Comparative Analysis of Design Optimization Techniques for Thermodynamic Radiators in Cooling Systems

Prayas Tiwari Dhirendra Patel Rishav Singh Rajput Mechanical Engineering Amity University Greater Noida Amity University Greater Noida Amity University Mechanical Engineering Assistant Professor

***

Abstract:

Thermodynamic radiators play a crucial role in cooling systems by providing efficient heat transfer. This research paper focuses on the optimization of thermodynamic radiator designs to improve energy efficiency in cooling systems. The paper presents an overview of various subtopics, including design optimization techniques, sensitivity analysis of design parameters, multi-objective optimization, advanced materials, smart control strategies, and economic analysis. The paper discusses the latest research and innovations in these areas, highlighting their potential for enhancing radiator performance and energy efficiency. The findings of this research contribute to the understanding of optimized radiator designs and their impact on energy efficiency in cooling systems. The paper provides valuable insights for researchers, engineers, and practitioners interested in the optimization of thermodynamic radiator designs for improved energy efficiency, with implications for sustainable cooling technologiesinvariousapplications.

Keywords:

Thermodynamic radiators, Optimization, Energy efficiency, Cooling systems, Radiator design, Mathematical modelling, Computational fluid dynamics

1. Introduction

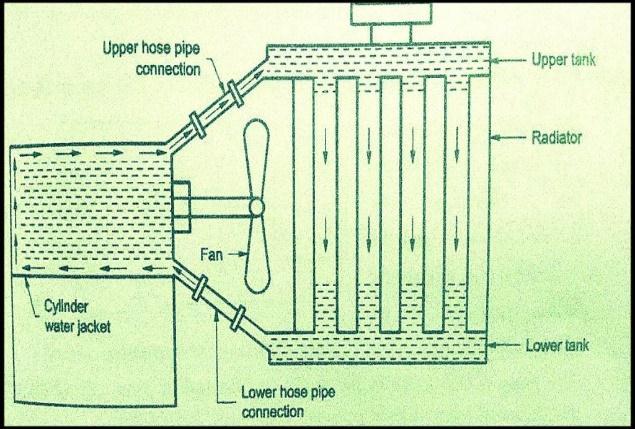

Overview of Thermodynamic Radiators in Cooling Systems

Thermodynamic radiators are critical components inmoderncoolingsystems,providingefficientheattransfer to achieve effective cooling. They are designed to transfer excessheatfromasystemtothesurroundingenvironment, thereby maintaining optimal operating conditions and preventingoverheating. Thermodynamic radiators operate on the principles of conduction, convection, and radiation, and are commonly used in various applications, including air conditioning systems, refrigeration systems, and heat exchangers.

The basic principle of thermodynamic radiators involves the transfer of heat from a higher temperature region to a lower temperature region. This is achieved

through the transfer of thermal energy from the working fluid or coolant inside the radiator to the ambient environment, typically through a combination of conduction,convection,andradiation.Conductionrefersto the transfer of heat through direct contact between the radiatorandthesurroundingmedium,suchasairorwater. Convection involves the transfer of heat through the movementofthecoolantormedium,whichisheatedbythe radiator and then moves away to be replaced by cooler coolant or medium. Radiation, on the other hand, is the transfer of heat in the form of electromagnetic waves, which can occur without any direct physical contact betweentheradiatorandthesurroundingmedium.

In cooling systems, thermodynamic radiators are crucial in dissipating excess heat generated by various components, such as compressors, condensers, and heat exchangers, to maintain optimal operating temperatures. They are typically designed to maximize heat transfer efficiency while minimizing energy consumption and environmental impact. Different types of thermodynamic radiators are used depending on the specific application, including finned tube radiators, plate-fin radiators, and tube-and-shell radiators, among others. These radiators can vary in terms of their geometry, materials, and design configurations to suit the specific requirements of the coolingsystem.

Thermodynamic radiators play a critical role in achieving energy efficiency in cooling systems. Optimized radiator designs can significantly improve the overall performance and energy efficiency of cooling systems by enhancing the heat transfer rate, reducing energy consumption, and minimizing environmental impact. As such, research and development efforts are continually being focused on the optimization of thermodynamic radiator designs to achieve improved energy efficiency in cooling systems. This includes advancements in design techniques,sensitivityanalysisofdesignparameters,multiobjective optimization, utilization of advanced materials, implementation of smart control strategies, and economic analysisofradiatordesigns.

2. Key Parameters Affecting Radiator Design Optimization

The optimization of thermodynamic radiator designs for improved energy efficiency in cooling systems requires careful consideration of various key parameters that impact the overall performance of the radiator. These parametersincluderadiatorgeometry,materialproperties, fluid properties, and operating conditions, and play a criticalroleinthedesignoptimizationprocess.

2.1.RadiatorGeometry

Thegeometryoftheradiator,includingthesize,shape,and arrangement of the heat transfer surface, has a significant impactonitsperformance.Thesizeandshapeofaradiator playacrucialroleindeterminingtheavailablesurfacearea for heat transfer. This, in turn, directly impacts the rate of heat transfer. Moreover, the arrangement of the heat transfersurface,suchasthefinspacingandtubepitch,also plays a crucial role in heat transfer performance. These factors affect the airflow pattern and pressure drop, which can have a significant impact on the heat transfer rate. Therefore, it is essential to optimize the size, shape, and arrangement of the heat transfer surface to achieve maximumheattransferperformanceinaradiator.

Optimization of the radiator geometry involves selecting the optimal size, shape, and arrangement of the heat transfer surface to maximize the heat transfer rate while minimizing the pressure drop and energy consumption.

2.2 MaterialProperties

The material properties of the radiator, including the thermal conductivity, density, and specific heat capacity, also play a crucial role in its performance. The thermal conductivity of the radiator material determines its ability to conduct heat from the working fluid to the ambient environment, and higher thermal conductivity materials resultinbetterheattransferperformance.Thedensityand

specific heat capacity of the material impact its thermal mass and heat storage capacity, which can affect the response time and transient behaviour of the radiator. Optimization of material properties involves selecting materials with appropriate thermal conductivity, density, and specific heat capacity to enhance the overall heat transferperformanceandenergyefficiencyoftheradiator.

2.3 FluidProperties

The properties of the working fluid or coolant used in the radiator also have a significant impact on its performance. The thermophysical properties of the fluid, such as its thermal conductivity, density, viscosity, and heat capacity, affect its ability to carry heat from the radiator to the surroundingenvironment.Thefluidpropertiesalsoimpact thepressuredrop,flowrate,andturbulencecharacteristics within the radiator, which in turn influence the heat transfer performance. Optimization of fluid properties involvesselectingthe appropriateworking fluidorcoolant with favorable thermophysical properties to enhance the heattransferperformanceoftheradiator.

2.4 OperatingConditions

The operating conditions of the radiator, such as the inlet andoutlet temperatures,flowrate,andpressuredrop,also affectitsperformance.Thetemperaturedifferencebetween theinletandoutletoftheworkingfluidisacriticalfactorin determining the rate of heat transfer. Higher temperature differences can lead to more efficient heat transfer. Additionally,theflowrateofthe working fluidplaysa vital role in the radiator's performance, as it affects the velocity and turbulence characteristics within the system. The pressure drop across the radiator is another important consideration, as it impacts the energyconsumption of the cooling system. Optimization of the pressure drop is necessary to minimize energy losses and improve the overallefficiencyofthesystem.

Optimizationofoperatingconditionsinvolvesdetermining the optimal inlet and outlet temperatures, flow rate, and pressure drop to achieve the best performance of the radiatorintermsofenergyefficiency.

The optimization of these key parameters in radiator design is crucial in achieving improved energy efficiency in cooling systems. A thorough understanding of their impact and interplay in the radiator performance is essential for designing radiators with optimal configurations that can maximize the heat transfer performance while minimizing energy consumption and environmental impact. Advanced computational techniques,suchasnumericalsimulationsandoptimization algorithms, can be employed to explore the design space and identify the optimal combination of these parameters forradiatordesignoptimization.

3. Design Optimization Techniques for ThermodynamicRadiatorDesigns

Design optimization techniques play a crucial role in improving the energy efficiency and performance of thermodynamic radiators in cooling systems. These techniques involve the use of mathematical modeling, computational fluid dynamics (CFD), multi-objective optimization, and machine learning-based approaches to optimize the radiatordesignforimprovedperformance.In thissection,wewill discussthese optimization techniques, evaluate their advantages and limitations, and highlight theirpotentialforenhancingradiatorperformance.

3.1 MathematicalModeling

Mathematical modeling involves the use of mathematicalequationsandanalyticalmethodstodescribe theheattransfer,fluidflow,andotherphysicalphenomena occurring in the radiator. These mathematical models can be used to predict the performance of the radiator under different operating conditions and design configurations. Designoptimizationusingmathematicalmodelingtypically involves solving mathematical equations to obtain an optimalsetofdesignparametersthatmaximizethedesired objective, such as heat transfer rate or energy efficiency. One common approach is to use numerical optimization algorithms, such as gradient-based methods or genetic algorithms, to search for the optimal design parameters. Advantages of mathematical modeling include its ability to provide analytical solutions, quick evaluation of design alternatives, and ease of implementation. However, limitations of mathematical modeling can include simplifying assumptions, limitations in capturing complex physicalphenomena,andtheneedforaccurateinputdata.

3.2 ComputationalFluidDynamics(CFD)

CFDisa powerful numerical simulationtechniquethat allows for the detailed analysis of fluid flow and heat transfer in complex geometries, such as thermodynamic radiators. CFD simulations can provide detailed information on flow patterns, temperature distributions, andpressuredropswithin theradiator, whichcan beused for design optimization. CFD-based optimization involves couplingtheCFDsimulationswithoptimizationalgorithms tosearchforthe optimal designparametersthatmaximize the desired objective. CFD-based optimization techniques can consider a wide range of design parameters, such as radiator geometry, material properties, fluid properties, and operating conditions, and can account for complex physics, such as turbulence and transient behavior. AdvantagesofCFD-basedoptimizationincludeitsabilityto capture complex physics, consider multiple design parameters,andprovidedetailedinsightsinto the radiator performance. However, limitations of CFD-based

optimization can include the computational cost, need for expertise in CFD modeling, and challenges in handling uncertaintiesininputdata.

3.3Multi-ObjectiveOptimization

Multi-objective optimization involves optimizing multiple conflicting objectives simultaneously, such as maximizing heat transfer rate while minimizing pressure drop or energy consumption. Multi-objective optimization techniques, such as Pareto-based methods, allow for the exploration of trade-offs between different objectives and can help in identifying a set of optimal design solutions knownastheParetofront.TheParetofrontrepresentsthe best compromise solutions, and the final design decision can be made based on decision-maker preferences. Multiobjective optimization can be applied to thermodynamic radiator designs to identify optimal design solutions that balance different performance objectives, such as heat transfer performance, pressure drop, and energy consumption. Advantages of multi-objective optimization include its ability to explore trade-offs between conflicting objectives and provide a range of optimal solutions. However, limitations of multi-objective optimization can include the need for decision-maker preferences, complexity in handling multiple objectives, and computationalcostinfindingtheParetofront.

3.4 MachineLearning-basedApproaches

Machine learning-based approaches are gaining increasing attention in the field of radiator design optimization.Machinelearningalgorithms,suchasartificial neural networks, support vector machines, and decision trees, can be trained on large datasets of radiator performance data to learn complex relationships between design parameters, operating conditions, and radiator performance. Oncetrained, these machinelearningmodels can be used for design optimization by predicting the performance of radiators for different design configurationsandoperatingconditions.Machinelearningbased approaches can offer several advantages, including their ability to capture complex relationships, handle uncertainties in data, and potentially reduce the computational cost compared to traditional numerical simulations. Machine learning-based approaches can also enable the exploration of a large design space and provide insights into the underlying factors that affect radiator performance. However, limitations of machine learningbased approaches can include the need for large and representative datasets for training, potential issues with overfitting, and challenges in interpreting the results and ensuringthereliabilityofpredictions.

4. Performance evaluation of optimized radiatordesigns

Performance evaluation is a crucial step in assessing the effectiveness of optimized radiator designs. Various methods and techniques can be employed to evaluate the performance of optimized radiator designs, including experimental measurements, numerical simulations, and performanceindicators.

Experimental measurements involve conducting physical experiments on real or scaled radiator prototypes to measure relevant performance parameters such as heat transfer rate, pressure drop, and energy consumption. Theseexperimentscanprovidevaluabledataforevaluating the performance of the optimized radiator designs in realworld conditions. Experimental measurements also allow forvalidationandverificationofthenumericalsimulations and performance indicators used in the optimization process. The results obtained from experimental measurements can provide insights into the actual performanceoftheoptimizedradiatordesignsandvalidate theeffectivenessoftheoptimizationtechniquesapplied.

Numerical simulations, such as computational fluid dynamics (CFD), are widely used in the evaluation of radiator performance. CFD simulations can provide detailed insights into the heat transfer and fluid flow behaviorwithintheradiator,allowingfortheassessmentof the impact of design parameters on performance. CFD simulations also enable the prediction of performance indicators, such as heat transfer rate, pressure drop, and temperaturedistribution,fordifferentradiatordesignsand operating conditions. These simulations can be used to compare and evaluate the performance of optimized radiator designs under different scenarios, and provide a cost-effectiveandtime-efficientwaytoassessperformance.

Performanceindicators,suchasheattransferrate, pressure drop, and energy consumption, are quantitative metrics used to evaluate the performance of optimized radiator designs. These indicators can be calculated based on the results obtained from experimental measurements ornumericalsimulations.Heattransferrateisanimportant performance indicator as it directly relates to the cooling capacity of the radiator. Pressure drop is another crucial indicator as it affects the fluid flow resistance in the radiator and can impact the overall system performance. Energy consumption is also an important indicator as it relates to the operational cost and energy efficiency of the radiator.

Theresultsofrelevantstudiesontheperformance evaluation of optimized radiator designs can be presented and analyzed in the research paper. These results can provide insights into the performance improvements

achieved through the optimization process, and highlight the effectiveness of the applied methods and techniques. Theanalysisoftheresultscanalsoincludeacomparisonof the performance of optimized radiator designs with conventional radiator designs or other cooling technologies, as well as an evaluation of the trade-offs betweendifferentperformanceindicators.

5.Conclusion

In conclusion, the optimization of thermodynamic radiator designs for improved energy efficiency in cooling systems is a significant and timely research topic. This research paper has provided a comprehensive overview of thermodynamicradiators,theirprinciples,andtheirrolein coolingsystems.Ithashighlightedthekeyparametersthat impact radiator design optimization, including radiator geometry, material properties, fluid properties, and operating conditions. Various design optimization techniques, such as mathematical modeling, computational fluid dynamics (CFD), multi-objective optimization, and machine learning-based approaches, have been discussed, evaluating their advantages, limitations, and potential for improvingradiatorperformance.

The paper has also discussed the importance of performance evaluation methods, including experimental measurements, numerical simulations, and performance indicators, in assessing the effectiveness of optimized radiator designs. The results of relevant studies and experiments can provide valuable insights into the performance improvements achieved through the optimization process and highlight the effectiveness of the appliedmethodsandtechniques.

Furthermore, the paper has highlighted the potential benefitsofoptimizedradiatordesignsintermsofimproved energy efficiency in cooling systems, which can lead to reduced energy consumption, lower operational costs, and reduced environmental impact. It has also identified current challenges and areas of improvement in radiator design optimization, such as the need for more accurate modeling techniques, improved performance indicators, andfurthervalidationofresults.

The findings of this research paper contribute to a comprehensive understanding of thermodynamic radiator design optimization and its potential for improving energy efficiency in cooling systems. The research can provide valuable insights for researchers, engineers, and practitionersinthe field of thermodynamics,heat transfer, and energy management. Further research in this area can contribute to the development of more advanced radiator designs and optimization techniques, leading to more energy-efficientcoolingsystemsandasustainablefuture.

[1] R.Zaky,A.H.Mahmoud,andM.A.Badr,“Modeling and simulation of a Peltier solar refrigeration system,” International Journal of Refrigeration, vol. 35, no. 7,pp.1934–1945,2012.

[2] R. Srivastava, J. Arun and D. K. Patel, "Amalgamating the Service Quality Aspect in Supply Chain Management," 2019 International Conference on Automation, Computational and Technology Management (ICACTM),London,UK, 2019, pp. 6367,doi:10.1109/ICACTM.2019.8776839.

[3] Bejan,A.(2013).ConvectionHeatTransfer,4thEdition. JohnWiley&Sons.

[4] Incropera, F.P., and DeWitt, D.P. (2006). Fundamentals ofHeatandMassTransfer,6thEdition.JohnWiley &Sons.

[5] Balani, R.S., Patel, D., Barthwal, S., Arun, J. (2021). Fabrication of Air Conditioning System Using the Engine Exhaust Gas. In: Kapur, P.K., Singh, G., Panwar, S. (eds) Advances in Interdisciplinary Research in Engineering and Business Management. Asset Analytics. Springer, Singapore. https://doi.org/10.1007/978-981-16-0037-1_29

[6] Holman, J.P. (2010). Heat Transfer, 10th Edition. McGraw-HillEducation.

[7] D.Patel,A.SharmaandA.Mishra,"StudyofConvective Heat Transfer Characteristics of Nano Fluids in Circular Tube," 2021 International Conference on Technological Advancements and Innovations (ICTAI), Tashkent, Uzbekistan, 2021, pp. 264-267, doi:10.1109/ICTAI53825.2021.9673432.

[8] Deb,K.(2001).Multi-objective Optimization Using EvolutionaryAlgorithms.JohnWiley&Sons.

[9] Dargahi, B., and Vinet, L. (2014). Advances in Heat TransferEnhancement.CRCPress.

[10] Kim, S., and Cho, J.Y. (2018). Heat Exchanger Design: Heat Transfer Analysis, Optimization, and ComputationalFluidDynamics.CRCPress.

[11] D. Patel, R. P. Singh, R. S. Rajput and P. Tiwari, "Thermophyscical Properties And Applications Nanofluids – On Review,"2022 5th International Conference on Contemporary Computing and Informatics (IC3I), Uttar Pradesh, India, 2022, pp. 1324-1328, doi: 10.1109/IC3I56241.2022.10072842.

[12] Patankar,S.V.(1980).NumericalHeatTransferand FluidFlow.CRCPress.

[13] A. K. Singh and D. Patel, "Optimization of Air Flow Over a Car by Wind Tunnel," 2020 International Conference on Computation, Automation and Knowledge Management (ICCAKM), Dubai, United Arab Emirates, 2020, pp. 1-4, doi: 10.1109/ICCAKM46823.2020.9051457.

[14] Luo,L.,andWang,Q.W.(2014).GeneticAlgorithms and Genetic Programming: Modern Concepts and PracticalApplications.CRCPress.

[15] D. Patel, A. Mishra and M. Nabeel, "Heat Transfer Characteristics of Nanofluids of Silicon Oxides (Sio2) with Conventional Fluid," 2022 2nd International Conference on Innovative Practices in Technology and Management (ICIPTM), Gautam Buddha Nagar, India, 2022, pp. 420-423, doi: 10.1109/ICIPTM54933.2022.9754181.

[16] Versteeg, H.K., and Malalasekera, W. (2007). An Introduction to Computational Fluid Dynamics: The Finite Volume Method, 2nd Edition. Pearson Education

[17] Patel D, VARMA IP, Khan FA. A Review Advanced VehiclewithAutomaticPneumaticBumperSystem usingTwoCylinder.

[18] Zhang, J., and Chen, G. (2015). Nanofluids: FundamentalsandApplications.CRCPress.

[19] Özerdem, B. (2019). Handbook of Research on Nanofluid-Based Heat Transfer in Renewable EnergySystems.IGIGlobal.

[20] Bishop, C.M. (2006). Pattern Recognition and MachineLearning.Springer.