International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

*Master of Civil Engineering (Construction Technology and Management).

*Master of Civil Engineering (Construction Technology and Management). ***

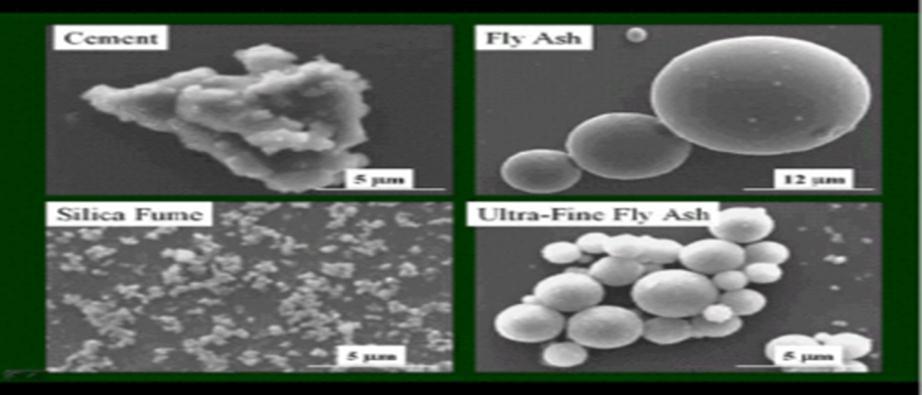

Abstract - This research indicates the Effect of Admixture on Properties of Concrete. Concrete is a man or a machinemade construction material that has more usage in the construction field, it is necessary to make construction secure and safe for making high strength concrete the admixture Silica fume is a good choice to make the compressive strength of concrete very high but for having a high strength concrete. Chemical Admixtures interact with hydrated cementitious materials and are divided into three categories of Admixtures with physical, chemical, and physical-chemical performance. Admixtures with a physical function are chemical Admixtures that do not have a direct effect on the cement dewatering reaction process, although they may affect its process and rate. These Admixtures generally show their effect and function before the initial setting of concrete and their effect does not continue after setting in hardened and hardened concrete. These Admixtures include water reducers, aerobes, gas generators, foaming agents, aerators, anti-scouring agents, pumping facilitators, colorants, and bonding agents. Admixtures with chemical function either affect the process and reaction process of pre-setting cement dewatering or alter the microstructure of dewatering products before and after setting. Therefore, in addition to the pre-set time, the reaction of chemical Admixtures may continue in the hardest stages of concrete. Reinforced concrete is brittle and has less tensile strength. In order to reduce the weakness of fragility, thin and short filaments that are randomly distributed in all directions in concrete are a very suitable method (these thin filaments are called fibers). The main reason for using fibers in concrete is to increase the hardness and tensile strength, improve crack control and deformation.

methods of construction in the world today is concrete buildings. After the Islamic Revolution, due to the lack of beams as a result of sanctions and the expansion of constructioninthecountry,theuseofconcretegrewgreatly. Inaddition,concretebuildingshaveadvantagesoversteel buildings,suchasgreaterresistancetofireandatmospheric factors(corrosion),easeof preparationofconcretedueto theabundanceofconcretematerials,andinsulationagainst heat and sound, which is the development of the day. In addition, it provides this type of building. One of the important disadvantages of concrete buildings is the very highweightofthebuilding,whichisdirectlyrelatedtothe amount of earthquake damage to the building. If we can make the separating blades and panels of lightweight concrete, the weight of the building and as a result, the destructionofthebuildingbytheearthquakewillbegreatly reduced.However,thelowstrengthoflightweightconcrete has been an important factor in limiting the scope of applicationofthistypeofconcreteandtakingadvantageof it.

Words: Admixture,Concrete,SilicaFume(SF),FlyAsh (FA),Grade43Portlandcement(PC)

The production of cement, the main adhesive in concrete, wasstartedinEnglandin1756byJohnSmeaton,whowas responsible for building the foundation of the Eddystone tower, and finally Portland cement in 1824 on the same island.ThenamewasregisteredintheUKbyJosephAspdin. Thepeopleofourcountryalsobecameacquaintedwiththe consumptionofcementsince1312withtheconstructionof theRayCement Factory,andwith thedevelopment of the country’s industries, today about 26 to 30 million tons of cement are produced per year. With the knowledge of engineersonhowtousecementincivilworks,thismaterial found its place in our country. One of the fastest-growing

The use of micro silica in the manufacture of lightweight concretehasincreasedthestrengthoflightweightconcrete andreducedthislimitation.Inthisresearch,whileexplaining concreteandtheeffectofwateronconcretestrength,more aboutlightconcreteandmethodsofincreasingitsstrength using micro silica, mechanical properties, and also its applicationsarediscussed.Atfirst,itmaybethoughtthatthe mainbuildingmaterialisaviscousmaterialresultingfrom thehydrationofcementandwaterandthataggregatesare cheap and filler materials of this adhesive. The second possibility is that coarse aggregates are considered as masonryjoinedbymortarandthismortariscementslurry andfineaggregates.Thethirdpossibilityisthatconcreteis considered as a material of two different phases, namely hydratedcementandstonegrains.Therefore,theproperties ofconcretedependonthepropertiesofeachofthephases andtheinterfacebetweenthetwophases.Eachofthesecond andthirdtheorieshaslimitationsandcanbeusedtoexpress thebehaviorofconcrete.Butinthefirsttheory,theseissues donotexist.

If it is thought that cement can be produced cheaper than aggregates,thequestionariseswhethercementandwater can be used alone as a building material (concrete)? The answerwilldefinitelybeno,duetothehigh-volumechanges inthecementpaste.Theshrinkageofpurecementpasteis

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

approximately 10 times that of concrete with 250 kg of cementpercubicmeter.Thesameistrueforcreepanddrop. In addition, the high heat generated by consuming large amounts of cement, especially in hot climates, will cause cracks.Italsomakesaggregatesmoreresistanttochemical attackthancementpaste,althoughthecementpasteisalso relativelystableinthesecorrosiveenvironments.Therefore, regardlessofthepriceofstonematerialsinconcretewillbe veryuseful.

• Cement:makesupabout7to15%ofthevolumeof concrete

• Water: makes up about 14 to 21 percent of the concretevolume

• Rockaggregates(sand):makeupabout60to75% oftheconcretevolume

• Air:Inairlessconcrete,theamountofairvolumeis between0.5to30%andinaeratedconcrete,theamountof airvolumeisbetween4to8%.

• Admixtures:Thesearechemicalsthatareaddedto the mixture in small amounts and as a percentage of the weight of cement to create the desired properties in concrete.

Any adhesive is called cement. However, the adhesive of stone materialsin concrete iscalledcement, whose roleis simplytostickthegrainstogetherandalonedoesnotaffect thestrengthandload-bearingcapacity. Table -1: Cementcomponents

• TypeIcement,ordinarycement,thistypeofcement isusedinnormalweatherconditionsandwherethereisno form in terms of sulfate (Uses: All concrete works such as streettables-mortars-coatingsand.....

• TypeIIcement,mediumcement,thistypeofcement ispartiallyretardantandalsopartiallyresistanttotheattack of sulfates. Uses: (For concreting in hot environments and bulkconcretingand...

• Type III quick-setting cement this, type of cement has the basic components of type I cement, but is finely groundandthereforehasafastersetting.Uses:Manufacture ofprecastconcreteparts,useincoldweather,inworkshops thatuseslipperymolds.

• TypeIVcement,quick settingcement,thistypeof cementisaretarderandhaslessC3sandC3Aandhasmore C2S. Uses: In bulk concreting, in hot environment temperature above 40 degrees, concreting in successive layers Note: Consumption of this cement in hot weather preventscoldconnection.

• Typefivecement,anti-sulfatecement,thistypeofcement is suitable for use in concreting that is exposed to sulfate attack.

If we can make the separating blades and panels from lightweight concrete, the weight of the building and as a resultthedestructionofthebuildingbytheearthquakewill begreatlyreduced.However,thelowstrengthoflightweight concretehasbeenanimportantfactorinlimitingthescopeof applicationofthistypeofconcreteandtakingadvantageofit.

The place of water use in concrete is very sensitive in termsofhydration.Lackofproperuseofwaterwillleadto thefollowingproblems:

• Cementsettingtimeisdelayed,concreteisdelayed

• Decreasesthefinalstrengthofconcrete(sometimes reducesthestrengthbyupto30%)

• Causes corrosion and gradual deterioration of rebars.

Tricalciumsilicate:(3Cao-Sio2)abbreviated(C3S),Calcium silicate:(2Cao-Sio2)abbreviated(C2S),Tricalciumaluminate: 3Cao-Al2o3)withtheabbreviation(C3A),Aluminophytetetra calcium:(4Cao-Al2o3-Fe2o3)abbreviated(C4AF)

• Onthesurfaceofthefinaldriedconcrete,itcreates stains that are especially important in concretes whose surfaceisplacedinthefaçade

• Notacidicandalkaline(PHbetween6to8).

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

• Thepercentageofcarbonatesislessthan0.1%.

• Thepercentageofsolids(suspendedparticles)initis lessthan0.1%.

• The percentage of chlorides should be less than 0.05%.

• Thepercentageofsulfatesshouldbelessthan0.1%.

• The sum of calcium and magnesium carbonate in waterusedinconcreteisnotconsideredharmfulifitisupto 0.4%.

• Thetotalsaltsofmanganese,tin,zinc,leadshould notbemorethan0.5%.

• Ironsaltsinconcretewaterdonotaffectthestrength ofconcreteupto4%.

• One of the most unsuitable water impurities in concrete is sodium sulfide, which has a maximum vapor contentof1%.

• Theuseofseawaterduetothepresenceofsaltsof chlorides,sulfates,etc.,whichreducesthestrengthbyupto 15%,andontheotherhand,thechlorineinseawatercauses corrosion of rebars over time and its use in reinforced concreteisnotallowed..

• Stonegrains(sand)

1-Theseedsshouldbecompletelycleanandfreeofmud andchemicalimpurities.

2-Thegrainsmustberesistanttoabrasionandstress.

Note:Silicaaggregateshaveahardnessof7to8andare the most resistant aggregates used in concrete. Limestone grainshaveahardnessof3to4whichareusedinmaking concrete.

3.Theseedsmustberesistanttofrost,whichdependson thefollowing3factors.

A- Porosity: The higher the porosity of the grains, the lowertheresistancetofrost.

B.Impermeability:Thehigherthegrainpermeability,the lowerthefrostresistance.

C-Tensilestrength:Thehigherthetensilestrength,the greatertheresistancetofrost.

4.Theseedsmustberesistanttoweathering. Intermsoffinalstrengthofconcrete,concretethatismade withangledgrainswillbemoredurableduetothepossibility

of better aggregation of grains with each other and the friction of the best of them. It is recommended to use this typeofgrainincaseswhereveryhighresistanceisdesired (above350to400Kg/cm2),butinnormalworkwhereless resistanceisthecriterion,roundandirregulargrainscanbe used.

• Concreteismainlycomposedoftwoparts

• Stone materials: About 60 to 75% of the concrete volumeconsistsofstonematerials.

• Cementpaste:About25to40percentoftheconcrete volumeisfilledwithcementpaste.From25to40percentof cementpasteis17to15percentcementand14to21percent water.

• Watercontentincementpaste(W/C)

• WrepresentswaterandCrepresentstheweightof cement,sothatalowW/Cratiocanbeselected.

• Thisrateisabout0.4to0.6percent.

• Characteristicsofusinglesswatertocementratio

• Increase the compressive and tensile strength of concrete.

• Increasethesealingpropertyinconcrete.

• Reducedwaterabsorption.

• Better bonding between cardboard layers in concreting.

• Increasedadhesionbetweenrebarandconcrete.

• Increasedresistancetoadverseweatherconditions.

• Reduce drop rate, creep rate and reduce the possibilityofwaterdroppingconcrete.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

• Reducethepossibilityofgrainseparation.

• Concreteperformance(slump)

ConcreteismainlycomposedoftwopartsStonematerials: About 60 to 75% of the concrete volume consists of stone materials. Cement paste: About 25 to 40 percent of the concretevolumeisfilledwithcementpaste.From25to40 percentofcementpasteare17to15percentcementand14 to21percentwater.Watercontentincementpaste(W/C) WrepresentswaterandCrepresentstheweightofcementso thatalowW/Cratiocanbeselected.Thisrateisabout0.4to 0.6 percent. Characteristics of using less water to cement ratio Increase the compressive and tensile strength of concrete.Increasethesealingpropertyinconcrete.Reduced water absorption. Better bonding between the cardboard layersinconcreting.Increasedadhesionbetweenrebarand concrete.Increasedresistancetoadverseweatherconditions. Reduce drop rate,creep rate, and reduce the possibilityof water dropping concrete. Reduce the possibility of grain separation.Concreteperformance(slump).

1- Watering:

It seems that after concreting and polishing the concrete surface, a thin layer of water impregnated with cement appearsontheconcretesurface.Themostimportantreason is excessive slump. Another reason, such as excessive vibrationandinadequategranulation,increasethelikelihood ofconcretemelting.

Themostimportantreasonforgrainseparationishighand excessiveslump.Otherreasonssuchasexcessivevibration, movingtheconcreteintheformwitha shovel orvibrator, pouringconcretefromaheight,improperstorageofgrains, andlackofuniformandcorrectgranulationinconcrete,lead toseparationofgrainsandconcretefromthecompressive

Factor value:

and flexural strength will be weak and will not reach the desiredlevel.

Grain quality: Concrete made of silica grains has a higher strengththanconcretemadeoflimestone.Graincontent:The more grains are used in concrete, the stronger and more durable the concrete. Amount of cement: The higher the amountofcement,thehigherthestrengthofconcrete.Water tocementratio(W/C):Thelowerthisratio (about3.4to 0.4),thehigherthestrengthoftheconcretemade.Concrete life: 7-day strength in ordinary concrete is 70% 28-day strength,28-daystrengthofconcrete,whichisabout90to 95%ofthefinalstrength.

Note: The useful lifeof concrete buildingsisusually in the rangeof50to100years.Concretedifferentiationintermsof density(specificgravity).

1.1. Deferent Types of Concrete added Admixtures

1.2. Ordinary concrete

Concretesthataremadewithordinarycementsoftype(I)to type(V)haveaspecificweightof2200to2500kgpercubic meter,whichisduetothedifferenceingrainmaterialand concretedensity.

1.3. Light weight Concrete

It is concrete whose specific weight is 1.2 to 1.3 times the specificweightofordinaryconcrete,whichismadeofnatural or broken aggregates. The specific weight of this type of concrete is approximately 800 Kg / m3, which is used for facades,partitionwalls,roofsandbasicallywherethereisno resistance.Classificationoflightweightconcreteaccordingto theirtypeofapplication.

A-Lightweightstructuralconcretes:

Thistypeofconcretehasa specificmassbetween1400to 1900kg/m3anditsminimumcompressivestrengthisequal to17N/mm2.AggregatesthatareusedaccordingtoASTMC330standardforlightweightstructuralconcreteare:(1Shale,clayandslate2-Roastingprocess3-Expandableslags 1.4.- Pumice (mineral and industrial)

1.5. The main advantages of this type of concrete:

• Reducethecostofheatingorcooling.

• Reduce sound transmission between floors and buildingspace.

• Meanwhile,non-structurallightweightconcretesare dividedintotwogroupsbasedontheirbuildingcomposition.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

A-Foamconcrete:duringtheirconstructionbycreatingfoam, air bubbles in the cement paste or in the cement mortar, aggregatesarecreated.Specificmass(Kg/m3).

B-Concretewithlightgrains:whicharemadeusingperliteor vermiculite or expandable polyester fibers. The specific gravityofthismixture(Kg/m3960to240).

1.6.- Roasted fly ash)

B-Semi-structurallightweightconcrete:

Thistypeofconcretehasacompressivestrengthbetween7 to 17 Newtons per square millimeter and their specific gravityis800to1200Kg/m3.Semi-structuralconcretesare madewithaggregatessuchasperlite,polystyrenefibersand foamfloors.

C-Non-structurallightconcrete:

This concrete is used for filling and thermal insulation purposesandlightseparators(separatingbladesandsound insulationinthefloor).Ithasaspecificgravityoflessthan 3800 Kg / m and despite its low specific gravity, its compressivestrengthcanbeupto7N/m2.

Inmakingthistypeofconcrete,insteadofsand,steelchips, castironorbariumsulfateareused.Thisconcreteisusedto prevent X-ray, Y-radiation, etc., and is mainly used for structures related to nuclear facilities or wherever radioactiveradiationispossible.Thespecificgravityofheavy concrete is about 1.5 to 2.5 times the equivalent of the specificgravityofordinaryconcrete(6400Kg/m3).

Thistypeofconcretewasfoundedusinghigh-strengthsteel aswellasgoodqualityconcrete.Wovenconcreteapplications can be used in the construction of bridges and offshore structures (such as ports, offshore terminals, fixed and floating oil docks) and, most importantly, nuclear power plants. Lack of cracks in structures made of pre-stressed concrete prevents water and moisture from easily penetratingintoitandcausingcorrosionandrustbyreaching thesteel.

Reinforcedconcreteisbrittleandhaslesstensilestrength.In order to reduce the weakness of fragility, thin and short filamentsthatarerandomlydistributedinall directionsin concreteareaverysuitablemethod(thesethinfilamentsare calledfibers).Themainreasonforusingfibersinconcreteis toincreasethehardnessandtensilestrength,improvecrack controlanddeformation.

Applicationsoffiberconcrete:

• Remotecontrolofhighways-roadsandairports.

• Bridgesanddocks.

• On the surface of refractory walls of furnaces (petrochemicalindustries,steel,cementfactories).

• Floors of factories, bus stops, gas stations and industrialhalls.

• Explosion-proofstructures.

• Partsrelatedtotunnelingandminedrilling.

• Protectivewalls,sheltersandhangars.

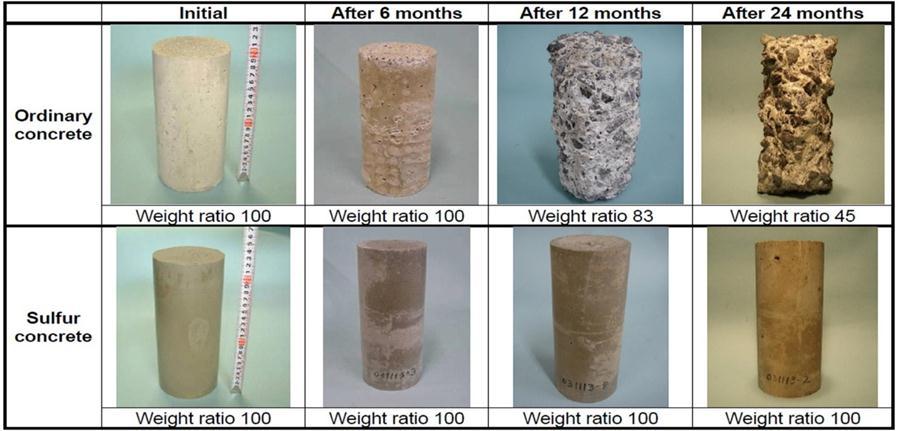

1.10. Sulfur concrete

Today,thistypeofconcrete,whichhasmanyadvantagessuch asresistancetoacidsandcorrosivesubstances,theabilityto meltandreuse,hasgoodflexuralandcompressivestrength, hasbeenconsideredtheuseofsulfurconcreteinareaswhere there is a high risk of corrosion Recommended. Sulfur concrete is made by hot mixing of sulfur and mineral aggregates (like the asphalt production method) and is a thermoplasticmaterial(freeofwaterandcement).Thebest weightratioforpreparingsulfurconcreteis20%sulfur,32% fine-grained,48%coarse-grainedand5%silicapowder.

Polymersareusedtoproducethreetypesofconcrete:

A-Concretewithinjectionpolymer(PIC):

Ithascompressive,tensileandimpactresistancesaswellasa very high modulus of elasticity and is more resistant to freezing,thawingandabrasionbychemicalattacks.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

Methacrylateandstyrenemethylmonomersandepoxyresins areusedtomakethistypeofconcrete.

Madebyaddinga polymerormonomertofreshconcrete, rubber,acrylicandacetatevinylareexamplesofmaterials usedwithananti-foamingagent.

Thistypeofconcreteisusedforrepairingexistingstructures aswellasworksthatdonotrequireformworkorcomplex shapeswithlowthickness.Itisgenerallyusedfortheinner liningoftunnels,tanksandprestressedconcretetanks,and other uses for stabilizing sloping rock cliffs, covering steel platestocreateafireshield.

Liquidconcretethatiscompactedunderitsownweightand hasextremelyhighperformanceandcanbeusedinsections withhighreinforcementwithouttheuseofvibratorsiscalled self-compactingconcrete(s.c.c).Thisconcrete,inadditionto havinghighperformance,non-separationofparticlesforming concrete in the fresh state, has low permeability, high durability and high strength in the hardened state. Its applications, especially in the production of ready-mixed concreteandprefabricatedparts,havebeenconsideredby theconstructionindustry.

1.14. Rolled concrete (RCC)

Itisconcretethatiscompactedbythemovementoftheroller whentheconcreteisnotyethardened.Theslipofthistypeof concrete is zero so that it can withstand the weight of the compactingroller.

• Intheconstructionofroads,freeways,runwaysand hangars, floors of warehouses, industrial roads, mines, stadiums,racetracks,portsanddocks,etc.

• Withstandheavytrafficload,especiallyonslopes

• Stiffnessandnodeformationagainsttheloadsand shockscausedbythefallofhardobjects

• Long-termdurabilitycomparedtobitumenasphalt inthetropics

• Earlyoperation

• Long-termdurabilityoftheconcretesurfaceinareas withfreezingandcoldcyclesofgarlic

• Save fuel consumption and remove contaminants duringcookingandtransportingasphalt

• Resistant to spills of petroleum products, hydrocarbonsandacids.

1.15. High performance concrete (HPC)

Thistypeofconcrete,whichiscalled(superconcrete)has one of the following strength properties:Its 4-hour compressivestrengthmustbeequaltoorgreaterthan175 Kg/cm2(initialearlyresistance).Itscompressivestrength after24hoursshouldbeequaltoorgreaterthan2350Kg/ cm (initial strength of concrete). The 28-day compressive strengthmustbeequaltoorgreaterthan700Kg/cm2The ratioofwatertocementislessthan35%.

It should be noted that concreting in the air has its own problems and difficulties. One of these problems in cold weather is the problem of concrete freezing, in which the water in the concrete freezes and prevents hydration operations. In general, it should be noted that low temperaturescausehydrationtooccurata slowerrate.In this way, the whole process of concreting and obtaining concretestrengthfacesmanyproblems.Theresultcanbea reduction in the durability and strength of the concrete, whichmakesthestructureunsuitablefortheuseofwhatitis designed for. In the long run, cracks may appear in the concreteortheconcretemayformintheformoflaminates, which are not structural engineers at all. To solve this problem, various ideas have been proposed, the most importantofwhichistheuseofantifreeze.Antifreezesmake hydration work well and also in cold weather can reach a suitable and desirable concrete so as not to reduce the strengthofthestructureandcanbeusedeasilyandwithout any problems from the existing structure. For a full explanation, I must say that another name for shotcrete is spray concrete, and as its name implies, this concrete is sprayedonthedesiredsurface.Itshouldbenotedthatthis typeofconcreteisusedtorepairexistingstructuresaswell asworkthatdoesnotrequireformworkorcomplexshapes withlowthickness.

Itiscommonlyusedfortheinnerliningoftunnels,tanksand prestressed concrete tanks, and other uses for stabilizing slopingrockcliffsincludecoveringsteelplatestocreatefire shields.Youmaybewonderingwhatthepurposeofshotcrete isandwhatcanbedonewithordinaryconcrete!Itshouldbe notedthatthepurposeofmakingshotcreteistomakeour finalproducthavehighstrengthandverylowpermeability. One of the main characteristics of concrete that is always mentionedisitshighductility(althoughyoumaynothave imaginedthatconcreteissoflexible,ofcourse,thisisbefore theconcretehardens)andinfactshotcreteisoneofthebest uses.Ourpropertiesareuniquetoconcrete.Toanswerthis question, it must be stated in which structure concrete is

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

used.Inbuildings,inallstructuralelementsofthestructure, suchasbeamsandbeams,structuralfoundationsandshear walls,etc.,theuseofrebarsorreinforcementismandatory becauserebarsagainstthebehaviorofconcretestructures against Improves lateral loads and gravity loads. As you know,concretehasaveryweakactionagainsttensile,sothe use of rebar in the tensile areas of the structure is a basic requirement, and in addition, according to the structural designer,theuseofconcreteinthecompressivepartsofthe structurealsocausestheperformanceofthestructurewill improve.Rebarsareanintegralpartofconcretestructures,it should be noted that insome casesconcrete will not need reinforcement.Likewhenweuseconcreteexceptforleveling under the foundation. As a result, the use of reinforced concrete,ieconcretewithreinforcement,ismandatoryinall partsofbuildings.Yes,itcanbedone,butitmustbesaidthat theopinionoftheexecutorisveryimportantandyoucannot addanyamountofwatertotheconcrete.Watershouldbe mixed withcement in a certainamountandshould notbe moreorlessthantheallowablelimit,whichiscalledtheratio of water to cement. If more or less water is added to the concrete,itwillchangethestrength(decreaseinstrength)of theconcreteandtheconcretewillbecometoofluid,which will lose its structural and load-bearing performance, therefore the ratio Watertocement isvery importantand mustbeobserved.Ifwewanttheconcretetobesmoother, we should not use water and instead it is better to use concrete Admixtures. Addition of materials other than Portland cement, aggregates, and water, in the form of powder(round)orliquid(watery),asoneoftheconstituents ofconcreteandtoimprovethepropertiesofconcrete,shortly before mixing, during mixing or before it is added from pouring. In other words, Admixtures are components of concreteotherthanhydrauliccement,water,aggregatesand fibersthatareaddedtoconcretetoimprovethepropertiesof fresh and hardened concrete and mortar. Concrete admixtures are divided into two groups: chemical and mineralAdmixtures.ChemicalAdmixturesareobtainedby processing, mixing, or blending organic and inorganic materialsinachemicalprocessandinpowderorliquidforms and in small amounts, usually up to 5% by weight of cementitiousmaterialatthetimeoffabricationandmixingor just before pouring concrete. Mixtures are added. Mineral Admixtures, which are either naturally occurring or industrial by-products, are divided into three categories: inert materials, pozzolans, and cementitious materials [1], andto improvethe properties ofcementitious mixturesin generalconsumptionamountsofmorethan5%.Theweight of the cement is added to the concrete during mixing. The scope of this publication (article) includes chemical AdmixturesinconcreteandthestudyofmineralAdmixtures is entrusted to other publications of the Iranian Concrete Association.

Chemical Admixtures interact with hydrated cementitious materialsandaredividedintothreecategoriesofAdmixtures withphysical,chemical,andphysico-chemicalperformance. AdmixtureswithaphysicalfunctionarechemicalAdmixtures that do not have a direct effect on the cement dewatering reaction process, although they may affect its process and rate. These Admixtures generally show their effect and functionbeforetheinitialsettingofconcreteandtheireffect does not continue after setting in hardened and hardened concrete.TheseAdmixturesincludewaterreducers,aerobes, gas generators, foaming agents, aerators, anti-scouring agents,pumpingfacilitators,colorants,andbondingagents. Admixtureswithchemicalfunctioneitheraffecttheprocess and reaction process of pre-setting cement dewatering or alterthemicrostructureofdewateringproductsbeforeand aftersetting.Therefore,inadditiontothepre-settingtime, the reaction of chemical Admixtures may continue in the hardeningstagesofconcrete.

Slow retardants, retarders, quick hardeners, expanders, dehydrationreactioncontrollers,andinhibitorsareamong the Admixtures with chemical function. Physico-chemical AdmixturesAlthoughtheydonotinterferewiththechemical reactionprocessofcementdewatering,theycontrolsomeof the chemical reactions or physical behaviors of hardened concreteinthefuturebyinjectingspecialchemicalsintothe concrete. Corrosion inhibitors, silica alkaline reaction expansion reducers, sealants, permeation reducers, fungicides, microbicides, and insecticides fall into this categoryofAdmixtures.

Chemical Admixtures are divided into seven general categoriesbasedonthetypeofeffectandthemainfunction theyhaveinconcrete.

Reducing Admixtures are used to increase the fluidity of concreteinagivenamountofwater,ortoreducetheamount of water consumed by maintaining fluidity, or both, and includelubricants,superplasticizers,andtransducers.

Itisanadditivethat,duringmixing,createsahomogeneous structureofdiscontinuousmicrobubblesinconcrete,mortar, or cement paste, improving efficiency (workability) and increasingreliabilityagainstfreezingandthawingcycles.

Retardersdelaythesettingofconcretebyslowingdownthe dewateringprocessofthecementandincluderetardersand retarders.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

Accelerators accelerate, harden, or both accelerate the cement dewatering process. Accelerators include accelerators,stimulators,andaccelerators.

Expandersareusedtoincreasethevolumeoffreshconcrete (mortar), compensate for shrinkage of hardened concrete (mortar), or create controlled expansion in hardened concrete (mortar). These Admixtures include shrinkage compensators,gasgenerators,andfoamingagents.

Fasteners improve the reliability of hardened concrete by reducing the penetration of harmful agents, monitoring rebars, or controlling harmful reactions. Permeation reducers, sealants, corrosion inhibitors, and silica alkaline reactionexpansionreducersareincludedinthiscategoryof Admixtures.

SpecialAdmixturesareagroupofchemicalAdmixtureswith special and limited use. Antifreezes, colorants, aerators, pumping facilitators, anti-scourers, dehydration reaction controllers,latexes,andthickenersareexamplesofspecial Admixtures.

Eachadditiveisdefinedandgroupedaccordingtoitsmain function. The main function of an additive is the main expected effect it has on concrete and indicates the performanceofitsadditiveindex.Anancillaryfunctionisthe effect or effects that the additive has on the concrete on a smallerscalethanthemainfunction.SomeAdmixturesmay be multi-purpose and affect several properties of fresh or hardenedconcrete.Forexample,dampingwaterreducers,in additiontoreducingtheamountofwater,alsoslowdownthe concrete.Tip1-1- SomeAdmixturesmayhavesideeffects. For example, the main function of water-reducing Admixturesistoreducethewatercontentofconcrete,but they mayalsohave side effectsof slowing or aerobic. Side effectisanunwantedand,insomecases,evenundesirable effectthattheadditivehasonthepropertiesofconcreteand it should be remembered that it is different from the subfunction.Tip1-2-TheincreasingexpansionofAdmixtures andtheireffectiveapplicationsmayleadtotheemergenceof new Admixtures that do not fit into this weekly categorization. In such cases, the role of regulations, instructions and special technical specifications issued by manufacturersorreputableinternationalscientificsocieties have a special place for the evaluation and acceptance of theseAdmixturesandareacriterionformeasuringthistype ofmaterial.

Concretemustbehomogeneous,efficient,payable,durable, reliable, and low permeability. In many cases, these characteristicscanbeachievedbyselectingtheappropriate materialsandmixingratiosandapplyingthemethodsand using the appropriate equipment and experienced people. TheuseofchemicalAdmixtures,alongwiththeirnumerous benefits, will make it possible and easier to achieve these properties.

In this regard, the most important reasonsand benefits of usingchemicalAdmixturescanbecategorizedasfollows.

The use of Admixtures can lead to various savings and in additiontooffsettingthecostsofpurchasingAdmixtures,it canalsobringeconomicbenefits.Reducingconstructioncosts isdividedintothreecategories:direct,indirect,andcovert savings.Directsavingsarepartofthecostreductionthatcan be easily calculated and measured. These savings include reducing the amount of cement and water, increasing the productivity of manpower, reducing execution time, facilitating and increasing the efficiency of concrete operations, enabling the use of available aggregates and materials,facilitatingthetransferandpouringofconcrete, speedinguptheopeningAndeaseinmanyotherexecutive cases.Indirectsavingsincludereducingthecostofimproving concrete quality, increasing mechanical strength, ensuring uniformity of production, reducing problems and shortcomings during execution, reducing or eliminating rework,improvingtheappearanceandreducingrepairsof concretesurfaces,andcountlessotherthings.Hiddensavings includereducedinvestmentcosts.Theseincludereducingthe depreciation of equipment and machinery, reducing the volume and dimensions of structural members, the possibility of various designs, optimal use of land by designingtallerstructures,andthepossibilityofeliminating thefacade.Eachoftheadd-onsmayprovideonlyoneormore

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page941

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

economic benefits that should be considered when calculatingthecostsavings.

Although many desired properties of concrete can be achieved bychoosing the right materials and mixing ratio, adjusting and achieving some properties of fresh and hardened concrete using Admixtures is more efficient, economical,andmoreeffectivethananyothermethod.With the use of chemical Admixtures, the properties of fresh concretecanbeadjustedinaccordancewiththeperformance and environmental conditions, and the properties of hardenedconcretecanbemodifiedinaccordancewiththe technical criteria and operating conditions. Properties of fresh concrete that can be adjusted using chemical Admixtures include: Increase efficiency without additional water consumption, Reduce water consumption without reducingefficiency,Accelerateorslowdowninitialandfinal setting,Expandtocompensateforshrinkage,Reducewater dropMaintainconsistency,reducegrainseparation,improve pumping, correct slump loss, and control exotherm at an early age. Properties of hardened concrete that can be modified or improved by the use of chemical Admixtures include: Acceleration or delay in the process of gaining strength,Increasedmechanicalstrength,Improvedreliability, Reduced permeability, Expansion control and Alkaline reaction damage Increase adhesion to steel, improve adhesion of new concrete to existing concrete, produce concreteorcoloredmortar,andcontrolrebarcorrosion.

Some chemical Admixtures allow the implementation and continuationofconcretingoperations,whilemaintainingthe requiredquality,inadverseweatherconditions.Forexample, with the use of retardant lubricants, concrete can be transported over long distances or pumped over long distances; Aggregates and anti-scouring make underwater concretingoperationseasier;Quickheatersallowconcreting incoldweather;Andwiththehelpofdecongestants,concrete can be applied in lowaccess points,suchas turbine water supplypipelinesinhydroelectricpowerplants,withoutthe needforvibration(self-compactingconcrete).

Duringconcretingoperations,thereisapossibilityofsudden and unforeseen events such as clogged pump pipes, mold collapse, sudden drop in temperature, etc. Some of these events can be overcome with the help of chemical Admixtures. An example of this is the use of dewatering control materials to prevent clogging and reuse of built-in concreteincaseswherethereareinterruptions.

Reducing noise pollution, increasing the safety and productivity of labor (manpower), reducing heat from frictionofequipmentandmachinery,notthrowingawayand usingtheremainingconcreteinthemachineryforthenext shift(additivetocontroltheneedforwater)Theendofeach shift and the failure to drain the washing water in the environment (non-stick additive), are among the items of environmentalfriendlinessthatcanbeachievedwiththehelp ofchemicalAdmixtures.

Some properties of concrete, no matter how careful the choiceofmaterialsandproportionsofconcretecomponents, can not be achieved except with the use of Admixtures. Amongtheseuniquepropertiesandpropertiesthatcanonly be achieved with the use of chemical Admixtures are aerobics, foaming, self-compaction, acceleration, prehardening,deceleration,andexpansion.

Reducingcementconsumptionontheonehandbysavingon theconsumptionofnaturalresources(rawmaterials)andon theotherhandbyreducinggreenhousegasesfromcement production,inordertohelppreservetheenvironmentand sustainabledevelopment.Achievingearlyresistancebyusing Admixturesandeliminatingtheneedforevaporationinthe processofmanufacturingprefabricatedparts,called"energyfree",leadstoenergysavingsandcontributestosustainable development.Improvingthereliabilityofconcretestructures during operation, which is achieved due to the use of Admixtures,willalsocontributetosustainabledevelopment by increasing the useful life of the structure. Note 1-3Regardlessofalltheabove,itshouldberememberedthatno Admixturesofanytypeandamountcanbeconsideredasa substituteforthedesignofconcreteandproperexecutionof concrete.

ConsumableAdmixturesmustmeettheneedsandcriteriaof concreteregulationsandnationalstandardsofIranandvalid internationalstandardssuchasAASHTO,ASTM,BS,DIN,EN. Thesesourcesdescribeindetailthetechnicalspecifications, minimumconsumptionexpectations,andhoweachadditive iseffective,andareaverygoodguideforusingAdmixtures. In addition to these standards, manufacturers of these Admixturesalwaysprovideaccuratetechnicalspecifications of their products and the range of consumption and their effectonconcrete,whichinsomecasescanbehelpful.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

Although the technical specifications provided by the manufacturersincludetherangeofconsumptionproposed, but the amount of additive consumption should be determinedbasedontheresultsobtainedwiththematerials usedintheworkshop.

Since the composition and properties of cementitious materials,waterandaggregatesaswellastheirmixingratio haveasignificanteffectontheperformanceofAdmixtures, theevaluationofeachadditiveshouldbebasedontheresults obtained with the materials used in the workshop. In evaluatinganadditive,itseffectonthevolumeofthemixture mustbeconsidered.Iftheadditionoftheadditivechanges thevolumetricyieldofthemix,asoftenhappens,thechange inthepropertiesoftheconcretewillnotbeduetothedirect effectsoftheadditivealoneandmayalsobeduetoachange in the proportion of concrete components. In such cases, Admixturessuchascement,aggregatesandwatershouldbe considered as one of the components of concrete in the mixing plan.If more than one additive isusedinconcrete, they mayaffect each other's performance. For example,in concretewithaerobicAdmixtures,theuseoflubricantcan increaseaerobicefficiency,whilesomedecongestantsreduce itsefficiency.InevaluatingAdmixtures,theirinteractionon each other's performance should be considered. Environmental factors such as temperature and humidity haveasignificanteffectonthebehaviorofconcreteandthe performanceofAdmixtures.Admixturesthatareknownto work at normal temperatures may have very different functions at very high or very low temperatures. The performanceofeachadditiveshouldbeevaluatedunderthe expectedenvironmental conditionsatruntimeandnotbe limited to laboratory results performed at standard temperatures.InevaluatingtheperformanceofAdmixtures, operatingconditionssuchashowandwhentomix,howand when to transport, temperature of fresh concrete, how to pour and spread concrete, how to compact and polish concrete,andthemethodofprocessingshouldbeconsidered because each of these can Affect additive function. For example,excessivemixingreducestheefficiencyofaerobes.

ThetimeandmannerofaddingAdmixturestotheconcrete mix also affect their performance, which should be consideredintheirevaluation.Forexample,ifwater-reducing Admixtures are added to the dry mix of cement and aggregate,theirefficiencywillbegreatlyreduced,whereasif they are added to the concrete after adding a portion of mixing water and cement paste, they will perform better. Economicsofeachadditiveshouldbeconsideredinthecost of preparation, transportation, maintenance and addition alongwiththeeconomicsavingsthattheadditivebringswith it in the execution of concrete operations. Although the functionandthemaineffectofanadditiveontheproperties offreshandhardenedconcreteisusuallythemaincriterion for evaluation and selection of Admixtures, but the side advantages of each product are significant concrete producers, contractors, executors and employers and is of particularimportance.Theseadvantagesincludeproperties such as efficiency (workability), ease of pumping and molding, surface polishing, early resistance, faster use of molds,appearanceofconcretesurfacesandeliminationor reduction of vibration time. For quality control of Admixtures,inadditionOntheuniformityofappearance,the uniformityoftheirperformanceonconcreteshouldalsobe evaluated.

AdmixturesmustcomplywithIraniannationalstandardsor other valid international regulations. In addition, the instructionsandrecommendationsprovidedbytheadditive manufacturermustbecarefullyconsidered.Theeffectsofan additive should be evaluated as far as possible using the intended materials in the workshop. This issue becomes especiallyimportantwhen:

• The additive has not been used before with the desired materialsortheircombination;

•Useofspecialtypesofcementitiousmaterials;

•Consumemorethanonetypeofadditive;

Mixing and concreting should be done at temperatures outside the range usually recommended for concreting. In addition,theuseofAdmixturesmayrequiremodificationsto theconcretemixingdesign,suchaschangesinthetypeor amount of cement, changes in the type or aggregation of aggregates,ormodificationstothemixingratio.Byadjusting the amount of water and cementitious materials and modifyingthetypeanddurationofmixing,theeffectsofsome Admixturesaredramaticallyimproved.

ManyAdmixturesaffectmorethanonepropertyofconcrete and may even adversely affect the desired properties. Admixtures that improve the properties of fresh concrete maycauseprematurehardeningorexcessiveslowingofthe concrete and cause problems. By examining the effect of Admixturesonthecementitiousmaterialsused,thecausesof

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

abnormal setting behaviorscanbe understood. Premature hardening often occurs due to a change in the reaction process between the existing tricalcium, aluminate, and sulfate ions. Excessive retardation can be due to delayed calciumsilicatedehydrationduetooveruseoftheadditiveor decrease in ambient temperature. Another important considerationintheuseofAdmixturesisthelimitationofthe allowable amount of chlorine ions in concrete. These restrictions are given in the Iranian Concrete Regulations. These limitations are usually expressed as the maximum percentageofchlorineionsrelativetothemass(weight)of the cement, although sometimes the amount of "watersoluble" chlorine ions in concrete is also measured. Regardlessofhowthislimitisset,theconsumershouldknow the amount of chlorine ions in the additive so that when determiningthetypeandamountofadditiveconsumption, hedoesnotexceedthelimitssetfortheamountofchlorine ions.Tip1-6-Theusershouldbeawarethatevenassuming that chlorine ions are not present in the structure of a chemicaladditive,thereisalwaysthepossibilityofchlorine ionsenteringthroughthewaterusedtoproducetheliquid additive, as Admixtures are often made with water that contains Small but measurable amounts of chlorine ions. Therefore, caution should be exercised when dealing with termssuchas"chlorinefree".

Admixtures are chemicals that are added to the mixtureinsmallamountsandasapercentageoftheweight ofcementtocreatethedesiredpropertiesinconcrete.

WrepresentswaterandCrepresentstheweightof cement,sothatalowW/Cratiocanbeselected.

Tricalciumsilicate:(3Cao-Sio2)abbreviated(C3S), Calciumsilicate:(2Cao-Sio2)abbreviated(C2S),Tricalcium aluminate: 3Cao-Al2o3) with the abbreviation (C3A), Aluminophytetetracalcium:(4Cao-Al2o3-Fe2o3)abbreviated (C4AF).

The main reason for using fibers in concrete is to increase the hardness and tensile strength, improve crack controlanddeformation.

Theuseofseawaterduetothepresenceofsaltsof chlorides,sulfates,etc.,whichreducesthestrengthbyupto 15%,andontheotherhand,thechlorineinseawatercauses corrosion of rebars over time and its use in reinforced concreteisnotallowed..

Silicaaggregateshaveahardnessof7to8andare the most resistant aggregates used in concrete. Limestone grainshaveahardnessof3to4whichareusedinmaking concrete.

It seems that after concreting and polishing the concrete surface, a thin layer of water impregnated with

cementappearsontheconcretesurface.Themostimportant reasonisexcessiveslump.Anotherreason,suchasexcessive vibrationandinadequategranulation,increasethelikelihood ofconcretemelting.

Reinforced concrete is brittle and has less tensile strength. In order to reducethe weakness of fragility, thin and short filaments that are randomly distributed in all directionsinconcreteareaverysuitablemethod(thesethin filamentsarecalledfibers).

Foamconcreteduringtheirconstructionbycreating foam, air bubbles in the cement paste or in the cement mortar,aggregatesarecreated.Specificmass(Kg/m3).

Concrete with light grains which are made using perlite or vermiculite or expandable polyester fibers. The specificgravityofthismixture(Kg/m3960to240).

[1].IS:6491-1972,MethodsforsamplingofFlyash,Bureauof Indiastandards,India.

[2].TattersallG.H.andP.F.G.Banfill,1983,Rheologyoffresh concrete,pitmanadvancedpublishingprogram.

[3].SandorPopovics.,1993,PortlandCement-FlyAsh-Silica Fume Systems in Concrete, journal of Elsevier Science PublishingCo,Vol1065-7355193156.00.

[4]. Okamura, H. and Ozawa, K. 1999, Mix design for selfcompactingconcrete,concretelibraryofJapanesesocietyof civilengineering,June25,,pp,3-14.

[5].MichaelFAshbyandDavidRHJones,2002,Engineering Materials1,LinacreHouse,JordanHill,OxfordOX28DP,225 WildwoodAvenue,Wobum,MA01801-204.

[6].Nielsen,P.K.2003,handbookofnondestructivetesting equipment for concrete, federal highway administration, Washington,D.C.

[7]. Terence C. Holland, 2005, Silica Fume User’s Manual, FederalHighwayAdministration,Washington.

[8].R.S.KhurmiandN.Khurmi,2008,StrengthofMaterials, RamNagar,Newdelhi-110055,India.

[9]. L S Negi, 2008, Strength of Materials, A.P. offset Pvt., 25/487,Zulf-e-Bengal,DilshadGarden,NewDelhi-110095, India.

[10].S.Chand,2008,ConcreteTechnology,RamNagar,New Delhi-110055,India.

[11]. Arnon Chaipanich, Thanongsak Nochaiya., 2009, ThermalanalysisandmicrostructureofPortlandcement-fly

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

ash-silica fume pastes, journal of Therm Anal Calorim, Vol (2010)99:487–493.

[12]. Ken Ward-Harvey and ASTC, LFRAIA, 2009, FundamentalBuildingMaterials,Universal-Publishers,Boca Raton,Florida,USA.

[13].MLGambhir,2009,ConcreteTechnology,NewDelhi, India.

[14]. Ken Ward-Harvey and ASTC, LFRAIA, 2009, FundamentalBuildingMaterials,Universal-Publishers,Boca Raton,Florida,USA.

[15]. Braja M.Das, 2013, Foundation Engineering, cengage learningindiaprivatelimited,418,F.I.E.,Patparaganji,New Delhi,India.

[16].Dr.R.K.Bansal,2014,StrengthofMaterials,113,Golden House,Daryaganj,Newdelhi-110002,India.

[17]. P. Kumar Mehta and Paulo J. M. Monteiro, 2014, Concrete Microstructure, properties and Materials, P-24 GreenParkextension,NewDelhi-110016,India.

[18]. S.P. Timoshenko and D.H. Young, 2015, Elements of Strength of Materials, 105 Nirmal Tower, 26 Barakhamba RoadNewDelhi-110001,India.

“Khalil Rahman Farhat is currently employee of Swedish Committee for Afghanistan as construction specialist at The Area Based Approach to DevelopmentEmergencyInitiatives.He completed master degree ME (Construction Technology & Management) in Civil Engineering Department of Chandigarh University Mohali, Punjab, India. However, completed his BTech in Civil Engineering Faculty from Nangarhar Universityin2014”

“MasoodJamaliiscurrentlyemployee of Ministry of mine and petroleum as general construction manager He completed master degree ME (Construction Technology & Management) in Civil Engineering Department of Chandigarh University Mohali, Punjab, India. However, completed his BTech in Civil Engineering Faculty from Dawat Universityin2016”

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal