International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

1 Department of Mechanical Engineering of ENSET, Systems Technology Research Laboratory, 210 Avenue des Grandes Écoles, 3989 Libreville, Gabon ***

Abstract - In manufacturing industries, emphasis is placed on the suitability for the use of the parts produced. The suitability for use also depends on the parameters and machining conditions and the nature of the material used during the shaping of the parts.

As the use of recycled materials is topical, recycled aluminum alloy 6061 is the material chosen for the study. This study consisted in optimizing the parameters and machining conditions in dry turning and with wet, to guarantee a better surface quality of the alloy.

The design of experiment method was used to analyze the data, and the desirability function for the optimization of the feed rate and the cutting speed according to the machining conditions. This study allowed the implementation of a model to obtain the optimum surface roughness, the recycled alloy 6061, if the combination of parameters and cuttingconditions is respected.

Key Words: Surfaceroughness,cuttingparametersand condition,optimization,recycledaluminumalloy

Manufacturingindustriesaregenerallyconcernedwiththe quality of products from the production process. As machiningisoneoftheprocessesusedintheseindustries,it appearsthatthequalityofthesurfacesgeneratedisoneof theaspectsonwhichtheemphasisisplaced.Ingeneral,the surfacesproducedhavesomedefectsthatcanhaveaneffect on their suitability for use (functional constraints). These defectsareduetotheinfluenceofseveralelementsduring machining.Amongtheseelementsaretheconditionsunder whichmachiningisdone(withorwithoutlubrication),since thequalityofthesurfacedependsonit.Inadditiontothese cutting conditions, there are others such as: cutting parameters, the nature of the machined material, the geometryofthecuttingtool,vibrations...).Thecombination ofalltheseelementsthereforehasaconsiderableimpacton the generated surfaces defined in terms of surface roughness,mainlytheaveragearithmeticroughness(Ra).

This study is made to determine the optimum surface roughness (Ra), depending on the combination of

parametersandcuttingconditionsthathaveaconsiderable influenceonthequalityofthesurface.Wecanrealizethat several researchworkshavebeendone,tostudyand/ or optimizetheparametersandcuttingconditionsinorderto look for the best surface finish on different materials (aluminum alloys, steels). Some research focuses on the effects of cutting parameters (feed rate, cutting speed, cutting depth) and lubrication conditions (dry machining, MQL,wet)SasiPrasathThangamani[1].TheMQLlubrication mode, according to Sreejith [2], is a good compromise betweendrymachiningandwetmachiningforbettersurface quality.Y.Zedanetal[3]haveshownthatwhenmachining alloy6061-T6,dryandMQL,theincreaseincuttingspeed leads to a decrease in surface roughness, and lubrication minimizesandeliminatesthedeteriorationoftheresulting surface.OtherworkssuchasthoseofKouametal[4]during theturningofthealuminumalloy6061-T6,haveshownthat surface roughness is a function of the feed rate under differentlubricationconditions.Thesurfacefinishofother aluminum alloys, such as 2024-T351, 7075-T6 and 6061T65,ismoreinfluencedbytheKamguemetaltowerlead[5]. By analyzing the influence of lap advance under different lubrication conditions on surface roughness, Leppert and Tadeusz[6]indicatedthatincreasingtheleadperlapleads to increased roughness and the MQl guarantees the best surfacefinish.

Thesestudiesarenotlimitedtothesearchfortheeffectsof cutting parameters and conditions. There is also the optimizationoftheseparametersandcuttingconditionsto knowtheoptimumofthesurfaceroughness.Thus,several optimization methods are used. Statistical, analytical and experimentalmethodswereusedbyKH.Chibaneetal[7]to combine cutting parameters, in order to obtain predictive modelsofthesurfaceroughnessofa100C6steel.Taguchi's methods and analysis of variances were also used, in the studies of Vishal F et al [8] and Bouzid et al [9] for the optimizationoftheinfluenceofcuttingspeed,cuttingdepth andfeedrate,onthesurfaceroughnesswhenturningamild steel(0.18%carbon). Modelingandoptimizationtechniques withasignificantinfluenceinhardturning,werepresented by Sudhansu Ranjan D et al [10]. For them, the Tagichi method and that of ANOVA are the most effective in controllingtheeffectsofprocessparametersonthesurface finish. Among the methods used, there is the one that

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

imposes the definition of the desirability function. This desirabilityfunctionwasusedbyDerringer[11]andMyers etal[12],tofindaresultthatvariesbetweentwoextreme values0and1,andbyRamanaetal[13]toperformoptimal parameteradjustmenttoreducesurfaceroughness.

With regard to the roughness of recycled materials, in particularaluminumalloys,Mandatsyetal[14,15]reported a difference in surface roughness between two recycled aluminumalloys,machinedunderthesameconditions.They indicated a very significant influence of lubrication on roughness. Mandatsy et al [16] recycled and heat-treated aluminum alloy 6061, then did dry and lubrication machiningtodefinemodelsforevaluatingsurfaceroughness based on the feed rate, cutting speed and hardness of the material.

Inordertocontinuetheresearchinthesameaxis,butwith recycledaluminumalloys,weusethestudyofMandatsyetal [16].Inthisstudy,theyrecycledbyfoundrythemachining chipsofaluminumalloy6061.Someofthesealloysobtained were heat treated to T6, others remained without heat treatment.Theylimitedthemselvestopresentingroughness assessmentmodelsaccordingtothemostinfluentialcutting parameters and conditions. This study therefore complementstheoptimizationofthesameparametersand cuttingconditionsinordertodefineamodelforevaluating theoptimumofsurfaceroughnesswhenturninguntreated andtreatedrecycled6061aluminumalloys.

This study includes a part on the experimental procedure and the material used, another part on the results and discussion,andfinallyaconclusiontoclosethestudy.

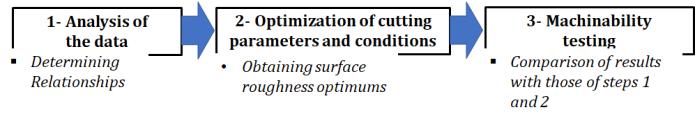

Figure 1 shows the three steps that make up the experimentalprocedureputinplace toconductthestudy. The first step was to apply the design of experiments (responsesurfacemethod).Theexperimentaldesignswere usedtodeterminetherelationshipbetweenthefeedrate(f), thecuttingspeed(Vc),thelubricationmode(drymachining, wetmachining)andthesurfaceroughness(Ra),andthento definethemodelsforassessingthesurfaceroughness.The secondstepwastooptimizethefeedrate,cuttingspeedand lubrication conditions to have the optimums of surface roughness (maximizing and minimizing). Using the definitionofthedesirabilityfunction,asderringer[11]and Myersetal[12],theoptimalvaluesofthefeedrateandthe cutting speed according to the lubrication mode were obtained.Intheend,thethirdstagefocusedonmachinability testing. The results of the optimization were taken into accounttogeneratesurfaces,whosesurfaceroughnesswas measured,inordertocomparetheresultswiththeprevious steps.

The data from a design of experiment (response surface) carried out by Mandatsy et al [16]were used to carry out thisstudy.

Statgraphicssoftware,softwarefordesignexperiments,was used to analyze the data and perform the optimization. A multi-response optimization study by the desirability functionwasdonetodeterminethecombinationoffeedrate andcuttingspeed.Thiscombinationmakesitpossibletofind theoptimum(maximumandminimum)surfaceroughnessof treated and untreated recycled 6061 alloys (obtained dry machiningandwetmachining).Thedesirabilityfunctionwas usedconsideringthatallsurfaceroughness’shavethesame importance.

This study required the use of recycled aluminum alloys (untreatedrecycled6061alloyandT6-treatedrecycled6061 alloy)producedbyMandatsyetal[16]. Inthisstudy,these alloysweredesignatedasfollows:

Untreatedrecycled6061alloy:6061-RNT

Recycled6061alloytreatedwithT6:6061-RT

Theoptimizedvaluesofthefeedrateandthecuttingspeed weretakenintoaccount,tobeintroducedintothemodelsof Mandatsy et al [16] in order to calculate the surface roughness. Then, machinability tests were done based on optimizedthefeedrateandcuttingspeed,andtomeasure surface roughness. For machinability tests, a turning machine was used, for dry machining and wet machining. Surfaceroughnessmeasurements,arugosimeterequipped withSurfPack-SJdataacquisitionsoftware,wasused.

Table 1 contains values of the surface roughness of each alloyobtainedaftereachtest(machiningatacuttingdepth of0.6mm)accordingtothecuttingparametersconsidered (lapadvance0.05–0.13–0.2mm/rev,cuttingspeed100–155 – 210 m/min) and the cutting conditions considered (drymachiningandwetmachining).

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

Table -1: Surfaceroughnessvaluesatacuttingdepthof 0.6mm(Mandatsyetal[16])

Dry machining Wet machining

f Vc 6061 R 6061 RT6 6061 R 6061 R-T6

0.2 155 4.771 3.856 2.618 1.5 0.05 210 3.336 1.971 1.69 0.866 0.13 100 3.907 2.662 1.91 1.108

0.2 100 4.513 3.724 2.506 1.375 0.05 155 2.83 1.889 1.67 0.873

0.05 100 2.602 1.867 1.633 0.824 0.13 210 4.611 3.703 2.1 0.951 0.13 155 3.801 3.655 1.9 0.965

0.2 210 5.023 3.976 2.879 1.479 0.13 155 3.801 3.655 1.9 0.966 0.13 155 3.801 3.655 1.9 0.968 0.13 155 3.801 3.653 1.9 0.965

0.13 155 3.803 3.655 1.904 0.965 0.13 155 3.801 3.655 1.906 0.965 0.13 155 3.801 3.657 1.9 0.968 TheanalysisofANOVAhasallowedtohavemodels adjustedaccordingtotheformoftherelation1. 2 0

(1) With Y variableexplained, Xi explanatoryvariable, XiXj interaction between explanatory variables, effectofthevariable,aiieffectofthequadraticterm relative to i, aij effect of the interaction between i andj,ɛtermofunobservableerrorsofthemodel

ThestatisticsR2 foreachalloyareveryclosetothevalueof 1.So,wehave: R2 explains 98.061% variability in the surface roughnessofthealloy6061-RNT,drymachined. R2 explains 94.934% variability in the surface roughnessofthealloy6061-RT,drymachined. R2 explains 99.654% variability in the surface roughnessofthealloy6061-RNT,wetmachined R2 explains 95.835% variability in the surface roughnessofthealloy6061-RT,wetmachined.

Themodels obtained are slightly different from those of Mandatsy et al [16]. This difference is due to the fact that some values had been increased. Models 2 to 5 are those selectedtobeappliedinthecalculationofsurfaceroughness. Thisanalysisshowedthatthewetmachiningimprovesthe surface finish. The improvement in surface finish is also relatedtothehighhardness,thereductionofthefeedrate andthenatureofthealloy. Alloy6061-RNTdrymachined. 72 782

2.9392119.6932* 208813.10*21.2695* 133351.10**9185.10*

Raf Vcf fVcVc

(2)

Alloy6061-RNTwetmachined 62 6102

2.364097.13284* 7811.10*43.4722* 19559.10**234711.10*

Raf Vcf fVCVc

(3)

Alloy6061-RTdrymachined 72 7102

1.807932.9551* 276009.10*86.9991* 112776.10**799873.10*

Raf Vcf fVcVc

6061-RTwetmachined 82 8112

1.136544.88892* 154568.10*33.533* 313341.10**359822.10*

Raf Vcf fVcVc

Inordertooptimizethesurfaceroughnessofalloy6061RNT (dry machined and with abundant lubrication) and alloy 6061-RT (dry machined and wet machined), the elemental desirability function (di) was used to maximize (relationship6)andminimize(relationship7).

(7) With Y max – highest value of the response that is not suitable, Y mini + lowest value that is suitable, Y mini –

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

lowestvaluethatisnotsuitable, Y maxi+strongestvalueof theresponsethatissuitable

A common weight of 1 and a common impact of I=3 are considered,tomakethecombinationoftheadvanceperlap and the cutting speed, with the aim of simultaneously optimizingallsurfaceroughness.Sinceoptimizationismultiresponse,overalldesirability(D)wasdefinedaccordingto elementary desirability. The overall desirability that presentsacompromisebetweentheadvanceandthecutting speediscalculatedbytherelationship8.

Tominimize,theoptimumvalueofdesirabilityis0.9980022 for alloy 6061-RNT and 0.962218 for alloy6061-RT. The contouroverlaygraphs,Figures4and5showthatthebest points are at f = 0.05 mm/rev and Vc = 118.5 m/min (for alloy6061R)and121.42m/min(foralloy6061-RT). This gives:

Graphiquedesuperpositiondescontours

Graphiquedesuperpositiondescontours

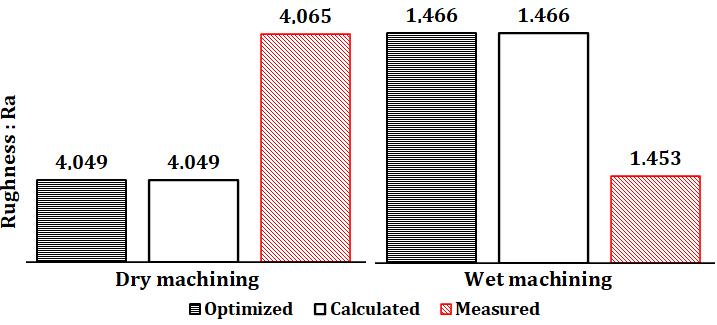

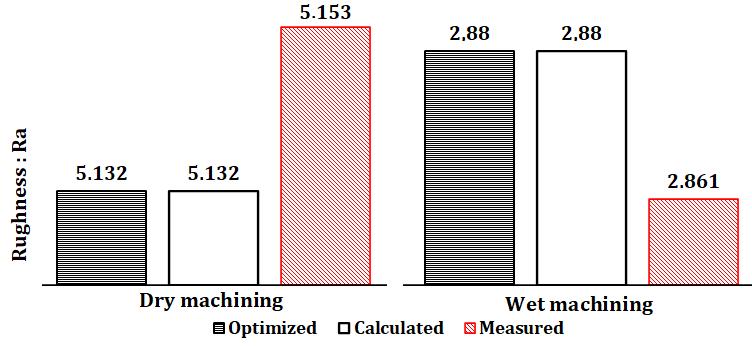

Tomaximize,theoptimumvalueofdesirabilityis0.996044 for alloy 6061-RNT and 0.974986 for alloy6061-RT. The contouroverlaygraphs,Figures2and3showthatthebest pointsaren’tatf=0.2mm/revandVc=210m/min. This gives: Alloy6061-RNT,theoptimumsurfaceroughnessis 5.132 μm for dry machining and 2.88 μm for wet machining(chart1). Alloy6061-RT,theoptimum surface roughness is 4.049 μm for dry machining and1.466μmforwetmachining(chart2). 2.9

3.2 3.5 3.8 4.1 4.4 4.7 5.0 1.75 1.9 2.05 2.2 2.35

2.8 Vc (m/min) f(mm/rev)

Graphiquedesuperpositiondescontours

2.65

2.5

Chart-2 : Overlaygraphshowingtheoptimumsurface roughnessofalloy6061-RT

3.2

Alloy6061-RNT,theoptimumsurfaceroughnessof 2.6 μm for dry machining and 1.63 μm for wet machining(chart3). Alloy6061-RT,theoptimum surfaceroughnessof1.86μmfordrymachiningand 0.86μmforwetmachining(chart4). 2.9

3.5 3.8 4.1 4.4 4.7 5.0 1.75 1.9 2.05 2.2 2.35

2.65

2.5

2.8 Vc (m/min) f(mm/rev)

Vc (m/min)

220

6061R-T0S

200

180

160

140

120

Chart-3 : Overlaygraphshowingtheoptimumsurface roughnessofalloy6061-RNT 1.85 2.1 2.35 2.6 2.85 3.1 3.35 3.6

Graphiquedesuperpositiondescontours 6061R-T6 6061R-T6 0,05 0,08 0,11 0,14 0,17 0,2 100

0.9 0.98 1.06 1.14 1.22 1.3 1.38 1.46 f(mm/rev)

3.85

Chart-4 : Overlaygraphshowingtheoptimumsurface roughnessofalloy6061-RT

6061R-T6S

To find the calculated values of surface roughness, models 2 to 5 were used. This calculation consisted in introducing into these modelsthe optimized valuesof the feedrateandthecuttingspeed.

Inthecaseofmaximizingsurfaceroughness,wehavef=0.2 mm/revandVc =210m/minfor alloy6061-RTand alloy 6061-RNT. Theresultsare:

Ra=5.132μmdryandRa=2.88μmwetforalloy 6061-RNT.

Ra=4.049μmdryandRa=1.466μmwetforalloy 6061-RT.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

Inthecaseofminimizingsurfaceroughness,wehavef=0.05 mm/rev,Vc=118.5m/minforalloy6061-RNTand,f=0.05 mm/revVc=121.42m/minforalloy6061-RT.Theresults are:

Ra=2.607μmdryandRa=1.633μmwetforalloy 6061-RNT.

calculatedsurfaceroughnessvalues(Ra=5.132μm).Onthe otherhand,theyaredifferentfromthevaluesofthesurface roughnessmeasuredaftermachining(Ra=5.153μm).There isaslightdifferencedenotedΔ(Δ=+0.021).

Ra=1.867μmdryandRa=0.862μmwetforalloy 6061-RT.

The machinability tests (the trolley operation with a cutting depth equal to 0.6 mm) were carried out using as cuttingparameters,theoptimizedvaluesofthefeedrateand thecuttingspeed,accordingtoeachcase.Eachtestcarried out,indrymachiningandwetmachining,requiredtheuseof atypeofcuttingtool(CPGT09T308HP,positiveuncoatedcut ofgradeKC5410,rɛ=0.8mm,α=11°).Aftermakingthree identicalsamplesofeach(lengthof200mm,diameterofthe piece50mm),anaverageroughnessofoverfacewasmade.

Tables 2 and 3 present respectively the optimum values of surface roughness measured when maximized and minimized.

Table -2: Optimumvaluesofmaximizedroughness

Paramètresde coupe Ra(µm) Maximisée f Vc Dry Wet

6061-RNT 0.2 210 5.153 2.861 6061-RT 0.2 210 4.065 1.453

Table -3: Optimumvaluesofminimizedroughness

Paramètresde coupe Ra(µm) Minimisée f Vc Dry Wet

6061-RNT 0.05 118.5 2.617 1.63 6061-RT 0.05 121.42 1.887 0.859

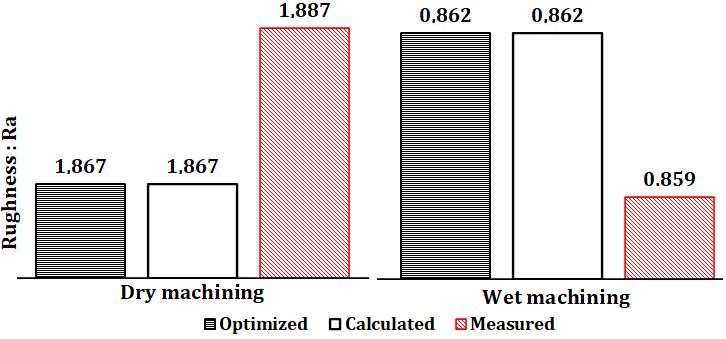

These experimental results were compared with those calculated on the basis of models 2 to 5 and those of optimization. Charts 5 to 8 are graphs that show the differencesbetweentheseresults. Onthesegraphs,thereis a clear difference between the results, although this differenceisverysmall.

Whenmaximizingtheroughnessofthedrymachinedalloy 6061-RNT, chart 5 shows that the optimized surface roughness values (Ra = 5.132 μm) are identical to the

When machining is done wet machining, the optimized surfaceroughnessvalues(Ra=2.88μm)arealsoidenticalto thecalculatedsurfaceroughnessvalues(Ra=2.88μm).On the other hand, they are different from the values of the surface roughness measured after machining (Ra = 2.861 μm).ThereisaslightdifferencedenotedΔ(Δ=-0.019).

Whenmaximizingtheroughnessofthedrymachinedalloy 6061-RT, chart 6 shows that the optimized surface roughness values (Ra = 4,049 μm) are identical to the calculatedsurfaceroughnessvalues(Ra=4,049μm).Onthe otherhand,theyaredifferentfromthevaluesofthesurface roughnessmeasuredaftermachining(Ra=4.065μm).We see a slight difference denoted Δ (Δ=+0.016). When machining is done wet machining, the optimized surface roughnessvalues(Ra=1.466μm)arealsoidenticaltothe calculatedsurfaceroughnessvalues(Ra=1.466μm).Onthe otherhand,theyaredifferentfromthevaluesofthesurface roughnessmeasuredaftermachining(Ra=1.453μm).There isaslightdifferencedenotedΔ(Δ=-0.013).

Chart-5 : Surfaceroughnessvaluesoptimizedforalloy 6061-RNT

Chart-6 : Surfaceroughnessvaluesoptimizedforalloy 6061-RT.

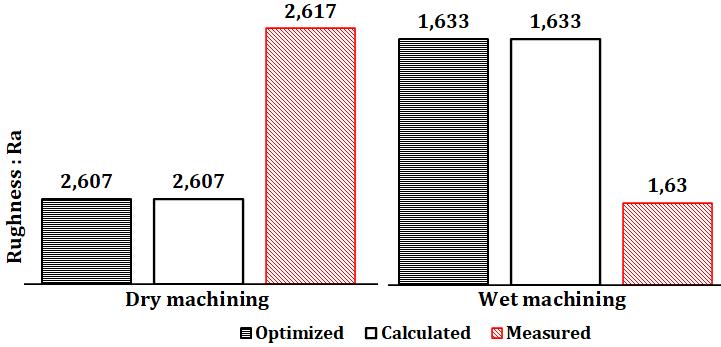

Whenminimizingtheroughnessofthedry-machinedalloy 6061-RNT, chart 7 shows that the optimized surface roughness values (Ra = 2,607 μm) are identical to the

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

calculatedsurfaceroughnessvalues(Ra=2,607μm).Onthe otherhand,theyaredifferentfromthevaluesofthesurface roughnessmeasuredaftermachining(Ra=2.617μm).There isaslightdifferencedenotedΔ(Δ=+0.01).Whenmachining is done wet machining, the optimized surface roughness values(Ra=1.633μm)arealsoidenticaltothecalculated surface roughness values (Ra = 1.633 μm). On the other hand, they are different from the values of the surface roughnessmeasuredaftermachining((Ra=1.63μm).There isaslightdifferencedenotedΔ(Δ=-0.003).

Whenminimizingtheroughnessofthedry-machinedalloy 6061-RT, chart 8 shows that the optimized surface roughness values (Ra = 1.867 μm) are identical to the calculatedsurfaceroughnessvalues(Ra=1.867μm).Onthe otherhand,theyaredifferentfromthevaluesofthesurface roughnessmeasuredaftermachining(Ra=1.887μm).We dare a slight difference denoted Δ (Δ=+0.02). When machining is done wet machining, the optimized surface roughnessvalues(Ra=0.862μm)arealsoidenticaltothe calculatedsurfaceroughnessvalues(Ra=0.862μm).Onthe otherhand,theyaredifferentfromthevaluesofthesurface roughnessmeasuredaftermachining(Ra=0.859μm).There isaslightdifferencedenotedΔ(Δ=-0.003).

machined dry or wet machined. Model 9 can therefore be considered.

optiRaRa (9)

+Δ will apply to both recycled aluminum alloys when machineddry,and–Δwhenwetmachined.

Attheendofthisstudy,itappearsthatthemachiningoftwo aluminumalloys6061-RNTand6061-RTispossiblewhen thereisacombinationofparametersandcutconditionsby applyingmodel9.

Ifitisnecessarytomaximizethesurfaceroughness,itis possibletocombinethefeedrate(0.2mm/rev)withthe cuttingspeed(210m/min)tohaveanoptimumsurface roughnessbydrymachiningandwetmachining

Ifitisnecessarytominimizethesurfaceroughness,itis possibletocombinethefeedrate(0.05mm/rev)with thecutting speed(118.5m/min) tohavean optimum surfaceroughness(alloy6061-RNT)andthefeedrate (0.05mm/min)withthecuttingspeed(121.42m/min) tohaveanoptimumroughness(alloy6061-RTbydry machinedandwetmachining.

Thisstudyalsoindicatedtheinfluencesoflubricationand alloytypeonsurfaceroughness.Inanycase,wetmachining improvesthesurfacefinishwellregardlessofthematerial. Thesurfacefinishofalloy6061-RNTissignificantlybetter thanthatofalloy6061-RT.

Chart-7 : Surfaceroughnessvaluesoptimizedforalloy 6061-RNT.

[1] SasiPrasathThangamani,KaruppasamyRamasamyand Milon Selvam Dennison The Effect of Cutting Fluid on Surface Roughness of Lm6 Aluminium Alloy During Turning Operation, International Research Journal of Engineering and Technology, Volume: 05 Issue: 02 | Feb-2018pp1198–1200e-ISSN:2395-0056,p-ISSN: 2395-0072

[2] Sreejith,PS.2008.«Machiningof6061aluminiumalloy with MQL, dry and flooded lubricant conditions ». Materials letters, vol.62,no2,p.276-278.

Chart-8 : Surfaceroughnessvaluesoptimizedforalloy 6061-RT.

InadditiontothestudybyMandatsyetal[16],thevariation Δ is added to models 2 to 5, to evaluate the surface roughnessofaluminumalloys6061-RNTand6061-RTwhen

[3] Zedan, Y.; Khettabi, R.; Zaghbani, I.; Kouam, J.; Masounave,J.;Songmene,V.Experimentalinvestigation of cutting fluid influence on drilled aluminum part quality. Int. J. Civil Eng. Build. Mater. 2012, 2,78–84.

[4] Kouam,J,VSongmene,MBalazinskietPHendrick.2012. « Dry, Semi-Dry and Wet Machining of 6061-T6 AluminiumAlloy».

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

[5] Kamguem, R, A Djebara et V Songmene. 2013. « Investigation on surface finish and metallic particle emission during machining of aluminum alloys using responsesurfacemethodologyanddesirabilityfunctions

». The International Journal of Advanced Manufacturing Technology, vol.69,no5-8,p.1283-1298.

[6] Leppert, Tadeusz. 2011. « Effect of cooling and lubrication conditions on surface topography and turningprocessofC45steel». International Journal of Machine Tools and Manufacture, vol. 51, no 2, p. 120126.

[7] KH. Chibane et al, Mise en œuvre d’une optimisation multi-objectif en tournage d’un d’un acier 100C6 : compromis entre qualité de surface et productivité. 20ème Congrés Français de Mécanique. Besançon, 29 aoûtau2septembre2011

[8] Vishal Francis, Ravi S.Singh, Nikita Singh, Ali. R. Rizvi, Santosh Kumar “application of taguchi method and anovainoptimizationofcuttingparametersformaterial removal rate and surface roughness in turning operation” International Journal of Mechanical EngineeringandTechnology(IJMET),ISSN0976–6340 (Print), ISSN 0976 – 6359(Online) Volume 4, Issue 3, May - June (2013) © IAEME Volume 4, Issue 3, MayJune(2013),pp.47-53

[9] BouzidL,BoutabbaS,YalleseM,BelhadiS,GirardinF. Simultaneous optimization of surface roughness and materialremovalrateforturningofX20Cr13stainless steel. Int J Adv Manuf Technol DOI 10.1007/s00170014-6043-92014

[10] SudhansuRanjanDas,DeepakKumarMohapatra,Purna Chandra Routray, Biswaranjan Rout, Journal of Engineering Innovation and Research, Volume: V, Issue:1,January-March2015ISSN2230-9373 Available onlineatwww.a2zknowledge.com

[11] Derringer,George.1980.«Simultaneousoptimizationof several response variables ». Journal of quality technology, vol.12,p.214-219.

[12] Myers,RaymondH,DouglasCMontgomeryetChristine MAnderson-Cook.2009. Response surfacemethodology: process and product optimization using designed experiments,705.JohnWiley&Sons.

[13] Ramana, M Venkata, G Krishna Mohan Rao et D Hanumantha Rao. 2014. « Optimization and Effect of Process Parameters on Tool Wear in Turning of TitaniumAlloyunderDifferentMachiningConditions».

[14] MandatsyMoungomoJ.B.Nganga-Kouya,D.Songmene, V.Kouam,J.;Kenné,J.P.MachinabilityStudyofRecycled

Aluminum Cans and Machining Chips. Adv. Manuf. Technol. 2016.

[15] MandatsyMoungomoJ.B.Nganga-Kouya,D.;Songmene, V. Tourning and Drilling Machinability of Recycled AluminumAlloys. Key Eng. Mater. 2016, 710,77–82.

[16] MandatsyMoungomo,J.B.Kibouka,G.R.Nganga-Kouya, D. Influence of Heat Treatments, Parameters and MachiningConditionsonMachinabilityintheTurningof Recycled6061AluminumAlloy. J. Manuf.Mater.Process. 2021, 5,37.https://doi.org/10.3390/jmmp5020037

Dr. Jean Brice Mandatsy Moungomo isateacherresearcheratENSET.Heis AssistantProfessoratCAMES.Member of the Systems Technology Research Laboratory(LARTESY),hefocuseshis research on the continuous optimizationofproductionprocesses, the recomposition of materials and theircharacterizations.

Dr. Guy Richard Kibouka is a teacher-researcherattheENSET.Heis AssistantProfessoratCAMES.Member of the Systems Technology Research Laboratory(LARTESY),hefocuseshis research on the continuous optimizationofproductionprocesses, the reliability and maintenance of productionequipment.

Dr. Jean Marie Lauhic Ndong Mezui isaresearchprofessoratENSET.Heis AssistantProfessoratCAMES.Member of the Systems Technology Research Laboratory (LARTESY), his areas of research relate to the modeling and digital design of systems, modeling, design and control applied to mobile robotics.

Mrs. Merline Ndilou isaPhDstudent at EDGE and a teacher-researcher at ENSET. Member of the Systems Technology Research Laboratory (LARTESY), his research focuses on modeling,designandcontrol applied tomobileroboticsandthecontinuous optimizationofproductionprocesses,