International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

PG Student, Department of Civil Engineering Galgotias University Gr. Noida, Uttar Pradesh, India 22nd Karthikeyan Murugesan Assistant professor, Department of Civil Engineering

***

Abstract - In this analysis, an effort is made to assess the performance and sustainability of concrete with adding pure milky white HDPE granules. The mechanical characteristics were explored experimentally in this investigation. five high density Polyethylene (HDPE) granules weight fractions (1%, 2%, 3%, 4%, 5%), concrete grade M25 were used to investigate their effects on the fissure tensile properties and compression characteristics, and flexuralstrength,modulusof elasticity, as well as the ductility, workabilityandtoughnessof the concrete. For combination HDPE granules reinforced concrete, an unique failure mechanism was identified and a new behavior categorization was developed. Incomparisonto plain concrete, the combination of HDPE granules reinforced concrete demonstrated superior flexural strength, beginning post-cracking strength, and magnificent energy absorption and decreasing the effect of harmful chemicals. pure high density Polyethylene (HDPE) granules seems to be more durable than some other types of fibers because it does not rust with time, like steel fibers do. Compressive strength improved from 27.84 N/mm2 to 34.94 N/mm2 in this study, while flexural strength grew from 15 N/mm2to16.66N/mm2 and tensile strength improved from 3.45 N/mm2 to 7.6 N/mm2 and the small change in new concrete’s workability with the increasing percentage of HDPE

Key Words: “Fiberreinforcedconcrete”,“Highdensity Polyethylene granules”, “glass fiber reinforced concrete”, “workability”, “Compressive strength”, “Tensile strength”, “Flexuralstrength”

The advancement of the structural engineering field has resultedina growingneedforengineeringmaterialswith high“tensile,compressive,andflexuralstrengths,aswellas good durability and combat” to environmental influences. Concrete is a mixture type material which is assemble of sand,aggregates,cementandfluidandthathardensovera period of time. Concrete is the lion’s share and most frequentlyutilizededificematerialinthewholeplanet.The advancementofcontemporarycivilstructuralengineering constructionhascreatedagreatneedforthemodificationof concretecharacteristicsandtheproductionofnewkindof concretes. Mixing fibers to concrete is an effective way to improve concrete characteristics [1]. The idea of concrete reinforcedusingfiberstoincreaseitstensilequalitiesisnot

new. Since ancient times, fibers have been utilised to reinforceconcrete.TheinsertionofHDPEfiberstoconcrete upgradeitstensilestrength,ductility,andfractureresistance [4-5]. The fibers inside the concrete operate as a fracture arrester, improving almost all mechanical characteristics, impactresistance,andbrittleness.

Polyethylenequalitiesdifferfromspeciestospecies,owing mostlytomolecularstructureanddensity.Polyethyleneis widely utilised as a fundamental raw material in the chemical process industries, mostly for the production of films,containers,pipelines,monofilaments,wiresandcables, everydayrequirements,andsoon.It'salsoutilisedasahighfrequencyinsulatorforTVandradar,amongotherthings. PolyethylenearepresentindifferentstructuresuchasLDPE, HDPE,andLLDPE[2].

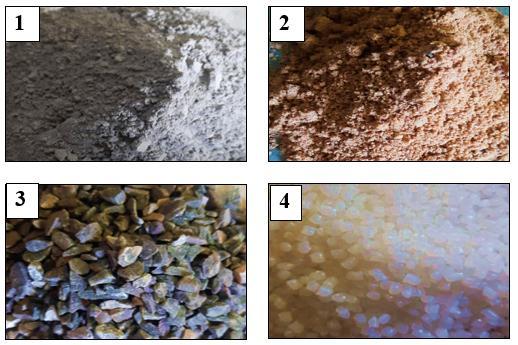

In this paper, HDPE granules are used to upgrading the almost all properties of concrete, and here the HDPE granulesaremilkywhiteincolour,whichisshowninfig.1 High density Polyethylene reinforcement concrete is a differentvarietyofconcretewhichismadebytheadditionof highdensityPolyethylenegranules.polymerreinforcement concreteisextensivelyusedinstructures,Becauseconcrete is a brittle kind of material with poor tensile and flexural strength,reinforcementsuchashighdensityPolyethylene polymer, steel, or other kinds increase these mechanical qualitiesaswellasductilityandstrength.

HighdensityPolyethylenereinforcementconcretemaybe utilizedfornewkindofconstructionaswellasrenovationof old concrete. HDPE as polymer additives to concrete [3]. Polymerconcrete'sadhesivequalitiesenablefortherepair of both polymer and traditional cement-based concretes. HighdensityPolyethylenePolymerconcretecanbeutilized in swimming pools and sewer construction and drainage channelsandelectrolyticcellsandothertypeofstructures thatcontainacidsandalkalisorcorrosivechemicalsdueto its corrosion resistance and acids resistance and low permeability.

Becauseofitscapacitytotoleratepoisonousandcorrosive sewage gases and harmful bacteria often found in sewage systems, it is particularly suitable to the building and restoration of manholes. High density Polyethylene reinforcement concrete, unlike traditional concrete buildings, does not require coating and welding of PVC-

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page65

1 Galgotias UniversityInternational Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

protectedlayers.andBecauseofitssmoothsurface,itmay alsobeusedasanasphaltpavementbondedwearingcourse, for increased durability and strength on a concrete foundation,andinskateparks.

Amaterialormixtureofsubstancesthatmakesupanitemis referred to as a material.Materialscan be either pureand impure in nature. The constituent materials, such as reinforcingfibers,cement,sand,andaggregates,canhavea significant impact on the mechanical properties of HDPC. Theseconstituentmaterialsarediscussedinthissection.

AccordingtoIScode:269-2015[10]Inthisstudy,General Purpose ordinary Portland cement was employed as the binderandAchemicalinteractionbetweenthedrymaterials and water causes to set and become sticky or work as a binder.Tableliststhephysicalcharacteristicsandchemical characteristicsofthisbinder.

Table -2: Propertiesofcement

Chemical&physicalpropertiesofcement

CaO 68.98% SiO2 20.54% Al2O3 5.12%

Fe2O3 3.26% MgO 1.14% Na2O 0.26% SO3 3.04% K2O 0.78% Ignitionloss 1.32

Specificsurfacearea(m2/kg) 3640 SpecificGravity 3.14 Consistency(%) 28.3 compressivestrength(MPa) 54

Settingtime(min) 101atinitialstage 158atfinalstage

Here we use high density polyethylene (HDPE) which is granulesinshapeandmilkywhiteincolourseeninfigure.1. HDPEisarrangebyheatingofpureetheneinhydrocarbon solventat333-343Kunder6-7atmpressureintheaddition

ofacatalystandhereweusetriethylaluminiumandtitanium tetrachlorideasacatalyst(zieglernattacatalyst).thechemical reaction is given belowandall the mechanical propertyof HDPEisgivenintable.3

[nCH2=CH2 -(-CH2-CH2-)n-]

HighdensitypolymerProperties

Young'smodulus 1000 Mpa Shearmodulus 750 Mpa

Tensilestrength 43 Mpa Density 0.995 g/cc Resistivity 5.00E+17 Ohm*mm²/m Elongation 2230 % Compressivestrength 23 Mpa Fatigue 19 Mpa Thermalconductivity 0.49 W/m*k

Maximumservice temprature 120 °C

Minimumservice temprature -200 °C Bendingstrength 32.5 Mpa Waterabsorption 0.01 %

AccordingtoIScode:383-1970[7],thefineaggregatepassing from4.75mmISsievewhichisarrangedandresultingfrom naturaldisintegrationofrockanddepositedbystreamsand agenciesofglacial.Andcoarseaggregatearethoseaggregate which is hold on 4.75mm IS sieve which is arranged and resulting from crushing of gravel or hard stone. the mechanicalandphysicalpropertyoffineandcorseaggregate seenintable.1

Table -1: Physicalpropertiesofcoarseandfineaggregates

Specifications

C.A F.A

Specificgravity 2.44 2.84 Unitweight(kg/m3) 1450 1600

Finenessmodulus 7.67 2.74 Absorption(%) 2.78 1.19 Moisturecontent(%) 2.8 1.5

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page66

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

Figure 1: Materials(1.Cement,2.Fineaggregate,3. Coarseaggregate,4.HDPEgranules)

Inthisstudy,theapproachandproceduresemployedwere basedontheindianstandardcodes.[6]IScode:456-2000 [1]IScode:516-1959[16]IScode:5816-1999aswellasIS code:10262-2019[17]fig.2showsthefullmethodologyof this study and the following work procedure was devised andimplemented:

Arrangement of raw material such as standard Portlandcement,sand,andcoarseaggregate,HDPE granuelsandwater.

Preparation of concrete with mixing under the guidanceofIS:10262-2019

Specimens were cast in different shape and size withthehelpofindianstandardcodes.

TestingalltheSpecimensforobtainingmechanical properties under the guidance of indian standard codes.

Analysesofvariousoutcomesinordertomeasure thequalityofconcrete.

Theconcretewasmixedaccordingtoa1:1:2weightratioof standard Portland cement, sand, and coarse aggregate. Without the use of water-reducing admixtures, the W/Cratioof0.48wasmaintainedthroughoutthemix.

Theconcretewasmadebycombiningalloftheingredients inthelaboratoryusingamixingmachineattheirspecified proportions. To make the HDPEGRC mixes in this investigation,hdpeganuleswereaddedinfivepercentages byweightofcement:1%,2%,3%,4%and5%.

Forexperiment,sixgroupsaredividedbytheconcretewith the different level of 1%, 2%, 3%, 4% and 5% of HDPE respectively,asbyweight.Seetable.4.

Identifyapplicablefundingagencyhere.Ifnone,delete thistextbox

CalculationofQuantityofMaterialsisdoneaccordingtothe laboratorymix.

Cement volume = (ratio of cement / 4) × 1440 × 1.57=565.2Kg.

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page67

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

Sandvolume=(ratioof sand/4)×1600 ×1.57 = 628Kg.

Coarseaggregatevolume=(C.Aratio/4)×1450× 1.57=1138.3Kg W/Cratio=0.48

Theunitweightofcement=1440-kg/m3 Fineaggregateshaveaunitweight=1600-kg/m3 Here unit weight of coarse aggregates = 1450kg/m3 WetakeUnitweightofwater=691-kg/m3

Becauseweallknow,whenwetconcreteisplacedduringthe concretingprocess,ithardensandhardensafterasetperiod of time. To offset the effect of shrinkage, the educated engineer in the discipline of civil and raising construction havesuggestedthefactorofsafetytobeset(F.O.S=1.54to 1.57)

Forcompositiondryconcretevol.shouldbe1.54to 1.57timesthatofthewetconcretevolume.

CP0=controlspecimen

CP1=1%HDPEgranulesmixwithconcrete

CP2=2%HDPEgranulesmixwithconcrete

CP3=3%HDPEgranulesmixwithconcrete

CP4=4%HDPEgranulesmixwithconcrete

CP5=5%HDPEgranulesmixwithconcrete

Inthisresearchpaper,AllSpecimenswerecastinconcrete gradeM25accordingtoIScode,theratiooftheseconcrete grade are listed in table.4. In the laboratory for optimal resistance of high density polyethylene granules, the 12 cubesarecastedwiththeperfectmeasurementsof“150mm *150mm*150mm”andthe12cylinderarecastedwiththe measurements of “D =150 mm *L = 300 mm”todevelop compressive quality and tensile quality and flexure prism alsocastwiththesizeof“100*100*500mm”toperform flexuraltest.Thesedifferentshapeofspecimenswascasted for7days&28daysaspernormalprocedures.

formakingspecimens“ordinaryPortlandcement”isutilised as a binder. According to IS 383-1970, river sand passing throughanISsieveof4.75mmisutilisedforfine-aggregate. The river's sand is devoid of dust particles and filters out unwanted materials and tiny piece particles. The coarse aggregate utilised is a locally available crushed angular gravelswithasievesizeof10mm.theincreasingpercentage of HDPE also used for preparation of Specimens with differentgradeofconcrete.

For examining the specimens and the behaviour of specimensunderthetestbyacertainmethodofcompletion. Several mechanical parameters were investigated for all mixes, including “compressive strength, fissure tensile strength,flexuralstrengthandworkability”ofconcrete.

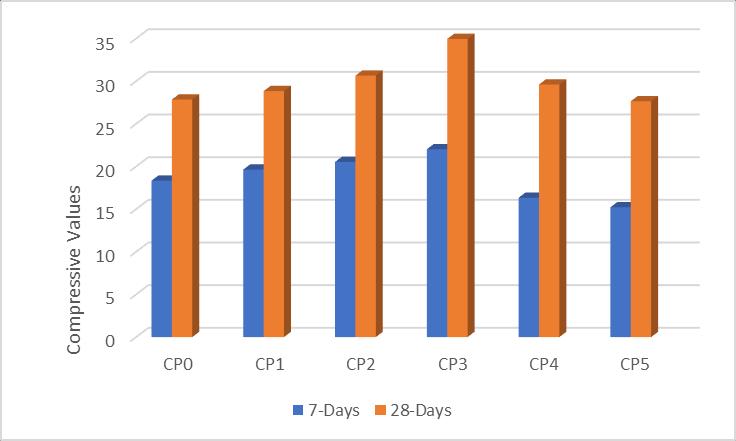

After specimens had been cured for 7days and 28 days, compression tests were performed in accordance with IS Code516:1959.BecausetheHDPEgranules,acubespecimen size (150mm × 150mm × 150mm) was used. A cube specimenhas been placed as depicted in the experimental setup, Aimil version of compression testing machine was used to apply loading and the vertically load is gradually appliedtothecubeshapetestedpiece,andtheultimateload is recorded at the cube's failure, and the compressive strengthofthecubeiscalculated.C.S=P/Aistheformulafor calculating compressive strength of concrete. Table.5. and Figs.3illustratethecompressivestrengthtestassembly.

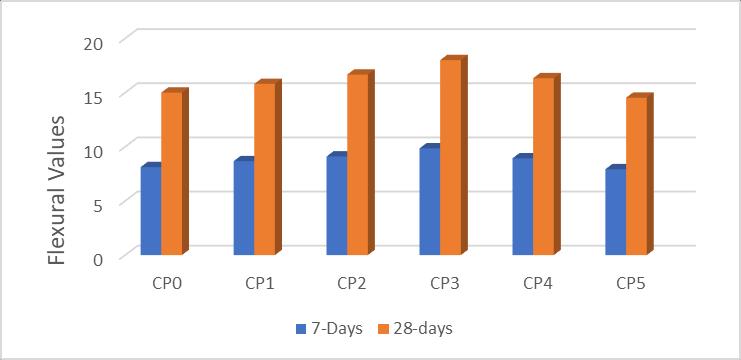

Flexural testing were carried out with the help of IS Code 516-1959. The flexural strength was calculated using the equationF.S=PL/BD2.Thetensilestrengthofthespecimen isestimatedindirectlybytheflexuraltestandflexuraltest findingsareprovidedasarupturemoduledenotedbyMPa. Rectangularshapespecimenswithperfectdimension(100 mm×100mm×500mm)andcuredfor7daysto28days, after specimen were dried out and revealed to air. The specimen is placed in the aimil version flexural testing

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page68

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

machineforgettingdatawhichisindicatedintable6andFig. 5.Loadwasappliedatafrequencythatcausesthemaximum stresstoriseuntilitbreaks.Thefracturedisplaysthewidth ofthemiddlethirdofthestresszone.

Thetensilepropertiesofaspecimenisdeterminedindirectly using separated tensile testing. The cylindrical test piece withaperfectdimension(D=150mmandL=300mm)were evaluatedaftersevenandtwenty-eightdaysofcuringphase. These measurements were carried out with the aid of a compressionqualitytestingmachinewithapowerratingof 2000kn.Thetestspecimenisshownbelow.

Acc.ToIScode5816:1999Thetensilestrengthcylinderis determinedby

T.S=2A/πLϕ

T.S=FissureTensileStrength A=Failureloadinnewton

ϕ=CylinderDia.

L=Lengthofsampleinmm

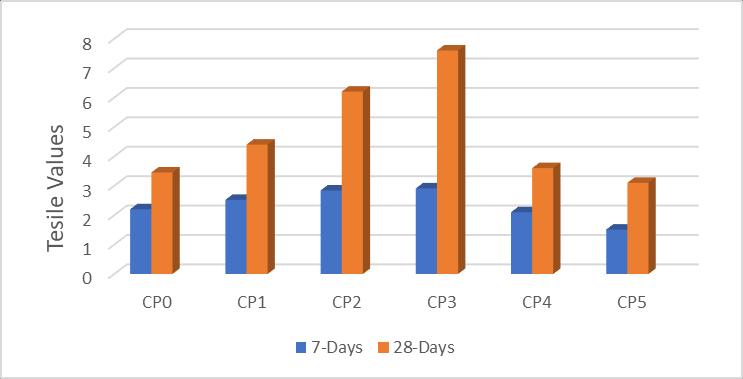

Tables7andFig.6showsthetensilevaluationwhichis gettingfromtensilestrengthtestassembly.

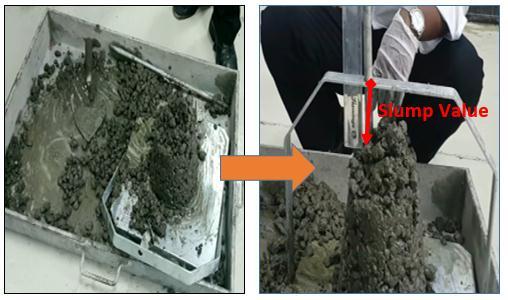

Slump tests was carried out in accordance with IS code 456:2000 [6] and IS code 1199:1959 [11] to evaluate the workability of new concrete. After a satisfactory mix, the latestconcretewascategorizedinto3equallevelsinacone shaped,roddingtwenty-fivetimes.Thesurplusconcretewas thenremovedfromthetop,andtheconeshapewaselevated vertically.Slumpwasdefinedastheinterspaceb/wheightof thefrustumshapeframeandtherelocatedoriginallocation ofthetoplevelofnewconcrete(seeFig.7)

Accordingtothefig.4.thecompressivestrengthofM25grade concretewithHDPEgranulesincreasedupto34.94N/mm2 from27.84N/mm2andafterthatmoderatelydroppedupto 27.64 N/mm2. The compressive quality test results of individualconcretemixcubetestpiecehavingdimensionof 150mm*150mm*150mmforpreservingintervallike7days aswellas28dayswhichisshowninTable5.

According to the fig.5. the flexural strength of M25 grade concretewithHDPEgranulesincreasedupto16.66N/mm2 from 15 N/mm2 and after that moderately dropped up to 14.53N/mm2. Theflexuralquality test resultsofdifferent concretemix rectangular test piecehaving100 mmin H× 100mminW×500mminLforpreservingphaselike7days aswellas28dayswhichisshowninTable6.

Accordingtothefig.6.thefissuretensilestrengthofmodified concretewiththecompanyofHDPEgranulesincreasedupto 7.6 N/mm2 from 3.45 N/mm2 and after that severely dropped up to 3.1 N/mm2. The fissure tensile quality test resultsofvariantconcretemixcylindricaltestpiecehaving dia. of 150 mm and lengthwise 300 in mm for preserving phaselike7daysaswellas28dayswhichisshowninTable 7.

According to the chart above, the “compressive, fissure tensile,andflexuralstrength”ofnewconcreteisincreasedby upto3%andafterthatmoderatelydroppedby4%and5%. Afractionorgranule'spercentagewereswapwithgravel(1 to5percent).

According to the fig.8. the workability of concrete small increasewiththeincreasingupto2%percentageofHDPE granulesandafterthatdecreaseslowlywhichismeasuredby mmwiththehelpofslumpconetestandthedatashownin table.8.

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page69

Figure7:Slumptest.International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

Mix label Cement (kg/m2 ) Fineaggregate (kg/m2) coarseaggregate (kg/m2) Fiber (kg/m2) water (kg/m2) W/C ratio

CP0 1440 1600 1450 0 691 0.48

CP1 1440 1600 1450 14.4 691 0.48

CP2 1440 1600 1450 28.8 691 0.48

CP3 1440 1600 1450 43.2 691 0.48

CP4 1440 1600 1450 57.6 691 0.48

CP5 1440 1600 1450 72 691 0.48

Table 4: Materialsincompositionmixes

S.No. Samples Ageofconcrete Load(KN) Compressivestrength(N/mm2)

1 CP0 7-DAYS 412.4 18.33 28-DAYS 626.4 27.84

2 CP1 7-DAYS 442 19.63 28-DAYS 649 28.83

3 CP2 7-DAYS 462 20.53 28-DAYS 689.4 30.64

4 CP3 7-DAYS 495.2 22.01 28-DAYS 786.1 34.94

5 CP4 7-DAYS 367.4 16.33 28-DAYS 666 29.6

6 CP5 7-DAYS 342.2 15.21 28-DAYS 620 27.64

Table 5: Outcomesofcompressivestrengthtest

Figure 4: Compressivestrengthat7and28days.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

S.No. Samples Ageofconcrete Load(KN) Flexuralstrength(N/mm2)

1 CP0 7-DAYS 16 8.12 28-DAYS 30 15 2 CP1 7-DAYS 17.3 8.67 28-DAYS 31.5 15.8 3 CP2 7-DAYS 18.2 9.1 28-DAYS 33.3 16.66 4 CP3 7-DAYS 20 9.85 28-DAYS 36 18 5 CP4 7-DAYS 18 8.93 28-DAYS 33 16.32 6 CP5 7-DAYS 15.8 7.93 28-DAYS 29 14.53

Table 6: OutcomesofFlexuralstrengthtest

Figure 5: Flexuralstrengthat7&28days

S.No. Samples Ageofconcrete Load(KN) Tensilestrength(N/mm2)

1 CP0 7-DAYS 156 2.2 28-DAYS 244 3.45 2 CP1 7-DAYS 178 2.52 28-DAYS 311 4.4 3 CP2 7-DAYS 201 2.84 28-DAYS 438 6.2 4 CP3 7-DAYS 206 2.91 28-DAYS 537 7.6

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page71

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056 Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

5 CP4 7-DAYS 148 2.1 28-DAYS 255 3.6 6 CP5 7-DAYS 107 1.51 28-DAYS 219 3.1

Table 7: OutcomesofTensilestrengthtest

Figure 6: Tensilestrengthat7&28days

S.No. Typesofconcrete Valuesofslump(mm) 1 CP0 52mm 2 CP1 59mm 3 CP2 57mm 4 CP3 49mm 5 CP4 46mm 6 CP5 42mm

Table 8: OutcomesofSlumptests

Figure 8: SlumpValuation

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page72

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

The properties of new concrete with calculative partial substitution of coarse aggregate with pure high density polyethylene granules were discovered to be greater enhanceascomparetoregularconcretewhichhavinggrade M25properties.

According to the results, HDPE granules boosts the compressive properties which is good and flexural characteristics and fissure tensile strength which is most importanttoeverystandardconcrete.theoptimalamountis 3%,andthevaluesaregrowingby4%and5%,respectively. Itisthoughttobeeconomicallybeneficialtoreplacesome coarseaggregatewithHDPEgranules,whichalsoimproves concretecapacity.

Compressive strength rose by employing HDPE granules, increasingfrom27.84N/mm2to34.94N/mm2witharatio of 3% HDPE granules by volume of concrete; however, addingadditionalgranulesloweredcompressivestrength; hence,3%isthebestHDPEgranules.

Tensile strength rose from 3.45 N/mm2 (for reference mixes)to7.6N/mm2(for3%granules)thendroppedwhen additionalhighdensitypolyethylenegranuleswereadded.

Flexuralstrengthrosesignificantlyfrom15N/mm2to16.66 N/mm2,andfailureofbeamsundertwoconcentratedloads (third point loading) demonstrates ductile failure when comparedtostandardconcrete,whichfailsbybreakingin twopiecesstraight.

WorkabilityofconcreterosebyemployingHDPEgranules, increasingfrom52mmto59mmwitharatioof1%granules however, adding additional HDPE granules lowered workabilityofconcrete.

The authors state that they all have no known competing financial interests or personal ties that may seem to have influencedtheworkdescribedinthisstudy.

[1] Mastali, M., and A. Dalvand. "Fresh and hardened properties of self-compacting concrete reinforced with hybrid recycled steel–polypropylene fiber." Journal of MaterialsinCivilEngineering29.6(2017):04017012.

[2] Chen, Longsheng, and Zewei Lin. "Polyethylene: Properties, Production and Applications." 2021 3rd InternationalAcademicExchangeConferenceonScienceand TechnologyInnovation(IAECST).IEEE,2021.

[3] Hınıslıoğlu, Sinan, and Emine Ağar. "Use of waste high density polyethylene as bitumen modifier in asphalt concretemix."Materialsletters58.3-4(2004):267-271.

[4]Selvi,M.Tamil,A.K.Dasarathy,andS.PonkumarIlango. "Mechanicalpropertiesonlightweightaggregateconcrete usinghighdensitypolyethylenegranules."MaterialsToday: Proceedings(2021).

[5]Alkraidi,AfrahAbdulwahhabJaber,etal."MECHANICAL PROPERTIES OF HIGH-DENSITY POLYETHYLENE FIBER CONCRETE."micron55:25-60.

[6] IS:456-2000, Plain and Reinforced Concrete-Code of Practice,BureauofIndianStandards,NewDelhi.

[7] IS:383-2016, Coarse and Fine Aggregate for ConcreteSpecification,BureauofIndianStandards,NewDelhi.

[8] IS:1489 (Part I)-2015, Specification for Portland pozzolana cement,Part1:Flyashbased, BureauofIndian Standards.

[9]IS:10262-2019,ConcreteMixProportioningGuidelines, BureauofIndianStandards,NewDelhi.

[10]IS:269-2015,OrdinaryPortlandCement,CentralMarks Department-3.

[11] IS:1199 (Part II)-2019, Fresh Concrete-Methods of Sampling,TestingandAnalysis,BureauofIndianStandards, NewDelhi.

[12]IS:516(PartI/SecI)-2019,HardenedConcrete-Methods of Test-Part 1 Testing of Strength of Hardened ConcreteSection1Compressive,FlexuralandSplitTensileStrength, BureauofIndianStandards,NewDelhi.

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page73