 35 0.3 7-21 14 0.075 2-8 5

Cumulative % by weightof total aggregate passing

Bitumen (%) Min4.5%

Followingpropertiesaredeterminedforeachspecimen

Bulk specific gravity or density of the mix (Gm)

When air voids are taken into account, the bulk specific gravityofthemix(Gm)isobtained.It'sgivenby, Theoritical specific gravity (GT)

Percent air voids (Vv)

The following formula is used to determine the percentage of air voids by volume in thespecimen

Percent volume of Bitumen (Vb)

The Volume of Bitumen (Vb) is the volume of bitumen dividedbythetotalvolume,computedasfollows

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

The following formula is used to compute the volume of voidsinmineralaggregates(VMA),

Voids Filled with Bitumen (VFB)

Voids Filled with Bitumen are the voids in the mineral aggregate frame work that are filledwithbitumen(VFB). Where,

Wm -istheweightofthemixinair;

Ww -istheweightofthemixinwater;

W1, W2, W3 etc., are the weights of different sizes of aggregatesusedinthemix;

Wb -Weightofthebitumenused;

G1, G2, G3 etc., are the apparent specific gravity of different sizes of aggregatesusedinthemix;

Gb -Apparentspecificgravityofthebitumenused;

Gm –BulkSpecificGravity.

3.4.2 Optimum binder content determination for DBM mix

(a)Plot the graphs

Densityvs.asphaltbindercontent.

Marshallstabilityv/sasphaltbindercontent.

Asphaltbindercontentvs.flow.

Asphalt binder content vs. air voids. Percent air voids should decrease with increasing asphalt bindercontent.

(b) Calculate the amount of asphalt binder needed for the mix design by averaging. the following three bitumen contents derived from the graphs created in step one.

Binder content corresponding to maximum stability.

Binder content corresponding to maximum bulkspecificgravity(Gb)

Binder content corresponding to the median ofdesignedlimitsofpercentairvoids(Vv)in thetotalmix(i.e.,4%)

ITS test is a measure of tensile strength of bituminous mixes and is commonly used for determining tensile strength ratio (TSR) of bituminous mixes. As per the MoRTH-V revision,the minimum TSR requirement for DBM-II mixes is 80%. The test is conducted as per ASTM D 6931-12. Marshall specimens were prepared at 7% air void level and Tensile strength ratio (TSR) was determined as per AASHTO T283 for conditioned and unconditioned samples. Overall,itcanbesaid thatadding RAP with a lower RAP percentage (< 30%) could reduce theHMAmix'sdrystrength,butaddingRAPwithagreater RAP content could increase dry strength (>30 percent ). Additionally, the strength in dry conditions may not be diminished bythe addition of RAP to WMA mixes [22] Along with that sasobit(3%) is added to mixes conduct themoistureresistancetest.

���� =2��/������

Where, St-Horizontalstress(N/mm²)

P - Load at Failure or maximum load (N) LSpecimenheight(mm)

D-Specimendiameter(mm)T-Thickness(mm)

The tensile strength ratio is computed using the formula below.

Asphalt binder content vs. VMA. Percent VMA should decrease with increasingasphalt binder content,reachaminimum,andthenincrease.

Asphalt binder content vs. VFA.Percent, VFAincreases with increasing asphalt binder content.

������ =��1/��2

Where, TSR-TensileStrengthRatio,%

S1-stressesofunconditionedstatein,kpa S2-stressesofconditionedstatein,kpa

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

Fatigue cracks typically happen at intermediate temperature condition. Different approaches are used by researchers to evaluate the fatigue cracking due to repeated load for similar climatic and environmental conditions. These approaches include fracture mechanics, energy-based techniques, and stiffness reduction criteria. At three different strain levels fatigue life of organic and chemical WMA mixes was analysed. The study also showed fatigue resistance is improved with addition of Sasobit to native binder improved. The type of WMA additivesalsoinfluencesthefatigueperformanceofmixes. BasedonthefieldstudiesinFrance,GermanyandNorway, it is observed that Sasobit exhibited better cracking resistancetoHMA[22].

Permanent deformation or rutting is another factor that determinestheperformanceofbituminous mixes.Rutting of mixes depends on binder grade, aggregate gradation, tyrepressureandtesttemperature.Studiesindicatedthat rutting resistance of bituminous mixes reduced with additionofWMAadditive.Thisisduetolessageingofmix. However, several researchers reported that some warm mixadditivesincreasetheruttingresistanceofbituminous mixes due to after crystallization of additives in binder The inconsistency in results indicate that that the rutting performanceisdependingonthetypeofWMAadditiveor method.[24].

Based on the Marshall test results, Marshall Stability increased with increase in RAP percentage less than 30% for warm bituminous mixes

[1] Mallick, Rajib B. and Bergendahl, John(2009) “A laboratory study on CO2 emission from asphalt binderanditsreductionwiththeuseofwarmmix asphalt”, International Journal of Sustainable Engineering,2:4,275 283

[2] Peng Bo, Fan Xueyong, et al, “Key steps of carbon emission and low-carbon measures in the construction of bituminous pavement”, International Journal of Pavement Research and Technology(10.03.2017)476–487

[3] Gui-juan Zhao, Ping Guo “Workability of Sasobit Warm Mixture Asphalt”, Energy Procedia 16(2012)1230-1236 (March2016)

[4] Yousefi, A. Behnood, A. Nowruzi et al., “Performance evaluation of asphalt mixtures containing warm mix asphalt (WMA) additives and reclaimed asphalt pavement (RAP)”, Construction and Building Materials(2020), https://doi.org/10.1016/j.conbuildmat.2020.121 200.

[5] Afshar A. Yousefi ,Saeid Sobhi , et al., “Cracking Properties of Warm Mix Asphalts Containing Reclaimed Asphalt Pavement and Recycling Agents under Different Loading Modes” (2021), https://doi.org/10.1016/j.conbuildmat.2021.124 130.

[6] Sharma, A., Kumar, P., Walia, A.: Use of Recycled Material in WMA- Future of Greener Road Construction. In: Transportation Research Procedia.pp.3770–3778.ElsevierB.V.(2020)

The indirect tensile strength increased with increase in RAP content and Sasobit when comparedtoconventionalmixes.

The tensile strength ratio increased with addition of warm mix additive to conventional and RAP mixes indicating, better resistance to moisture resistivity.

[7] Dinis-Almeida, M., Castro-Gomes, J., Antunes, M.D.L.: Mix design considerations for warm mix recycled asphalt with bitumen emulsion, (2012). In Construction and Building Materials (Vol. 28, Issue 1, pp. 687–693). https://doi.org/10.1016/j.conbuildmat.2011.10.0 53

Additionof sasobitasa warmmixadditivetothe warm mixes gives better fatigue and rutting resistanceproperty.

Thus, integrating WMA, and RAP in bituminous mixes optimizes the advantages towards durable andsustainablepavements.

[8] Baghaee Moghaddam, T., Baaj, H.: The use of rejuvenating agents in production of recycled hot mix asphalt: A systematic review, (2016). In ConstructionandBuildingMaterials(Vol.114,pp. 805–816). Elsevier Ltd. https://doi.org/10.1016/j.conbuildmat.2016.04.0 15

[9] Harpreet Singh , Tanuj Chopra,et al,“Effect of zycotherm additive on performance of neat bitumen and bituminous o concrete mixes”, International Journal of Civil Engineering and

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056 Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

Technology (IJCIET) Volume 8, Issue 8, August 2017,pp. 232–238

[10]Lokesh Gupta , Ashik bellary “Comparative study on the behavior of bituminous concrete mix and warm mix asphalt prepared using lime and zycotherm as additive”.www.materialstoday.com/proceedings Materialstoday:Proceeding5(2018)2074-2081

[11]Xu,S.,Xiao,F.,Amirkhanian,S.,&Singh,D.(2017). Moisture characteristics of mixtures with warm mix asphalt technologies – A review. In Construction and Building Materials (Vol. 142). https://doi.org/10.1016/j.conbuildmat.2017.03.0 69

[12]Guo, N., You, Z., Zhao, Y., Tan, Y., Diab, A.: Laboratory performance of warm mix asphalt containing recycled asphalt mixtures. Construction and Building Materials. 64, (2014). https://doi.org/10.1016/j.conbuildmat.2014.04.0 02

[13]Gui-juan Zhao, Ping Guo “Workability of Sasobit Warm Mixture Asphalt”, Energy Procedia 16(2012)1230-1236

[14]Sukhija, M., &Saboo, N. (2021). A comprehensive review of warm mix asphalt mixtures-laboratory to field. In Construction and Building Materials (Vol. 274). https://doi.org/10.1016/j.conbuildmat.2020.121 781

[15]Capitão, S. D., Picado-Santos, L. G., &MartinhoF. (2012). Pavement engineering materials: Review on the use of warm-mix asphalt. In Construction and Building Materials (Vol. 36). https://doi.org/10.1016/j.conbuildmat.2012.06.0 38

[16]Lekhaz,D.,Goutham,S.,&Saravanan,K.(2018).A ReviewonthePerformanceofAdditivesin Warm Mix Asphalt. https://doi.org/10.1061/9780784482032.004

[17]Bureau of Indian Standards (BIS): IS: 2386 (Part I)-1963- Indian Method of test for aggregate for concrete. Part I - Particle size and shape. Indian Standards.(1963)

[18]Bureau of Indian Standards: IS 2386 (Part III) Methods Of Test For Aggregates For Concrete Specific Gravity, Density, Voids, Absorption And Bulking.IndianStandard.2386Part,(2016)

[19]Bureau of Indian Standards (BIS): IS : 2366 (Part IV )-1963-Methods of test for Aggregates for Concrete, part 4 : Mechanical properties. Indian Standards.(2002)42.MoRTH:

[20](BIS), B. of I.S.: IS 383: 1970 Specification for CoarseandFineAggregatesFromNaturalSources forConcrete.IndianStandards.(1970)IS73-2013: ‘Indian Standard Paving Bitumen - Specification,’ Bur.IndianStand.NewDelhi,2013.,”2013.Indian Standards.(2013)

[21]IS:1203: Indian standard methods for testing tar and bituminous materials: Determination of penetration,(1978)

[22]Oliveira, M.S., Farias, M.M. de, Silva, J.P.S.: Fatigue analysis of hot recycled asphalt mixtures with RAP incorporation. Case Studies in Construction Materials. 16, (2022). https://doi.org/10.1016/j.cscm.2022.e01132

[23]Mehrara, A., &Khodaii, A. (2013). A review of state of the art on stripping phenomenon in asphalt concrete. In Construction and Building Materials (Vol. 38). https://doi.org/10.1016/j.conbuildmat.2012.08.0 33

[24]Shiva Kumar, G., Suresha, S.N.: State of the art review on mix design and mechanical properties of warm mix asphalt. Road Materials and Pavement Design. 20, 1501–1524 (2019). https://doi.org/10.1080/14680629.2018.147328 4

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page180