International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

1Student, Department of Chemical Engineering, University of Calcutta

2Student, Department of Chemical Engineering, University of Calcutta ***

Abstract – As a result of the growing world population, the consumption of petrochemicalandpetroleumresourcesisalso abruptly increasing. Such an abrupt increase results in increased global warming and also causesfastdepletionofthe petroleum reserves. Therefore, an immediate,eco-friendlyand cost-effective alternative is required in order to meet the necessary demands and also reduce the harmful environmental impacts. Cashew nut shell is a byproduct that we throw off as an agro-industrial waste after obtaining the edible cashew in a cashew processing industry. But due to the phenolic lipid content, Cashew Nut shellliquid(CNSL)canbea potential replacement of the fossil fuel.

Since the shell is generally thrown off as a waste, CNSL will be comparatively much cheaper. Cardanol and other CNSL derivatives find their applications in a varied range of disciplines including production of biodiesel, larvicides, vulcanized rubber, brake linings, foundry chemicals, surface linings, surfactants and the list is yet to be continued and discovered. This critical review has been conducted to throw some light on the chemical composition, extraction procedure and various applications of Cashew Nut Shell Liquid (CNSL).

Key Words: CashewNutShellLiquid(CNSL),Cookingoil, biofuel/biodiesel, green fuel, petrochemical feedstock, sustainableenergy,CNSLaslarvicide

The cashew tree, whose scientific name is Anacardium occidentale L.,belongstotheAnacardiaceaefamilythatalso includes mangoes and pistachios. Cashew nut is generally thefalsefruitortheaccessoryfruitofthecashewtreewhich isusedformakingsweetsandbeveragesandalsousedina varied range of food products. But still cashew nut is the mosteconomicalproductofthecashewtree.Thepericarp whichcontainsthecashewnut,iscommonlyknownasthe cashewnutshell.Thecashewnutshellconsistsofadarkand abrasiveliquidknownasthecashewnutshellliquid(CNSL) whichcan be obtained duringtheindustrial processing of thecashewnut.Cashewnutshelloilgenerallyisareliable element of the cashew fruits. This CNSL is generally composed of phenolic lipids which makes it a noteworthy replacementofpetroleumproducts.

Withthegrowingworldpopulation,thedemandtosupply ratioofthepetrochemicalresourcesisincreasingbyalargescale day by day. This if continued, can exhaust our petrochemicalfeedstockandasaresultaffectthelifeofour future generation. In order to maintain the human living standardsandkeepuptheindustrialeconomy,scientistsare in search of an alternative source of fuel. The cashew nut shell is generally thrown off as an industrial waste of the cashewnutprocessingindustries. Scientists,throughtheir research have recently found that Cashew nut shell liquid (CNSL), due to its content of phenolic lipids and other comparablechemicals,canbeasubstantialreplacementof thepetrochemicalproductsandasaresultitwillhelpusto maintainourglobalpetroleumreserves.

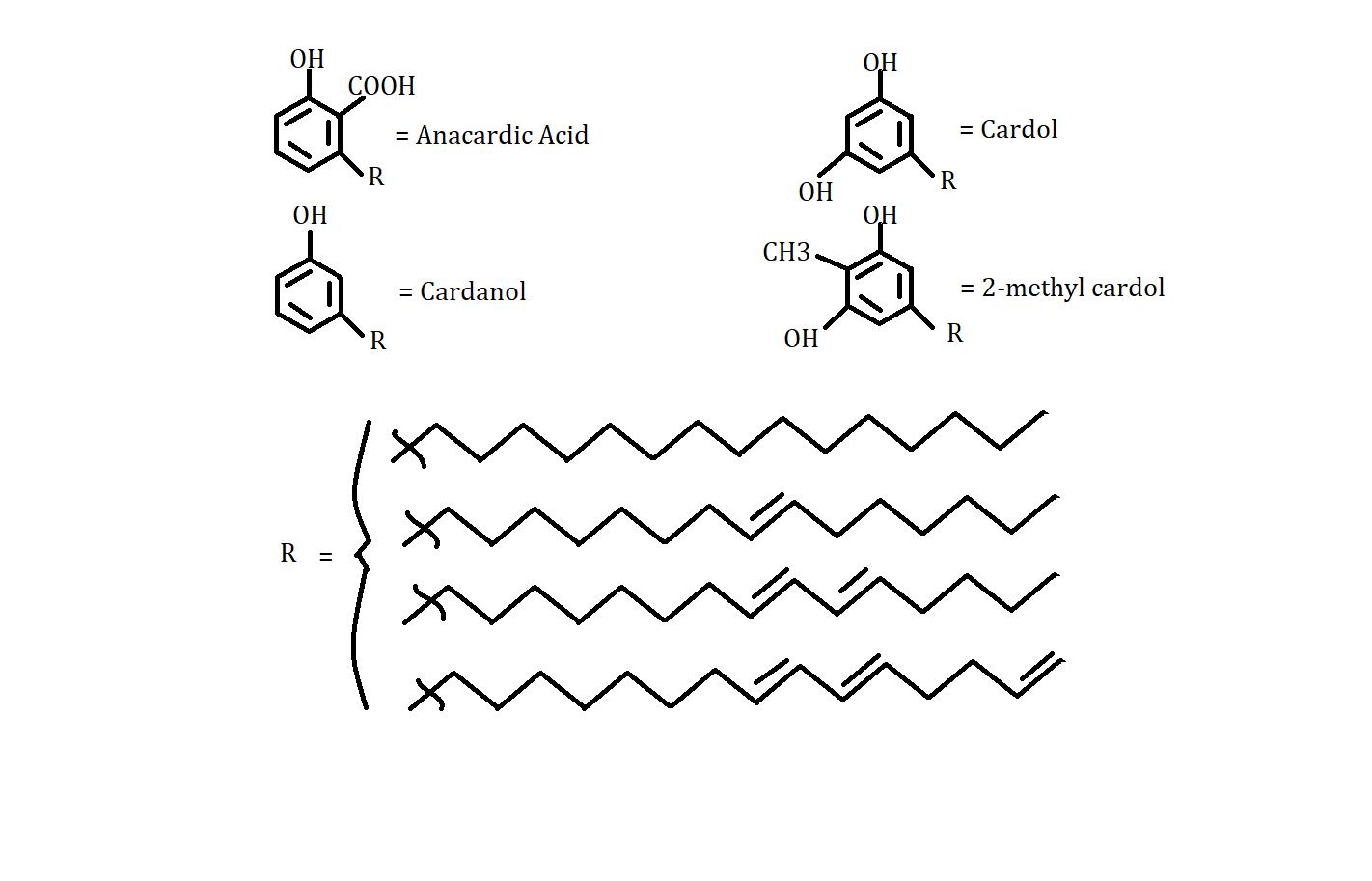

CNSLisared,brown,abrasiveanddarkishoilwithastrange odor. Cashew nut shell oil is the prime source of nonisoprenoid phenolic lipids and is mainly comprised of chemical compounds namely: (1) mono-unsaturated anacardic acid, (2) mono-unsaturated and saturated cardanol, (3) cardol (mono-unsaturated, saturated, diunsaturated), (4) Stigmasterol, (5) β-sitosterol, (6) Octacosene, (7) Triacontene and some other unknown hydrocarbons, depending on the type of CNSL we obtain, whetheritisNaturalCNSLorTechnicalCNSL.

Thesephenolicderivativesmaypossesscomplicatedorganic structurealongwithalongalkylsidechainwhichconsistsof 15 carbons. The hydrocarbon chain is located at the meta positionwithrespecttothehydroxylgroupintheorganic structure.Thehydrocarbonchainmaybesaturatedwithno double bonds or unsaturated with 1 to 3 double bonds at 8th,11th or 14th Carbon. Some basic structures of the componentsinCNSLhavebeenshownbelowinFig-1.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

IthasbeenstudiedandreportedthatrawCashewnutshell consists about 20% of oil. Oil bath processes leave about 10%oftheoilcontentasaby-productalongwiththeused shell. By using expellers for oil extraction, we can utilize moreoftheoilcontent.Basedontheprocessofextraction Cashewnutshelloil(CNSL)canbeclassifiedintoNaturalor actual(solventextracted)CNSLandTechnicalCNSL.

TechnicalCNSLcanbeobtainedbyhotmethodslikehotoil roasting,openpanroastinganddrumroastingwhereascold methodslikecoldextrusion,solventextractionandpressing areusedtoobtaintheNaturalCNSL.

NaturalCNSLcangenerallybepreparedbyusingdifferent solvent extraction techniques that commonly include Soxhlet,supercriticalcarbondioxide(SC-CO2),orsubcritical water (SCW) in order to obtain the components of the cashew nut shell oil under mild conditions or at room temperature,withoutanychemicalchangetakingplace.In this way, natural CNSL signifies the chemical composition that is naturally present in the shell of the cashew nuts, whichisbasicallycomposedbyanacardicacids(about60–70%),cardol(about10–20%),cardanols(about3–10%),2methylcardols (about 2–5 %), and minor percentages of someotherconstituents.

The exact percentage however depends on the type of extraction method used. It has been reported that more percentagesofmono-unsaturatedcardanolfromSCWand Soxhlet extraction methods. Additionally, operating conditions like temperature and pressure and time also affectthepercentageofchemicalspresentintheextracted oil. So, the selectivity of different compounds during the extractionprocessesdependsonavariedrangeoffactors. UnlikethenaturalCNSL,theTechnicalCNSLcanbeobtained fromtheindustrialprocessingofthecashewnutswherewe

only require the edible cashew or the fruit kernel and cashewnutshellisobtainedasaby-productorsecondary productthere.PreviouslytechnicalCNSLwasconsideredas phenolic source to help in the manufacturing of Bakelite (phenol-formaldehyde resin). After conducting a lot of researches,theTechnical CNSLhasbeenrecognizedas an economically viable source of phenolic compounds. Industrially, CNSL can be obtained by extraction through high temperature processes in order to crack open the cashew nut shell and obtain the edible cashew kernel. In these processes, more commonly known as ‘hot-oil processes’, the cashew nut shells are generally kept in an immersed condition in the previously extracted technical CNSLoreveninnaturalCNSLandheatedtoatemperatureof about 180–190 °C. Under this temperature range, the anacardic acid present in natural CNSL of the nut shell undergoesadecarboxylationreactionandtheanacardicacid getsconvertedintocardanol,generatingtechnicalCNSLasa result.ThechemicalcompositionoftechnicalCNSLismuch different from natural CNSL. Technical CNSL is mainly composedofcardanol(about60–70%),cardol(about10–20 %), 2-methylcardol (about 2–5 %) and other polymeric materials(about5–10%).Minorpercentagesoffewother componentsmightbepresentdependingupontheoperating conditions and ambient conditions. A flowchart of the technicalCNSLgeneratingprocesshasbeendrawnbelowin Fig-2.RefiningandpurificationofCNSLincludesthevacuum distillation of the raw liquid obtained upon pressing. However,theoperatingparametersmayplayanimportant role

bathat30°C)

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

AcalibratedpHmetermodelcanbeusedtodiagnosethepH ofthesample.

APycnometercanbeusedtodeterminethespecificgravity oftheoilsample.

AnOxygenBombCalorimetercanbeusedtogetthecalorific valueoftheCNSLsampleunderadiabaticconditions.

Anelectrolytecanbeusedtoregulatetheheatofthesystem.

ThecalorificvalueofthespentcakeofCashewnutshellcan bemeasuredbyplacingthe spentcakeina capsulewhich canthenbeputinthecalorimetercrucible.

The calorific value can be calculated by the following equation:

CalorificValue(kcal/kg)= where,

W=weightofthewaterinthecalorimeterinkg,

w=waterequivalentwithrespecttotheapparatus,

T1=initialtemperatureofthewaterindegreeCelsius,

T2=finaltemperatureofthewaterindegreeCelsius,

X=weightofthefuelsample(CNSLsampleinthisparticular case)takeninkg

LightDieseloil(LDO)andfurnaceoilmainlybelongtothe intermediateboilingrangeproductsofcrudeoildistillation. Asaresult,LDOandfurnaceoilhaveahighmetalliccontent alongwithotherimpuritieswhichisdetrimentaltoourdaily usage and additionally the petroleum reserves are stiffly exhausting.Pricesofpetrochemicalderivativesarerising.So, an urgent replacement is needed in order to maintain the stabilityofoureconomy.

Inanexperiment,thepropertiesofbothLDO,furnaceoiland CNSLweretestedandtheresultswerecompared.According to obtained results, CNSL was found to have a higher ash contentascomparedtobothLDPandfurnaceoil,butthatis onlymoreby1%.So,thislittleamountofdifferencecanbe toleratedinour industrial heatingapplications.TheGross CalorificValue(GCV)andrelativedensityoftheLDO,furnace oil and CNSL are the same. Moisture content is same for CNSLandfurnaceoilbutislowerforLDO.So,themoisture ofCNSLneedstoberemovedtosomeextentbeforebeing usedinreplacementofLDO.Themoisturecontentcaneasily beremoved.

Themostnotablepointofdifferenceisthattheflashpoint forCNSL(170°C)ismuchhigherthanthatforLDO(66°C) andfurnaceoil(66°C).ThepourpointofCNSL(2°Cforboth summer and winter) is much lower than LDO (120 °C for winterand20°Cinsummer).Thecomparativelyhigherflash pointandlowerpourpointindicatethattheCNSLinmuch safer to use and will be much more commercial if used in placeofLDOandfurnaceoil.

Studiesandresearcheshavereportedoverandoveragain that CNSL upon being consumed, raises high-density lipoproteins(HDL)andlowersthelow-densitylipoproteins (LDL).TusCNSLindirectlyhelpstheHDLinremovingexcess cholesterol from our hearts and carrying it to liver for getting oxidized in the liver. Thus, CNSL reduces excess cholesterol and also positively and efficiently controls the oxidativestress,swellingandinflammatoryissuesandthe cardiacfunctions.ThelipidsinCNSLhaveanti-inflammatory, heartprotectingandanti-cancercharacteristics.

Zea-Xanthine is an antioxidant pigment that is present in CNSL. The retina in our eyes rapidly and immediately absorbstheZea-Xanthinethatprovidesaprotectiveshieldto oureyesagainsttheharmfulultravioletradiation.CNSLthus contributes to our eye health and the Zea-Xanthine also preventsmusculardegradationduetoageinginanelderly adult.

Cashew Nut Shell Liquid (CNSL)’s main components are Anacardicacid,Cardanol,Cardolandsomesmallamountsof other phenolic derivatives. Cardanol, which is separated fromCNSLcanbeusedindieselengineasabiofuel.Biodiesel on being blended with petroleum diesel, is commonly referred to as a biodiesel blend. It can be used as fuel in unmodifieddieselengine.TheCardanolbiofuel/biodieselis hydrophobic and remains flexible and liquid at very low temperatures.Cardanolimprovesflexibilityandgooddrying after baking. It also significantly improves electron insulationpropertiesandthermalstability.Cardanolalsohas alowfreezingpointofabout-20°C.Allthesecharacteristics of cardanol make cardanol an effective substitute for the petroleum-based phenol. Viscosity which is a major drawbackforeverybiomasscanbereducedwhileblending withdieselorinadditiontotheethanol.FlashandFirepoint ofCNSLarehigherthandiesel.FlashpointandFirepointof Cardanolareapproximately92°Cand96°C.HigherFlashand Fire point indicates the oil is well suited for storage, transportationandhandling.Calorific valueofCardanolis veryclosertodiesel,whichenableshigherquantityofheat liberation during combustion. Cardanol is added to diesel withoutanyadditives.Biodieselisagreenenergysourceand

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

ecofriendly due to its phenolic contents, which reduces environmentalpollution.Theuseofbiodieselisgoodforthe environment because it made from bioresources and has loweremissioncomparedtopetroleumdiesel.Besides,India is2nd largestproducersofcashewintheworld,whichisthe rawmaterialofCNSL.CNSLcanbeusedindieselgenerators and vehicles in the form of effective biodiesel blend. PerformanceofanenginewhenrunwithCNSLwasfoundto be poorer compared to diesel and it can be improved by modifying the fuel by blending, preheating, using fuel additivesetc.

Nowadays, increasing number of the world population is gettingaffectedwithdenguefever.Someofthepeopleare facingthemoresevereformoffeverknownisDHF(Dengue Hemorrhagic Fever). Dengue is generally caused by a mosquito type with the scientific name of Aedes aegypti Despite a lot of researches and investigation, still no medicinal cure has been found out against this disease. Larvicidesareusedtopreventthebreedingofmosquitoes. Theyareusedatthelarvalstagesinceitiseasiertocontrol atthatspecifictime.Thecommonlyusedlarvicideshavea disadvantageofgivingrisetoresistantinsectspecieswhich willnotgetaffectedbytheuseofthoselarvicidesanymore.

Cardanolanditsderivativescanbeapotentialsourceforthe development of larvicides in the countries which lead in cashew production. It can also be a hefty addition to the economyofthatcountrysincedenguefeverisbecominga worldwide problem and we immediately need to use all kindsofalternativestopreventthebreedingofmosquitoes.

Automobileexpertsaddfrictiondusttothebrakeliningsin ordertoadjustthefrictionalandwearandtearproperties. Recordsofimprovisedskidresistanceandmuchlessnoise during brakes have been reported. Friction dust is commerciallymanufacturedbythecrosslinkingofcardanolformaldehyde resins with paraformaldehyde or hexamine andthentheobtainedproductispowderedaccordingtoour requirements. Friction dust, on being impregnated with boricacid(popularlyknownasboratedfrictiondust)finds applicationinairbrakepads.Also,nofirecatchesduringthe transportation of CNSL-formaldehyde based resins and frictiondust.CNSL-Formaldehyde(CF)resinsonbeingused in friction dust reduces fade significantly by faster heat dissipation ascompared to the phenol-formaldehyde(PF) resins.CF resinsalsooffera greaterrepellencetowater in conditionsofwetting.CFresinsresultintheproductionof muchsoftermaterialswhicharemuchmoreadvantageousin casesofcoldwearconditions.CFresinsarealsomuchmore costefficientascomparedtoPFresins.CFbasedfrictiondust

alsoresultsinsilentbrakeswhicharemuchdesiredinthe currentsituationofincreasednoisepollution.Tonsofbrake linings are manufactured for being used in automobiles everyyear.So,withtheincreasinguseofautomobiles,there isgreatopportunityofusingCNSLbasedresinsasfriction dust in vehicles as CNSL is much more eco-friendly in comparisonofotherformaldehyderesins.

Theadditionofchemical additivestocrudeoilinorder to reduce its viscosity prevent wax formation, is becoming quitecommon.Inthepresenceofasphaltenes,naturalCNSL cansignificantlyreducethepourpointofwaxycrudeoil.If the molecular weight of CNSL can be controlled properly then that modified CNSL can be used as a potential pour point depressant in oil industries. The modified CNSL reduces the viscosity of waxy crude oil and removes the waxynatureoftheoilasaresult.

The soaring development of rubber is increasing the requirementofnewingredientsandalternativeswhichmay be applied during the time of rubber compounding for vulcanization.ImpregnationofCNSLderivativesinrubber improvestheelasticstrengthandresistanceofferedagainst abrasion.Italsoreduceswearandtearandpromotesselfadhesion properties of rubber. Cashew modified phenolformaldehyderesinsimprovethechemicalresistivityofthe vulcanizedrubber.

CNSLresinshavetheability todecreasethebrittle nature andenhancetheflexibilityoflamination.Cardanolandother CNSLresinousproductsaresignificantlyusedinlaminating industries for effective outcomes. CNSL resins of this categoryaremanufacturedbycondensationpolymerization ofCashewnutshellliquid(CNSL),phenolandformaldehyde. Theseresinsalsoimpartenhancedhardeninguponageing andstrongerbondingwiththesubstrate.Ahugeamountof CNSL is required by the laminating industries for the manufactureofCNSLbasedlaminatingresins.

Nowadays,constructionswidelyusepolymer-basedcements due to their good adhesive qualities and resistance to moisture,acidsandbases.Thephosphorusmodified-CNSL polymericresinhighlysuitsthisrequirement.Thispolymer stickswellontothesurfaceofporousbricks,concreteand steel.Theycanbeeasilysetatlowtemperaturesbytheslow andgentleadditionofheat.CNSL-basedpolymerscanalso befoundusefulinsealingleakspresentintheroofs.These

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

CNSL-basedpolymerson beingmixedwitha curingagent formsaputtywhichcanbefilledintothecavitiesoftheleaks inordertosealthem.

SurfacecoatingswhicharederivedfromCashewnutshell liquid(CNSL)exhibitexcellentlustreandsurfacefinishwith optimizedlevelsoftoughnessandelasticproperties.CNSL resins are impregnated into synthetics by paint manufacturingindustriestomodifythepaintpropertiesand todecreasethecost.Ithasanti-thermiteandanti-microbial properties.DuetoitsdarkishbrowncolorCNSLisusedto make dark-colored paints and enamels. CNSLderivativescanalsogiveahighlyefficientperformance aslacquers.Thedrylacquerfilmsaremuchbetterthanthe ordinaryoil-basedpaintssincethedrylacquersareresistant tooildamages,moisturedamagesandisalsoresistanttoany kind of chemical action. CNSL resins in combination with some other polymers can contribute to a good roof protection.Anti-corrosivepolymersmanufacturedfromthe cashew nut shell liquid derivatives can be used as a protective lining for the bottoms of sea ships. Zinc incorporated CNSL polymers may be used as surface coatingswhicharerust-proof.

Cardanol or CNSL derived epoxy-resins offer much more stronger and efficient characteristics as compared to the commonphenolicsandpolyestersthosewhichweuseinour dailylives.Nowadays,inmanyresearchsectorsepoxy-resins are being produced from cardanol. The epoxy-resins are generallymanufacturedelectrophilicreactionofphenolwith cardanolinpresenceofanacidcatalystinordertoobtaina bisphenolwhichinordertoattainthefinalproductisthen further epoxidized. The side chains in the final product enhancetheflexibilityandtheresistanceofferingcapacityas comparedtotheconventionalepoxy-polymersavailablein themarketsfortheconsumers.

Specializedwoodproductsaremanufacturedandsoldafter incorporationoftheCNSLderivedmonomersinrawwood followedbyin-situpolymerization.Generally,cardanoldoes not get polymerized by the traditional energy irradiation methods or the free radicals. So special methods are requiredforthispurpose.CNSLbasedadhesiveshavebeen studied and diagnosed to possess notable and efficient characteristicsthat would playa huge role in meeting the ever growing want for excellence and permanence in bonding plywood. Varied range of CNSL-aldehyde resins, upon being impregnated into woods of lower grades e.g., rubber wood, have been reported to show a significant upgradation in quality. CNSL derived composites are also

value:

equallyapplicableinthemanufactureofwoodenboardsas wellasboardsmadeoutofcoconutleaf.SuchCNSLbased compositesarealsocost-effectiveandthuscanbeapotential efficientalternativeforthemankindtouse.

Sincethemoderngenerationfacestheproblemofincreasing energy demand and continuous depletion of fossil fuels, alternativesustainableinnovationsareneededtomeetthe presentdemandsandpreventthegrowthofnewproblems. Thethoughtofusingtheagro-industrialwaste,CNSLasan alternativerawmaterialsourcehasdrawntheattentionof scientists. Nowadays, with increasing cashew production, CNSLisbecominganefficientalternativefortheproduction offunctionaloutputsandalargenumberofresearchpapers arebeingcontributedtothispurpose.However,isolationof pure cardanol is still a great challenge for us and since cardanol is the prime source of all these applications, researches are being conducted now to obtain the purest form of cardanol by extraction. Cardanol and other CNSL derivatives find their applications in a varied range of disciplines including production of biodiesel, larvicides, vulcanizedrubber,brakelinings,foundrychemicals,surface linings, surfactants and the list is yet to be continued and discovered. Thus, CNSL can perform as a promising supplementtothepetrochemicalderivativesobtainedfrom petroleum reserves, that are currently getting exhausted. India,beingthesecondlargestproducerofcashews,exports its cashew and CNSL to USA and China, the importing countries. So CNSL can also serve as a great source of economy.

[1] Andrade TJAS, Araújo BQ, Citó AMGL et al (2011) Antioxidant properties and chemical composition of technicalCashewNutShellLiquid(tCNSL).FoodChem 126:1044–1048

[2] Balachandran VS, Jadhav SR, Vemula PK et al (2013) Recent advances in cardanol chemistry in a nutshell: fromanuttonanomaterials.ChemSocRev42:427–438

[3] Balgude D, Sabnis AS (2014) CNSL: an environment friendlyalternativeforthemoderncoatingindustry.J CoatingTechRes11:169–183

[4] Yuliana M, Tran-Thi NY, Ju Y-H (2012) Effect of extractionmethodsoncharacteristicandcomposition of Indonesian cashew nut shell liquid. Ind Crop Prod 35:230–236

[5] Sanjeeva SK, Pinto MP, Narayanan MM et al (2014) Distilledtechnicalcashewnutshellliquid(DT-CNSL)as aneffectivebiofuelandadditivetostabilizetriglyceride biofuelsindiesel.RenewEnergy71:81–88

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

[6] Patel RN, Bandyopadhyay S, Ganesh A (2006) Extractionofcashew(Anacardiumoccidentale)nut shell liquid using supercritical carbondioxide. BioresourTechnol97:847–853

[7] ParamashivappaR,KumarPP,VithayathilPJ(2001) Novel method for isolation of major phenolic constituentsfromCashew(Anacardiumoccidentale L.) Nut Shell Liquid. J Agric Food Chem 49:2548–2551

[8] Lomonaco D, Maia FJN, Clemente CS et al (2012) Thermal studies of new biodiesel antioxidants synthesizedfromanaturaloccurringphenoliclipid. Fuel97:552–559

[9] Sagadevan Thenesh kumar, Tunga Himabindu and Vinithaa Raguram, Review on Various Methods of ExtractionofCashewNutShellLiquidandIsolation of Anacardic Acid, Department of Chemical Engineering, SRM University, Chennai- 603203, Tamilnadu, INDIA. International Journal of Institutional Pharmacy and Life Sciences, InternationalJournalofInstitutionalPharmacyand LifeSciences5(1): January-February2015,(ISSN): 2249-6807

[10] Oliveira MSC, Morais SM, Magalhães DV (2011) Antioxidant, larvicidal and anti acetylcho linesteraseactivitiesofcashewnutshell liquidconstituents.ActaTropic117:165–170

[11] ParamashivappaR,KumarPP,VithayathilPJ(2001) Novel method for isolation of major phenolic constituentsfromCashew(Anacardiumoccidentale L.) Nut Shell Liquid. J Agric Food Chem 49:2548–2551

[12] Patel RN, Bandyopadhyay S, Ganesh A (2006) Extractionofcashew(Anacardiumocciden tale)nut shell liquid using supercritical carbon dioxide. BioresourTechnol97:847–853

[13] RiosMAS,MazzettoSE(2012)Thermalbehaviorof phosphorus derivatives of hydrogenated cardanol. FuelProcessTechnol96:1–8

[14] Olife I C, Jolaoso M A, Onwualu A P. Cashew processing for econonic development in Nigeria. Agricultural Journal. 2013; 8(1), 45 - 50. DOI: 10.3923/aj.2013.45.50.

[15] PatelaR.N,BandyopadhyaybS,GaneshA.Selective extraction of cardanol and phe‐ nols from cashew nutshellliquidobtainedthroughpyrolysisofcashew nut shells. In: Proceedings of the Indian Chemical Engineering Congress, Novel Separation Processes

Session(CHEMCON-2005)14-17December2005; NewDelhi,India.

[16] AkinhanmiTF,AtasieVN,AkintokunPO.Chemical composition and physico‐ chemical properties of cashewnut(Anacardiumoccidentale)oilandcashew nut shell liquid. Journal of Agriculture, Food and EnvironmentalSciences.2008;2(1),10pp

[17] Pushparaj T, Ramabalan S. Influence of CNSL biodiesel with ethanol additive on die‐ sel engine performance and exhaust emission. International JournalofMechanicalEngineeringandTechnology (IJMET).2012;3(2),665-674

[18] HammedLA,AntiqueJC,AdedejiA.R.Cashewnuts andproductiondevelopmentinNigeria.AmericanEurasianJournalofScientificResearch.2008;3(1): 54-61

[19] FAOSTATdata,2013(lastaccessedbywww.top5of anything.com:December2014).

[20] Ojewola G S, Okoye F C, Agbakuru I. Performance value of cashew nut meal for soya bean meal in finishing broiler chickens. International Journal of Poultry Science. 2004; 3(8): 513-516. DOI: 10.3923/ijps.2004.513.516.

[21] Kozubek A, Tyman J H P. Resorcinolic iipids, the natural non-isoprenoid phenolic amphiphiles and their biological activity. Chemical Reviews. 1999, 99(1):1-25.DOI:10.1021/cr970464o

[22] SueAzam-Ali.Cashewnutprocessing–Anoverview of delicious cashew nut proc‐ essing and various choicesinmethods.Technicalbrief,PracticalAction. Schlumachercentre,bourtononDunsmore,Rugby, Warwickshire,U.K.2001,9pages.

[23] PatelRN,BandyopadhyayS,GaneshA.Extractionof cashew (Anacardium occiden‐ tale) nutshell liquid using supercritical carbon dioxide. Bioresource Technology.2006;97:847–853

[24] MazzettoSE,LemonacoD,MeleG.Cashewnutoil: opportunities and challenges in the context of sustainableindustrialdevelopment.QuímicaNova. 2009; 32(3): 732-741. DOI:10.1590/S010040422009000300017

[25] RodriguesFHA,FrançaFCF,SouzaJRR,RicardoN M P S, Feitosa J P A. (2011) Comparison Between Physico-chemicalpropertiesofthetechnicalcashew nutshellliquid(CNSL)andthosenaturalextracted fromsolventandpressing.Polímeros.2011;21(2): 156 -160. DOI: 10.1590/S0104-

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page1115

14282011005000028. 20 Advances in Petrochemicals

[26] DasP,SreelathaT,GaneshA.Bio-oilfrompyrolysis of cashew nut shell characteriza‐ tion and related properties.BiomassandBioenergy.2004;27:265275.DOI:10.1016/S0961-9534(02)00182-4

[27] Tsamba A J, Yang W, Blasiak W. Pyrolysis characteristicsandglobalkineticsofcoco‐nutand cashewnutshells.FuelProcessingTechnology.2006, 87:523-530.DOI:10.1016/j.fuproc.2005.12.002

[28] Shobha S V, Ravindranath B. Supercritical carbon dioxideandsolventextractionofthephenoliclipids of cashew nut (Anacardium occidentale) shells. JournalofAgricul‐turalandFoodChemistry.1991; 39:2214-2217.DOI:10.1021/jf00012a022

[29] SmithR.L,MalaluanR.M,SetiantoW.B,InomataH, AraiK.Biobasedmanufactureofalkylphenolsand polysaccharidesfromcashewnutwithsupercritical carbondi‐oxideandwater.BioresourceTechnology. 2003;88:1-3.

[30] Yuliana M,NgocYen Tran-Thi,Yi-HsuJu.Effectof extraction methods on character‐ istic and compositionofIndonesiancashewnutshellliquid. Industrial Crops and Products. 2012; 35(1): 230 –236.DOI:10.1016/j.indcrop.2011.07.007

[31] Patel R N, Bandyopadhyay S, Ganesh A. Economic appraisal of extraction of refined cashew nut shell liquidthroughsupercriticalfluidextraction.Journal ofchromatog‐raphyA.2006;1124:130-136.

[32] AOAC. Official Methods of Analysis of the AssociationofOfficialAnalyticalChem‐ists,Edited byKenethHelrich,15thed.1990.

[33] Strong F M, Koch G H. Biochemistry laboratory manual. 2nd ed. Dubuque, IA: W.M.C. Publishers. 1974.

[34] RodriguesFHA,FeitosaJPA,NágilaMPS,Ricardo F C F, de França A, José O B, Cario M. Antioxidant activityofcashewnutshellliquid(CNSL)derivatives on the thermal oxidation of synthetic cis-1,4polyisoprene. Journal of the Brazilian Chemical Society.2006;17(2):265-271.DOI:10.1590/S10350532006000200008

[35] Raghavendra Prasada S A. A Review on CNSL biodiesel as an alternative fuel for diesel engine. InternationalJournalofScienceandResearch(IJSR). 2014;3(7):2028-2038.

[36] Risfaheri T T I, Nur M A, and Sailah I. Isolation of cardanol from cashew nut shell liquid using the vacuum distillation method. Indonesian Journal of Agriculture.2009;2(1):11-20.

[37] GandhiT,PatelM,DholakiyaB.K.Studiesoneffect ofvarioussolventsonextractionofcashewnutshell liquid (CNSL) and Isolation of major phenolic constituentsfromextractedCNSL.JournalofNatural ProductandPlantResources.2012;2(1):135-142.

[38] BuchweishaijaJ,MkayulaLL.Theeffectofrotation andtemperatureontheinhibi‐tionperformanceof cashew(AnacardiumoccidentaleL)nutshellliquid oncorrosionCashewNutShellOil ARenewable and Reliable Petrochemical Feedstock http://dx.doi.org/10.5772/6109621ofcarbonsteel. Transactions of the Journal Engineering and Technology.2008;2(2):121-125.

[39] SangerSH,MohodAG,KhandetodeYP,ShrirameH Y,DeshmukhAS.Studyofcarbonizationforcashew nut shell. Research Journal of Chemical Sciences. 2011;1(2):43-55

[40] Velmurugan A, loganathan M. Effect of ethanol addition with cashew nut shell liq‐ uid on engine combustion and exhaust emission in a DI diesel engine.InternationalJournalofEngineeringScience andTechnology.2012;4(7):3316-3328.

[41] OliveiraMS,MoraisSM,MagalhãesDV,BatistaW P,VieiraIG,CraveiroAA,deManezesJE,CarvalhoA F,deLimaGP.Antioxidant,larvicidalandanti-acetyl chol‐inesteraseactivitiesofcashewnutshellliquid. Acta Tropica. 2011; 117(3): 165-170. DOI: 10.1016/j.actatropica.2010.08.003

[42] Lomonaco D, Cangane F Y, Mazzetto S E. Thiophosphate esters of cashew nutshell liquid derivatives as new antioxidants for poly(methyl) methacrylate. Journal of Thermal Analysis and Calorimetry.2011;104(3):1177-1183.

[43] Vasapollo G, Mele G, Sole R D. Cardanol based materialasnaturalprecursorsforolefinmetathesis. Molecules.2011; 16: 6871 -6882. DOI: 10.3390/molecules16086871

[44] VasapolloG,MeleG,SoleRD,PioI,LiJ,MazzettoS E. Use of novel cardanol-por‐ phyrin hybrids and their TiO2 -based composites for the photodegradation of 4-nitro‐ phenol in water. Molecules. 2011; 16: 5769 -5784. DOI:10.3390/molecules16075769

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056 Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page1116

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056 Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

[45] Fernando José Araújo da Silva and José Everardo XavierdeMatos.Anoteonthepo‐tentialofCNSLin fuelblendsforenginesinBrazil.RevistaTecnologia. 2009;30(1):89-96.

[46] PaisalNakpipatandHirooNiiyamaDieseloilfrom cashew nut shell liquid. Regional Symposium on ChemicalEngineering.1999.

[47] SolankiJH,JaviyaTV.Cashewnutshellliquidfuela substitute for diesel fuel to be used in C.I. engine. International Journal of Advanced Research in Science,Engineer‐ingandTechnology.2012;1(2):8 -12

[48] Ribeiro E A, Fernando Felipe Lopes Antunes, Verônica Teixeira Franco Castelo Bran‐ co, Sandra AguiarSoares,JorgeBarbosa Soares.Evaluation of moisturedamageinasphaltcontainingcashewnut Shellliquid(CNSL)modifiedbitumen.In:Proceed‐ings of the 5th Euro asphalt & Euro bitumen Congress;13-15thJune2012,Istanbul.10pages

[49] GangulyA,RajiG.Asbestosfreefrictioncomposition forbrakelinings.BulletinofMaterialsScience.2008; 31(1),19-22.DOI:10.1007/s12034-008-0004-622 AdvancesinPetrochemicals

[50] Murthy B.G.K, Sivasamban M.A. Recent trends in CNSL utilization. Cashew Re‐ search and Development: Proceedings of the International CashewSymposium,Co‐chin,Kerala,India,1985,12 -15.

[51] deLasaHI,AfaraS.Processingofcashewnutshell liquid. Final Technical Report; Mozambique. Chemical Reactor Engineering Centre, Faculty of EngineeringScience,UniversityofWesternOntario, London.August1,1995.

[52] Tuan Q Dang and Tien K Nguyen, Impact of ExtractionMethodontheOilYield,Physicochemical Properties,FattyAcidCompositionandStabilityof Cashew Nut (Anacardium occidentale L.) Oil, Department of Food Technology, International University -VNU, Ho Chi Minh City, Vietnam, EC Nutrition14.2(2019):165-171.

[53] Thierry Godjo, Development of an Oil Extraction Machine for Cashew Nut Shell Department of Mechanical Engineering, University Institute of Technology of Lokossa, B.P. 133 LOKOSSA, Benin Laboratory for Applied Energy and Mechanics (LEMA),EPAC,Abomey-Calavi,Benin,International Journal ofEngineeringand Techniques - Volume 2 Issue6,Nov–Dec2016.

[54] Uche J. Chukwu, Sampson Kofi Kyei & Onyewuchi Akaranta, Extraction Characterization and ApplicationofCashewNutShellLiquidfromCashew Nut Shells, Africa Centre of Excellence in Oilfield Chemicals Research, Department of Pure and IndustrialChemistry,UniversityofPort

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |