e-ISSN:2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN:2395-0072

e-ISSN:2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN:2395-0072

Saikiran Muppana1, Gaurav Wanjari2, Digmandar Kawadkar3

1Mechanical Engineer, 24th year Student Mechanical Engineering, st. vincent pallotti college of engineering and technology, Nagpur,34th year Student Mechanical Engineering, st. vincent pallotti college of engineering and technology, Nagpur. ***

Abstract - Formula SAE is an annual international university-level design competition organized by the Society of Automotive Engineers. Formula SAE (FSAE) competitions offer a great opportunity for an engineering student where can practice and develop various engineering skills. This increases the practical and application-oriented approach toward a real engineering practice. The purpose of this project is to design and optimize the Formula SAE Vehicle Spool Drive. A Spool is a device that connects the two axles directly A 3D cad model of the Spool Drive and its shape optimization is done using Fusion 360 and Solidworks 2021 software and analysis is to be done using the same software. All the design considerations are taken by keeping in mind the various rules of the formula student community. Different materials are used for manufacturing Spool Drives like Aluminum alloys Al 7075-T6 for lightweight applications, Al alloy 6061-T6 for a moderate weight, and moderate cost or steel in case of low-cost applications.

Key Words: SpoolDrive,Sprocket,Bearings,Fusion360, Alalloy6061T6,Alalloy7075T6.

The Spool Drive assembly consists of Spool – Spool is a type of Differential. The spool can lock the axles together to provide 100% of the available torque to the wheel with traction.

Chain Sprocket -A sprocket is a toothed wheel designed to engage and directly move a flexible indented or perforated item, like a chain. The sprocket is assembled on a spool with a sprocket mount with fasteners.

Bearings – A bearing is a machine element that constrains relative motion to only the desired motion and reduces friction between moving parts. The bearing is press fitted on the spool and spool mounting is fitted on the bearing.

Spool Drive needs to be designed in such a way that it is capable to withstand the forces and moments acting on it due to bumps, braking, and acceleration. To obtain the

possibly best riding characteristics of a vehicle and to achieve it, the unsprung mass of the vehicle should be reduced. So, our goal isto design a SpoolDrive whichhas the lowest possible weight. During material selection, the main aim is to have high strength and less weight as compared to other commercially available materials. We are using Al 7075 T6 for Spool, Sprocket, and Spool Mountings.

ThecompositionofAluminum6061T6isMagnesium0.80 - 1.20% ,Silicon 0.40 - 0.80%, Iron 0.0 - 0.70%, Copper 0.15 - 0.40% Chromium 0.04 - 0.35%, Zinc 0.0 - 0.25%, Titanium0.0-0.15%,Manganese0.0-0.15%,etc.Itoffers better weldability but for knuckles, we need a material with good machinability. It is not as strong as Al 7075. It has no problem with corrosion as having less amount of copper.

Young’sModulus(GPa) 68.9 Density (g/cc) 2.7 ShearModulus(GPa) 26 Poisson’sRatio 0.33

UltimateTensileStrength 310 YieldTensileStrength 276

The composition of Mild Steel A36 is Carbon 0.25-0.29%, Copper0.20%,Iron97%,Manganese1.03%,Phosphorous 0.04%,Silicon0.2%,Sulfur0.05%.Itisoneofthecheapest materialsonthelist.Thematerialiseasilyavailableinthe market. It is very heavy. The strength to weight ratio is verybadascomparedtoAl6061T6andAl7075T6.

e-ISSN:2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN:2395-0072

Young’sModulus(GPa) 200

Density (g/cc) 7.8

ShearModulus(GPa) 79.3 Poisson’sRatio 0.26

UltimateTensileStrength 500 YieldTensileStrength 250

Stainless Steel AISI 304

The composition of Stainless Steel AISI 304 is Iron 66.7471.24%, Chromium 17.5-19.5%, Nickel 8-10.5% Manganese 2%, Silicon 1%, Nitrogen 0.11%, Carbon 0.07%, Phosphorus 0.05%, Sulphur 0.05%. The formabilityofAISI304isverygood.

Young’sModulus(GPa) 195 Density (g/cc) 8 ShearModulus(GPa) 86 Poisson’sRatio 0.29

UltimateTensileStrength 505 YieldTensileStrength 215

All materials are mostly used where high tensile strength and toughness are required. So, Aluminum alloys are suitedforthewheelassemblycomponents.Duetothislow weight of materials,itcan decrease fuel consumption and it has a low density and sufficient yield strength. Al 7075 T6 being lighter and stronger than Al 6065 T6 makes it suitabletouseforthemanufacturingofKnuckle,Hub,and Brakedisks.

The composition of Aluminum 7075 T6 is 5.6–6.1%Zinc, 2.1–2.5%Magnesium, 1.2–1.6%Copper, and some other materials which are very less in composition like Silicon, Iron, Manganese, Titanium, Chromium, etc. The specific strength of Al 7075 is very high. Al 7075 offers better strength for the Spool drive. As in the table given below, wecanseethatyieldandtensilestrengthsarehigherthan compared to other materials. It is one of the aluminum alloyswiththehigheststrength.

Young’sModulus(GPa) 71.7 Density(g/cc) 2.81 ShearModulus(GPa) 26.9 Poisson’sRatio 0.33

UltimateTensileStrength 572

YieldTensileStrength 503

The Spool Is essentially a solid axle connection between the left and right wheels, or a fixed differential. Some people weld their differential fixed, for instance, to allow easier drifting. a spool ensures both left and right tires rotateatthesamespeed.Weareusinga70mmdiameter spool.

The axles are installed inside the snout of the spool, and the Sprocket is bolted directly to the larger diameter flange.

Thissetupeliminatesthedifferentialsidegearsandcauses therearaxlestoactasiftheyareweldedtogethersothat each axel turns at the same speed under any driving circumstance

GearRatio4:1 No.ofteethondrivenSprocket -44

ChainNo.50 ChainLinkpitch(P)-15.875mm

PitchDiameterofDrivenSprocket Dp=P/Sin(180/T2) Dp=15.875/Sin(180/44) Dp=222.598mm

WidthofTeeth(to) to=0.56P-0.15 =0.56*15.875-0.15 to =8.7428mm

Transversepitch(A)

A=1.1525P =1.1525*15.875 A =18.3017mm

e-ISSN:2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN:2395-0072

cornerrelief(e)

e =0.125*15.875 e =1.985

6)ChamferRadius(r)

r=0.54*P =0.54*15.875 r =8.5752

7)OuterDiameter(Do)

Do=15.875[0.6+cot(180/44) Do=232mm

8) RootDiameter(Dr)

Dr=Dp-0.625P =223-0.625*15.875 =213.075 Dr =213mm

1.4 Force on Sprocket:

MaxTorqueatmotor=68Nm Radiusofsprocket= 0.033m

Forceonsprocket=68/0.033 = 2060N

1.5 Bearing Calculation Data

BearingUsed-62082z

BasicDynamicload C - 32.5kN

BasicStaticload C0-19kN

Fatigueloadlimit Pu-0.8kN

Referencespeed -18000r/min

Limitingspeed -9000r/min

Minimumloadfactor kr-0.025

We use Fusion 360 for the analysis and acceptance of the design. The design has been topologically enhanced as it neededtobeasfewerpartsintheassemblyweighextra.

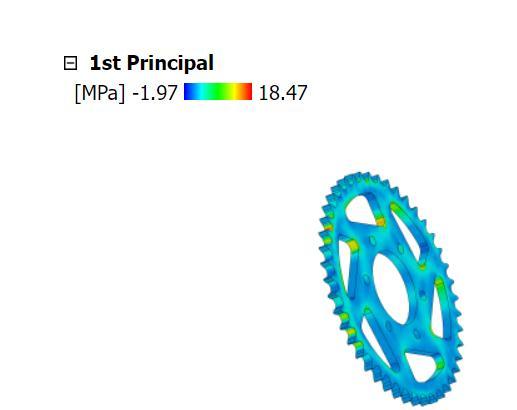

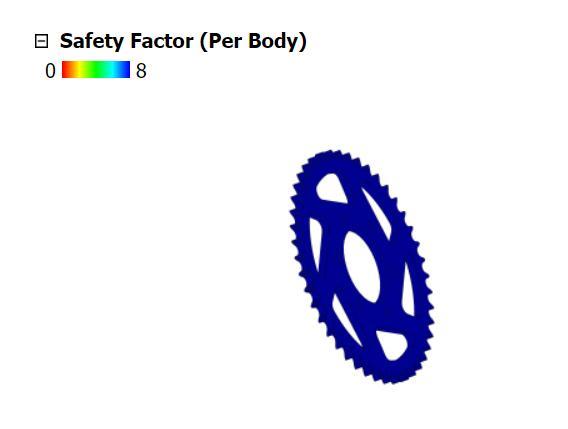

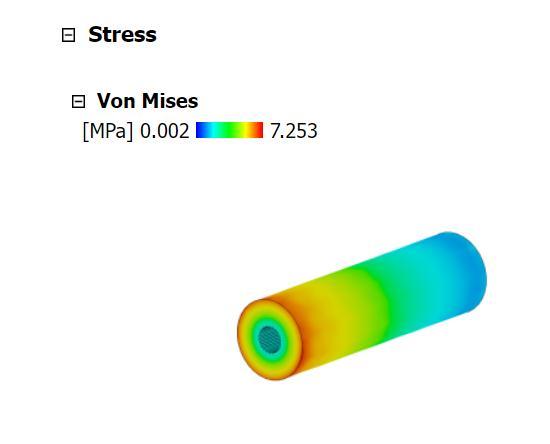

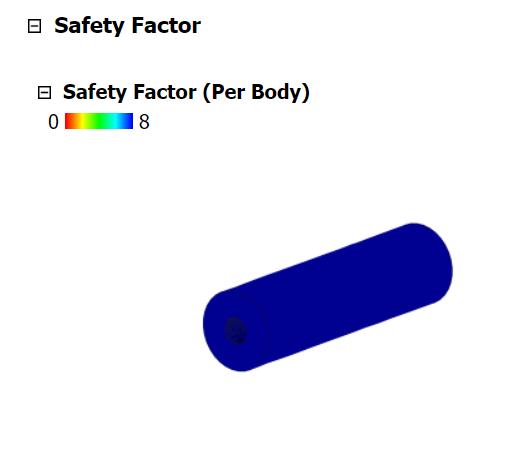

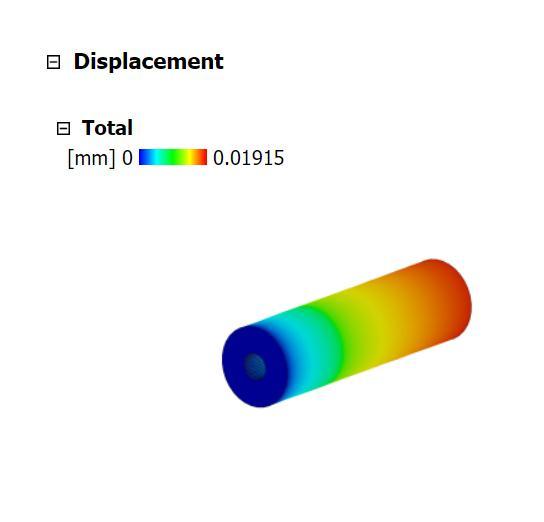

According to the selected final drive ratio of 4:1, the number of teeth of the driving sprocket is 11, and similarly,thedrivensprockethas44teeth.The520chains wereused.ThesprockethasbeendesignedonFusion360 considering the holes on the differential for mounting. Afterthedesign,thesprocketwasanalyzedonFusion360. ThematerialUsedfortheSprocketisAl7075t6.

Fig. 1st Principle

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page 749

International Research Journal of Engineering and Technology (IRJET)

e-ISSN:2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN:2395-0072

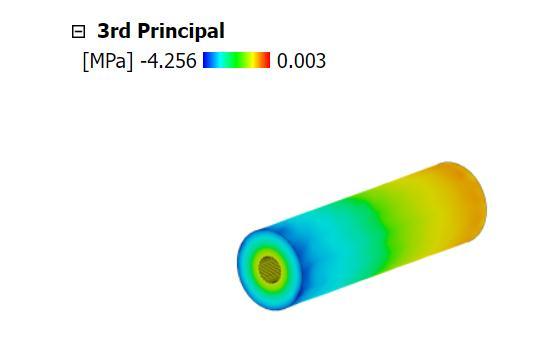

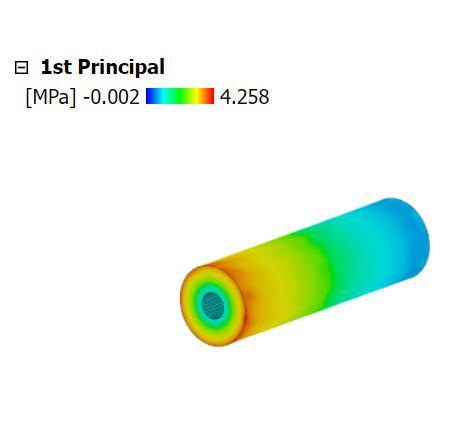

MaterialUsed-Al7075T6 OuterDiameterofSpool-70mm

Fig.

Analysis of Spool

Fig. Von Mises

Fig. 1st Principle

Fig. 3rd Principle Fig. Total Displacement

e-ISSN:2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN:2395-0072

We have designed the Spool Drive of an Electric Formula Student race vehicle. We have fulfilled all the criteria askedbytheFormulaBharatRulebook2022.

The material Selected for the manufacturing of componentsoftheSpoolDriveisAl 7075t6.

[1] https://www.skf.com/in/products/rollingbearings/ball-bearings/deep-groove-ballbearings/productid-6208-2Z

[2] V.B.Bhandari,DesignofMachineElements,Tata McGraw-HillEducation.

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page 751