ANALYSIS OF THERMAL PERFORMANCE OF SOLAR COLLECTOR WITH LONGITUDINAL FINS

Abhilash Kumar Pandey1 Asst. Prof. Shailendra Kumar Shukla21Mtech Scholar, dept of mechanical Engineering, Rewa Institute of Technology, Rewa

2 Asst.Prof., dept of mechanical engineering, Rewa Institute of Technology, Rewa ***

Abstract-The performance of solar collectors as a means of generating renewable energy is the primary emphasis of this work. To begin, a numerical simulation will be carried out and then contrasted with the results of previous studies in order to validate the findings that were achieved. There are a total of six unique collector models that have been created; three of these collector models feature various fins (2, 4, 6), while the remaining three collector models have varying fin heights The thermal and dynamic behavior of the air flow inside these various cases was analyzed for different values of solar radiation and for other different values of air velocity at the collector inlet. The values of solar radiation and air velocity were determined by measuring the amount of energy that was absorbed by the surface area of the collector. This report presents, analyzes, compares, and interprets in considerable depth the temperature contours, velocity fields, and temperature change at the collector outlet as functions of solar radiation and air velocity for each model. All of this was accomplished with the assistance of the ANSYS FLUENT calculation code, which was used to solve the conservation equations of mass, amount of motion, and energy by using the approach of finite volume.

Keywords: solar collectors, renewable energy, fins, solar radiation

INTRODUCTION

Solar energy

Solarenergyisapromisingsourceofrenewableenergythat has gained significant attention in recent years due to its sustainability and environmental benefits. One of the key componentsofasolarthermalsystemisthesolarcollector, whichabsorbssolarradiationandconvertsitintoheatthat can be used for various applications such as space heating and hot water production. In order to improve the efficiency of solar collectors, researchers have been exploringvariousdesignmodifications,includingtheuseof longitudinalfins.Longitudinalfinsarethin,elongatedstrips that are attached to the absorber plate of a solar collector. Theyincreasethesurfacearea oftheabsorberplate,which enhancesheattransferandimprovesthermalperformance.

Theuseoflongitudinalfinshasbeenshowntoincreasethe efficiency of solar collectors in a variety of applications. However, the optimal design and configuration of longitudinal fins depend on several factors, including the operatingconditionsofthesolarcollectorandthematerials used in the fins. Therefore, a detailed analysis of the thermal performance of solar collectors with longitudinal fins is necessary to identify the most effective design parameters for different applications. In this research paper, we present an analysis of the thermal performance ofasolarcollectorwithlongitudinalfins.Weinvestigatethe effects of fin height, fin thickness, and fin spacing on the thermalefficiencyofthecollectorunderdifferentoperating conditions. We also examine the impact of the material properties of the fins on the overall performance of the solarcollector.

METHODOLOGY

Physical model

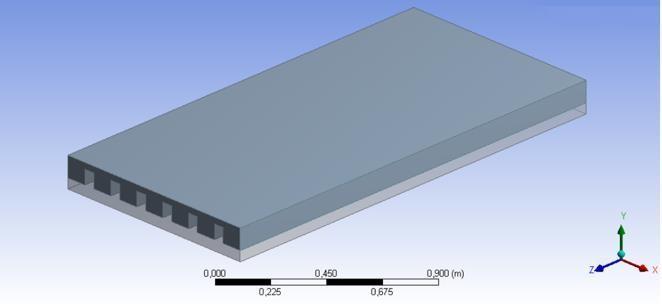

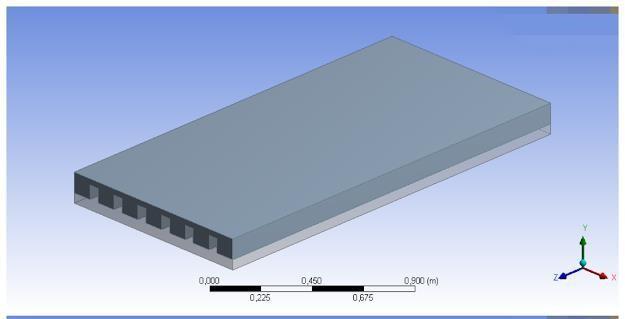

The geometric configuration of the problem under study is shown schematically in Figure 3.1. The dimensions of the solar collector presented and used in this work are based onexperimentaldatapublishedbyA.Dahmanietal[39].It isasolarcollectorof1.97minlengthand0.98minwidth.

During this study, an interest is given to the study of the effectofsystemsizeonthedynamicandthermalbehaviour of the fluid, for this, three heights and three numbers of different fins (Table 3.1) were examined and compared in detail. The dimensions and details that accompany each modelarealsopresentedinTable3.2.

Simplifying assumptions

The formulation of the problem studied is based on a number of simplifying assumptions, hypotheses related to geometry, type of flow, transfer mechanisms and phase change problems. In order to allow a simple and realistic resolution”,weconsideredthefollowingassumptions:

Thefluidflowisassumedtobepermanentandlaminar.

TheviscousfluidisNewtonianandincompressible.

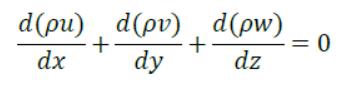

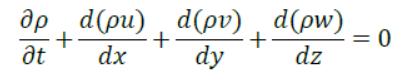

Conservation of mass

Theequationforconservationofmassis:

The selection of physical models: in fact, these are rarelytheexactequationsof

Part of geometry

We created the geometry with ANSYS Design Modeler software, which allows you to make 2D plots (Sketch), to create 3D objects from sketches (by extrusion etc... ) and manipulate3Dobjects.

Sincetheflowispermanent

Sotheequationbecomes:

Principles of CFD codes

CFD codes make it possible to solve numerically the “equations governing the motions of a fluid, i.e. the equations reflect the conservation of the mass and momentum of the fluid (Navier-Stokes equations), as well as the conservation of its enthalpy. There are a large number of CFD codes available, for our work, we have chosen the Fluent CFD code (Workbench version 14.0), the latterallowsustomeetourcalculationneeds.

TobuildaCFDmodel,thereareseveralsteps:

Theconstructionofgeometry.

Theconstructionofthemesh.

Mesh part

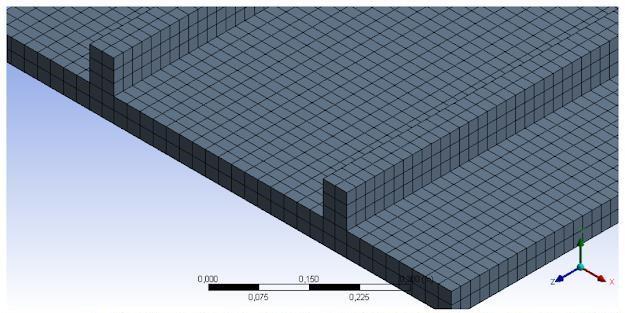

Tocreatethemesh,welaunchedANSYSMeshingbydoubleclicking on Mesh in the Workbench box. The choice of mesh isanessentialstepindigitalsimulation[45].

Itisthereforeimportanttochooseameshthatbestadaptsto theproblemsconsidered.

In this study, a uniform structured hexahedral mesh refined at the walls was chosen. The generated mesh results are presentedinTable3.3”

Choice of the two calculation methods Fluent of two calculation modes:

Double-precision mode: In double-precision mode, floating-pointnumbersarerepresentedusing64bits.

Single-precision mode: Single-precision mode uses a 32-bitrepresentation.

The thermophysical properties of the materials used

Table 3.4: The thermo-physical properties of the materials used.

Numerical diagrams

(a) Resolution of the speed-pressure coupling

Boundary conditions

Depending on the physical problem being addressed, the boundary conditions are different and their compatibility withnumericalmodelsisassociatedwithadirectimpacton the convergence and realism of the results of numerical simulations. Several types of boundary conditions are offeredinCFDs”.

Inourcase,tosolvethesystemofequationobtained,it is necessary to introduce the following boundary conditions:

Input: a uniform air velocity and temperature are imposedontheinputofthecalculationdomain.

At the level of the absorber and the glazing: A radiativefluxofdifferentsolarintensitiesisapplied.

Output: At the exit of the calculation domain, an atmospheric pressure is applied as boundary conditions.

The “Navier–Stokes equations consist of the mass conservation equation and the momentum conservation equations. Their resolution requires obtaining at all times, a coherent pressure field and a velocity field. Fast-pressure couplings tricky to deal with for incompressible flows because pressure does not appear explicitly in the mass conservationequation.

RESULTS AND DISCUSSION

Introduction

The governing equations are solved by the finite volumemethodusingaFluentcalculationcode.Thevelocity and temperature fields were obtained and presented for all the geometry considered at different heights and number of fins. The variation of the average velocity as well as the average temperature for all the cases studied is also presented in this chapter for different values of entry velocityandfordifferentintensityofsolarradiation.

Validation of the numerical model

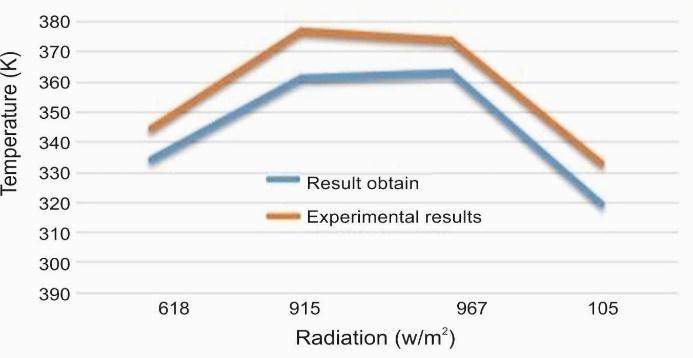

Before starting the numerical simulation dealing with the influence of the various parameters, a comparison of the resultsofthepresentstudywiththoseobtainedbyDahmani etal [39]wascarriedoutundertheconditionsusedintheir experimental workcarriedoutonasolarcollectorofsimple form.

Figures4.1representtheevolutionoftheairtemperatureat the collector outlet as a function of solar radiation obtained numerically by Fluent and experimentally by Dahmani et al. [39].

For the outlet temperature, it can be seen that the mean error of the results obtained with the experimental values [39] is of the order of 1.42%. Then the results obtained are veryaccuratecomparedtothoseofDahmanietal.[39].

This comparison shows the good accuracy of our results compared to those proposed by Dahmani et al. [39] Thismayprovidevalidationfortheresultsdevelopedbelow.

Influence of number of finned rows

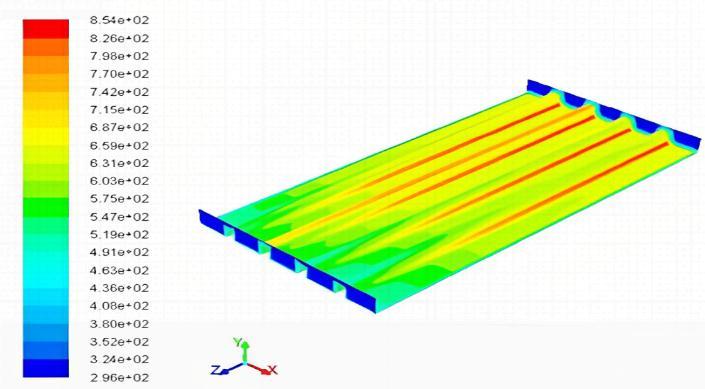

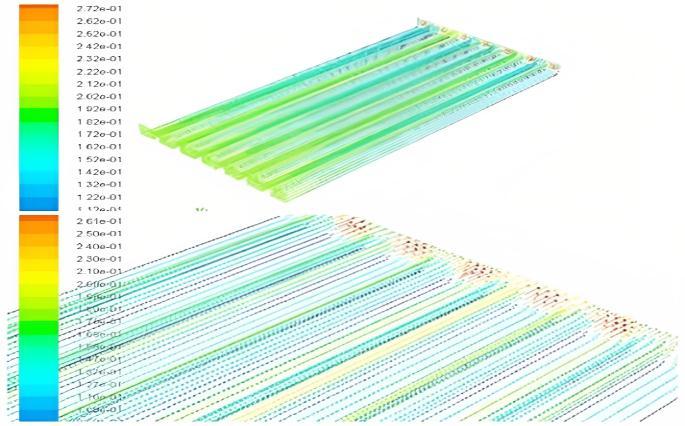

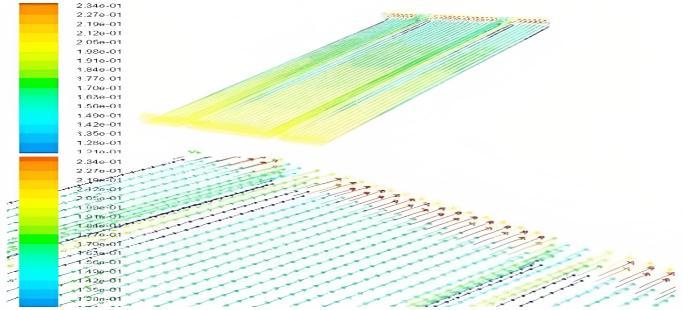

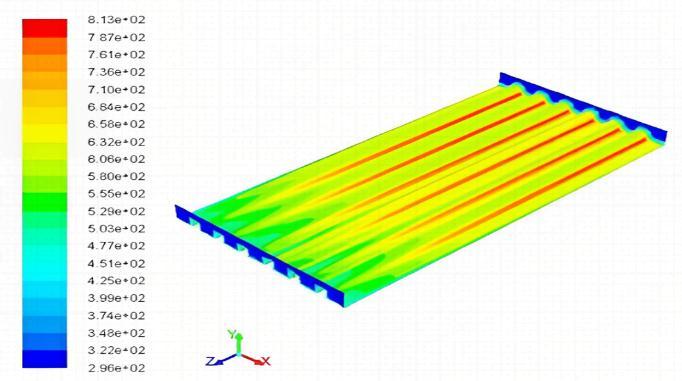

For an air inlet velocity of 0.2 m/s, ambient temperature of 296 K and solar intensity of 618W/m2. Figures (4.2) and (4.3) illustrate respectively the temperature contours and velocity vectors of a flow relative to a solar vector1.98 m long and for different numbers of fins (2 ranges, 4 ranges and6ranges).

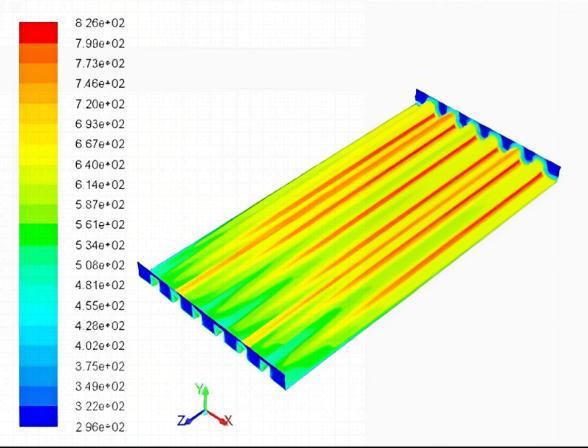

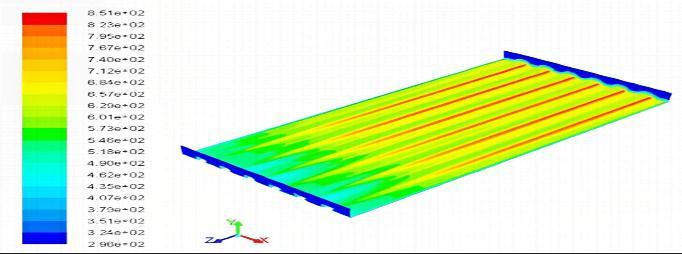

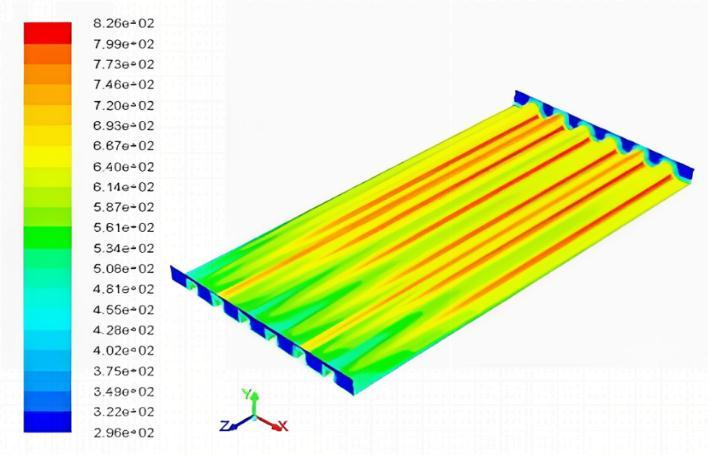

Temperature contour

Figure4.2showstheheatdistributioninthesystem alongthecollector"1.97m"andfordifferentrownumbersof fins2,4and6respectively.Thetemperaturefieldsshownin Figure 4.2 reflect the convective and dynamic structures of laminar flow. Indeed, it is clear that small temperature gradients are generated near the collector inlet, because fresh air of low temperature is always sucked in. However, the temperature began to rise more and more from 1/3 of the channel as it approached the outlet. This is due to the heatexchangebetweentheabsorberandtheair.

Wenoticethatthefluidacceleratesjustupstreamof the channel and it begins to decrease as it approaches the exit, this is explained by the friction with the walls of the collector and also with the fins, this friction generates in general the resistance to movement and consequently gives

risetoa phenomenonofbraking.Thelowestvelocityvalues areobservedinthevicinityoftheabsorber-fincontactangle.

Table4.1:Comparisonbetweentheaverageairvelocityat theoutletforthethreenumbersofrows.

Accordingtofigure4.3and table4.1,theaveragevelocityof the air outlet at the system level remains constant for all threecases.Becauseofflowconservation(Qinput=Qoutput)

We know that there is a direct relationship between flow, areaandspeedQ=V.S

VenturedSinput=VoutputSoutput(Sinput=SoutputVin =Voutput).

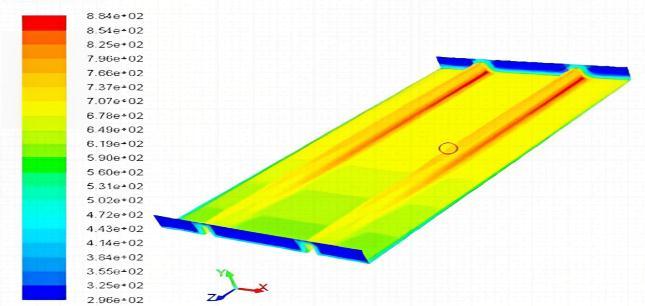

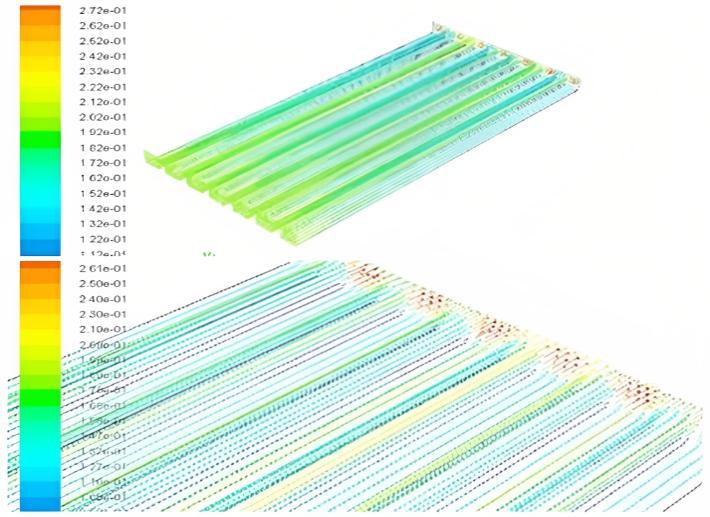

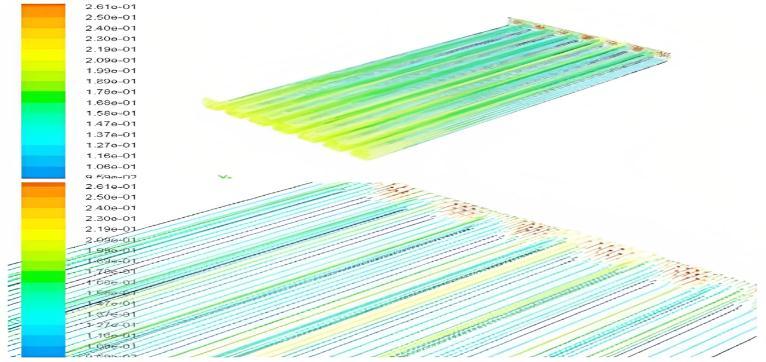

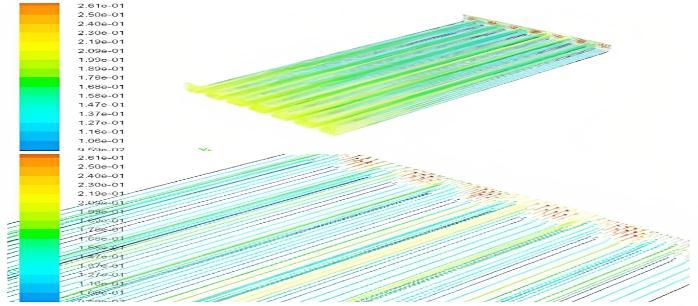

Influence of fin height

The results shown in Figures 4.4 and 4.5 illustrate the evolution of the velocity fields and the temperature contour ofa flowrelativetoa solarcollectorfordifferentfinheights in a collector of length and width of 1.97m and 0.98m respectivelyandforasolarintensityof618W/m2.

Figure 4.4 shows the heat distribution in a system 1.98mlongand0.98mwidewithsixrowsoffinsofdifferent heights:0.03,0.05and0.07m.Themeantemperaturevalues at the collector output for the three different fin heights are shown in Table 4.2. The results show a significant temperaturedifferencefromonecasetoanother,thecaseof

the solar collector of 0.07m height of fins has a significant average temperature at the exit compared to the other two cases. Result shows a proportionality between the height of finsandthetemperatureattheoutletandthisbecauseofthe increaseinthecatchmentsectionwhichdependsdirectlyon theheightoffins.

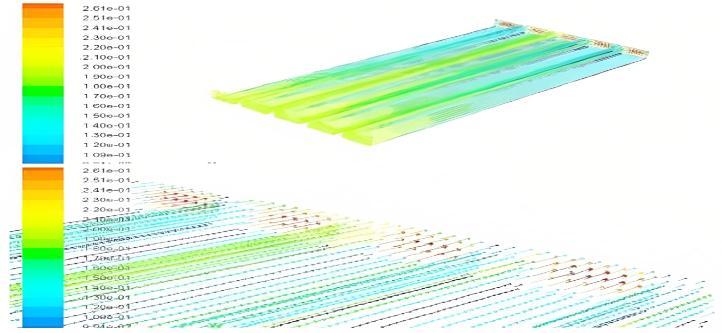

Velocity fields

Figure 4.5 shows the velocity vector field for a solar collectorwithsixrowsoffinsofdifferentheights:0.03,0.05 and 0.07m. From the figures presented, it can be seen that thereisnodifferenceinvelocitybetweentheinletandoutlet in the stack for all three cases, a logical result because it confirmstheprincipleofconservationofmass.

Thevelocityvectorfieldspresentedforthedifferent cases show low velocities in the vicinity of walls, this is frictionphenomena.Theincreaseinfinheightcontributesto the increase in the exchange surface and therefore has a thermal advantage but on the other hand it is associated by additionalpressuredrops.

Evolution of the average temperature as a function of solar intensity

The results were taken for the following input parameters foreachmodel:

Aninputspeedof0.2m/s.

Anambienttemperatureof298K.

a. For the three different

b. For the three different fin heights

rowsoffins.

Figures4.6and4.7showthevariationofthemean temperature at the collector output as a function of the intensityofsolarradiationforthesixmodels studied.There isalinearincreaseinalltemperatures. AccordingtoFigures 4.6 and 4.7, the temperatures at the collector output of 6 ranges and the collector of 0.07 fin heights are high compared to other models, therefore, the figures above confirm the proportionality between the temperature at the collectoroutputanditsexchangeface.

As expected, temperature values and flow are gradually increased until they reach a maximum value at noon,andthendecreaselaterattheendoftheday.Itshould be noted that the maximum values of the average temperatureatthecollectoroutputreach394.56and404.95 respectivelyforthegreatestheight0.07andforthecaseof2 rows.

Average temperature evolution at output as a function of input velocity

The results were taken for the following input parameters foreachmodel:

Asolarintensityof618W/m2.

Anambienttemperatureof298K.

a. For the three different number of rows

behaviour of air in a solar collector. Therefore, in order to achieve the desired goal, ANSYS FLUENT code was used to perform a numerical simulation of convective flow and visualizethevariousphenomenaaffectingtheflow.

Forthesuccessofthisthesisandtoputourresults in accuracy, a validation work of our numerical model was carriedoutbycomparingthemwithexperimentalresults.A goodagreementwasreachedbetweenthem.

In this study, we proposed six solar collector models in total, three different number of rows and three different heights of fins. The thermos convective structure and dynamic behaviour of the flow were also analysed and interpreted for different values of solar radiation and air velocityattheinletofthecollector.Thisallowedustodraw multipleconclusions.

Theincreaseinthenumber ofrowsplays a veryimportant role in the thermal structure of the air flow, it significantly increases the absorber temperature and the air temperatureattheoutletofthecollector[19].

The increase in temperature at the solar collector outlet lays the radiative flux capture section and thereforeincreasesproportionallywiththe increase of this section. The air temperature through the collector decreases with increasing air velocity at the chimney inlet. A very significant increase in the temperature of the collector absorber related to the increase in the height of thefins.

In short, given our study, for a good result of a solar collector in the presence of an absorber equipped with longitudinal fins, the collector which has a large number of rows and a fin height exactly the same as the height of the surfacecorepresentstheoptimalcollector”.

Figures

Thefiguresaboveshowthatthereisaninverserelationship between velocity and temperature, where each time air velocity entering the collector increases, the more the averagetemperatureatthecollectoroutputisdominated.

CONCLUSION

The main objective of this “work is to improve the performance of a solar collector in the presence of an absorber equipped with longitudinal fins. This thesis consists of a numerical study of the thermal and dynamic

REFERENCES

[1] Sharma, S.P. and Saha, S.N. (2017) Thermohydraulic Performance of Double Flow Solar Air Heater with Corrugated Absorber. International Journal of Energy andPowerEngineering,11,779-785.

[2] Kalash, A.R., Shijer, S.S. and Habeeb, L.J. (2020) Thermal Performance Improvement of Double Pass Solar Air Heater. Journal of Mechanical Engineering ResearchandDevelopments,43,355-372.

[3] Ozgen, F., Esen, M. and Esen, H. (2009) Experimental Investigation of Thermal Performance of a Double-

Flow Solar Air Heater Having Aluminium Cans. Renewable Energy, 34, 2391-2398. https://doi.org/10.1016/j.renene.2009.03.029

[4] González, S.M., Larsen, S.F., Hernández, A. and Lesino, G. (2014) Thermal Evaluation and Modeling of a Double-Pass Solar Collector for Air Heating. Energy Procedia, 57, 2275-2284. https://doi.org/10.1016/j.egypro.2014.10.235

[5] Adil,M.,Ibrahim,O.,Hussein,Z.andWaleed,K.(2015) Experimental Investigation of SAHs Solar Dryers with Zigzag Aluminum Cans. International Journal of Energy and Power Engineering, 4, 240247.https://doi.org/10.11648/j.ijepe.20150405.11

[6] Korti, A.I.N. (2015) Numerical 3-D Heat Flow Simulations on Double-Pass Solar Collector with and without Porous Media. Journal of Thermal Engineering, 1, 10-23.

https://doi.org/10.18186/jte.86295

[7] Nowzari, R., Aldabbagh, L.B.Y. and Mirzaei, N. (2011) Experimental Study on Double Pass Solar Air Heater with Mesh Layers as Absorber Plate. International Journal of Electronics, Mechanical and Mechatronics Engineering,3,673-682.

[8] Ho, C., Lin, C., Yang, T. and Chao, C. (2014) Recycle Effect on Device Performance of Wire Mesh Packed Double-PassSolarAirHeaters.Energies,7,7568-7585.

https://doi.org/10.3390/en7117568

[9] Aldabbagh, L.B.Y., Egelioglu, F. and Ilkan, M. (2010) Single and Double Pass Solar Air Heaters with Wire Mesh as Packing Bed. Solar Energy, 35, 3783-3787

https://doi.org/10.1016/j.energy.2010.05.028

[10] Ramani, B.M., Gupta, A. and Kumar, R. (2010) PerformanceofaDoublePassSolarAirCollector.Solar Energy, 84, 1929-1937. https://doi.org/10.1016/j.solener.2010.07.007

[11] Omojaro, A.P. and Aldabbagh, L.B.Y. (2010) Experimental Performance of Single and Double Pass Solar Air Heater with Fins and Steel Wire Mesh Absorber. Applied Energy, 87, 3759-3765. https://doi.org/10.1016/j.apenergy.2010.06.020

[12] Maraba, G. (2012) An Experimental Study on Enhancement of Heat Transfer in a Solar Air Heater

Collector by Using Porous Medium. October 2012 Izmir, Department of Mechanical Engineering, Iztech. A Thesis Submitted to the Graduate School of Engineering and Sciences of İzmir Institute of Technology.