LITERATURE SURVEY ON APPLICATION OF CERAMIC WASTE IN CONCRETE

Rohan Dewangan

Rohan Dewangan

M.Tech. (Structural Engineering), Department of Civil Engineering, Guru Ghasidas Vishwavidyalaya, Bilaspur, Chhattisgarh, India, 495009

Abstract – Concrete is one of the important construction materials widely used around the world to develop infrastructures and it is also one of the major factor affecting economies. Infrastructural development is at its peak all over the world and is a symbol of growth for any country.Theproductionofconcreteconsumeslotsofnatural resources, which releases CO2 into the atmosphere and thus leads to global warming. Due to the day-by-day innovations and development in construction field, the use of natural coarse aggregates is very high as well as production of solid wastes from the demolitions of constructions is also very high. Because of these reasons the reuse of demolished wastes came to reduce the solid waste and to reduce the depletion of natural aggregates. Ceramic is industrially processed by being cut, polished, and used for decorative purposes, and thus, economically valuable. During the cutting process, 20 - 30% of ceramic get wasted. Ceramic waste leads to a serious environmental problem as well. Therefore, the use of ceramic waste in the concrete production has increasingly become an important issue. Ceramic tile waste, which is obtained from construction sites, demolition sites, and manufacturing industries, has a negative impact on the environment. Recycling these ceramic tiles to produce concrete could be a useful strategy for preserving the environment and enhancing the concrete's inherent qualities. Ceramic waste concrete has economical and environmental advantages. It also makes concrete sustainable, but precaution needs to be required, especially for higher replacements that may influence the compressive strength and thus partial replacement is suggested.

Key Words: Ceramic Waste, Natural Resources, Concrete, Demolished Waste, Recycling, Natural Coarse Aggregate,FineAggregate.

1. INTRODUCTION

Concrete is the most extensively used construction material, concrete made from blending coarse aggregate, fine aggregate, cement and water. Because of its high compressive strength and flexibility in structural forms, thisblendedmaterialcanbeplacedandmouldedintoany shapeandsize. Coarse aggregate isa prime material used forpreparationofconcreteandwhichplaysamajorrolein

mix design. It is mostly obtained from the underground mining and extensive mining of rocks has reportedly causing damages to the environment. We also see that dependency on this source has led to high material costs also.

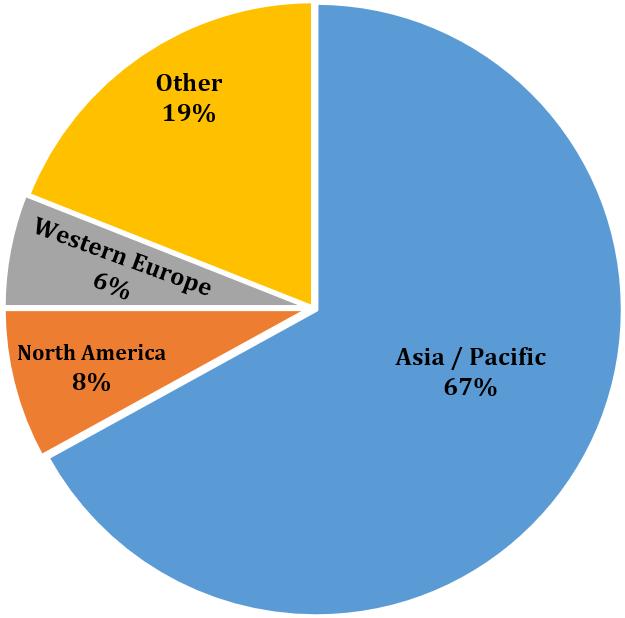

EconomicalandEnvironmentalImpacttheevolutioninthe construction industry introduces several concerns regarding availability of natural coarse aggregate resources, as they are being rapidly depleted. Recent statistics showed the increasing demand of construction aggregate to reach 48.3 billion metric tons by the year 2015 with the highest consumption being in Asia and Pacific as shown in Fig. 1 (The Freedonia Group 2012). This increasing demand is accompanied by an increase of construction waste. As per survey, construction waste from European Union countries represents about 31 % of the global waste generation per year. Similarly, in Hong Kong, the waste production was nearly 20 million tons in theyear2011, whichconstitutesabout50%ofthe global waste generation. Disposal in landfills is the common method to manage the construction waste, which creates large deposits of construction and demolition waste near the sites. After demolition of old infrastructure and buildings, the wastage is often considered worthless and disposedofasdemolitionwaste.

Waste materials specifically ceramic industry wastes represent a major environmental issue. Growing construction sector and demolition of buildings creates huge quantities of waste causing a serious environmental issue. Producing concrete containing waste materials like ceramic waste seems to be a good partial solution to reduce the effect of this environmental issue. Many researchers have used waste materials in concrete mostly as partial replacement for the fine or coarse aggregate depending on the type or size of the waste materials. By collectingtheused ceramic wastetilesandbreakingit up, ceramicwasteaggregate(CWA)iscreated.

Thispaperfocusedontheuseofceramicwasteasacoarse aggregate to form green concrete. The use of CWA in new construction applications is still a relatively new technique. The use of CWA on a large scale may help to reduce the effects of the construction on these factors by reusing waste materials and preventing more natural aggregatefrombeingharvested.

2. CERAMIC MATERIALS

The word “Ceramic” is traced back to the Greek term Keramos,meaning“apotter”or“pottery”.Sincetheinfancy of ceramics, up to this day, the process is still very much same for the manufacturing of all the ceramic materials, they need to bake the mixture of clays at very high temperature. Ceramic products are manufactured at extremely high temperatures between 1000°C - 1250°C which results in very hard, highly resistant to chemical, freezingandthermalshock.

InIndiathereportedCeramicIndustryapproximateworth of Rs. 21,000 crores, the Indian Ceramic Tiles industry grew by around 11% in 2013-14 and expected to reach worth ofRs.310billionby 2025.Asina presentreportof Global Ceramic Tiles Market of February 2016, the global ceramic tiles market will grow at a CAGR (Compound AnnualGrowthRate)of9.59%duringtheperiodof20162020.GloballyIndiaisranked3rd andresponsibleforover 6%oftotalglobalproduction.

Evenwithan enormousgrowthintheceramicproduction there is an unseemly consumption. Thus, resulting to a huge wastage which is reported to be around 15% - 30% annuallygeneratedfromthetotalproduction.Considering thepropertiesofceramicstheirwastesuchasbrokentiles should be included in concrete as a substitute to conventional construction material.Thiswill help tosolve problemslikecost,scarcityaswellasotherenvironmental issues that may arise due to improper dumping of such waste. The chemical composition of ceramic shows a higher percentage of silica, alumina and calcium oxide. Iron, magnesium and alkali oxides are also present in small amount. Ceramic waste contains silica and alumina which are responsible for pozzolanic reactivity and

cementitious property, making it a suitable substitution material for the production of concrete. The specific gravityoftheceramicmaterialsrangesfrom2.30to2.80.

3. ADVANTAGE OF USING CERAMIC WASTE

WasteManagementTechnique

ReductionofemissionofCO2intheenvironmentusing asacementreplacement

Helpsinattainingsustainabledevelopmentofsociety

Improvedstrengthatcertainreplacementlimit

Reducedcostinconstructionduetotheuseofwaste

4. LITERATURE SURVEY

R.M. Senthamarai et al. (2005), substitutedconventional crushed stone aggregate with ceramic electrical insulator. Different watercement ratioof 0.35, 0.40, 0.45,0.50,0.55 and0.60wereadopted.Compressivestrength,splittensile strength, flexural strength and Modulus of elasticity were found out. It is found that the compressive, split tensile andflexurestrengthofceramiccoarseaggregatearelower by 3.8%, 18.2% and 6% respectively when compared to conventionalconcrete.

A. Mohd Mustafa et al. (2008), studied on various types of ceramic waste like flower pots, tiles and clay bricks. Different water cement ratios were adopted such as 0.4, 0.5and 0.7 with concrete of characteristicsstrength of 20 MPa. Flower pots gave the best results for compressive strength of about 2.50% lesser than that of conventional concrete.

Torkittikul et al. (2010), conducted a study to get compressivestrengthofmortar mixesand concrete mixes with the use of ceramic waste as a fine aggregate substitution at the age of 7, 14 and 28 days. A higher amount of compressive strength was found for concrete containing ceramic waste (up to 100% substitution) with respect to reference concrete. For 10% ceramic waste replacement, compressive strength was 42.2 MPa and for 50% replacement, compressive strength was 50.2 MPa at 28 days, so it was concluded compressive strength improvedwithrisinginCWAreplacement.Thisincreasein strength could be due to the bonding between paste and aggregateandtheroughertextureofaggregateusedinthe study.

R.M. Senthamarai et al. (2011), studied the durability properties of ceramic industry waste as coarse aggregate in concrete. Water cement ratios from 0.35- 0.60 were used and properties such as volume of voids, water absorption, chloride penetration and sorption were studied. Water absorption ranges from 3.74-7.21% whereas that of conventional concrete from 3.1 – 6.52%. ConcretewithCeramicshowshigherresultsinalltests.

Senthamarai et al. (2011), performed water absorption test on ceramic ware insulator waste coarse aggregate concrete and normal concrete at 28 days curing period. The results showed a similar pattern of increasing water absorption value with increment in water-cement ratio. It was also concluded that water absorption is not the measure of the quality of concrete whereas, good quality concrete water absorption should be below 10%. In this study water absorption for ceramic ware insulator waste coarse aggregate concrete for different water-cement ratiosisbetween3.74and7.21%andfornormalconcrete isliebetween3.1and6.25%forrespectiveW/Cratios.

D. Tavakoli et al. (2013), investigatedonthepossibilityof usingceramictileinconcrete.Coarseaggregateisreplaced intherangeof0-40%.Thereisanincreaseincompressive strength by 5.13% whereas there is a decrease in slump, water absorption and unit weight by 10%, 0.1% and 2.29%respectivelywith10%substitution.

Sudarsana et al. (2013), investigated on the influence of water absorption of ceramic waste aggregate on strength properties of ceramicaggregate concrete. M20 concrete is used with 0.48 water cement ratio. Ceramic waste water absorption is 0.08% more than conventional aggregate. Compressivestrengthisbestat20%replacementreaching 93.45%, 98.84% to that of conventional concrete at 7 and 28 days. There is decrease in density with increase of percentage replacement; at 100% replacement density is 4.43%lesswhencomparedtoconventionalconcrete.

Medina et al. (2013), investigated the water absorption and porosity for concrete containing ceramic waste as coarse aggregate replacement in the amount of 0%, 20% and 25%. An increase in water absorption value was noticed by 36% and 46% for 20% and 25% ceramic aggregate replacement respectively with respect to the reference concrete. Since the values found are under 4% andnormallyconsideredbydifferentauthorsitshouldfall under 10%, so it is concluded concrete falls under good quality. A slight decrease in porosity was also identified and this might be because of the greater porosity of ceramicaggregate.

Alves et al. (2014), reported split tensile strength values of concrete after 28 days with fine aggregate replacement bytherecycledfinesanitarywareaggregateintheratioof 0%, 20%, 50% and 100%. Reduction in split tensile strength value was observed and this could be due to increment in the porosity of paste with the rise in replacement ratios. The modulus of elasticity of concrete also falls with an increase in substitution ratio. This elasticityreduction ismainlydue to recycledfine sanitary ware aggregate has lower stiffness than fine natural aggregate.

Maya et al. (2014), studied the mechanical properties of roof tilesascoarse aggregate with differentratios of 0.40, 0.45and0.50,subjectedtoelevatedtemperature.Thereis a decrease in compressive strength and Split Tensile with increaseinwatercementratioandtemperature.

Amir Javed et al. (2015), analysed the compressive and flexural strength of concrete with stone dust as natural sand at 20%, 40%, 60%, 80% and 100% along with ceramicwasteasstoneaggregateat20%replacement.Itis found that at 40% stone dust and 20% ceramic waste compressive strength reaches upto 77.32% of that of conventional concrete whereas there is an increased in flexurestrengthby25.62%.

Aruna et al. (2015), experimented on clay roof tile in concrete, pervious concrete and another combination of fly ash as cement and tile as coarse aggregate. Tile is replaced at 0%, 5%, 10%, 15%, 20% and 25% as T0, T5, T10,T15,T20andT25.Inperviousconcrete,as0%,10%, 20% and 30% as P0, P10, P20 and P30. Similarly T0F0, T5F10, T10F20, T15F30, T20F40 and T25F50 for fly ash and tile combination. Water cement ratio adopted is 0.41. Density and slump is least at T25 as 4.59% and 75mm respectively.InperviousconcreteatP30densityislessby 8.68%than conventional concrete. And alsoatT25F50 by 6.27% and slump as 75mm. Maximum compression is attained at T15F30 as 81.26% to that of conventional concrete.

J. Swathi et al. (2015), partially replaced fine aggregate with copper slag as 20%, 40% and 60% and coarse aggregate with waste ceramic tiles as 10%, 20% and 30%.M40 grade of concrete was used. Compressive strength increased by 7.59N/mm2 at a combination of 40% copper slag with 10% waste ceramic tiles and also Flexureincreasedby4.07%.

V. Giridhar et al. (2015), experimented on concrete with ceramic waste as natural coarse aggreagate at 0%, 20%, 40%, 60%, 80% and 100%. M20 concrete is adopted. Maximum compression attained at 20% replacement reached 93.45% and 98.84% to that of conventional concrete. Similarly split tensile strength reaches 97.38% and 93.78% to that of conventional concrete at 7 and 28 daysrespectively.

T. Subramani et al. (2015), focusedontheproduction of light weight concrete by replacing conventional coarse aggregatewithwasteceramictilesat20%,25%and30%. M30gradeconcreteisadoptedwithwater-cementratioof 0.43. There is increase of 16.33%, 76.76% and 37.07% in Compressive strength, Split tensile strength and Flexure strengthat30%replacement.

Medina et al. (2016), examinedcompressivestrengthtest of concrete prepared with ceramic coarse aggregate replacing coarse aggregate up to 20%. Results showed a rise in compressive strength value by 12% compared to thecontrolmixture.

Kannan et al. (2017), examined the fresh properties of concrete containing CWP as cement substitution with the amountofreplacement10%-40%.Initialandfinalslump values were noted. Initial slump value was found higher for 20% and 30% replacement level in comparison to all other replacement levels including the control mix. This was due to the high specific surface area of the CWP as a comparison to cement and hydration of cement. The compressivestrengthvaluesofconcreteafter28daysand 90dayscuringmadewithceramicwastepowderreplacing cement up to 40%. As the amount of CWP replacement increased compressive strength value reduced by 15%, 17%, 18% and 20% on addition of CWP 10%, 20%, 30% and 40% respectively. The marginal increase in compressive strength was observed for all concrete mixtures at the age of 90 days. All the results obtained showthatCWPcanbeactsasfillerratherthanpozzolanic material. The decrement in strength could be due to a decreaseincementbindercontent.

Subasi et al. (2017), usedceramicwasteasfillerinSCCat different amount of cement replacement (0%, 5%, 10%, 15% and 20%). Fresh properties were investigated and it was found that the flowability properties increased up to 15%replacementand decreasedwith20% wasteceramic replacement.Itwasobservedthatslumpflowvariesinthe rangeof760–850mm.

Nayana et al. (2018), calculated water absorption of mortar mix after 28 days curing period having ceramic wasteasfineaggregatereplacementintheamountof0%, 15%, 30% and 50%. It was found that the percentage of water absorption for 15% replacement decreased by 1.17% with respect to the control mixture. Reduction in pores is the main reason for a decrease in water absorption. The compressive strength of mortar mixtures made using ceramic waste as the replacement of fine aggregate at 0%, 15%, 30% and 50% by weight with and silica fume addition of 0%, 5% and 10% by weight of cement.Theadditionofsilicafumeshowedanincrease in strength. Results show higher strength with 15% replacement of ceramic waste with sand and decreased strengthwasobservedwithfurtheraddition.Thisincrease in strength could be due to the filling effect and the pozzolanic effect of ceramic waste. It was also reported a noticeable rise in compressive strength with the addition ofsilicafumewhichisreplacedbycement

Siddhique et al. (2018), examined the compressive and split tensile strength results of concrete made by fine

aggregatereplacementtoBCCFA(BoneChinaCeramicFine Aggregate)inratioof0%,20%,40%,60%,80%and100% by weight. An increase in both compressive and split tensile strength was observed for concrete containing BCCFA replacement with respect to the control mixture. This could be possible due to formation of denser CSH (calcium silicate hydrate) gel which was produced due to the presence of extra water in the fresh mix which is further released by BCCFA which provides better bonding propertytothemixandgivesaninternalcuringeffect.

Nepomuceno et al. (2018), prepared concrete by replacing natural coarse aggregate with recycled coarse ceramic aggregates in a complete volume percentage of 0%,10%,30%,50%and75%.Propertiesoffreshconcrete were found by slump test, degree of compatibility and air contenttest.Workabilityvalueinasimilarrangeof50–70 mm was found for different concrete mixtures. The compressiveandsplittensilestrength wasobservedat28 days curing period. It was noticed that compressive strength falls with a rise in recycled coarse ceramic aggregate replacement. Also the replacement up to 30%, tensile strength decreases at a lower rate and maximum reductionfoundwas6.4%ascomparedtocontrolmixture. The maximum reduction observed was 22.2% for 75% replacement.

El-Dieb et al. (2018), conducted a compressive strength test on concrete cubes having ceramic waste in replacementtocementupto40%.Theadditionofceramic waste increased compressive strength up to 20% replacement. The replacement beyond 20% showed a reduction in compressive strength. This can be due to the replacement of hydraulic binding material to nonhydraulic ones. The increase in compressive strength was noticed with the increase in curing period. This higher strength could be because of the presence of the pozzolanicpropertyofceramicwastepowder.

Awoyera et al. (2019), conducted a slump flow test on concrete containing ceramic waste 0%, 25%, 50%, 75% and 100% as fine and coarse aggregate replacement. Increasedslumpvaluewiththerangeof80mmto120mm wasfound with anincrease inreplacementratio, whereas the slump value of 40 mm was observed for 100% coarse aggregate replacement. The Compressive and split tensile strength test on concrete was observed at different age 3, 7, 14 and 28 days Result showed 36.1% strength increment in concrete with 100% coarse aggregate replacement in comparison to the control mix. Also the split tensile strength increases with an increase in the content of ceramic coarse aggregate. Split tensile strength results ranged between 2.8 N/mm2 and 3.6 N/mm2. It could be due to the irregular shape and rough surface of ceramic coarse aggregate that gives the proper bonding between aggregates and hardened cement paste. The

compressive strength was increased by 22.1% for 100% ceramic fine aggregate replacement. The better result couldbe because of thehigher waterabsorption property of ceramics and also because of the pozzolanic activity of ceramicparticles.

Zareei et al. (2019), conductedthecompressiveandsplit tensilestrengthtestonconcreteattheageof7,28and90 days of curing period which is made by recycled waste ceramicaggregatereplacingwithnaturalcoarseaggregate in the amount of 0%, 20%, 40% and 60% by weight. Incorporation of recycled waste ceramic aggregate enhanced the compressive and split tensile strength of concrete than of the samples without recycled waste ceramic aggregate. Compressive strength increased by (6%, 16% and 4%) and split tensile increased by (5%, 11% and 8%) on the addition of recycled waste ceramic aggregate by 20%, 40% and 60% respectively in replacement of natural coarse aggregate for 28 curing days.Thisincrementinstrengthcouldbeduetoenhanced interlocking between the coarse aggregate and the paste which occur due to the rough and angular surface texture of RWCA The modulus of elasticity on cylindrical specimensshowsbetterperformanceofconcretewhenits natural coarse aggregate is interchanged with RWCA. An increment of 3% was observed when the replacement amountofNCAis40%byRWCA.

Huseien et al. (2020), conducted a compressive strength test on self-compacting concrete specimens made with CWP up to 80% Granulated blast furnace slag replacement. GBFS was used as a complete cement replacement. The result shows that increment in the amount of CWP replacement reduced the compressive strength. The best result of compressive strength of 52.6 MPa was noticed for the control mixture at the age of 3 days (i.e. 100% GBFS) and at 10% CWP replacement compressive strength reduced to 47 MPa. The least compressive strength value was observed 18.6 MPa with 80% CWP replacement at the age of 3 days. This loss in compressive strength due to the reduction in CaO content which follows the increment in silicate to calcium ratio (SiO2: CaO) and gives the adverse impact in compressive strengthandlowerstrength.

4. SUMMARY AND CONCLUSION

The research paper summarizes the use of ceramic waste for the production of green construction concrete. On the basis of results attained from the published literature followingconclusioncanbedrawn–

The ceramic waste can be utilized as an alternative to cement replacement in concrete due to presence of high alumina and silica. This high alumina and silica reactswithpresentcalciumincementandproducesCS-Hgel.

Utilizationofceramic wasteascement, fineandcoarse aggregate replacement reduces cost of construction andsustainableconcretecanbeproduced.

Ceramic waste powder exhibits very good pozzolanic reactivity and can be useful material as a cement replacement.

Increase in percentage of water absorption was observed by many researchers for increasing ceramic wastereplacementlevel.However,thevalueswereless than 10%, therefore, it can be used as a good constructionmaterial.

Low compressive strength at early ages was found by many researchers. However, with increasing ages, higher strength was observed. Most of the researchers used10%-40%andup-to100%ofceramicwasteasa replacement ofcementand aggregate respectively. The decrease in strength at earlier stage could be because oflowerpozzolanicactivityatinitialstages.

Increase in durability properties were observed with the inclusion of ceramic waste in concrete by many authors. The finer size of particles is the most suitable reasonforincreasingthedurabilityperformance.

The optimum level of ceramic waste replacement should be between 5% to 30% in order to obtain maximumstrengthoftheconcrete.

Research should be made with low grade concrete like M15andM20asthistypeofconcreteonlyiscommonly adopted,after whichresearchcanbe carried withhigh strengthconcrete.

The ceramic tiles waste to be used should be deglazed and lower water - cement ratio should be adopted to achievethedesiredtargetedstrength.

REFERENCES

[1] R.M. Senthamarai and P. Devadas, “Concrete With Ceramic Waste Aggregate”, Elsevier, Cement and ConcreteComposites,(2005).

[2] A. Mohd Mustafa Al Bakri, M.N. Norazian, H. KamarudinandG.CheMohdRuzaidi, “ThePotential of Recycled Ceramic Waste as Coarse Aggregates For Concrete”, Malaysian Universities Conferences onEngineeringandTechnology,(2008).

[3] P. Torkittikul, A. Chaipanich, “Utilization of ceramic waste as fine aggregate within Portland cement and fly ash concretes”, Cement and Concrete

Composites, (2010). https://doi.org/10.1016/j.cemconcomp.2010.02.004

[4] R. Senthamarai, P.D. Manoharan, D. Gobinath, “Concrete made from ceramic industry waste: Durability properties”, Construction and Building Materials, (2011) https://doi.org/10.1016/j.conbuildmat.2010.11.049

[5] R.M. Senthamarai, P. Devadas Manoharan and D. Gobinath, “Concrete Made From Ceramic Industry Waste: Durability Properties”, Elsevier, ConstructionandBuildingMaterials,(2011).

[6] C. Medina, M.I. Sanchez De Rojas, M. Frías, “Properties of recycled ceramic aggregate concretes: Water resistance”, Cement and Concrete Composites, (2013) https://doi.org/10.1016/j.cemconcomp.2013.04.005

[7] Sudarsana Roa hunchate, Giridhar Valikala and Vaishali. G. Ghorpade, “Influence Of Water Absorption of the Ceramic Aggregate on Strength Properties Of Ceramic Aggregate Concrete”, International Journal of Innovative Research in Science,EngineeringandTechnology,(2013).

[8] D. Tavakoli, A. Heidari and M. Karimian, “Properties of Concrete Produced with Waste Ceramic Tile Aggregate”, Asian Journal Of Civil Engineering, (2013).

[9] A.V. Alves et al., “Mechanical properties of structural concrete with fine recycled ceramic aggregates”, Construction and Building Materials (2014), https://doi.org/10.1016/j.conbuildmat.2014.04.037

[10] T.M.Maya and Nivin Philip, “Mechanical Prroperties of Concrete Containing Roof Tile Aggregate Subjected To elevated Temperature”, International Journal of Innovative Research in Advanced Engineering,(2014).

[11] Amir Javed, Salman Siddique and V.S. Ram Prasad, “InvestigationOnCeramicWasteandStoneDustas Aggregate Replacement in Concrete”, International Journal of Engineering Technology, Management and AppliedSciences,(2015).

[12] D. Aruna, Rajendra Prabhu, Subhash C Yaragal, Katta Venkataramana, “Studies On Usage Potential Of Broken Tiles As Part Replacement To Coarse Aggregates In Concrete”, International Journal of ResearchinEngineeringandTechnology,(2015).

[13] J. Swathi and V. Gnanadevi, “An Experimental Investigation On Concrete By Partial Replacement Of Copper Slag For Fine Aggregate And Ceramic Waste With Coarse Aggregate”, International JournalofEmergingTechnologyinComputerScience AndElectronics,(2015).

[14] V. Giridhar, H. Sudarsana Rao and G. Ghorpade, “DevelopmentofRegressionModels ForStregthOf Ceramic Waste Aggregate Concrete”, International Journal Of Emerging Trends In Engineering and Development,(2015).

[15] T. Subramani and B. Suresh, “Experimental Investigation Of Using Ceramic Waste As A Coarse Aggregate Making A Light Weight Concrete”, International Journal of Application or Innovation in EngineeringandManagement,(2015).

[16] C. Medina, M.I. Sanchez De Rojas, C. Thomas, J.A. Polanco, M. Frías, “Durability of recycled concrete made with recycled ceramic sanitary ware aggregate”. Inter-indicator relationships, Construction and Building Materials (2016) https://doi.org/10.1016/j.conbuildmat.2015.12.176.

[17] D.M. Kannan et al., “High performance concrete incorporating ceramic waste powder as large partial replacement of Portland cement”, Construction and Building Materials, (2017) https://doi.org/10.1016/j.conbuildmat.2017.03.115

[18] S.Subasí,H.Ozturk,M.Emiroglu, “Utilizingofwaste ceramic powders as filler material in selfconsolidating concrete”, Construction and Building Materials, (2017) https://doi.org/10.1016/j.conbuildmat.2017.05.180

[19] A.M. Nayana, P. Rakesh, “Strength and durability study on cement mortar with ceramic waste and micro-silica”, Materials Today Proceedings (2018). https://doi.org/10.1016/j.matpr.2018.10.276

[20] S. Siddique, S. Shrivastava, S. Chaudhary, “Durability properties of bone china ceramic fine aggregate concrete”, Construction and Building Materials, (2018) https://doi.org/10.1016/j.conbuildmat.2018.03.262

[21] M.C.S. Nepomuceno, R.A.S. Isidoro, J.P.G. Catarino, “Mechanical performance evaluation of concrete made with recycled ceramic coarse aggregates from industrial brick waste”, Construction and Building Materials, (2018). https://doi.org/10.1016/j.conbuildmat.2018.01.052

[22] A.S. El-Dieb, D.M. Kanaan, “Ceramic waste powder an alternative cement replacement –Characterization and evaluation”, Sustainable Materials and Technology, (2018)

https://doi.org/10.1016/j.susmat.2018.e00063

[23] P.O. Awoyera et al., “Characterization of ceramic waste aggregate concrete”, HBRC Journal, (2019)

https://doi.org/10.1016/j.hbrcj.2016.11.003

[24] S.A. Zareei et al., “Green high strength concrete containingrecycledwasteceramicaggregatesand waste carpet fibers: Mechanical, durability, and microstructural properties”, Journal of Building Engineering, (2019).

https://doi.org/10.1016/j.jobe.2019.100914

[25] G.F. Huseien et al., “Effects of ceramic tile powder waste on properties of self-compacted alkaliactivated concrete”, Construction and Building Materials, (2020)

https://doi.org/10.1080/19648189.2016.1175974