International Research Journal of Engineering and Technology (IRJET)

e-ISSN:2395-0056

Volume:09Issue: 10 | Oct 2022 www.irjet.net p-ISSN:2395-0072

International Research Journal of Engineering and Technology (IRJET)

e-ISSN:2395-0056

Volume:09Issue: 10 | Oct 2022 www.irjet.net p-ISSN:2395-0072

1MTech Student, Department of Civil Engineering, Jain College of Engineering, Belagavi, Karnataka, India

2Assistant Professor, Department of Civil Engineering, Jain College of Engineering, Belagavi, Karnataka, India ***

Abstract – Ready mixed concrete is an advanced technology, which involves high degree of mechanizationand automation. Ready mix concrete is a ready to use material that is mixed in a batching plant accordingto the specification of the customer and is delivered through transit mixers to the clients site.

The owner/client wants to set up a new RMC plant in Belagavi. The clients entrust the engineer or contractor to propose a plan for setting up of a new RMC plant in Belagavi.

The ready mix concrete sector is less familiar and requires significant investment , therefore a thorough investigation is required before establishing a new plant. In this work a feasibility analysis for construction of new RMC plant is carried out. A case study on an existing RMC plant in Belagavi is conducted to examine all the prerequisites required to establish a new RMC plant. With reference to the case study a plan for the proposal of new RMC plant is developed

Key Words: Readymixedconcrete,Feasibility,Casestudy ,Projectmanagement,Planning,Schedulingetc.

The construction industry in India has historically been labour-orientedandsimplebuildingswerebuiltyearsago,as mechanisation progressed rather slowly. Therefore, as technologyadvanced,concretebecamemorevaluablethan anyotherbuildingmaterial,anditsusagehasbeenincreasing rapidly. Prior to undertaking the actual building process, contractorsandbuildershadtobuy,gatherandstockpilethe rawmaterialsneededfortheproject.However,thismethod cannotbeusedin smallandcrowdedregionswithlimited spacesinceitrequiresclean,vacantspaceforthestorageof raw materials at the building site. As a result, ready mix concretewasdesignedasasolutiontothisissue.Nowthe rapidlyexpandingurbanizationhasresultedincommercial projects like shopping malls, retail stores, multiplexes, conventioncentres,andotherrealestateprojects,whichhave significantlyincreasedthemarketdemandforhigh-quality concrete while also making the structures earthquakeresistant.Indevelopednations,ready-mixconcreteaccounts for roughly70% ofcement utilization, with recastcement accountingfortheremaining25%.Theready-mixconcrete sectoristhelargestintheworldandisexpectedtogenerate morethan$600billioninrevenueby2025.

Feasibility analysis is the process where the proposed strategicplanordesignisevaluatedandconfirmedbefore approval.Thegoalofafeasibilityanalysis,alsoreferredtoas a feasibility study, is to fairly and logically consider the advantages and disadvantages of a current or proposed business,potentialrisks,theresourcesneededtocarryout operations,andultimatelythechancesthattheventurewill succeed. Thefeasibilityanalysisinvolves thefollowingsteps

A preliminary survey always comes first in a feasibilitystudy.Itinvolveskeepingtrackofremarks made about the project or considering the solutions andsuggestionsputforthbystakeholders andother business-relatedindividuals.

Theproposedproposalorremedyisevaluatedfor merit by thoroughly examining the above preliminarystatistics.

Surveys and market research are conducted thereafter to evaluate consumer demand and the probabilitythattheprojectwillbesuccessful.

Finally,wedecidefirmlywhetherornottocarryout thestrategy.

The main objective of a market feasibility study is to comprehend the market and analyze whether there is sufficient demand for the business to be successful. A market's depth condition and capacity to sustain a given development are all assessed through a market feasibility study.Itisagreatwayfordeterminingthelikelihoodthata newbusinessinitiativewillsucceedorfail.

It is a analytical and intellectual process that outlines the goalsofanorganizationandoffersmanyactionplanstoassist the company achieve their objectives and goals .Before beginningaprojectinconstruction,planningisessentialto ensuringthatitwillbecompletedeffectivelyandonschedule. Intheconstructionindustry,planningandmanagingvarious aspects in accordance with the plans are two crucial components.

Itpromotesthecoordinationofoperations,givesdirection foraction, identifies futureopportunitiesandthreats,and

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume:09Issue: 10 | Oct 2022 www.irjet.net p-ISSN:2395-0072

establishes criteria for managing. It assists managers in enhancingfutureperformance.

Microsoft Project is a set of project management tools developedanddeliveredbyMicrosoft.Itissoftwaredesigned tohelpprojectmanagersinscheduling,allocatingresources toprojects,trackingprogress,keepingcostsundercontrol andevaluatingworkloads.

Theprojectcreatesbudgetsinaccordancewithassignment work and resourcecosts. When resourcesareallocatedto tasks and assignment work is planned, the programmer estimatesthecost,thatisequaltotheworkmultipliedbythe rate,androllsituptothetasklevel,thentoanysummary tasks, and finally to the project level. Every resource has access to a calendar that lists the days and shifts during whichtheyareaccessible.

InthisworkafeasibilityanalysisforconstructionofnewRMC plantiscarriedout.AcasestudyonanexistingRMCplantin Belagavi is conducted to examine all the prerequisites requiredtoestablishanewRMCplant.Withreferencetothe case study a plan is for the proposal of new RMC plant is developed

Thefollowingmethodologyisadoptedinthiswork.

Belagavi,thefourth-largestcityinKarnataka,ishometothe country'sfirstdesignatedSEZcenterforaerospaceprecision engineeringandmanufacturing.With24sugarfactories,8 MEUs (medium-sized enterprises), an aluminum factory owned by Hindalco, 5 ready-mix concrete plants, and 24 sugarfactoriesarelocatedinthearea.

Underthe Prime Minister Narendra Modi'sflagshipSmart CitiesMissionSmartBelagavi,Belagaviis selectedasasmart cityinthefirstphaseoutof20cities.AsBelagaviisthecenter for two main national highway there are many high cost projectsbeingconstructedinandaroundBelagavi whichisa boostforreadymixconcreteindustry.

The need for ready-mix concrete is being fueled by the increasingnumberofinfrastructureprojects,suchasbridges, highways,andairportdevelopmentprojects.Therearemany number of residential projects ongoing and numerous residential constructions are still in progress. Thus, it is anticipated that the ready-mix concrete industry would experiencerapidexpansionintheyearstocome.

YES NO

FeasibilityAnalysis Casestudy

Proposalforanew RMCplant

Estimatingthe costrequiredto setupRMC

TounderstandthefeasibilityfortherequirementofRMCin Belagaviandtoachievetheobjectiveanopinionsurveyinthe formofquestionnairesurveywasconductedamongseveral engineersanddatawascollectedontheirpreferencesover readymixconcreteandsitemixconcrete.Thesurveystudy coveredavarietyofimportantfactssuchasthesatisfactory factor,need,typeofconcretemixpreferred.

1.NameoftheContractor/Engineer/firm 2.Whichtypeofconcreteisfeasible/preferredforuse?

Sitemix

RMC 3.Whichtypeofconcreteiseasytohandle?

Sitemix

RMC 4.Inwhichtypeofconcretequalityisachieved?

Sitemix

RMC 5.IsRMCservicesatisfactoryinBelagavi?

6.IsthereanecessityforanewRMCplantinBelagavi?

FigNo1-FlowchartforMethodology

FigNo.2-Sampleofquestionarysurveyform

TogainknowledgeaboutthereadymixconcreteIvisitedone ofthewell-knownRMCplantinBelagaviinordertolearnand understand more about the plant. The study covered a number of significant information, such as the materials, productionvolume,manufacturingandstorage,equipments used,operationandfunctioningetc.

2.2.1Sitevisitdetails.

Thedetailsofthefollowingwerecollectedfromthesitevisit:

ThepresentareaoftheexistingRMCplantis2acres, whichwasprocuredonaleasebasis,withamonthly rentof2lakhs.

Thevariousunitsincludedinthetotalplantareaare

Plantsetuparea

MaterialStoragearea

Transportmovementarea

Plantofficearea

Thematerialsrequiredfortheproductionofready mixconcreteare:

Cement

Aggregate

Water

Admixture

TableNo.1 Summaryofmaterialsused

Aggregatestorage(Inlinebins)

Inreadymixconcrete,aggregatesarestoredinbins that are separated for different sizes ,4-5 compartmentsareprovideddependingontheneeds tostorethedifferentsizedaggregates.

Itconsistsofahopperintowhichthefineandcoarse aggregateisdischargedusingaloaderinaccordance withthedesignandtheclient'srequirements.With thehelpofloadcellsandanindicator,theaggregate weighinghopperweighstheaggregatesrequiredfor themix.

Cement Cementisstoredinsilos.Silosareairtightcontainers usedtostorecementandflyash.

Admixture Admixturesarestoredindrumsorinsmalltanks.

TableNo.2 Summaryofcapacityandnumberof material storageused

Capacityof1aggregatestoragebin 200Ton Capacityofinlinebins 2500kg Skipbucketcapacity 2000kg Numberofsilos 2 Capacityofsilos 150Toneach 3. Equipmentsused

Concretepump

ControlPanel

International Research Journal of Engineering and Technology (IRJET)

e-ISSN:2395-0056

Volume:09Issue: 10 | Oct 2022 www.irjet.net p-ISSN:2395-0072

4.Productioncostanalysisfor1m3ofconcrete.

Costanalysisoftheproductioncostfor1cumofM20 gradeofconcretefortheexistingplantisasfollows

TableNo.4 TotalmaterialcostofexistingRMCplant

Particular

Content perCum inKgs RatesinRs perkg

Totalcost perCum in Rs

Cement 310 5.15 2111.5

Sand 820 0.76 623.2

20mm aggregate 840 0.57 478.8

12.5mm aggregate 330 0.57 188.1

Water 155 0.1 15.5

Admixture 3.1 34.75 107.725

Total 2458.1 3009

TableNo5 TotalproductioncostofexistingRMCplant

Totalmaterialcost 3009Rs

Totalofothercost (Remainsfixed) (35 to 37.5 %) i.e. 1130Rs

Total RMC cost for M20 grade 4139.825Rs

GST18%ofabove 745.1685Rs

Total RMC cost for M20 gradeconcrete 4885Rs

Costreduction

Production cost can be reduced by managing the costofmaterialsandbypropervendormanagement

Cost-saving efforts in the supply chain may be made simpler by improving negotiating skills and developing trust with suppliers. We should look for supplierswhocanprovidethemostvalueformoney in terms of quality, delivery and lead time at the lowestprice Itiseffectivetonegotiatealowerprice with the present supplier, or a new supplier is chosenwhochargeslessfortheidenticalitem.

Costcanbereducedbypracticingthefollowing:

Neverassumethatpreferredornearbysellerwill always be the best choice for purchasing raw materials.

Requestatleastthreepricequotationsfrommaterial suppliers.

Reviewandcomparethreetofourvendorstofind the best deal including the quote numbers, lead times, expiration dates, and other pertinent information.

Don'tbeuncomfortableindiscussingwithvendors aboutthepricesinreferencetotheothermaterial quotationsacquired.

Benefitsofvendormanagement.

Improvedqualityofgoodsandservices

Reducedcosts

ImprovedEfficiency

Maintainsbusinesscontinuity

Increasedcustomersatisfaction

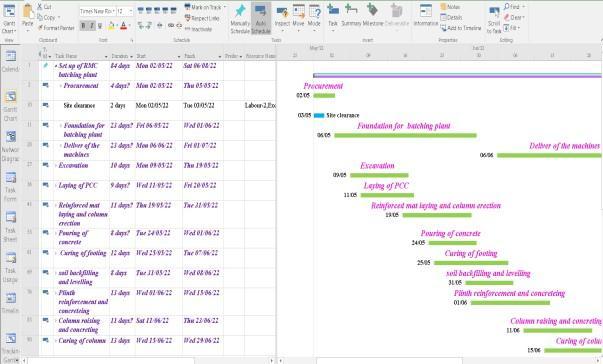

AdetailedscheduleusingMSPisdevelopedforexecutionof constructionactivitiesonthesite.Theconstructionofoffice ,labourroom,staffroom,batching plantplatform,watertank ,aggregatestorage,QA/QCcontrollab,Wetlab,washareais planned.TheplanningandschedulingincludesGanttchart, entrytableandbarchart.

AGanttchartisasequentialbarchart.Itisasimple easy to understand timeline that converts the project’s specifics into comprehensible visual representation.

Itistheonethatwilllistallofthetasksinvolvedin the project and provide the estimated points of interest for each activity. Segments such the indicatorfield,taskmode,taskname,term,begin, andfinishareincludedintheentrytable.

Thetimespansofeachactivityareshownbybarson thisgraphthatareplacedonacalendartimescale.

Inthisworkacasestudywasundertakeninwhichdetailed studyofanexistingRMCplantwasdoneinordertodevelop anewRMCplant.Adetailedplanning,costingandanalyzes wascarriedoutforproposinganewRMC plantinBelagavi.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume:09Issue: 10 | Oct 2022 www.irjet.net p-ISSN:2395-0072

Theresultsofthesurveyaregraphedasfollowsin theformapiechart.

i. Theresponsesforthesecondquestionareshown below;30%ofrespondentschosesitemixconcrete, while70%ofthemchoosereadymixconcrete

Whichtypeofconcreteis feasible/preferredforuse? RMC Sitemix

Site mix 30% RMC 70%

FigNo.3-PiechartshowingRMCispreferredthansitemix concrete

ii. Theanswerforthe5thquestionisdisplayedbelow. ThecurrentreadymixconcretefacilitiesinBelagavi provides a service that leaves only 38% of respondents pleased, while 62% of them are not satisfiedwiththeserviceprovided.

IsRMCservicesatisfactoryinBelagavi?

YesNO No 62% Yes 38%

FigNo4-PiechartshowingthepresentserviceofRMC plantinBelagaviisnotsatisfactory

iii. To analyze the demand for a new RMC plant in Belagavi6thquestionwasposed.Accordingtothe findings,68percentoftherespondentsbelievethat BelagavineedsanewRMCplantfacility

3.2ResultsofcostrequiredforsettingupofanewRMC plant

ThevariouscostsrequiredforsettingupanewRMCplant includethefollowing:

Arearequired:2acresapprox.

AsthepreferredlocationoftheclientisAmbewadi ,thecostof2acreoflandisamountedto90lakhs.

CostofMachinery

Particular Costper unitinRs Number of units required

Total cost (approx.)in Rs

Batching plant (CP60) 1crore 1 70Lakh to 75Lakh

Transitmixer 35to40 Lakh 4to5 1.75Crto 2.Cr

Loaders 25to30 Lakh 2to3 50Lakh to 60Lakh Tippers 30to35 Lakh 2to3 60Lakh 70Lakh to

Diesel generator 2 to Lakhs 5 1 2Lakh 5Lakh to Lab equipments 10Lakh 10Lakh Building infrastructure 50Lakh 50Lakh Total 4.5Crto5Cr

TableNo.6 CostofMachineries

FigNo5-Piechartshowingthatthereisnecessityforanew RMCplantinBelagavi.

FigNo6- Piechartillustratingthecostsrequiredfor settingupaRMCplant

International Research Journal of Engineering and Technology (IRJET)

e-ISSN:2395-0056

Volume:09Issue: 10 | Oct 2022 www.irjet.net p-ISSN:2395-0072

A pie chart illustrating the cost required for setting up an RMC plant shows the proportional contribution of each componenttotheoverallcostrequired.Theaveragecostto establishanewRMCincludingthelandcostisintherange 5Crto5.5Cr,ofwhichthetwocomponentsthatrequirethe biggestsumofmoney arelandcostwhichaccountsfor16% ofthetotalcostandtransitmixers whichaccountsfor35% oftheoverallcost.

Theproductioncostofreadymixconcreteisgivenistermsof 1m3.Theproductionpriceofreadymixconcreteincludes variouscost:

Additionalcost

Around 35-37 % of other additional cost are includedinthetotalproductioncostofconcrete.

Theotheradditionalcostincludedintheproduction costofRMCareoperationalcost,Dieselcost,labour cost,miscellaneouscost

Taxation - 18% of Goods and service tax (GST) chargesareapplied.

long-term partnership. Therefore the new rates of the materials were adopted and the production cost was calculated.

Cost analysis for the production for1cum ofM20 gradeofconcreteofnewRMCplantisasfollows:

TableNo7 TotalmaterialcostofnewRMCplant.

Particular Content per Cum inKgs

Rates in Rs perKg

Total cost perCum inRs

Cement 310 5 1550 Sand 820 0.76 623.2 20mm 840 0.55 462 12.5mm 330 0.55 181.5 Water 155 0.1 15.5 Admixture 3.1 33.89 105.059 Total 2458.1 2937.259

TableNo8 Totalproductioncost

Totalmaterialcost 2937Rs

Total of other cost(Remainsfixed) (35to37.5%) i.e. 1130Rs

Total RMC cost for M20grade 4067.259Rs GST18%ofabove 732.10662Rs

Total RMC cost for M20gradeconcrete 4800Rs

FigNo7- Piechartshowingthe distributionofdifferent costincludedinthetotalproductioncostofconcrete

Thematerialcostthatis62%dominantsthetotalproduction cost Thereforeproductioncostcanbereducedbyreducing the cost of materials and this can be reduced with proper vendormanagement.

As a result, we used vendor management for the material inventories for the new plant setup. The existing firm procured the material from two to three suppliers for the sameproduct,whichledtoalackoflong-termrelationships andtrust.Asaresult,itwaschallengingtonegotiatelower costsandshorterleadtimes.Aftertakingthisinformation intoconsideration,westartedthevendorselectionprocess, which included finding and contacting relevant suppliers, requesting bids, shortlisting and choosing vendors. The vendor offering the most value for the money, the lowest price,andthequickestleadtimewaschosenoutofthethree receivedquotes,andtheywereguaranteedofdevelopinga

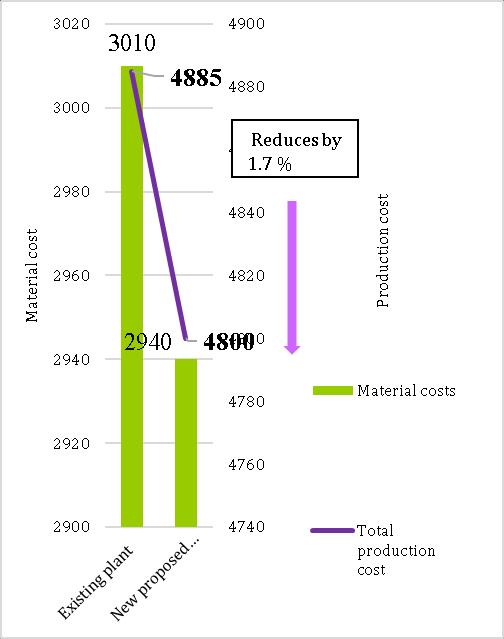

TableNo9 Costcomparisonbetweentheexistingandnew RMCplantfor1cumofconcrete.

Existing plant New proposed plant Difference

Units 1cum 1cum 1cum Materialcostin Rs 3010 2940 70 Totalproduction costinRs 4885 4800 85

International Research Journal of Engineering and Technology (IRJET)

e-ISSN:2395-0056

Volume:09Issue: 10 | Oct 2022 www.irjet.net p-ISSN:2395-0072

Thefollowinggraphshowsthatasthematerialcost reduces there is reduction in the total production cost.

FigNo8- Costcomparisonbetweenthematerialandtotal productioncostofconcrete

Theconstructionofcivilworkrequiredforsettingupanew RMCplantisscheduledinMSProjectsoftware.Theproject involves the construction of foundation for installation of batchingplant,constructionoflabourrooms,office,water tank,staffroom,QA/QClab,wetlab,washarea,aggregate storage.

FigNo.9 -Summaryofschedulingfromprocurementof batchingplanttillplinthbeamreinforcement

1. It is concluded by feasibility analysis that it is feasibletosetupanewRMCplantnearBelagavi.

2. ThetotalcostrequiredforthesetupofanewRMC plantisaboutRs5Crore.

3. The production cost of 1m3 of M20 grade of concrete of existing plant is 4885Rs whereas that for the new proposed plant is 4800 Rs .A cost reduction of 85 Rs per m3 of concrete can be achievedinthenewproposedplant.

4. ThetotaltimerequiredforsettingupofanewRMC plantasobtainedbyusingMSProjectis84days

[1] A.S.M.FahadHossainandDr.Md.MahmudurRahman, “Study on Ready-Mix Concrete with Survey and Experiments in the Context of Bangladesh” Journal Of ScienceAndTechnologyVol.4,2013;ISSN2072-0149

[2] MehdiRavanshadniaandMiladGhanbari,“Minimizing MaterialInventoryinReadyMixedConcretePlantsby Applying a Fuzzy Neural Network Approach” InternationalJournalofInnovativeScience,Engineering &Technology,Vol.1,Issue8,October2014.

[3] Chirag R. Parmar., Ashish H. Makwana., Jayeshkumar Pitroda., Jaydev J. Bhavsar, “A Study On Ready Mixed Concrete Using Independent Sample T-Test Through SpssSoftwareInCharotarRegion OfCentral Gujarat“ Journal Of International Academic Research For Multidisciplinary,Volume1,Issue11,December2013; ISSN:2320-5083,

[4] Prajakta Prasad Gauns and Prof. Amey A. Kelkar, “Application of Microsoft Project for Planning and Scheduling of a Residential Project” International Research Journal of Engineering and Technology (IRJET), Volume: 06 ,Issue: 07, July 2019 ; ISSN: 2395-0056

[5] H A. Rani1., R S Bonenehu., and M H Mubarak, “Financial Feasibility Study Of Batching Plant Investment On Sigli – Banda Aceh Highway ConstructionProject”

[6] Mr. K. H. Gupta1and Mr. A. K. Gaikwad, “Analytical Hierarchy Process (AHP) for Feasibility of Ready Mix Concrete Plant”, IOP Conference Series: MaterialsScienceandEngineering,2020

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056 Volume:09Issue: 10 |2022 www.irjet.net p-ISSN:2395-0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal