Designing a Heat sink for motor controller unit

Abstract - This research paper presents a detailed investigation into the design and optimization of a heat sink specifically tailored for the motor control unit (MCU) in an electric vehicle which controls the motor of power rating of 1500 Watts, while taking into account constraints such as mass, temperature, and dimensions. The primary objective is to develop a heat sink design that efficiently dissipates the heat generated by the MCU, while simultaneously satisfying the thermal requirements and minimizing size and weight. A systematic and analytical approach is employed, including computational simulations and numerical analysis techniques to model and predict the thermal behavior of the heat sink. By iterating through different configurations, optimal dimensions are identified, balancing heat dissipation efficiency and the overall mass of the heat sink.

Key Words: Heat sink, MOSFETs, MCU, Electric Vehicles, Heat dissipation

1.INTRODUCTION

The increasing demand for electric vehicles (EVs) has spurred remarkable advancements in the field of electric powertrain technology. Within an electric vehicle, the motorcontrolunit(MCU)playsacrucialroleinmanaging thepowerflowandensuringefficientmotorperformance. However, the operation of the MCU generates substantial heat, which, if not properly dissipated, can lead to performance degradation, reliability issues, and even component failure. Therefore, effective thermal management of the MCU is of paramount importance to ensureitsoptimalfunctioningandlongevity.

The investigation focuses on the design and optimization of a heat sink specifically tailored for the MCU in an electric vehicle. The aim is to develop a heat sink design that efficiently dissipates the heat generated by the MCU whilesimultaneouslysatisfyingcriticalconstraintssuchas mass,temperature,anddimensions.Theultimategoalisto minimize the size and weight of the heat sink while maintaining its thermal performance within acceptable limits.

To achieve this objective, a systematic and analytical approach is adopted, combining computational simulations and numerical analysis techniques to model and predict the thermal behaviour of the heat sink. By employing these methods, various heat sink configurations and dimensions are explored, enabling the identification of optimal designs that strike a balance

betweenheatdissipationefficiencyandtheoverallmassof theheatsink.Inthisresearch,acasestudyisconductedto evaluate and compare the thermal performance of two differentheatsinkdesignsundervariousparameters.The case study provides insights into the effectiveness of different design choices in enhancing heat dissipation for theMCUinelectricvehicles.Byanalyzingtheperformance ofthesedesignsunderdifferentoperatingconditions,this study aims to identify the most efficient heat sink design thatoptimallydissipatesheatgeneratedbytheMCUwhile considering factors such as geometry, surface area, and overalldimensions.

Thedesignprocessbeginswithathoroughunderstanding of the thermal characteristics of the MCU, considering factors such as the power dissipation of the MCU and the ambient operating conditions. An accurate thermal model is established, serving as the foundation for conducting computational simulations to evaluate different heat sink designs under varying thermal loads. For the current study peak loads are considered which could be achieved at maximum output of 2500 W which produces 70A of peakcurrentthroughtheMCUcircuit.

Through iterative simulations and analyses, the performanceofeachheatsinkdesignisassessedinterms of its ability to dissipate heat effectively and maintain acceptabletemperatureswithintheMCU.Thesimulations provide insights into the thermal behaviour of the heat sink, helping to identify areas of improvement and optimization.

Furthermore,thenumericalanalysistechniquesemployed inthisresearchaidinpredictingthethermalperformance of the heat sink under real-world operating conditions. Factorssuchasnaturalconvection,forcedconvection,and radiation heat transfer are considered, leading to a more accurate representation of the heat sink's behavior and enhanceddesigndecisions.

The findings of this research contribute to the development of an optimized heat sink design that effectivelydissipatestheheatgeneratedbytheMCUinan electric vehicle having set to the current configuration of poweroutputs. Theproposeddesignnotonlyensuresthe thermal reliabilityandlongevityoftheMCUbutalsoaims to minimize the size and weight of the heat sink, addressing the weight and space constraints typically associatedwithelectricvehicles.

The rest of this paper is organized as follows. Section 1 provides an overview of the significance of thermal management in electric vehicles, highlighting the importance of efficient heat dissipation in the MCU. Section 2 discusses the methodology employed in this research, outlining the computational simulations and numerical analysis techniques utilized. Section 3 presents the results and analysis, showcasing the optimized heat sink designs and their corresponding thermal performance and discusses the implications and practical applications of the research findings, highlighting the potentialbenefitsforelectricvehiclemanufacturers.While concluding the paper by summarizing the key contributions

By addressing the critical issue of heat dissipation in the motor control unit of electric vehicles, this research aims to enhance the thermal management strategies in electric powertrain systems, contributing to the overall design, efficiency,andreliabilityofMCUsinelectricvehiclesinthe emergingeraofsustainabletransportation.

1.1 Topography of MCU:

A motor controller unit, or MCU, is an electronic device designed to regulate the operation of an electric motor. It plays a vital role in receiving input signals, processing them, and generating output signals to control various aspects of the motor's performance, including speed, direction, and other relevant parameters. To understand the technical workings of an MCU, we delve into its core functionalities:

TheMCUispoweredbyasuitablepowersource,suchasa battery or power supply unit, which provides the necessary voltage and current levels for both the MCU's internal circuitry and the connected motor. The motor takenintoaccount has a ratedpower output of the motor is 1500 W which produces peak current of 70 amperes andpeak poweroutputof2500W.Themaximumvoltage dropratingforthisspecificationofmotoris48Volts.

Control inputs, sourced from switches, sensors, or microcontrollers, are received by the MCU. These inputs encompass commands relating to motor speed, direction, andotheroperatingparameters.

ToensuremotorandMCUsafety,protectionfeaturesmay be included. These features encompass overcurrent protection, overtemperature protection, short-circuit protection,andfaultdetectionmechanisms.

By combining these components and functionalities, the MCU effectively regulates the operation of an electric motor, offering precise control over its speed, direction, torque, and other parameters according to the specific requirementsoftheapplicationathand.

Because of various factors involved, there is fundamental risk of overheating the MCU. Overheating in an MCU can have significant consequences on its performance and reliability. Two primary effects of overheating in an MCU arereducedefficiencyanddegradedcomponentlifespan.

When an MCU operates at high temperatures, its internal resistanceincreases,leadingtohigherelectricallossesand whichalsoleadstolowerpoweroutputforthemotor.This decreaseinefficiencyaffectstheoverallenergyconversion and utilization within the MCU. As a result, the motor control system may experience reduced efficiency, increased power consumption, and potential degradation in system response and accuracy. Overheating can also accelerate the aging and deterioration of electronic componentswithintheMCU,suchascapacitors,resistors, and integrated circuits. This degradation shortens the lifespan of these components, leading to more frequent failuresandtheneedforreplacementorrepairs.

Moreover, overheating can trigger a phenomenon known asthermal runaway.In extremecases, the heat generated by the MCU surpasses its ability to dissipate heat effectively, resulting in a rapid increase in temperature. Thermal runaway can lead to system failures, compromised motor control, and potential damage to the MCU and connected components if not promptly addressed.

To mitigate these effects, proper thermal management techniques should be employed. This includes ensuring sufficient airflow around the MCU, utilizing heat sinks or cooling systems, and regularly monitoring temperatures. By maintaining optimal operating conditions and preventing excessive heat buildup, the MCU's efficiency canbepreserved,andthelongevityofitscomponentscan beextended,ensuringreliablemotorcontroloperations.

1.2 Importance of MOSFETs:

MOSFETs (Metal-Oxide-Semiconductor Field-Effect Transistors) have a pivotal role in motor controller units (MCUs), contributing to efficient and precise control of electric motors. They primarily function as power switches,regulatingthecurrentflowtothemotor.Within thecontextofaresearchpaper,wecanexplorethespecific rolesperformedbyMOSFETsinMCUs:

OnefundamentalfunctionofMOSFETsispowerswitching. Thesesemiconductordevicesserveaselectronicswitches, enabling or interrupting the connection between the power supply and the motor. MOSFETs, known for their high current and voltage handling capabilities, provide reliable control over the motor's operation. When turned on, MOSFETs deliver power to the motor, while turning themoffblocksthecurrentflow.

MOSFETs play a vital role in Pulse-Width Modulation (PWM), a commonly used technique in motor control. Within the motor drive circuitry of the MCU, MOSFETs facilitate the conversion of PWM signals into high-power signals that effectively drive the motor. By rapidly switching the MOSFETs based on the PWM duty cycle, precise control over the motor's speed is achieved by regulatingtheaveragevoltageappliedtothemotor.

Efficiency and heat dissipation are key considerations in motor control. MOSFETs contribute significantly to these aspects.Withtheirlowon-resistance(Rds(on)),MOSFETs exhibit minimal resistance when fully activated, resulting in reduced power losses and improved system efficiency. In the current circuit there are total of 24 different MOSFETswhichareconnectedinseriesinsetsof4. Their fast switching characteristics minimize switching losses. Effective thermal management techniques ensure proper heat dissipation, maintaining optimal operating conditions.

MOSFETs also provide crucial protection and safety features. They incorporate overcurrent protection, swiftly interrupting the current flow when it exceeds predefined thresholds, thus safeguarding the motor from potential damage. Additionally, MOSFETs offer short-circuit protection, preventing excessive current flow during fault conditions,ensuringthesafetyoftheMCU.

Furthermore, MOSFETs enable dynamic braking and motor reversal capabilities, enhancing control over motor operations.Bystrategicallyactivatinganddeactivatingthe MOSFETs, the motor's current flow can be rapidly interrupted or reversed. This capability enables smooth andcontrolledbrakingorreversalofthemotor'srotation, expanding the versatility and functionality of the motor controlsystem.

In conclusion, MOSFETs serve critical functions in motor control applications within MCUs. Acting as power switches, they enable efficient PWM control, provide protection mechanisms, facilitate dynamic braking and motor reversal, and enhance overall system performance. By harnessing the capabilities of MOSFETs, precise and effectivecontrolofelectricmotorscanbeachieved.

2. Comparing two distinct designs:

The two designs in question have gone through rigorous drawing board designing and both being completely distinct from each other, pursues different design philosophies. Design “A” follows a much more conservativedesignlanguagewhileonthecontrastdesign “B” has bolder approach. Fundamental characteristics of both the designs are discussed in sections 2.2 and 2.3 Both the designs follow a design constrains which are inheritedbythemfromthesystem,alltheconstraintsand

design methodology is discussed in section 2.1 further along.

2.1 Design approach:

Heat sink design involves considering all the given constraints ad optimizing the design after going through various iterations of hand calculations and computational simulations. Though it is bit tough to determine the exact step to step guide for the designing process as each case tend to vary a lot, basic design tree looks something similartothis:

1. Determinationofheatsinkrequirements:Startby understanding the specifications and thermal characteristicsofthecomponentyouwanttocool. Identify its maximum heat dissipation, operating temperature, and any thermal limitations providedbythemanufacturer.

2. calculationofthermalrequirements:Calculatethe required thermal resistance (Rth) for your heat sink. Rth is the temperature difference between the component and the ambient air, divided by thepowerdissipated,inthiscasepeakpowerand current passing through the component. The lowertheRth,themoreefficienttheheatsinkwill be.

3. Analyze the dimensional constraints: Assess the available space and physical constraints where the heat sink will be installed. Consider the dimensions, shape, and any mounting requirements. Ensure that the heat sink can fit withinthegivenspace.

4. Selection of heat sink material: Choose an appropriate material for your heat sink. Aluminumand copperarecommonlyuseddueto theirhighthermalconductivity.Copperhasbetter heat conductivity but is more expensive than aluminum. Consider other factors like weight, cost,andcompatibilitywithyourapplication.

5. Determination of heat sink size: Determine the size of the heat sink based on the amount of heat itneeds todissipate.Thisinvolvescalculatingthe surface area required to achieve the desired heat transfer. The heat sink's surface area is directly proportionaltoitscoolingcapacity.

6. Choosing the heat sink configuration: Decide on the heat sink configuration based on your requirements and available space. Common configurations include finned heat sinks, pin heat sinks, and heat pipes. Fins increase the surface areaforbetterheatdissipation.

7. Design the heat sink structure: Design the heat sink structure considering the selected configuration. Decide on the number, shape, and arrangement of the fins or pins. Ensure uniform spacing for efficient airflow. The design should promote laminar airflow and minimize pressure drops.

8. Perform thermal simulations and calculations: Use thermal simulation software or manual calculations to assess the heat sink's thermal performance.Analyzeparameterssuchasthermal resistance, pressure drop, and temperature distribution. Modify the design as needed to optimizetheperformance.

9. Incorporate other cooling methods: Consider other cooling methods to complement the heat sink, such as fans or liquid cooling systems. Determine if these additional methods are necessary based on the heat load and ambient conditions.

10. Prototype and test: Once you have finalized the design, create a prototype of the heat sink. Conduct testing to evaluate its effectiveness in real-world conditions. Measure temperature differentials and assess thermal performance. Iterateonthedesignifrequired.

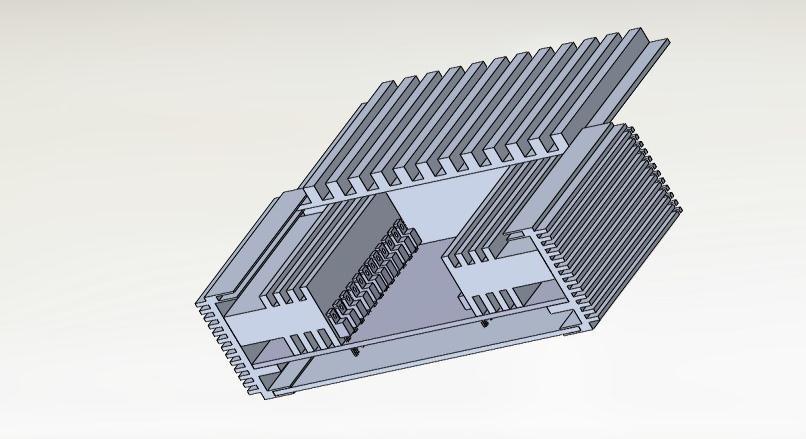

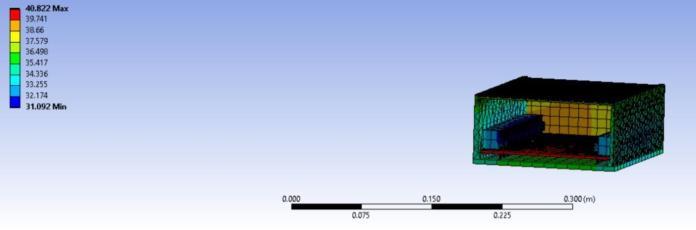

Design A:

Design A has been developed with holding the conservativedesignlanguage.Thedesignhaddimensional constraints of (250*160*10 mm) given that the heat sink needs to be mounted on the top of the MCU. The Target temperature T is 60° C. The current passing through the MOSFETs is 70 A with junction resistance of 0.0031 ohm ThevoltagedropinMOSFETsisabout0.217Volts.Thefin gaps areoptimized inDesignAto 4 mmandfinthickness is 6 mm with fin length being 5 mm. The temperature reached after heat dissipation with ambient temperature being 40 degrees Celsius. The MOSFETs are fixed to an aluminum block with thermal paste which acts as a mountingpointfortheMCUinsidethealuminumencloser. Aluminum is chosen here because of its thermal conductive properties and its relatively inexpensive nature as compared to other materials like copper. The encloser is designed with ease of access as a priority and primarygoal,thereforeithasaremovableslidingpanel in oneofthesides.

Thesimulationanalysisshowsthatthedesignreachesthe target temperature with the current fin dimensions quite comfortably with the mounting of the MOSFETs on the aluminumblock

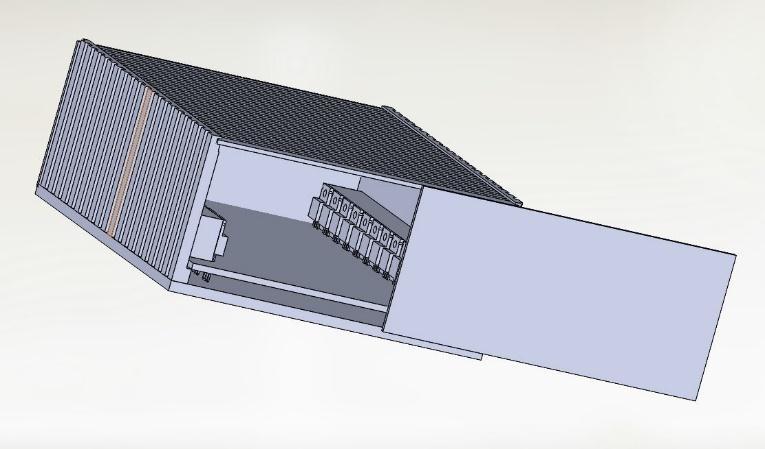

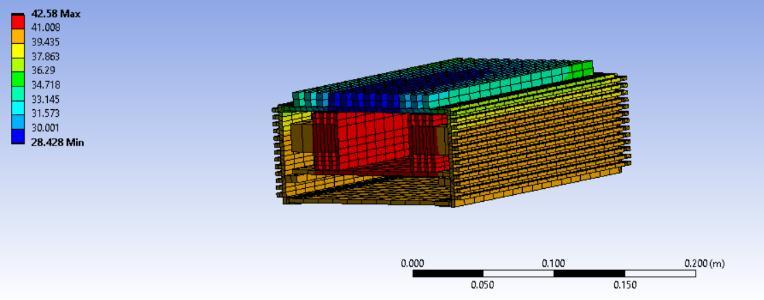

Design B:

Design B falls under similar constraints which are, (250*16*10mm).Thetargettemperatureforthisdesignis 50°C as there are changes in fin dimensions as well as change in the mounting point. The junction resistance is 3.1 mili ohms. The ambient temperature around the thermalenclosureis40°Celsius TheMOSFETsarefixedto theheatsinkwiththehelpofthermalpasteandthePCBis bolted to the enclosure The external fins have 5 mm gap with10mmlength.Andtheinternalfinshave7mmlength with4mmgapbetweenthem.

3. CALCULATIONS

3.1 Heat flow rate:

Heatflowrate, Q=(K*A*n*ΔT)*X1/X2

Where,

K=thermalconductivityconstant

A=Areaoffins

n=numberoffins

⍙T=changeintemperature

Finwithw=200mm

Finthickness=5mm

⍙T=40

Plugginginthevalueswegetheat

Q=63.084Watts.

3. CONCLUSIONS

In conclusion, the above manuscript provides a comprehensive investigation into the design and optimization of a heat sink tailored specifically for the motor control unit (MCU) in electric vehicles operating under peak load. The study aims to develop an efficient heat sink design that effectively dissipates the heat generated by the MCU, while satisfying the thermal requirementsandminimizingsizeandweightconstraints.

To achieve this objective, a systematic and analytical approach was employed, which showed that both designs arecompatibleto the MCU underpeak currentconditions (70 A) both in terms of heat dissipation and dimensional constraints.

This findings contribute to the advancement of thermal management in electric vehicles, addressing the critical challenges associated with designing the heat sink and explaining the step-by-step process of designing a heat sink.

The computational simulations and numerical analysis techniques employed in this research provide a robust frameworkforevaluatingthethermalbehavioroftheheat sink.Moreover,theiterativenatureofthestudyallowsfor the exploration of a wide range of configurations, facilitatingtheidentificationofthemosteffectiveheatsink design. This iterative process involves evaluating various geometries, materials, and structural features, ensuring thatthefinaldesignmeetsthethermalrequirementswhile minimizing the size and weight of the heat sink. By leveraging computational simulations, the performance of eachdesigniterationcouldbeassessed,reducingtheneed forcostlyandtime-consumingphysicalprototypes.

References:

1) K Tripathi and M Shreejeth, “Thermal Study of MOSFET heat sinks for Motor Controller in Neighborhood Electric Vehicles (NEV),” International Journal of Electric and Hybrid Vehicles·April2022.

2) S. Ravikumar and P Chandra, “Experimental and Transient Thermal Analysis of Heat Sink Fin for CPU processor for better performance,” IOP Conference Series: Materials Science and Engineering,Volume197,FrontiersinAutomobile andMechanicalEngineering7–9July2016.

3) A. kumar and K. Londhe, “Heat sink design for optimal performance of compact electronic appliances-a review,” Research gate, October 2017.

4) S Deshmukh and Chandrashekhar Nagendra, "Review on Heat Sink Design and Material," International Journal of Trend in Scientific Research and Development (ijtsrd), Volume-5, Issue-3,April2021.

5) Krishnamoorthy and T. Jayakumar, “Design and Development of Aluminum-based Heat Sink for Electronic Gadgets,” International Journal of Recent Technology and Engineering (IJRTE), Volume-7,Issue-5S3,February2019

6) P.S. Patel and D.G. Shubhedar, “Cooling performanceanalysisofheatsink,”IJAR,Volume1, Issue9,June2012.

BIOGRAPHIES

AryanRaval Aspiring automobile engineer, currently pursuing bachelor’s in automobile engineering from L.D.CE

VishalDagra Student in L.D.C.E pursuing bachelor’s degree in automobile engineering.

JaydeepPrajapati

StudentinL.D.C.Epursuing bachelor’sdegreeinautomobile engineering

ParthPrajapati

Student in L.D.C.E pursuing bachelor’s degree in automobile engineering

KalpeshVaghela

Assistant professor, Automobile department, L.D college of engineering.