International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

1 M.Tech Scholar, Dept. of Civil Engineering, Shri Rawatpura Sarkar University, Raipur

2 Assistant Professor, Dept. of Civil Engineering, Shri Rawatpura Sarkar University, Raipur

3 Assistant Professor, Dept. of Civil Engineering, Shri Rawatpura Sarkar University, Raipur

4 Assistant Professor, Dept. of Civil Engineering, RSR Rungta College of Engineering and Technology, Bhilai ***

Abstract - Due to over increasing population and limited resources of land we have to look to the sky to accommodate this increasing population andforthatwearesomuchfocused on making high rise buildings and other mega structures to utilise the resources of land to its fullest, but this cannot be achieved without improving our construction technique and materials. As we know that Concrete is one of the most widely used structural material hence its property and quality influence the construction a lot. Here in my projectIhavetried to evaluate those properties of concrete and the improvement in those properties by adding silica fume. Silica fume act as a filler material and fills the pores between cement particles, making it more dense and improving the microstructure of concrete and thus improving the mechanical properties of concrete, such as strength, impermeability, durability, elastic modulus and so on. It also improve the concrete by chemically reacting with hydration precipitation of Ca(OH2) and producing hydratedcalciumsilicateinalkalineconditionsthus improving the consistency of concrete and workability. Compressive strength of concrete is the most important property of concrete, because other properties like stressstrain relationship, tensile strength,bondstrength,modulusof elasticity, density, impermeability, durability etc. can be inferred from the compressive strength using established correlations. Therefore in this project I have focused on observing the improvement in compressive strength of concrete by adding silica fumes and finding the mostoptimum proportion of silica fume which gives us the best result. Different mix design are prepared following IS code and different proportion of silica fume (i.e. 0%, 5%, 10%, 15%, 20%) are added and the results of 7 and 28 days compressive strength are found and compared. The result shows a progressive increase in compressive strength of concrete (corresponding to 28 days strength) till15%ofsilicafumeand then it slightly decreases hence we can correlate thatthemost optimum proportion of silica fume that should be added in concrete is about 15% of total cementations material. Adding silica fume also improves the early strength of concrete (i.e. 7days strength), durability etc as discussed in the project.

Key Words: consistency of concrete, workability. Compressive strength, tensile strength, bond strength, modulus of elasticity, density, impermeability

Concreteisamixtureofsand,gravel,waterandcementto form a hard mass. Concrete has compressive strength but lowtensilestrength.Itstensilestrengthisapproximately

1 of its compressive strength. Recently, everyone is interested in improving the properties of concrete by mixing/addingvariouspozzolanicmaterialstotheconcrete mix.One of these substances are silica fume. Silica fume is also known as microsilica, concentrated silica fume, "Micropoz"™, silica fume, volatile silica, etc. Mumbai's Bandra worli sea link used fumed he silica concrete primarilytoimprovedurability.Silicafumeisaby-product oftheproductionofferrosiliconandsiliconmetalinelectric arc furnaces. Silica fume extracted in this way is typically composedofover90%silicondioxideandtraceamountsof otheroxides.Silicafumewasfirstcollectedinhis1947,and trialsbeganin1961.Silica particlesareverysmall,witha finenessof15,000to30,000m2/kgandaspecificgravityof about 2.22. This is about 100 times less than cement particles,makingiteasierformicrosilicaparticlestooccupy theinterstices(voids)leftbycementparticles.

CementCement is generally composed of two components.OPC(CommonPortlandCement)Components:

Lime (CaO) (62-67%): Givesstrengthandstrengthtothe cement.Ifenoughispresent,thecementbecomesunhealthy and difficult to expand. If you don't have enough, the strength of the cement will decrease and it will harden quickly.Strength→resistancetoimpactandmoderatestress Toughness→resistancetoabrasionHardness→resistance toimpact(suddenstress)

Silica (SiO2) (17-25%): also provides strength to the cement.Toomuchwillincreasethestrengthofthecement, butwillalsolengthenthehardeningtimeofthecement.If initial hardening is desired, ingredients such as (because silicaandlimearelonghardeningingredients)needtobe changed.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Aluminum Oxide (Al2O3) (3-8%): Gives cement quicksettingproperties.Thisactsasafluxandhelpsreducethe clinker temperature. Exceeding that weakens the cement. Thetemperatureatwhichcementclinkerisformediscalled clinkertemperature.

Calcium Sulfate (CaSO4) (3-4%): Commonlyavailablein the form of gypsum, it helps extend the initial hardening timeofcement.

Iron Oxide (Fe2O3) (3-4%): Providesstrength,hardness andcolortocement.

Magnesia (MgO) (1-3%): Providesstrength,hardnessand colortocement.Cementisunsuitableifitsamountisgreater thannecessary.

Sulphur (S) (1-3%): Sulphurincementcausesvolumetric changesandthereforeunhealthycement.

Alkalis (Na2O, K2O) (0.2-1%): Alkalis in cement cause stressandefflorescenceinstructuresusedinconstruction.

If these cement components are ground together and burnedTheyfusetogethertoformcomplexcompoundsthat are not formed at the same time, called Borg compounds. TheBorgcompoundsfoundincementare:

Tricalcium aluminate (3CaO.Al2O3) (C3A) (4-14%): knownascalcite.Hydratewithin24hoursofaddingwaterto cement. This is responsible for the instant hardening of cement and also leads to changes in cement volume. As a result,itcausestheoccurrenceofcracks.Releasesmaximum heat of hydration during formation. Hydration by C3A occurs,andshrinkageoccursduetothevolumechange of thecement.

Tetra Calcium Alumo Ferate (3CaO.Al2O3.Fe2O3) (C4AF) (10-18%): knownasferrite.Italsohydrateswithin24hours of adding water. It has been observed to have the worst cementproperties.Itisofnotechnicalsignificanceasitdoes notimpartanypropertiestothecement.

Tricalcium silicate (3CaO)SiO2) (C3S) (45-65%): known asalite.Afteraddingwatertothecement,itwillbehydrated inaboutaweek.Itisinvolvedinthedevelopmentofinitial strength of concrete. Therefore, when early strength is required in engineering structures, the C3S content is significantly increased. Examples include cold concrete, pavingandprefabconstructionwhereformworkisreused for rapid construction. It also increases the cement's resistancetofreezingandthawing.

Dicalcium Silicate (2CaO.SiO2) (C2S) (15-35%): Known as Belite. It is responsible for the gradual strength developmentofcementbecauseithybridizeswithinayear of adding water to cement. It also makes cement more resistant to chemical attack. If engineering structures

requireprogressivestrength,theC2Sfractionisincreased accordingly.B.Dams,hydraulicstructures,bridges,etc.

Physical Contribution: Due to the very small size of silica fumecomparedtocementparticles,itactsasafiller,filling thevoidspresentincementparticlesandgreatlyreducing permeability.Thisphenomenonisknownasmicrofilling.or particle filling, which itself significantly improves the propertiesofconcrete.

Chemical Contribution: HighlyamorphousSiO2fromsilica fumeisahighlyreactivepozzolanicmaterialthatreactswith CaOHliberatedbythecementreactioninconcretetoform additional binders in concrete. It forms calcium silicate hydratesthatactashydratesandimprovethepropertiesof concrete.

Improves Cohesion: Inwetconcrete,silicafumeincreases the cohesion of concrete, making it less likely to separate duringplacementandcompaction.Thesepropertiesresultin improved blowing due to reduced rebound and increased blowingefficiency.

Reduced bleed: Microsilicahasaveryhighsurfaceareaand averylowwatercontentistypicallyusedinfumedconcrete, which minimizes concrete bleed-out. When bleeding is reduced,thecapillariesformedbybleedingarealsoreduced, makingthemlesspermeableandmoredurable.Thisbleed reduction allows the finishing process to start earlier, resultinginfasterbuildtimesandincreasedbuildefficiency.

Improving mechanical properties: Initially, microsilicic acidwasmainlyusedtoincreasethecompressivestrengthof concrete, but other effects such as improving the flexural strength and modulus of high-rise buildings were investigated.ricefield.

Reduced Permeability: Durabilityisalsoaveryimportant propertyofconcretethatisdirectlyrelatedtopermeability. Therefore,addingsilicatoreducepermeabilitycanincrease the durability of concrete and increase the life and maintenancecostsofstructures.

Chloride attack: RCC fails primarily due to corrosion of rebar.Thisiscausedbychlorideingressintoconcretefrom theseaandothersources.Chloridespenetratetheconcrete through the pores present in it and corrode the reinforcement.Thisisminimized/retardedbyaddingsilica fume to the concrete mix to reduce permeability. Adding silicafumetoconcretecanaddyearstothelifeofastructure.

Workability: Wetconcretecontainingmicrosilicicacidhas highercohesionandlesssegregationthanconcretewithout microsilicicacid.Silicafumehasbeenfoundtoimprovethe workabilityofconcrete.

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page716

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

Allmaterialsusedaredescribedinthefollowingsections. Grade43madebyUltraTechCementLtd.Thecementmeets all American Society for Testing and Materials (ASTM) requirementsandisIS8112:1989certified.

OrdinaryPortlandCement(OPC)isthemostcommonly usedcementforavarietyofapplicationsincluding:

•HighStrengthConcrete

•MasonryandPlastering

•MediumStrengthConcrete

•PipesandBlocks

Aggregates: Theaggregatesusedareprovidedbylocal suppliersinaccordancewithIS3831970andconsistoftwo types:ConsistsofType:

Coarse Aggregate:Thecoarseaggregateusedincluded two size variations of 10mm and 20mm. 20mm aggregate accounts for 69% of the total coarse aggregate and 10mm aggregateaccountsfor31%ofthetotalcoarseaggregate.

Fine Aggregate:Thefineaggregateusedwassandfroma nearby river area that passed perfectly througha 4.75mm sieveandwasfreeofclumpsandgravel.

Silica Fume:Thesilicafumeusedwasfresh,suppliedbya localsupplier,andinfinegranularform(powder).Silicafume is a by-product of the manufacture of silicon metal or ferrosiliconalloysinindustry.Alsoknownasmicrosilica,itis anamorphouspolymorphofSiO2andconsistsofspherical diameterswithaparticlesizeof150mm.Duetoitsphysical andchemicalproperties,itisahighlyreactivepozzolana

Additives: Air entertainers, water retardants, water reducersandacceleratorsaremostcommonlyused.Theyare addedtogivespecialpropertiestowetorhardenedconcrete. Itcanimprovetheworkability,durability,propertystrength, etc.ofcertainconcretemixtures.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

Design grade of concrete used for testing purpose is M40

Percentagesofsilicafumeusedinmixare:

• 0%

• 5%

• 10%

• 15%

• 20%

Result of 0% silica fume concrete

Table -4: Resultof0%silicafumeconcrete

Specimen Strength (MPa) at 7th day Strength (MPa) at 28th day 1 30.62 45.71 2 31.57 46.98 3 29.95 44.99 4 28.16 45.1 5 30.95 46.87

Result of 5% silica fume concrete

Table -5: Resultof5%silicafumeconcrete Specimen Strength (MPa) at 7th day Strength (MPa) at 28th day 1 31.25 48.9 2 32.63 46.26 3 32 47.1 4 33.3 48.35 5 33.67 48.89

Result of 10% silica fume concrete

Table -6: Resultof10%silicafumeconcrete

Specimen Strength (MPa) at 7th day Strength (MPa) at 28th day 1 37.65 50.3 2 38.5 51.85 3 38.2 49.84 4 39.23 52.63 5 39.02 52.18

Result of 15% silica fume concrete

Table -7: Resultof15%silicafumeconcrete

Specimen Strength (MPa) at 7th day Strength (MPa) at 28th day 1 44.26 57.23 2 46.65 59.35 3 44.55 59.02 4 45.52 55.68 5 43.02 55.92

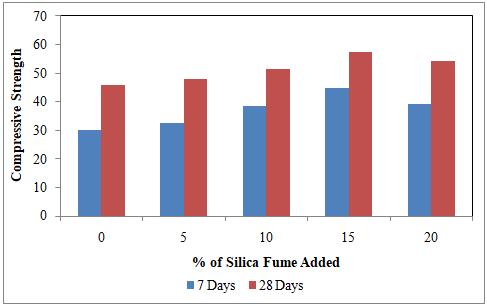

Thedatasoobservedinhereplottedandcompared Table -8: Averagevaluesofcubestrength

Percentage of Silica used (%) Strength (MPa) 7 Days 28 Days 0 30.25 45.93 5 32.57 47.9 10 38.52 51.36 15 44.8 57.44 20 39.14 54.37

Chart -1:Comparisonofcompressivestrength

Based on this project, we can draw the following conclusions:

1. Both7daysand28dayscompressivestrengthincreases aspercentageofSilicaFumeincreases.

2. The optimum addition level of silica fume is about 15%.Thisisthelevelthatgivesthebestresults.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

3. Since most concrete properties are found to correlate with compressive strength, other properties such as stress-strain ratio, tensile strength, bond strength, modulus, density, impermeability and durability are dependentontheseproperties.Itisnoexaggerationto saythatisalsoimproved.

4. 4Due to these effects, fumed silica concrete is widely used around the world to produce high strength and durableconcrete.

5. Silica in small amounts can provide so many benefits thatitisaveryusefuladjuncttoconventionalconcrete.

[1] D. Kornack and P. Rakic, “Cell Proliferation without NeurogenesisinAdultPrimateNeocortex,”Science,vol. 294, Dec. 2001, pp. 2127-2130, doi:10.1126/science.1065467.

[2] UhrNeville&J.J.Brooks(ConcreteTechnology)

[3] ACICommission226 1987 SilicaFumesinConcrete –ReportACIMaterialsJournal,March-April,pp.158-166

[4] Ahmed Shuraim, Fahid Aslam, Raja Rizwan HussainundAbdulrahman M. Alhozaimy, (2016),“Combined effectofcoarse aggregate typeandsilicafumeoncreepmodulusofhigh-strength concrete,”Journal of Materials in Civil Engineering,Juli2016,28(12):04016159.

[5] Ajileye (2012).Untersuchungen zu Mikrosilika(Silica Fume)as teilweiser ZementersatzinBeton,Global Journal of Researches in Engineering Civil and StructuralEngineering.

[6] Amudhavari,N.K&Matthew, J(2012). Effect of silica fumeonstrengthanddurabilityparametersofconcrete. International Journal of Engineeringand NewTechnologies

[7] B.B. Sabir, (1997),"Mechanical PropertiesandFrost ResistanceofSilica-Fume Concrete,"Cement and Concrete Composites,Vol.19, Issue 4, 1997,pp.285294.https://doi.org/10.1016/S0958-9465(97)00020-6.

[8] Bhikshma (2009) AsianJournalof CivilEngineering(Building&Housing).

[9] Bradley Williams,T.S. 1986ProductionofMicrosilicaConcrete Magazine, Vol.20,No.8,pp.17-18.

[10] Safwan A.Khedr, one ASCE member,Ahmed F Idriss2, (1995),"The resistanceofsilica fume concretetocorrosion-related damage,"Journal of MaterialsinCivilEngineering,Mai1995,7(2):102-107.

[11] CDAtis*, F. Ozcan, A. Kılıc, O. Karahan, C.Vilim,M.H. Severcan, (2005),"Effectof dry and wet curing conditions on compressive strength offumed concrete,"BuildingandEnvironment,40:1678–1683.

[12] Cabrera,J.G.andClaisse,P.A.(2013),"Measurementof chloridepenetrationinfumedsilicaconcrete,"Cement andConcreteComposites,12(3):157-161

[13] Cakir2014Effectsofsilicafumeonthemechanicaland physical properties ofconcrete. National Research CenterforHousingandBuildings(HRBC)Journal.

[14] CananTasdemir,MehmetA.Tasdemir,FrankD.Lydon, BenI.G.Barr(1996),Effectofsilicafumeandaggregate size onconcrete brittleness,Cement and Concrete Research,vol.1,January1996,pp.63-68.

[15] Chao-ShunChang,Chung-HaoWu,TsongYen,Tsao-Hua Hsu,(2008),“Studyonshrinkagedeformationandcrack initiationofhigh-strength high-performance concrete containingsilicafume”,October2008.

[16] Gutke,V.S.&Bandari,P.S.(2014).Effectofsilicafumeon concrete.HisIOSR Journal of Mechanical and Civil Engineering.

[17] Ha-WonSong,Jong-ChulJang,VeluSaraswathyKeun-Joo Byun, (2007),Estimationof diffusivityin fumed concrete, Bauen und Umwelt, Vol.42,No.3,2007 3 Month,page1358-1367

[18] HochleistungsbetonvonShAhmed,SPSHAH

[19] Houssam A.Toutanjib,*, ZiidBayasia, (1999),Effectof curingprocedureon properties of silica fumeconcrete,CementandConcreteResearch,29:497–501.

[20] is10262:2009

[21] is15388:2003

[22] is456:2000

[23] m.l.Gambhir(Betontechnik)

[24] Marlova P.Kulakowskia*,Fernanda M. Pereirab, Denisec.C. Dal Molinc, (2009),"Carbonation-induced reinforcing corrosioninsilica fume concrete",Construction and Building Materials,März2009.

[25] N. Yazdani, F.ASCE1; M. Filsaime2;undS. Islam3, (2008),Accelerated hardeningofsilica fume concrete,Journal of Materials in Civil Engineering,August2008,20(8):521-529.

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page719

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

[26] Pradhan &Datta,D(2013). Effects ofsilica fumeinconventionalconcrete.InternationalJournalof EngineeringResearchandApplication.

[27] Roy,D.K.(2012). Effect ofpartial replacementofcementbysilica fumeonhardened concrete.InternationalJournalofNewTechnologiesand AdvancedEngineering.

[28] S.Bunger,B.Senguptab,(2002),InvestigatingtheCompre ssiveStrengthofFumedSilicaConcreteUsingStatistical Techniques,Cement and Concrete Research,Vol.32,No.9, September 2002, pp. 13911394.

[29] Sasikumar(2016).Experimental investigationofthe properties of silica fumeas apartial cement substitute.InternationalJournalforInnovativeScientific Research

[30] Seyedhamed Sadati, Mahdi Arezoumandi, Mohammad Shekarchi,(2015),Long-termperformanceofconcrete surface coatingsunder soil loadingin marineenvironments,July 2015, Construction and Building Materials94(10):656-663. , DOI:10.1016/j.conbuildmat.2015.07.094.

[31] Sharma&Seema(2012).Effectofpartialreplacementof cementbysilica fume on compressive strength of concrete.InternationalJournalofTechnologyandManag ementStudies.

[32] InstructionManualforSilicaDust2.

[33] Smita Sahooa,PravatKumarParhia,*,BikashChandra Pandab,(2021),“Durabilityofconcretecontainingsilica fume and rice husk ash”, Cleaner Engineering and Technology, 2: 100067, pp. 1-10,https ://doi.org/10.1016/j.clet 2021.100067

[34] Yunsheng Xu, D.D.L.improve strength,”Cement and ConcreteResearch,29:451-453.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page720