International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

Assistant Professor, Alasala University Engineering College, Department ofMechanical Engineering King Fahad Bin Abdulaziz Rd., P.O.Box: 12666. Amanah: 31483. Dammam, Kingdom of Saudi Arabia ***

Abstract - Steamcondensersareveryimportantpartof the equipment usedin power plants. The performance of steam condenser has a large influence on the overall energy efficiency of the steam power plant operating on Rankinecycle(RC) Largeeffortsmustbedonetomaintain the waste heat removal in the condenser and to improve itsperformance.Inthispaper,thepossibilityofimproving the steam condenser is provided. One important factor affects the steam condenser performance is entropy generation rate. Entropy generation rate was used to optimize the condenser performance by evaluating best operational parameters as well as fluid properties, which include the thermal conductivity and viscosity of nanofluid. The entropy generation rate due to frictional effect was much smaller than the one due to thermal effect. With increasing volume fraction of nanoparticles and angular orientation of pins for a given Reynolds number; Euler, Nusselt and Prandtl numbers increase, whereas, entropy generation rate decreases improving heat transfer performance of the system. Furthermore, with increasing the Reynolds number for a given volume fraction, Nusselt and Prandtl numbers and overall heat transfer efficiency increased while Euler number decreased for pins with the same orientation angle and it increasedforpinswithdifferentorientationangles.

Key Words: Steam Condenser, Power Plants, Nanofluid, PinFin,HeatSinkA Currently nine out of ten power plants in the worldthatgenerateelectricityfromsteampower require condensate cooling. These systems are categorized as either oncethrough or wet-recirculation. Once-through cooling systems discharge water directly after it has absorbed system heat. Wet-recirculating systems (wetcooling) operate in a closed loop where a considerable amount of water is lost in the cooling towers through evaporation cooling. The remaining power plants use air for heat removal in a process called dry-cooling. This processreduceswaterconsumptionbymorethan90%.

However,airasalowerheatcapacitythanwater making this power plant less efficient resulting in significant increases in size and cost. In summer, when electricitydemandpeaks,ambienttemperatureincreases, this significantly decreases the temperature difference betweensteamandambientairresultinginadecreaseof cooling capacity. In order to significantly reduce or eliminate the use of water for cooling power plants, a highly efficient heat exchanger for the vapor condensationisneeded.

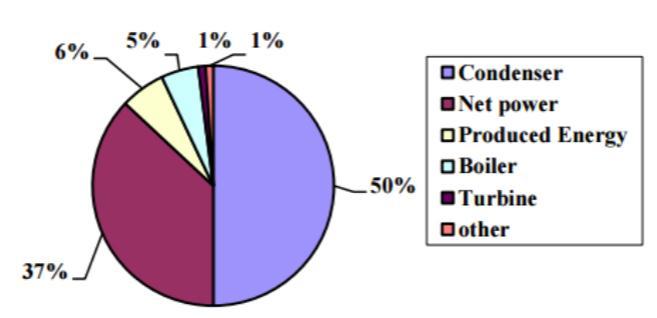

Itshouldbenotedthatmostoftheenergylostin steam power plants is in the condenser as shown in [Chart-1]. For a typical vapor condensation heat exchanger, thesteam from the power plant iscondensed inside the heat exchanger. The heat released from the condensation is transferred through the exchanger wall andremovedbytheforcedconvection.

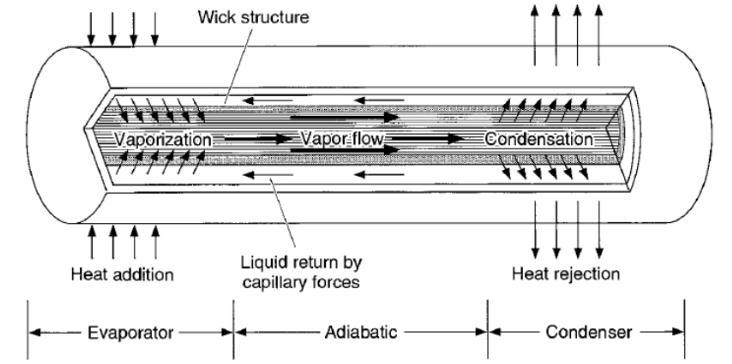

In order to enhance heat transfer of the condensation heat exchanger, the condensation heat transferoccurringinsidetheheatexchangerisneededto be increased and the forced convection heat transfer is needed to be enhanced as well. In the current investigation, the heat transfer enhancement of forced convection using nanofluid elliptical pin fins is investigated. At the same time, the vapor condensation occurring in the wick structure of the heat pipe is addressed.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

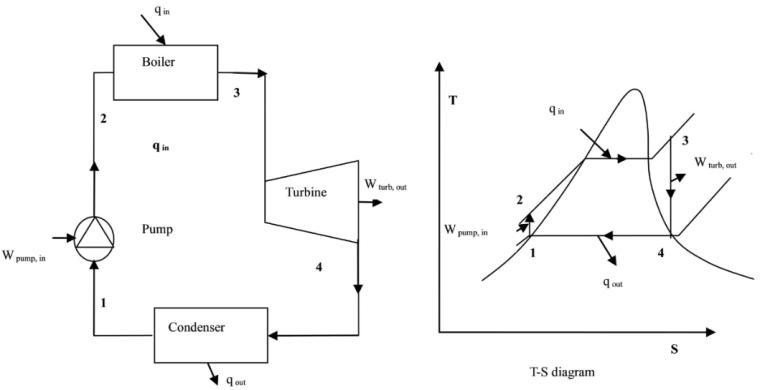

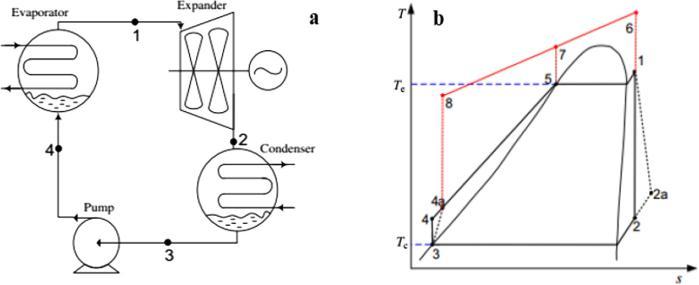

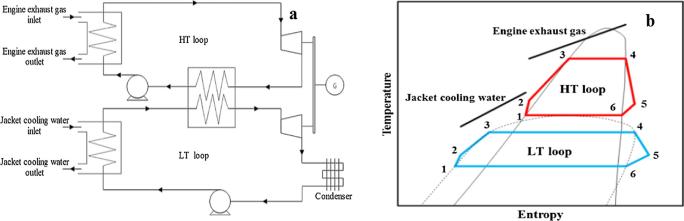

Ananofluidisafluidcontainingnanometersized particles, called nanoparticles. These fluids are engineered colloidal suspensions of nanoparticles in a base fluid. Nanofluids (NFs) have great potential for enhancingtheheattransfer capabilityofheattransferin powerplants[1-17].Hence,usingNFsasaworking fluid is great for use in high performing compact heat exchangers and heat sinks used in power plants operating on Rankine Cycle [Chart-2] In comparison to conventional coolants, Nanofluids have high thermal conductivities. And this depends on the particle diameter, volume faction, thermal conductivity of base fluid and nanoparticles as well as the Brownian motion ofnanoparticles.

Nanofluids have proven to have a great potential for enhancing the heat transport capability of power plants Therefore, using nanofluids as a working fluid is well suited for use in high performance compact heat exchangers and heat sinks used in power plants. One of the important characteristics of nanofluids is represented by their higher thermal conductivities with respect to conventional coolants. The enhancement of thermal conductivity of NFs depends on particle diameter and volume fraction, thermal conductivities of base fluid and nanoparticles as well as Brownian motion of nanoparticles, which is a key mechanism in thermal conductivityenhancement[18-22].

Chart -2:SchematicandT-SDiagramofRankineCycle

Thermal and hydraulic analyses of elliptical pin fin heat sinks are performed by using parametric variationsofmanydesignvariables.Theyincludebutnot limited to pin diameter, pin height, velocity, number of pin-fins, and thermal conductivity of the material. Optimization of elliptical pin fin heat sink design and parametric behavior are introduced and compared on the basis of the selected pin fin configuration and materialproperty.

In order to increase the heat transfer rate of the vapor condensation heat exchanger, the current investigation will focus on the condensation heat transfer and forced convection. For the vapor condensation, in ordertoincreasethecondensationheattransferrate,heat pipe wick [Chart-3] is utilized to increase the condensation area, and at the same time, the condensate canbeeffectivelyremovedbythecapillaryforce.Theheat released from the condensation must be efficiently removed for the forced convection. In order to increase the heat transfer coefficient of forced convection, the ellipticalpinfinswithnanofluidisinvestigated.

One important point is to analyze the hydraulic and thermalperformanceofcondenser(pinfinheatsink) with superhydrophobicandhydrophilicsurfacesusingdistilled water and SiO2 aqueous nanofluids with 0.015% and 0.030% concentrations and compare the results with conventional (without coating) condenser. Two pin fin copper micro channel heat sinks are manufactured with the help of CNC milling machine, then, they were sent to LiFong China for Super hydrophobic coating. LiFong has used modified repellix-2 technique for the required super hydrophobic coating with contact angle of 153 degree as wellascoatingthicknessof50to80nm.Manybasicthemo physical properties of nanofluids such as volume fraction of nanoparticles, density, viscosity and thermal conductivity are calculated using mathematical equations andexpressionsprovidedin[23].

The Nusslet number depend on mass flow rate and increaseswiththeincreaseinReynoldsnumberforallthe nanofluid. Power input has major effect on Nusselt

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

number. In the case of distilled water, Reynolds number doesnotincreasewithpowerinputatsamemassflowrate as viscosity remains the same. Super hydrophobic condenser surface provided 23.67%, 19.53% and 21.45% moreNusseltnumberthantheconventional(hydrophilic) condenser surface for distilled water, SiO2 (0.015%), and SiO2 (0.030%) nanofluids respectively. The increase in thermal performance is mainly due to the repelling property of super hydrophobic surfaces. The repellence enhances shear training and demolishes thermal boundary layer referred as heat transfer barrier. Hence, fresh layers of working fluids have more chances to come in contact with the heated surface resulting in greater conventional hydrophilic heat transfer. Churning effect and Brownian motion also contributed towards the enhancementinNusseltnumber[24].

Pressuredropisamplifiedwithincreaseinmassflowrate forall thefluidsand forcondensersurface.Pressuredrop doesnotchangewiththepowerinputbecauseviscosityof all the working fluids is not significantly affected due to very small concentration. Super hydrophobic coating has tremendous effect on pressure drop and pumping power andareductionof34.21%,29.73,and30.12%inpressure drop and pumping power is noted for super hydrophobic condenser surface as compared to conventional hydrophilicsurface for distilled water, SiO2 (0.015%) and SiO2 (0.030%) nanofluids accordingly at the same Reynolds number.The decrease in pressure drop for the super hydrophobic surface is mainly due to hydrophobicityofthesurface.Thereisa demolishment of thethermalboundarylayer.Thisdemolishmentdecreases the surface drag and friction and produces larger slip length[25]

The thermal resistance for both types of condenser surfacesandallHTFsarediscussedhereagainstReynolds number for water and SiO2-water nanofluids. Thermal resistance dwindled with amplification in Reynolds number, as expected and increases with the increase in power input. Nanofluids provided greater performance than the distilled water as the same Reynolds number for both types of surfaces. The super hydrophobic surface performed better than the conventional hydrophilic one with20.3%,17.6%and18.3%lower resistanceforwater, SiO2(0.015%)andSiO2(0.030%)nanofluidsrespectively The thermal boundary layer is reduced to a minimum value in the case of superhydrophobic surfaces. Hence, freshcurrentsoffluidhavemoreopportunitytotouchthe

heated surface and enhance cooling of the surface. This creates an amplified thermal performance and produces shearthinningwhichinturncausesthethermalresistance todecrease[26-27].

The following are the various types of RC. The first one is thebasicRC(BRC)[Chart-4].Whencomparedtotheother varieties of RC, BRC operates in subcritical settings and requiresthesmallestnumberofcomponents.BRChasfour separate processes; isentropic compression (3-4), heat addition (4-1), isentropic expansion (1-2), and heat rejection(2-3).

Chart -4 (a)SchematicofbasicRC(BRC)and(b)T-S diagramforBRC

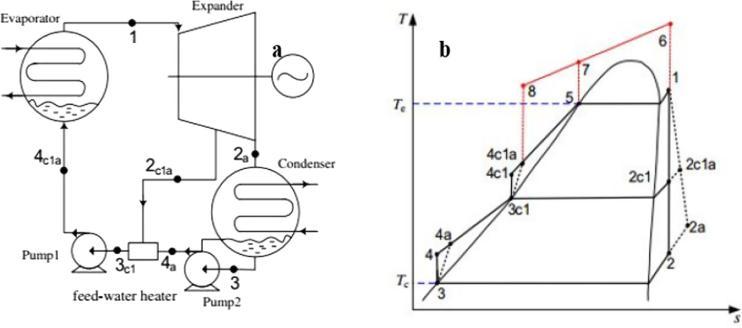

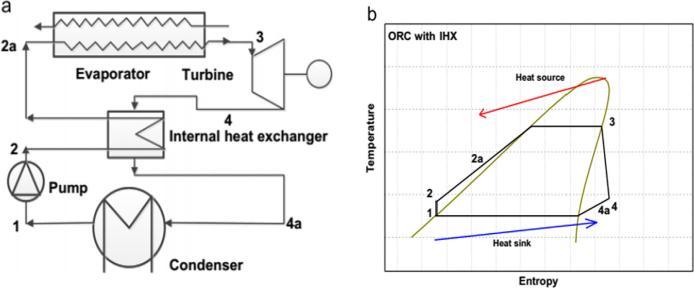

The second is the single stage regenerative RC (SRRC): A SRRC system is depicted in Chart 5 Part of the vapor is removed between 2 stages of the turbine & added to the feedwaterheaterinthissetup.Byloweringtheamount of heat added from the evaporator heat source, the regeneratorcanimprovecycleefficiency.

Chart -5(a)SchematicofsinglestageregenerativeRC (SRRC)and(b)T-SdiagramforSRRC

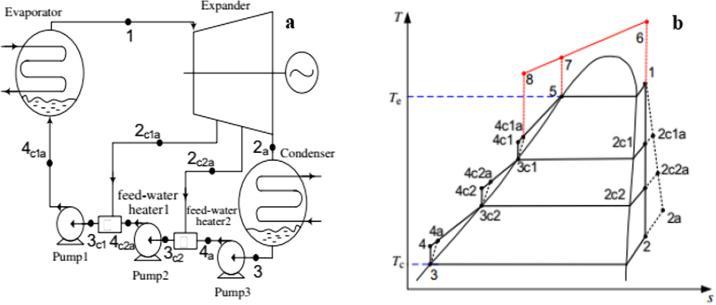

The nexttypeisthedouble stageregenerativeRC(DRRC): ADRRCsystemisseenin Chart 6.Thistechniqueissimilar to SRRC, except the extractionoccurs in two steps. By lowering the evaporator load,the DRRC improves the cycle'sthermalefficiency.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

technology improves the cycle's overall efficiency of the powerplant.

Chart-6 (a)SchematicofdoublestageregenerativeORC (DRRC)and(b)T-SdiagramforDRRC

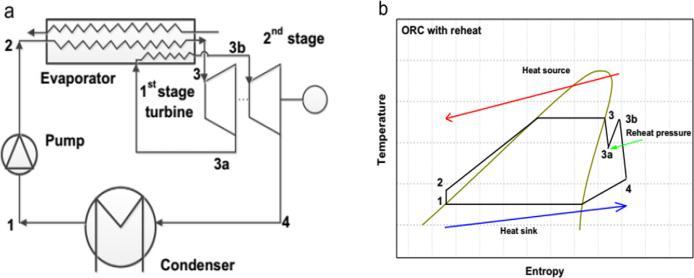

ARRCsystemisshownin Chart 7 Thefirstturbineinthis system receives high-pressure vapor from the evaporator portion. The exit vapor then returns to the evaporator, where it is warmed with the heat source prior to actually entering a new lower pressure turbine. The RRC system's goal is to remove the moisture from the steam at the end oftheexpansionphase.

Chart-9(a)SchematicofdualloopRC(DLRC)and(b)T-S diagramforDLRC

Investigationsintotheoptimizationofgeometrical structures of micro/mini heat sinks, and the use of nanofluids in cooling devices for cooling power plants are still embryonic; much more study is required in order to better understand the thermal and fluid dynamic characteristics of these equipments with this very promisingnewfamilyofcoolantsanddifferentgeometries.

Chart -7(a)SchematicofreheatRC(RRC)and(b)T-S diagramforRRC

An RC with something like a recuperator is shown in Chart 8. The elevated temperatureoperatingfluid from the turbine runs through the low-pressure side of IHX, whilethelowtemperatureoperatingfluidoutfrompump flows through the high-pressure side of IHX to increase efficiencyofthepowerplant

Ananalysiswasconductedtodeterminetheeffect of SiO2nanofluid on the heat transfer performance in an ellipticalpin-finheatsinkusedinpowerplantincludingthe influence of pin orientation. An effective thermal conductivity model, which takes into account the mean diameter of nanoparticles and Brownian motion,was utilized.

Chart-8(a)SchematicofRCwithrecuperatorand(b)T-S diagramforRCwithrecuperator

Dual loop RC(DLRC) system is shown in Chart 9. The HT loopisutilizedtoretrievethewastesourceofheatinthis system. The LT loop is utilized to retrieve the jacket cooling water as well as the HT loop's surplus heat. By reducingtheheatloaddissipatedtotheenvironment,this

The influence of changing volume fraction of nanoparticles causes the entropy generation rate toincrease. The influence of SiO2- water nanofluid coolant is large causing the thermal entropy generationrate to increase in the heat sink. When compared to pure water, SiO2- waternanofluid coolant had a smaller total entropy generation rate. Entropy generationrate due to thermal effect is much larger than the one due to frictional effect. The frictional contributionof entropy generation rate increases with increasing volume fraction, which means that the hydraulicefficiencyof thepower plant decreases withincreasing volume fraction, buttheamount of enhancementin frictional entropy isverysmall. Withincreasingvolumefaction ofnanoparticles, thetotal entropygeneration rate due toheattransfer decreases moretherebyimprovingtheheattransfer performanceof thepower plant. Optimization results of three parameters i.e., entropy generation, resistance and pressure ratioat different Reynolds, Nusselt and Prandtl numbers are providedin [Table 1]

Re, Nu,PrNu mbers

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

OptimizedDesignVaria bles Rhs oC/W Eu SgenW/ K(x103)

30,2,3.5

InLine 2.74 4.94 2×3 3.059 0.47 3.1 Stagge red 3.2 2.49 3×2 2.296 0.54 2.3

90,8.5,6 InLine 0.8 3.04 6×4 1.233 0.41 1.2 Stagge red 0.1 0.35 5×5 0.191 0.45 0.23

The thermal performance of the power plant system is predicted by LMTD. This is based on wall base temperature and thermal resistance. The wall base temperature and Rth are decreased by preparing super hydrophobic coating on the active surfaces of condenser (pin fin heat sink). The log mean temperature difference LMTD decreases with the increase in Reynolds number based on the normal phenomenon. Super hydrophobic coating has a huge effect on LMTD and it decreases by 21.03% for water, 18.13% for SiO2 (0.015%) and 19.23% for SiO2 (0.030%) nanofluid as compared to conventional hydrophiliccondenser surfaces. The LMTD is lower becauseoftheenhancedheattransfercausedbythesuper hydrophobicsurfaces[28]

Heat transfer and fluid flow analyses are employedinthisstudytooptimizethegeometryofsteam condenser such as heat sink in power plants. An entropy minimization technique is employed to optimize the overall thermal performance. The performance of heat sink is identified by its thermal resistance and pressure drop, because they substantially affect the thermal resistance during forced convection cooling of power plants.Thedesignofdifferentconfigurationsofheatsinks are studied and the thermal and hydraulic behaviors are compared.Entropygenerationrateisobtainedusingmass, energy and entropy balance over a control volume. The average heat transfer coefficient of the heat sink is developed using an energy balance equation over the control volume.Thisheattransfercoefficientisa function of the heat sink material, fluid properties, fin geometry, pin-fin configuration. The super hydrophobic condenser surface performed better than the conventional hydrophilicsurface with 24.76%, 20.93% and 23.18%

augmentation in Nusselt number for distilled water, SiO2 (0.015%) and SiO2 (0.030%) nanofluids respectively at thesameworkingparameters.

The support of Alasala Colleges is gratefully acknowledged.

1. Rajab,H.,Yin,D.,Ma,H.B., (2017)Numerical analysis ofeffectsofnanofluidandangularorientationonheat transfer performance ofan elliptical pin-finheatsink. HeatTransferResearch,48(2),161-175.doi:10.1615/ HeatTransferResearch.2016011084.

2. Rajab,H.,Yin,D.,Ma,H.,(2014)EffectsofAl2O3-water nanofluid and angular orientation on entropy generationandconvectiveheattransferofanelliptical micro-pin-fin heat sink. Paper presented at the ASME International Mechanical Engineering Congress and Exposition, Proceedings (IMECE), 8A, doi10.1115, IMECE2014-40335.

3. Ma, H.B., Wilson, C., Borgmeyer, B., Park, K., Yu, Q., Choi,S.U.S,andTirumala,M.(2006)EffectofNanofluid ontheHeatTransportCapabilityinanOscillatingHeat Pipe,AppliedPhysicalLetters88143116.

4. Ma, H.B., Wilson, C., Yu, Q., Park, K., Choi,S. U. S. and Tirumala,M.,(2006)AnExperimentalInvestigationof Heat Transport Capability in a Nano-Fluid Oscillating Heat Pipe, ASME Journal of Heat Transfer, 128, pp. 1213-1216.

5. Wilson, C., Ma, H. B., Yu, Q. and Park, P., (2006) High Thermal Conductivity of Diamond Nanofluid and Its Effect on the Heat Transport Capability in an Oscillating Heat Pipe, Proc. of IMECE, ASME Intl. Mechanical Engineering Congress and Exposition, Chicago,IL,pp.289-295.

6. Yin,D.,H.Rajab,andH.B.Ma."Theoreticalanalysisof maximum filling ratio in an oscillating heat pipe."International Journal of Heat and Mass Transfer74(2014):353-357.

7. W. A. Khan, J. R. Culham and M. M. Yovanovich, "Optimization of pin-fin heat sinks using entropy generation minimization," in IEEE Transactions on Components and Packaging Technologies,vol.28,no.2, pp.247-254,June2005,10.1109TCAPT.2005.848507.

8. Seyf, H.R., Zhou, Z., Ma, H.B., Zhang, Y. (2013)Three dimensionalnumerical study of heat-transfer enhancement by nano-encapsulated phase change

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

material slurry in microtube heat sinks with tangential impingement, International Journal of Heat andMass Transfer 56(1),561–573.

9. Wang, X.Q. and Mujumdar, A.S., (2007) Heat Transfer Characteristics of Nanofluids: A Review, International Journal of Thermal Science,46pp.1-19.

10. Koo, J. and Kleinstreuer, C., (2004) A new thermal conductivity model for nanofluids, Journal of Nanoparticle Research,(6)pp.577-588.

11. Prasher, R. S., Bhattacharya, P. and Phelan, P. E., (2005) Thermal Conductivity of Nanoscale Colloidal Solutions (Nanofluids), Physical Review Letters, (94) 025901.

12. Evans, W., Fish, J. and Keblinski, P., (2006) Role of Brownian Motion Hydrodynamics on Nanofluid Thermal Conductivity, Applied Physical Letters, 88 093116.

13. Namburu,P.K., Kulkarni,D.P.,Dandekar,A.andDas, D. K., (2007) Experimental Investigation of Viscosity and Specific Heat of Silicon Dioxide Nanofluids, Micro & Nano Letters,2(3)pp.67-71.

14. Vajjha, R.S. and Das, D.K., (2009) Experimental Determination of Thermal Conductivity of Three Nanofluids and Development of New Correlations, International Journal of Heat and Mass Transfer,52pp. 4675-4682.

15. Khanafer, K. and Vafai, K., (2011) A Critical Synthesis ofThermophysicalCharacteristicsofNanofluids, Int. J. Heat andMass Transfer (54)pp.4410-4428.

16. Kwak, H. S., Kin, H., Jae, M. H. and Tae-Ho, S., (2009) Thermal Control of Electroosmotic Flow in a Microchannel through Temperature-dependent Properties, Journal of Colloid and Interface Science, 335pp.123-129.

17. Seyf, H.R., Nikaeen, B., (2012) Analysis of Brownian motion and particle size effects on the thermal behavior and cooling performance of microchannel heat sinks, International Journal of Thermal Sciences, 58pp.36-44.

18. Shalchi-Tabrizi, A., Seyf, H.R., (2012) Analysis of Entropy Generation and Convective Heat Transfer of Al2O3NanofluidFlowinaTangentialMicroHeatSink, International Journal of Heat and Mass Transfer, 55(15-16)pp.4366-4375.

19. Shah, Tayyab Raza, Hasan Koten, and Hafiz MuhammadAli."Performanceeffectingparametersof hybrid nanofluids." InHybrid Nanofluids for

Convection Heat Transfer, pp. 179-213. Academic Press,2020.

20. Nawaz, Sonia, Hamza Babar, Hafiz Muhammad Ali, MuhammadUsmanSajid,MuhammadMansoorJanjua, Zafar Said, Arun Kumar Tiwari, L. Syam Sundar, and ChangheLi."Orientedsquareshapedpin-finheatsink: Performance evaluation employing mixture based on ethylene glycol/water graphene oxide nanofluid."Applied Thermal Engineering206 (2022) m118085.

21. Al-damook,A.,Azzawi,I.D.J.Multi-objectivenumerical optimum design of natural convection in different configurations of concentric horizontal annular pipes usingdifferentnanofluids.HeatMassTransfer(2021). doi.org/10.1007/s00231-021-03051-8

22. Al-damook, A., and Azzawi, I.D.J., The Thermohydraulic Characteristics and Optimization Study of Radial Porous Heat Sinks Using MultiObjective Computational Method. ASME. J. Heat Transfer. August 2021143(8):082701.doi10.1115/1.4051126

23. Rajab,H.,(2017)HeatTransferEnhancementofVapor CondensationHeatExchanger,2017PhDDissertation, University of Missouri-Columbia (MU) College of Engineering.https://hdl.handle.net/10355/63868, https://doi.org/10.32469/10355/63868

24. Hadi,Fazle,andHafizMuhammadAli."Hydrothermal performance evaluation of super hydrophobic pin fin minichannelheatsink."ThermalScience00(2022)

25. Khan A, Hadi F, Akram N, Bashir MA, Ali HM, Janjua MM,HussainA,PashaRA,JanjuaAB,FarukhF.Review of micro and mini channels, porous heat sinks with hydrophobic surfaces for single phase fluid flow. JournaloftheTaiwanInstituteofChemicalEngineers. 2022Mar1;132:104186.

26. Seyf, H. R., Kim, S. and Zhang, Y., (2013) Thermal Performance of an Al2O3-Water Nanofluid Pulsating Heat Pipe, Journal of Electronic Packaging 135 0310041-0310049.

27. Seyf, H. R., Feizbakhshi, M., (2012) Computational Analysis of Nanofluid Effects on Convective Heat Transfer Enhancement of Micro-Pin-Fin Heat Sinks, International Journal of Thermal Sciences 58, 168179.

28. Rajab, H., Pesyridis, A., Kourmpetis, M., Al-Noman, S., "Optimization and Thermal Performance Assessment of Elliptical Pin-Fin Heat Sinks."International PetroleumTechnologyConference.OnePetro,2022.