International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

1Aeronautical Engineer, Amity Institute of Technology, Amity University, Noida, India

2 Aeronautical Engineer, Amity Institute of Technology, Amity University, Noida, India 3Project Manager, Tata Technologies, Amity Institute of Technology, Amity University, Noida, India

4Consultant, Tata Technologies, Amity Institute of Technology, Amity University, Noida, India ***

Abstract - Inthedisciplineofaerodynamics,mostissuesare conventionally solved by solving the appropriate partial differential equations (PDE). However, some issues such as flow field prediction are often high dimensional, highly nonlinear,andmulti-scalemakingitextremelydifficulttodiscover an analytical solution or provide a completely acceptable explanation. In most cases, these difficult to solve issues are treated utilising numerical methods, which can aid in obtaining numerical answers and producing an approximationtoanalyticalsolution.Nonetheless,numerical approaches are typically time-consuming and have a significantlikelihoodofdivergingthroughoutthecalculation process.

Machine learning is currently widelyemployed ina variety of sectorstotacklechallengesofalltypes.Withtheadvancement ofcomputerscienceandtheincreasingmagnitudeofdatasets various efficient methods of computation have emerged.

This work involved obtaining aerodynamic characteristics of airfoils from numerical simulation tool JavaFoil and generation of Airfoil images based on coordinates obtained from UIUC Airfoil data repository. The images are later transformed to embed flow conditions (Reynolds Number, Mach Number). In reference to Neural Network, Pytorch software package was used and Python as programming language.

The developed convolutional neural network (CNN) models allow to choose any Mach number from 0-0.7, Reynold’s number from 30000-1630000 and work on any airfoil. They can predict aerodynamic characteristics of airfoils faster comparedtoComputationalFluidDynamics(CFD)methodor any other numerical software. Hence, reducing time expenditure and computational cost associated with CFD analysis.

Key Words: Computational Fluid Dynamics (CFD), Artificial Intelligence (AI), Convolutional Neural Network (CNN), Dataset, Airfoil, Aerodynamic Characteristics.

Choosingthecorrectairfoilisanimportantstepintheearly stageofanyaerialvehicledesignsinceitsshapehasadirect impact on the overall aerodynamic characteristics of the aircraft or rotorcraft. Aerodynamic characteristics in additiontoprovidingameasureofperformanceareusedto createadditionalsubsystemssuchasaflightcontrolsystem and to anticipate complex dynamic phenomena such as aeroelasticinstability.

Thesecharacteristicscanbederivedexperimentallybywind tunneltestingornumericallyvianumericalsimulationofthe underlyingbasicequationsoffluiddynamicsdependingon theaccuracyrequired.

Complex flows around the airfoils are modelled using computationalfluiddynamics(CFD)onadailybasisinthe areaofaerodynamics,sinceCFDtoolshavealreadyreached anappropriatedegreeofmaturity.However,thisimpliesa largecomputingcostwhichmaybeinfeasibleinsomecases presently.Toaddressthisconstraint,theCFDsolvermight be replaced by a surrogate model that generates a quick forecast of the aerodynamic characteristics based on past simulationsorwindtunneldata.

Machinelearningtechniqueswhicharewidelyutilisedinthe fieldofartificialintelligence(AI)canprovidesignificantaid inreducingthecomputingcostnecessaryforaerodynamic analysis. Machine learning techniques are currently being utilisedinavarietyofcommercialsectorstoexploitdatain ordertospottrends,findspecifictraits,patterns,andeven forecastthefuture.Oneofthemostimportantadvantagesof themachinelearningmethodisitshighworkingefficiency Asaresult,manyengineeringproblemsparticularlythose involvingnumericalcalculationscanbesolvedinarelatively short period of time when certain and proper machine learning methods are implemented. However, the use of theseconceptsinthefieldofaerodynamicsisstillinitsearly phases.

Methodology adopted for this work is application of Python language to create airfoil images using airfoil data

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

repository, Numerical analysis to obtain aerodynamic characteristics of airfoils. Generating master dataset involving flow conditions to develop Convolutional Neural Network (CNN) model for predicting aerodynamic characteristicsofairfoils.

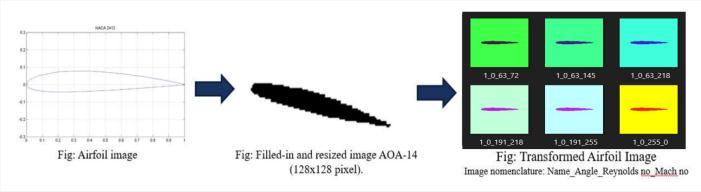

The key to processing airfoil data is to prepare the input images. The CNN prediction model typically receives an image as input,a two-dimensional matrix for grayscale images and three two-dimensional matrices for colour images.Theairfoilpictureisgrayscaleimagewhichcanbe useddirectlyasinputtotheCNNmodel.

Theflowconditionsarethreenumericalparameters(Angle ofAttack,Machnumber,Reynold’snumber)thatcouldnot beutiliseddirectlyasinputtotheCNNpredictionmodel.As a result, they are transformed into images in order to be identified.

Asrawdata,theUIUCAirfoilDataSite[1]whichprovides coordinates for almost 1600 mainstream airfoils ranging fromtheNACA4-digitseriestotheSeligseriesisused.The rawcoordinatepairsareconvertedintogreyscaleimages.

The coordinate matrix is initially plotted as a contour image of 128 pixels by 128 pixels for each airfoil sample. Because aerodynamic performance of airfoils is very sensitive to subtle changes in shape, image size is set to(128x128) pixels instead of the normally smaller size, such as (28x28) in MNIST dataset or (32x32) in NIST36 dataset as it is critical to maintain a decent resolution to maintainpredictionaccuracy.However,becausethereisnot toomanysubtle feature informationintheairfoil, making the contour size with resolution as high as (256x256) in thedataset would be computationally costly [2]. When accuracyandcomputationareconsidered,animagesizeof (128x128)willbetheoptimummatchfortheapplicationin airfoildata.

conditions.ThesegeneratedimagesareTransformedAirfoil Image (TAI) which are complex representation of airfoil shape,angleofattack,MachnumberandReynoldsnumber.

Theaerodynamicdataiscollectedbyaseriesofcomputer simulations.Giventheexpectedvariationinflowconditions andairfoilshapes, JavaFoil isselectedasthesimulationtool fordeterminingaerodynamiccharacteristics.

JavaFoil isasimplesoftwarethatanalysesairfoilsusing numerousstandardapproaches[3].

Forthiswork,rangeofMachnumberconsideredis0-0.7 withstepsizeof0.2andforReynoldsnumberfrom300001630000 with step size of 400000. A total of 102 airfoils comprisingNACA4andNACA6series areused formodel development.Outputfilesintextformatareobtainedusing JavaFoil for all the airfoils at different Reynolds and Mach number.

Fig -1:AsnippetofTransformedAirfoilImages(TAIs)of anairfoilatvariousanglesofattack,Reynoldsnumberand Machnumber.

Thegrayscaleairfoilimagesaregeneratedwiththehelp ofPythonatvariousanglesofattack.Forthiswork,angleof attackvariesfrom-5°to+20°.Later,theseimagesareused to generate three channel images involving all the flow

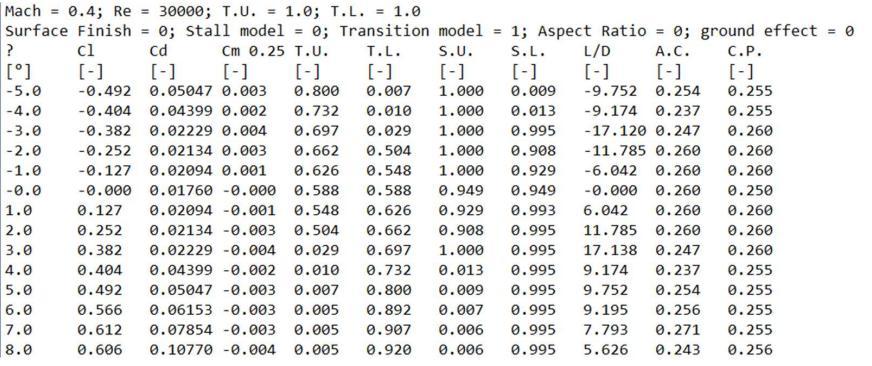

Fig -2:OutputFilefrom JavaFoil foranairfoilfor Re-30000andM-0.4

The first and most important stage in determining the relation between aerodynamic characteristics and airfoil geometry using a neural network is to provide input data withsuitable mathematical representationfor training the neuralnetwork.Flowconditions,aerodynamiccharacteristics andairfoilimagesconstitutetheairfoildata.

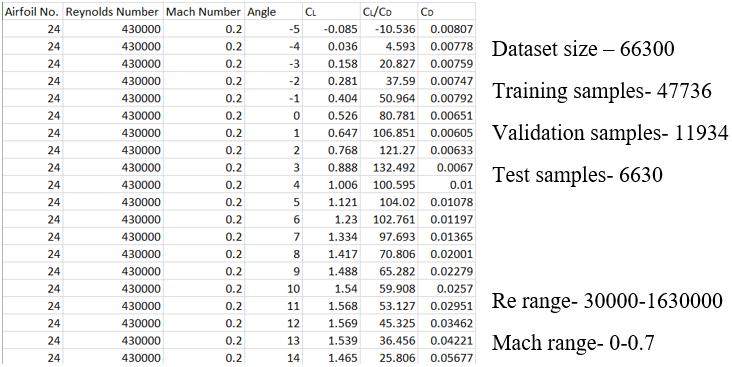

Aerodynamiccharacteristicsobtainedfrom JavaFoil arein text format. All the text files of various airfoils at different MachnumbersandReynoldsnumberarereadusingPython togenerateaconsolidatedfilewhichactsasmasterdataset fordevelopmentofthemodel.Fig3showsasnippetofthe masterdataset.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page2

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

2D convolution with input channel = 80, output channel = 160 and kernel size of 3x3. Followed by batchnormalizationandmaxpollingwithkernelsize of2x2.Lastly,ReLUasactivationfunction.

Fig -3:MasterDataset(csvformat)

AninitialmodelarchitecturewasselectedandlaterOPTUNA [4],ahyperparameteroptimizationframeworkwasusedto automatehyperparameterselection.Thehyperparameters optimized included dropout rate, batch size, learning rate andfullyconnectedlayerinputdimension.

Table -1: Hyperparameters

Hyper-parameter

LearningRate 0.00506 BatchSize 50 Drop-outRate 0.2 FC-2in-features 650

Finalmodelarchitectureisasfollows:

I. Layer1

2Dconvolutionwithinputchannel=3,outputchannel = 20 and kernel size of 5x5. Followed by batch normalization and max pooling with kernel size of 2x2.Lastly,ReLUasactivationfunction.

II. Layer2

2D convolution with input channel = 20, output channel=40andkernelsizeof3x3.Followedbybatch normalization and max pooling with kernel size of 2x2.Lastly,ReLUasactivationfunction.

III. Layer3

2D convolution with input channel = 40, output channel=80andkernelsizeof3x3.Followedbybatch normalization and max pooling with kernel size of 2x2.Lastly,ReLUasactivationfunction.

2D convolution with input channel = 160, output channel = 200 and kernel size of 2x2. Followed by batchnormalization,maxpollingwithkernelsizeof 3x1anddropoutsetto0.2.Lastly,ReLUasactivation function.

I. Firstfullyconnected(FC)layerhaslinearfunction which transforms the incoming data. Input features=1800andoutputfeatures=650.Drop outissetto0.2andReLUasactivationfunction.

II. SecondFClayerhasinputfeatures=650andoutput features=1.

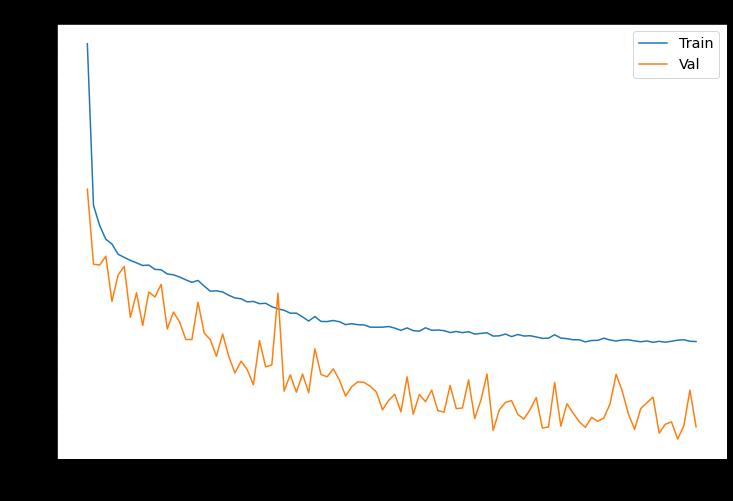

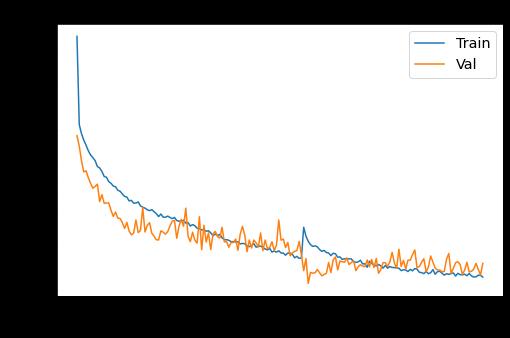

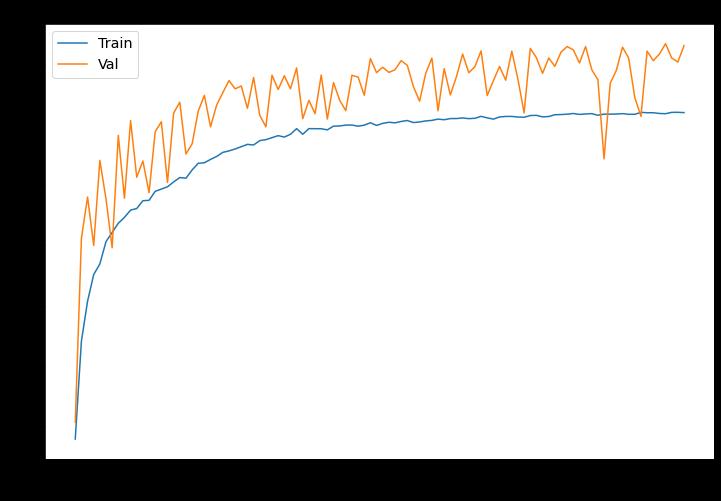

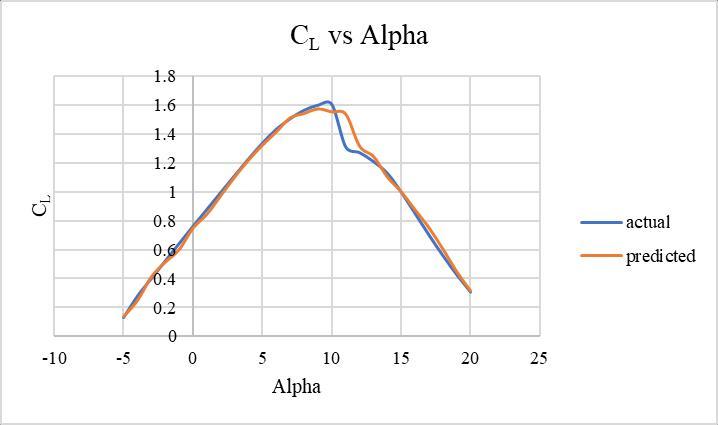

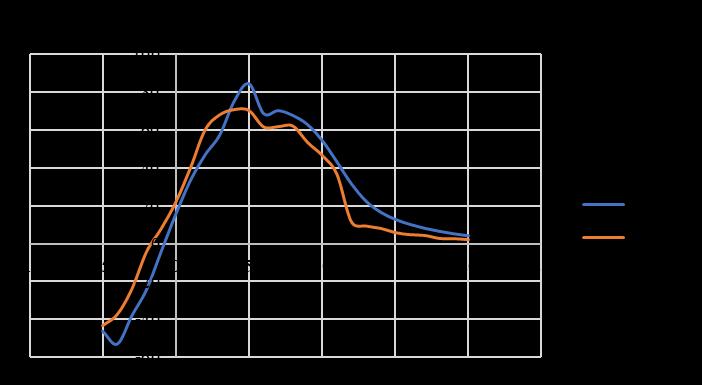

Modelistrainedonthetrainingdatawhichconstitutes 72%ofthemasterdatasetanditsperformanceisvalidated aftereachepochusingvalidationdatasetwhichconstitutes 18%ofthemasterdataset.Afterthetrainingiscompleted, model is evaluated on test dataset which is 10% of the master dataset. During the training process the model convergedafter100epochs,aslossesandaccuraciesofeach subsequent epoch remained same Also, further training couldoverfitthemodelcausingittoloseitsgeneralization capabilities. Fig -4:LossPlot

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

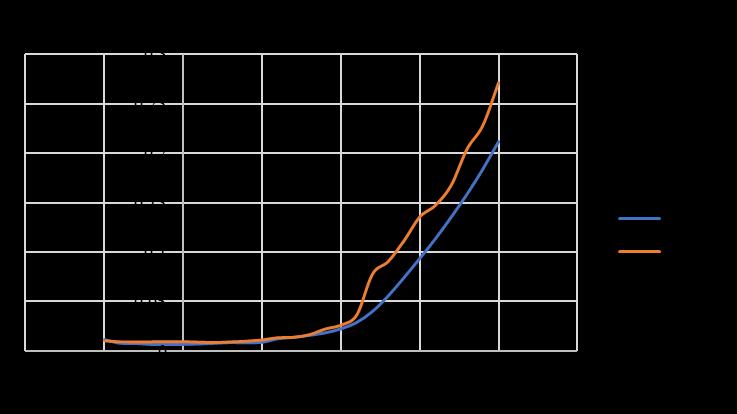

Fig -5:AccuracyPlot

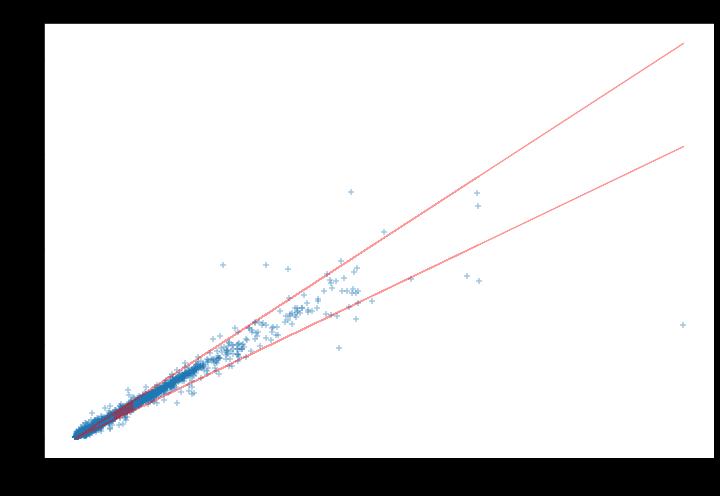

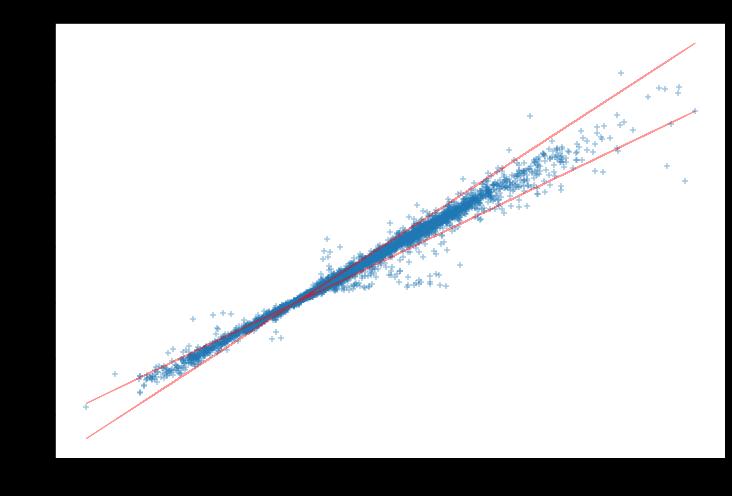

Testaccuracyobtainedis92.32%.Theconfusionmatrix showsthepredictioncapabilityofthemodel.

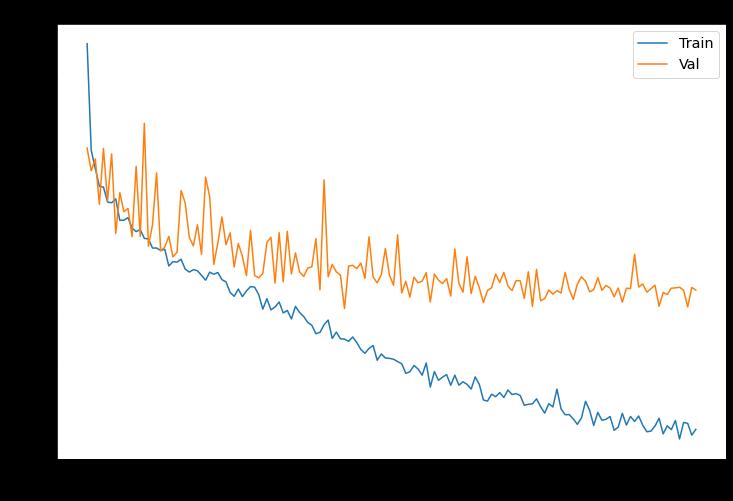

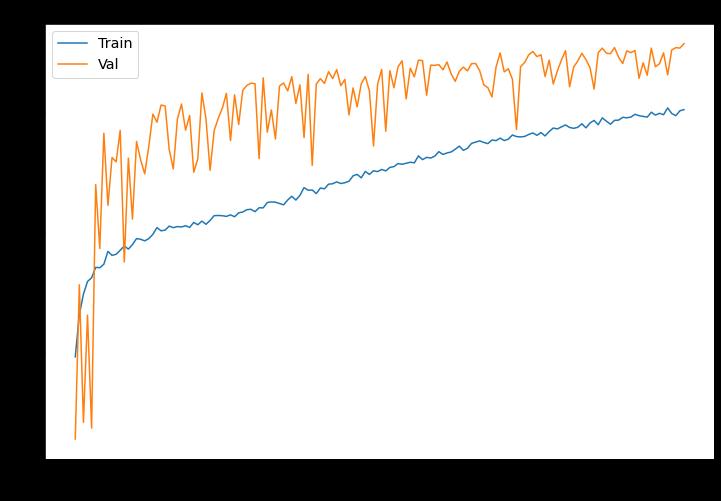

Fig -8:AccuracyPlot

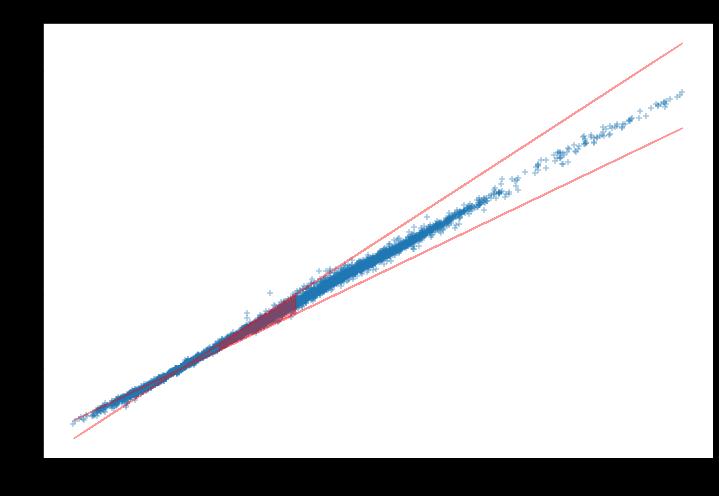

Testaccuracyobtainedis81.42%.Theconfusionmatrix showsthepredictioncapabilityofthemodel.

Fig -6:ConfusionMatrix

During thetraining process the model converged after 150 epochs, as losses and accuracies of each subsequent epochremainedsame.Also,furthertrainingcouldoverfitthe modelcausingittoloseitsgeneralizationcapabilities.

Fig -9:ConfusionMatrix

During the training process the model converged after 180 epochs, as losses and accuracies of each subsequent epochremainedsame.Also,furthertrainingcouldoverfitthe modelcausingittoloseitsgeneralizationcapabilities.

Fig -7:LossPlot

Fig -10:LossPlot

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

Two cases are considered for analyzing model performance:

1. Airfoilwhichispartofthedataset(NACA6409)

2. Airfoilwhichisnotpartofthedataset(NACA13013)

NACA 6409

Testaccuracyobtainedis81.29%.Theconfusionmatrix showsthepredictioncapabilityofthemodel.

These models developed can be used to predict each aerodynamiccharacteristicindividuallyorallthemodelscan be used at the same time to make inference. The models allow to choose any Mach number from 0-0.7, Reynold’s numberfrom30000-1630000andworkonanyairfoil.

Afterthemodeldevelopmentiscompleted,thenextstep is to put the model in inference mode to start using it for predictingtheaerodynamiccharacteristicsofairfoils.Input fileofanyairfoiliscreatedusingpythonforspecifiedflow conditionswhichallowsthemodeltocalltheinputimages andlateritpredictstheoutputandstoresitinthesamefile.

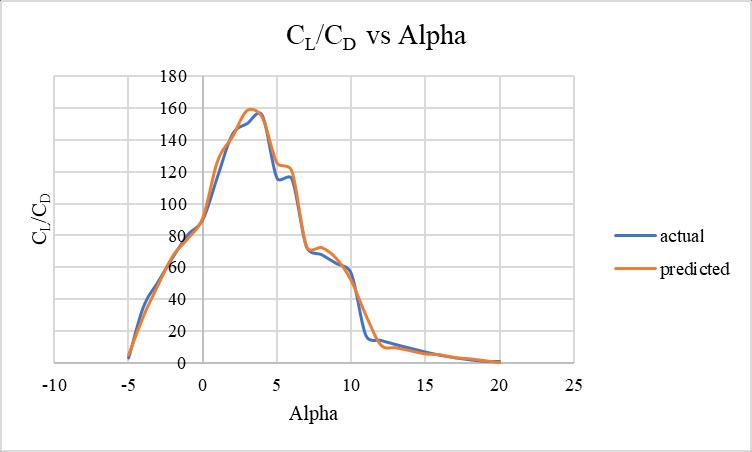

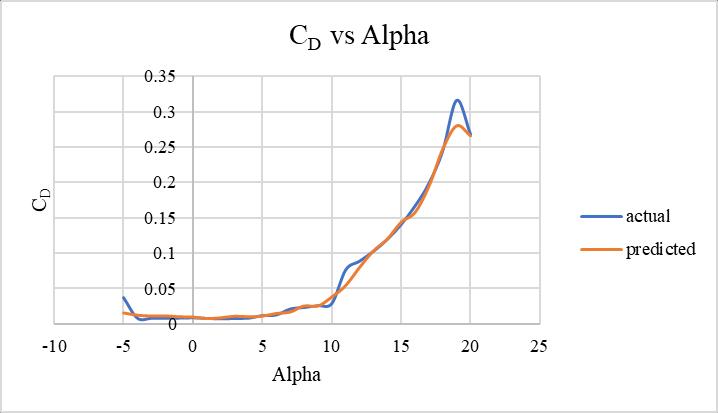

Fig -13:InferenceGraphsforNACA6409airfoil

Flowconditions-Reynold’sNo-430000,MachNo-0.2

Thegraphsofinferenceobtainedfromthemodelsand the actual data shows that the model has predicted aerodynamiccharacteristicsquiteaccurately.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

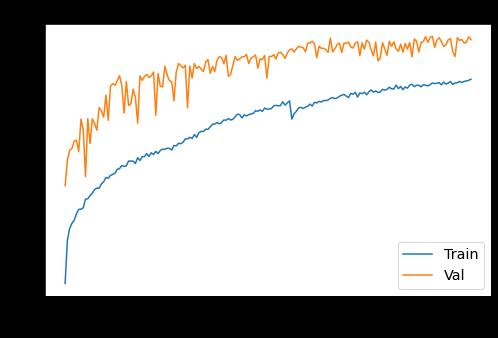

Table -2: EfficiencyComparison

Batch Size (sec) CNN (sec) XFLR5 (sec) 10 4.48 148.31 20 8.56 270.57 30 12.98 631.26 50 20.94 1256.4 100 40.45 2507.13

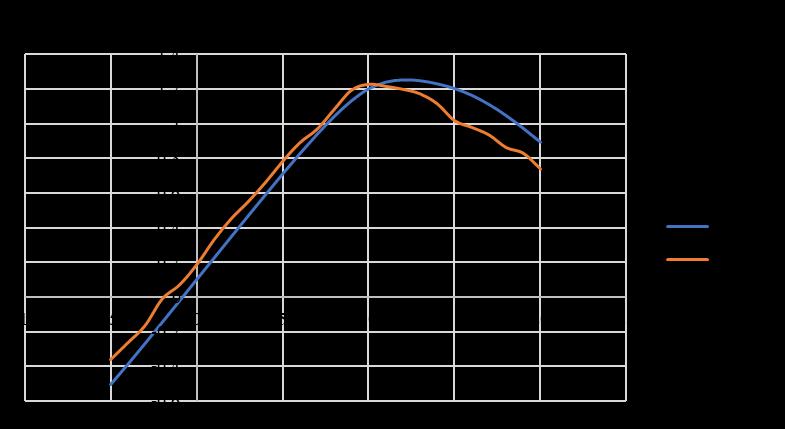

Fig -14:InferenceGraphsforNACA13013airfoil

Fig -15:InferenceGraphsforNACA13013airfoil

Flowconditions-Reynold’sNo-430000,MachNo-0.2

It can be observed that model has good accuracy on airfoils which were not part of the dataset. It took 0.66 secondforthemodeltomakepredictions(Allaerodynamic characteristics).However,thereislargeerrorispredicting comparedtootherparameters

A batch analysis involving prediction of aerodynamic characteristics of airfoils using the model and XFLR5 [5] shows,CNNmodelis50timesefficientcomparedtoXFLR5.

Fig -16:EfficiencyPlot

Thisworkcontributestowarddevelopmentofasurrogate model which can predict aerodynamic characteristics of airfoilsubjectedtovariousflowconditions.Thedeveloped CNN model can predict CL, CD and for different airfoils withthehelpofgeneratedTransformedAirfoilImages(TAI) usingflowconditionsandcoordinatesoftheairfoil.

TheCNNmodelhashighlevelofaccuracyforairfoilswhich werepartofdatasetaswellasairfoilswhicharenewtothe model. For CL model, accuracy is 92.32%, CD model it is 81.42%andfor itis81.29%.Ittook100epochstotrainCL model,150epochstotrainCDmodeland180epochstotrain model.

Model inference shows the capability of the model in predictionoftheaerodynamiccharacteristics.Ittook0.66 secondforthemodeltomakepredictions(Allaerodynamic characteristics) which is highly efficient compared to CFD analysisaswellasbatchmodeofXFLR5.CNNmodelis50 times efficient compared to batch mode of XFLR5. The modelsworkonanyairfoil TheyallowtochooseanyMach number from 0-0.7 and Reynold’s number from 300001630000.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 10 | Oct 2022 www.irjet.net p-ISSN: 2395-0072

However,thereishigherrorispredicting comparedto otherparametersforairfoilsduetohighdispersionofthe data.

The performance of the models can be improved by increasingthesizeofthedatasetalongwiththeapplication ofVirtualMachinestotrainthemodel,duetohightraining timerequirementofthemodel.

However,initscurrentstatethedevelopedmodelsareready topredicttheaerodynamiccharacteristicswith15%relative tolerance and it can help to curb the time taken during preliminarystageofairfoilselection.

[1] UIUCAirfoilDataSite,DepartmentofAeronauticaland Astronautical Engineering University of Illinois at Urbana-Champaign,1996.

[2] HaolinLiu,ZiLi,andFelixLu.AnAirfoilAerodynamic ParametersCalculationMethodBasedonConvolutional NeuralNetwork.2019.

[3] www.mh-aerotools.de/

[4] www.optuna.org/

[5] www.xflr5.tech/xflr5.htm

[6] Anderson Jr., John D. 2010. Fundamentals of Aerodynamics,5thEdition,McGraw-Hill.

[7] Y. Zhang, W. Sung, and D. Mavris. Application of convolutional neural network to predict airfoil lift coefficient.AIAASciTechForum,2018.

[8] Russell Reed and Robert J MarksII. Neural smithing: supervised learning in feed forward artificial neural networks.MitPress,1999.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |