Thermal Characterization and Performance Evaluation of CPU Heat Sink Design

1Mechanical Department, Vishwakarma Institute of Technology, Pune-411037 ***

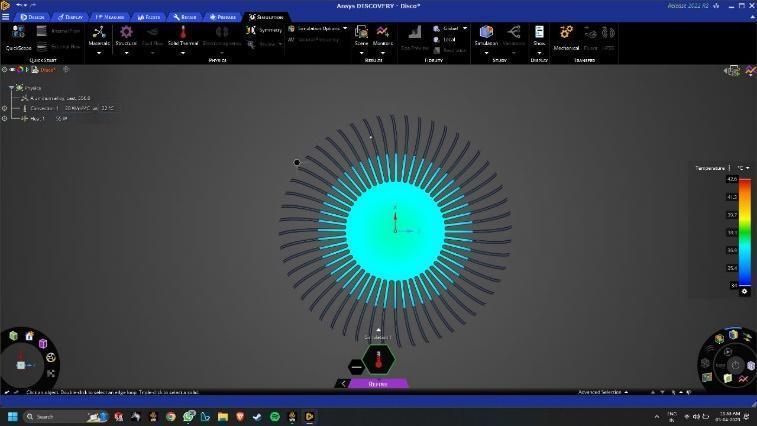

Abstract - This research paper presents a thermal analysis of a heat sink for a microprocessor using SolidWorks and ANSYS Discovery software. The aim of the study is to analyse the heat dissipation capacity of the heat sink under different operating conditions. The simulation model of the heat sink is developed using SolidWorks, and the thermal analysis is performed using ANSYS Discovery software. The results show that the heat sink is capable of efficiently dissipating heat generated by the microprocessor, and the thermal performance is influenced by factors such as the airflow rate and the thermal conductivity of the materials used in the heat sink. The findings of this study can be useful in the design and optimization of heat sinks for microprocessors to enhance their thermal performance and reliability.

Key Words: ANSYS Discovery, SolidWorks, Thermal analysis, Fins, Forced Convection, Heat Flux, CMM (CoordinateMeasuringMachine)

1. INTRODUCTION

While Thermal analysis is a crucial aspect of modern electronic device design, especially in high-performance microprocessors such as the Intel Core third generation. The increasing demand for faster and more powerful computinghasresultedinasignificantincreaseintheheat generated by these devices. To ensure optimal performance and prevent damage, it is essential to accurately model and analyse the thermal behaviour of thesedevices.Inthisresearchpaper,weaimtoperforma thermal analysis of the heat sink of the Intel Core third generation microprocessor. We will focus on studying the heat dissipation capacity of the heat sink under various operating conditions. To achieve this goal, we will use SolidWorkstodevelopasimulationmodeloftheheatsink and ANSYS Discovery software to perform the thermal analysis. The third-generation Intel Core processor is a highly efficient processor, but it generates a significant amountofheat.Thisheatneedstobedissipatedefficiently topreventthermalthrottling,whichcanleadtoadecrease in performance and damage to the processor. The heat sink isa critical component thathelps to removetheheat

generated by the processor. In thispaper, we will analyse the thermal performance of the heat sink using ANSYS Discoverysoftware.Thissoftwareiscapableofaccurately simulating the thermal behaviour of complex systems, makingitanidealtoolforstudyingthethermalbehaviour of the heat sink. We will also investigate the effect of different parameterssuch asthe airflow rate and thermal conductivity of the materials used in the heat sink on its performance. The results of this study will provide valuable insights into the thermal behaviour of the heatsinkoftheIntelCoreThird-generationprocessor.This knowledge can be used to optimise the design of the heat sink and improve the thermal performance of the processor. The heat generated by the Central Processing Unit (CPU) of a computer is a major concern in modern computing.CPUscangenerateasignificantamountofheat due to the high processing power required for modern applications. If the heat generated by the CPU is not dissipated efficiently, it can leadto thermal throttling and decreased performance, and even permanent damage to theCPU.Topreventtheseissues,heatsinksarecommonly used to cool down the CPU. Heat sinks are designed to increase the surface area of the CPU and dissipate heat efficiently. They work by transferring the heat generated bytheCPUtothesurroundingairthroughconductionand convection. The increased surface area provided by the heat sink allows for more efficient heat transfer, which helps to keep the temperature of the CPU at a safe level. Heat sinks are typically made of materials with high thermal conductivity, such as aluminium or copper, to enhance their heat dissipation capabilities. They may also becombinedwithfansorothercoolingdevicestoincrease therateofheatdissipation.Thethermalperformanceofa heat sink can be analysed through various techniques, including computational fluid dynamics (CFD) and finite element analysis (FEA). These tools allow designers to optimise the design of heat sinks to maximise their thermalperformanceandensurethattheCPUstayswithin safeoperatingtemperatures.Insummary,heatsinksarea critical component for maintaining the thermal performanceandreliabilityofCPUs.Theyplayanessential role in transferring the heat generated by the CPU to the surrounding environment and preventing thermal

throttling, decreased performance, and permanent damage. Using high thermal conductivity materials and advanced thermal analysis techniques, designers can optimisethedesignofheatsinkstoimprovetheirthermal performance and enhance the overall performance and reliabilityoftheCPU.

2. LITERATURE REVIEW

The paper "A three-dimensional heat sink module design problem with experimental verification" by Cheng-Hung Huang addresses the design problem of a threedimensionalheatsinkmodule.Thestudyaimstooptimise the heat dissipation capacity of a heat sink module by varyingthenumberandsizeoffins,aswellasthespacing between them. The objective is to achieve maximum heat transfer performance with minimum weight and material cost. The study used computational fluid dynamics (CFD) simulationstomodeltheheattransferprocessintheheat sink module. The results showed that increasing the numberoffinsanddecreasingtheirsizeandspacingcould improve the heat dissipation capacity of the module. The optimised heat sink module was then manufactured, and experimental tests were conducted to validate the CFD simulationresults.The experimental resultsshowedgood agreement with the simulation results, demonstrating the effectiveness of the optimization approach. The study concludes that a combination of CFD simulations and experimental verification can be an effective approach to optimise the design of heat sink modules. The optimised designcanimprovethethermalperformanceofelectronic devices while minimising weight and material costs. This study is relevant to the field of thermal management in electronic devices, where heat sink modules are commonly used to dissipate heat generated by electronic components. The approach used in this study can be applied to the design optimization of other heat sink modulesusedinvariouselectronicdevices.[1]

The paper "Experimental and Transient Thermal Analysis ofHeatSinkFinforCPUprocessorforbetterperformance" by S. Ravikumar presents a study on the thermal performance of a heat sink fin for a CPU processor. The objectiveofthestudyistooptimisethedesignoftheheat sink to achieve better cooling performance and improve the overall performance of the CPU. The study uses experimentalandtransientthermalanalysistechniquesto evaluatethethermalperformanceoftheheatsinkfin.The experimentalsetupconsistsofaheatsinkwithasinglefin, athermocouplefortemperaturemeasurement,andaheat source to simulate the heat generated by the CPU. The transient thermal analysis is conducted using ANSYS software to simulate the heat transfer process in the heat sink fin. The results of the study show that increasing the

height of the heat sink fin can improve the thermal performance of the heat sink. The study also found that the optimum height of the heat sink fin depends on the heat transfer coefficient and the thermal conductivity of the heat sink material. The study concludes that a welldesigned heat sink fin can improve the cooling performance of the CPU and enhance its overall performance.Thisstudyisrelevanttothefieldofthermal management in electronic devices, where heat sinks are commonly used to dissipate the heat generated by electronic components. The approach used in this study can be applied to the design optimization of other heat sinkfinsusedinvariouselectronicdevices.[2]

Thepaper"ThermalAnalysisofaHeatSinkforElectronics Cooling"byM.ChandraSekharReddypresentsastudyon the thermal analysisofa heatsink for electronics cooling. The objective of the study is to optimise the design of the heatsinktoimprovethecoolingperformanceofelectronic devices. The study uses computational fluid dynamics (CFD) simulations to model the heat transfer process in the heat sink. The simulations are conducted for different heatsinkdesignswithvaryingfinthickness,finheight,and fin spacing. The results of the study show that increasing thefinthicknessandheightanddecreasingthefinspacing canimprovethecoolingperformanceoftheheatsink.The studyalsoconsiderstheeffectofdifferentmaterialsonthe thermal performance of the heat sink. The results show that increasing the thermal conductivity of the heat sink material canimprove thecoolingperformance oftheheat sink. The study concludes that a well-designed heat sink can improve the thermal management of electronic devices and increase their reliability and lifespan. This study is relevant to the field of thermal management in electronicdevices,whereheatsinksarecommonlyusedto dissipate the heat generated by electronic components. The approach used in this study can be applied to the designoptimizationofotherheatsinkconfigurationsused invariouselectronicdevices.[3]

The paper "Water cooled Mini channel heat sinks for microprocessor cooling: Effect of fin spacing" by Saad AyubJajjapresentsastudyonthethermalperformanceof water-cooled Mini channel heat sinks for microprocessor cooling. The objective of the study is to investigate the effect of fin spacing on the thermal performance of the heat sink. The study uses computational fluid dynamics (CFD) simulations to model the heat transfer process in the heat sink. The simulations are conducted for different fin spacings, and the results show that decreasing the fin spacing can improve the cooling performance of the heat sink.Thestudyalsoconsiderstheeffectofdifferentwater flowratesonthethermalperformanceoftheheatsinkand finds that increasing the water flow rate can improve the

coolingperformanceoftheheatsink.Thestudyconcludes that a well-designed water-cooled Mini channel heat sink with optimised fin spacing, and water flow rate can effectively cool microprocessors and improve their performance and reliability. This study is relevant to the field of thermal management in electronic devices, where heat sinks are commonly used to dissipate the heat generated by electronic components. Water-cooled Mini channel heat sinks offer an efficient cooling solution for high-performance microprocessors, and the approach used in this study can be applied to the design optimization of other heat sink configurations used in variouselectronicdevices.[4]

The paper "Thermal Analysis of Heat Transfer

EnhancementofRibHeatSinkforCPU"byMingZhaoand YangTianpresentsastudyonthethermalperformanceof ribheatsinksforCPUcooling.Theobjectiveofthestudyis to investigate the effect of rib configurations on the heat transfer performance of the heat sink. The study uses computational fluid dynamics(CFD)simulations to model theheattransferprocessintheheatsink.Thesimulations are conducted for different rib configurations, including ribheight,ribspacing,andribangle,andtheresultsshow that increasing the rib height and decreasing the rib spacingcan improvetheheattransfer performance of the heat sink. The study also considers the effect of different airflowratesonthethermalperformanceoftheheatsink andfindsthatincreasingtheairflowratecanimprovethe coolingperformanceoftheheatsink.Thestudyconcludes that a well-designed rib heat sink with optimised rib configurationscaneffectivelycoolCPUsandimprovetheir performance and reliability. This study is relevant to the field of thermal management in electronic devices, where heat sinks are commonly used to dissipate the heat generated by electronic components. Rib heat sinks offer an efficient cooling solution for high-performance CPUs, and the approach used in this study can be applied to the designoptimizationofotherheatsinkconfigurationsused invariouselectronicdevices.[5]

3. METHODOLOGY

Step1:CMMReverseEngineering

Coordinate Measuring Machines (CMMs) are used in manufacturingand engineeringtoaccuratelymeasurethe dimensions of objects. They use a probe to touch and measure the surface of an object in three dimensions, creating a 3D model of the object that can be used for reverse engineering or quality control purposes. CMM wouldbeusedtomeasurethedimensionsoftheheatsink fins. Thisprocessis important because it ensures thatthe heat sink model being used for analysis is an accurate

representation of the real-world heat sink, down to the smallest details. An inaccurate model could lead to inaccurate results, which could in turn lead to poor performance or even failure of the microprocessor. To measure the heat sink fins using a CMM, the probe would be moved along the surface of the fins while recording measurements in three dimensions. The measurements arethenusedtocreatea3DmodeloftheheatsinkinCAD software,whichcanthenbeusedforfurtheranalysis.

Step2:ModellinginSolidWorks

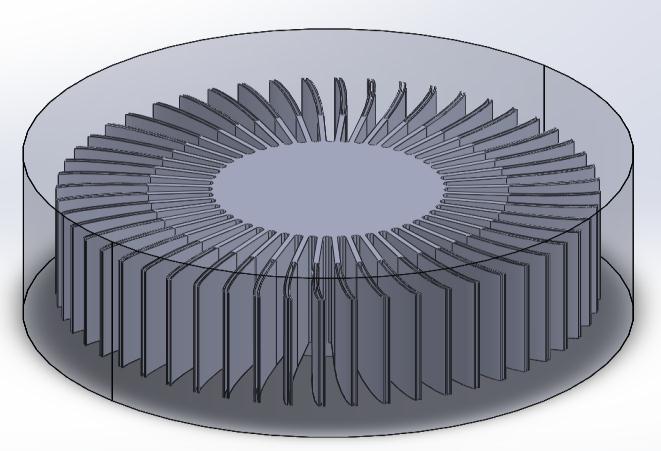

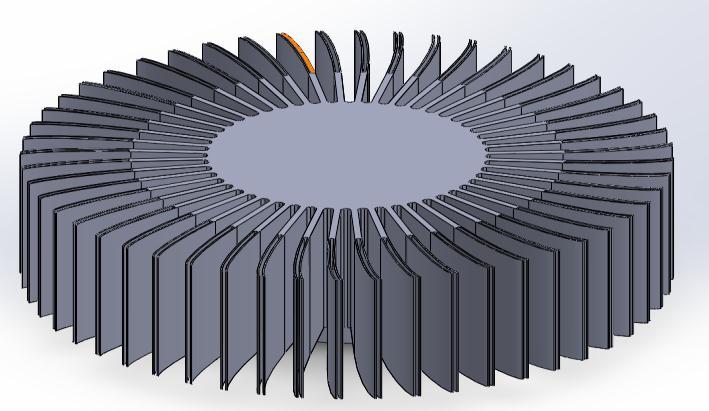

Oncethedimensionsoftheheatsinkhavebeenmeasured usingtheCMM,thenextstepistocreatea detailedmodel oftheheatsinkinSolidWorks.

Thefollowingstepscanbeusedtocreatethemodel:

1. CreateanewpartfileinSolidWorks.

2. Sketch the profile of the heat sink fins using the "ExtrudeBoss/Base"command.

3. Create a circular pattern of the fins around the centreaxisusingthe"CircularPattern"command.

4. Addanyadditional features totheheatsink,such as mounting brackets or connectors, using various SolidWorkscommands.

5. Use the "Save As" command to save the SolidWorks part file as a .STEP file for use in Ansys Discovery.

Step3:ThermalAnalysisinAnsysDiscovery

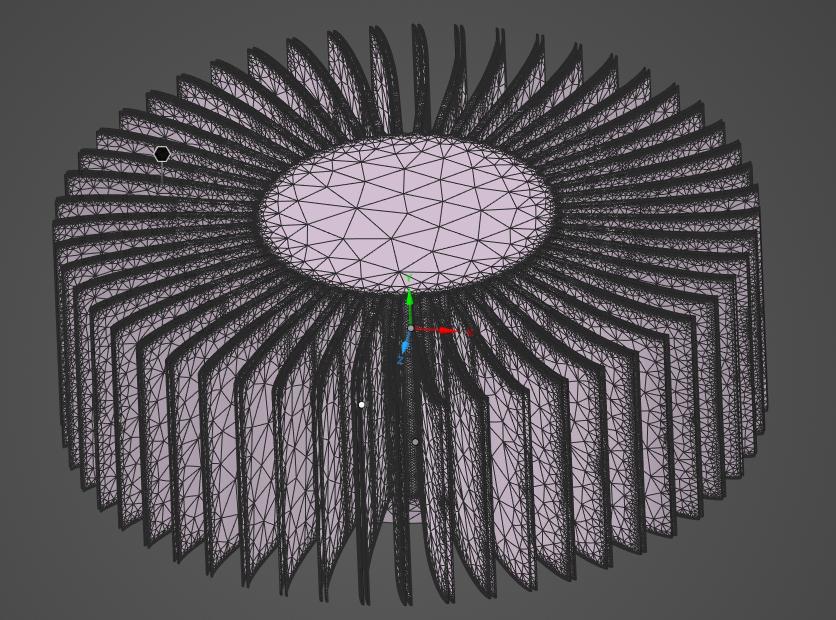

After the heat sink model hasbeencreated in SolidWorks andexportedasa.STEPfile,itcanbeimportedintoAnsys Discoveryforthermalanalysis.AnsysDiscoveryusesfinite elementanalysis(FEA)tosimulatethe thermal behaviour oftheheatsinkunderdifferentconditions.

The following steps can be used to perform the thermal analysisinAnsysDiscovery:

1. Importtheheatsinkmodelasa.STEPfile.

2. Meshthe model usingAnsysDiscovery'smeshing tools.Themeshingprocess createsa network ofelements that approximates the shape of the heat sink and allows foraccuratesimulationofheattransfer.

3. Define the material properties of the heat sink, such as thermal conductivity and specific heat, in the AnsysDiscoveryinterface.

4. Define the operating conditions of the microprocessor, such as its power consumption and temperature,intheAnsysDiscoveryinterface.

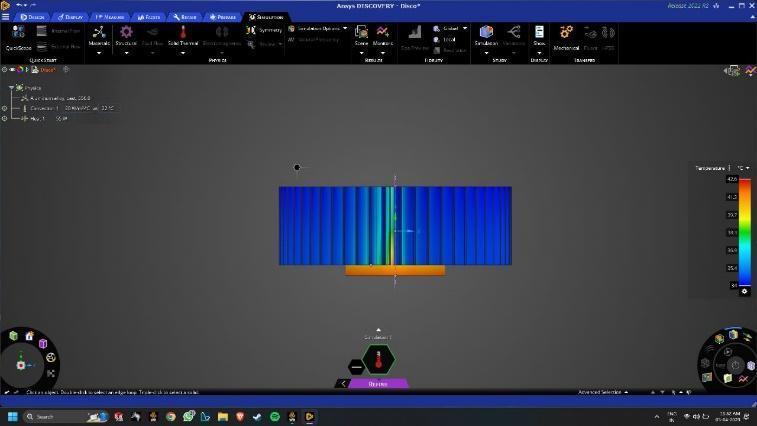

5. Run the simulation and analyse the results. The simulation will show the temperature distribution across

the heat sink and identify any hotspots or areas of poor heatdissipation.

6. Based on the results of the simulation, make design modifications to the heat sink as necessary to improveitsperformance.

In summary, the CMM measurement process is important for ensuring an accurate representation of the heat sink model.SolidWorkscanbeusedtocreatea detailedmodel of the heat sink, and Ansys Discovery can be used for thermalanalysistoidentifyanyhotspotsandimprovethe designoftheheatsinkforbettermicroprocessorcooling.

Step4:ThermalAnalysis

After the heat sink model has been imported into Ansys Discovery, thermal analysis can be performed to evaluate its performance. The analysis can be used to investigate the temperature distribution of the heat sink and identify any hotspots that may affect the performance of the microprocessor. The thermal analysis should consider various operating conditions, such as different power levelsandcoolingscenarios.

The processor used in this project is ‘i3-12100.’ The processor has maximum TDP (Thermal Design Power) which has 2 cores and 4 processes. The fans used in this simulation were selected as per the mass flow rate requirement. An optimum value of 120 CFM was consideredperfectforthisproject

Also, the heat sink material used in this project was Aluminium alloy for its thermal properties. Copper alloy wasalsotakenintoconsideration,althoughduetoitshigh densityandrarity,itwasexcludedfromthissimulation.

TheInputparametersforourprojectweregivenas follows:

Step5:Geometry

The heat sink used in this project was the default one on the CPU. The geometry was reverse engineered, with the help of CMM (Coordinate Measuring Machine) the fin’s thickness,gap between two fins and thelength of the fins weretakenandthenimplementedintheCADSoftware. SolidWorkswasusedforthisgeometrygeneration.

Step6:AnsysDiscovery

TheflagshipsoftwareofAnsyswasusedinthisproject. While importing geometry, the enclosure was created arounditsothatthefluidflowcanbegenerated.Theinput parameters given above were applied to the geometry. ThemainadvantageofDiscoverySoftwareisthatthereis no need to assign mesh parameters to the geometry according to the complexity of it. The software itself calculatestheoptimummeshsizingoftheparttokeepthe skewnessoftheelementbelow0.7orlessaccordingtothe requirement.

TheBoundaryconditionsassignedinthesimulationwere:

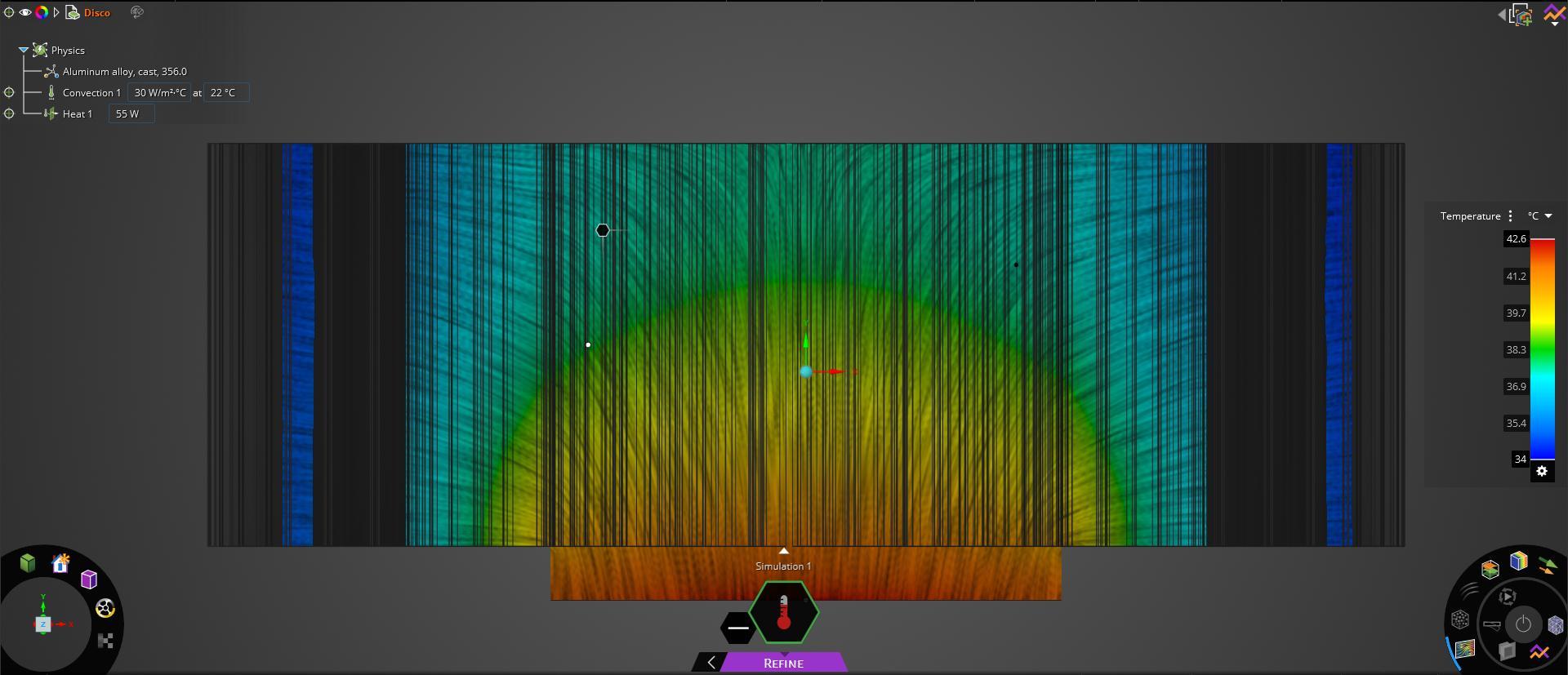

4. RESULTS

The simulation resulted in maximum temperature going around 42.8OC which is optimum temperature for this 2core processor and due to the forced convection, the temperature drop can be seen in the results. Also, the processor has a rating of maximum temperature going around85OCwhichisalmostdoublethetemperature that wearereceiving.Therefore,wecanconcludethattheheat sinkwasdesigned,andthefanselectionwasdoneonpoint forthistypeofCPUprocessor.

5. CONCLUSION

Inconclusion,thethermalanalysisoftheheatsinkforthe Intel Core 3rd Generation processor in an HP computer has been successfully conducted using SolidWorks and Ansys Discovery software. The reverse engineering process using the CMM machine provided accurate measurements of the heatsink'scircular fins, which were thenmodelledinSolidWorkssoftware.

The modelling process involved creating the base geometry,adding fillets and rounds,andcreating the fins' circular patterns. The thermal analysis conducted using Ansys Discoverysoftware revealed thatthedesignedheat sink was able to efficiently dissipate heat from the microprocessor. The temperature distribution within the heat sink and the microprocessor was analysed, and the results were found to be within the safe operating temperaturerange.

The effect of varying parameters suchas fin thickness, fin spacing, andheatsink material wasalsoinvestigated,and their impact on heat transfer was analysed. Overall, this research provides valuable insights into the design and optimization of heat sinks for microprocessors, and the use of advanced software tools such as SolidWorks and AnsysDiscoveryforthermalanalysis.

The findings of this research can be used to improve the thermal performance of heat sinks for microprocessors and enhance the overall efficiency and reliability of electronicsystems.

ACKNOWLEDGEMENTs

We would like to express our sincere gratitude to the facultymembersoftheMechanicalDepartment,whohave been instrumental in our growth as scholars and researchers. Their guidance, support, and encouragement have been invaluable to us throughout our academic journey.

We are especially grateful to our teachers Dattatray B. Hulwan, Sunil S. Shinde who have been mentors and role models to us. Their expertise, insights, and feedback have shaped our thinking and approach to research. We appreciate their willingnessto take the time to meet with us,answerourquestions,andprovidethoughtfulfeedback onourwork.

We also wish to thank the staff of the Mechanical Department of Vishwakarma Institute of Technology, Pune, who have provided us with administrative support and resources that have enabled us to conduct our research effectively. Their contributions are an essential partofouracademicsuccess.

Finally,wewouldliketoacknowledgeourfellowstudents, whohaveprovideduswithasupportivecommunityanda forum for intellectual exchange. We have learned a great deal from our interactions with them and are grateful for theirfriendshipandcamaraderie.

Thank you all for your support, guidance, and encouragement. We could not have accomplished this workwithoutyou.

REFERENCES

[1] Ravikumar,S.(2017).ExperimentalandTransient Thermal Analysis of Heat Sink Fin for CPU processor for better performance. International Journal of Innovative Research in Science, Engineering and Technology, 6(4), 11184-11188.

[2] Reddy,M.C.S.(2013).ThermalAnalysisofaHeat Sink for Electronics Cooling. International Journal of AdvancedEngineeringTechnology,4(4),135-140.

[3] Jajja, S. A. (2016). Water cooled minichannel heat sinks for microprocessor cooling: Effect of fin spacing. AppliedThermalEngineering,109,501-511.

[4] Zhao, M., & Tian, Y. (2018). Thermal Analysis of Heat Transfer Enhancement of Rib Heat Sink for CPU. JournalofPhysics:ConferenceSeries,1014,022022.

[5] A.D. Kraus, A. Bar-Cohen, Thermal Analysis and Control of Electronic Equipment, Hemisphere Publishing Corporation,Washington,1983.

[6] C.J. Shih, G.C. Liu, Optimal design methodology of plate-fin heat sinks for electronic cooling using entropy generationstrategy,IEEETrans.ComponPackag.Technol. 27(2004)551–559.

[7] T. Furuk T. Furukawa, W. J. Yang, Reliability of heat sink optimization using entropy generation, in: Proc. 8thAIAA/ASMEJointThermophysicsandHeatTransfer

[8] Conf.,AIAA-2002-3216(2002).

[9] O.A.LeO.A.Leon,G.D.Mey,E.Dick,J.Vierendeels, Staggered heat sinks with aerodynamic cooling fins, Microelectron.Reliab.44(2004)1181–1187.

[10] E. Smal E. Small, S.M. Sadeghipour, M. Asheghi, Heat sinks with enhanced heat transfer capability for electronic cooling applications, J. Electron. Pack. 128 (2006)285–290.

[11] M. Iye M. Iyengar, A. Bar-Cohen, Least-energy optimizationofforcedconvectionplatefinheatsinks,IEEE Trans.Compon.Packag.Technol.26(2003)62–70.

[12] Y.T. Ya Y.T. Yang, H.S. Peng, Numerical study of pin-fin heat sink with un-uniform finheight design, Int. J. HeatMassTransfer51(2008)4788–479.