Treatment Of Black Cotton Soil To Increased It’s Stability And Bearing Capacity Using Cement Slurry

1 Asst. Professor, Dept. of Civil Engineering at Dhole Patil College of Engineering, Pune, Maharashtra

2,3,4,5,6 Under Graduated, Dept. of Civil Engineering of Dhole Patil College of Engineering, Pune, Maharashtra ***

Abstract - Black cotton soils are good for agriculture but it has low bearing capacity than other soils and prefer for the construction of high-story buildings and highways. The black cotton soil has high swelling properties inthe rainyseasonand has high shrinkage in the property in the summer season. Soil stabilization is having different methods and material that improves physical soil characteristics such as an increased bearing capacity of soil and increased shear resistance can be done by adding waster material, jute fiber, fly ash, lime, cement, and adding different admixture for compactingfor the subgrade stabilization of the building, high storage, heavy bridges, railway track, and highway

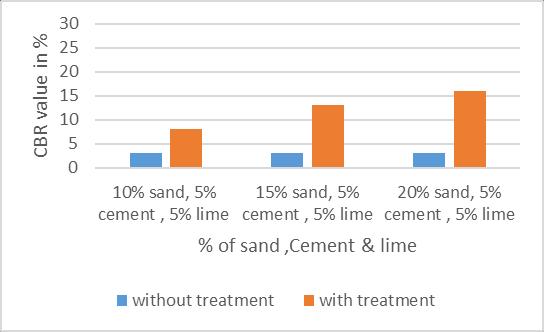

Hence in this paper, we conducted soil stabilization using cement, lime, and sand on black cotton soil for the improvement in the properties of black cotton soil as stability, reduced in reduced shrinkage by using cement slurry, sand, and lime in varying percentages. (Soil + 10%Sand+5%Lime + 5% Cement, Soil + 15% Sand +5% Lime + 5% Cement, Soil + 20% Sand +5% Lime + 5% Cement) Laboratory tests were undertaken to study the strength characteristics of back cotton soil with cement, sand, and lime

Key Words: Black cotton soil, Stabilization, Cement slurry, increasing stability

1. INTRODUCTION

Blackcottonsoilcovers20%ofIndia'slandarea,mostlyin Gujarat, Maharashtra, M.P., South U.P., and portions of Karnataka, A.P., and Tamilnadu. Soils have high consolidation settling and are particularly compressive whentheyaresaturated.Thehighswellingcharacteristicof these soils causes harm to the structure. Black cotton soil losesalotofitsbearingabilityduringtherainyseasonasa resultof waterfilling up the cracksandcrevices. Thissoil contracts during the dry season, causing uneven building settlement,cracksinwallsandfloors,etc.

Enhancingthestrengthorcarryingcapacityofsoilthrough controlledcompaction,proportioning,and/ortheadditionof theappropriateadmixtures orstabilisersisknownassoil stabilisation.Inordertobooststrengthanddurabilityunder designusageconditionsandtoextendthedesignlifeofthe engineeringproject,soil,anaturallyoccurringsubstance,is

stabilised.Thecharacteristicsofthesoilwillvarydepending on its location, physical characteristics, and other factors. Several ways are available to stabilise the soil, but they shouldfirstbetestedinalabsettingwithactualsoilbefore beingusedinactualfieldsettings.

Image no 1 black cotton soil in India

Itisnecessarytoimprovethedesirablepropertiesofthose soils because the fundamental property of the soil should have sufficient strength & load bearing capacity so that externalloadsmaybepassedtothelowerlayerseffectively withoutexperiencinganystructuralfailure.

The long-term physical and chemical change of soil will improve its physical properties, which can improve shear and unconfined compressive strength and permanently lower the soil's permeability to water. Soil stabilisation shouldbecost-effective.

2. LITERATURE REVIEW

I. Likhitha. H, Raghavendra.H. N, Rakesh. K.P (2018): Thelaboratorytestwasconductedonblack cottonsoilwherethestabilizerusedwherecement, andM-sandatvaryingpercentages,Herethebasic test was conducted like specific gravity, water content,liquidlimit,plasticlimit,optimummoisture content, and maximum dry density they conclude thatengineeringpropertiesofsoilcanbeincreased bymakinguseofstabilization.

II. BadalBankar,Dr.SatishPatil,RajshekharRatho (2021): In this paper behavior of soft soil was studied by stabilizing it with geogrid as a reinforcement element and various proportions (0%,2%,4%,6%,&8%)ofcement.Thisshowsthe increaseinthestabilityandbearingcapacityofthe subgradesoilatdifferentproportions.Inproportion to(BCsoil+Geogrid+6%cement)theCBRtestwas highestat18.24andat(BC+Geogrid+8%cement)the CBRvaluedecreasedto17.59.

III. V. Ramesh Babu, V. Ramesh Babu, Dr. B. Ramesh Babu (2016): The present work is done in stabilizingtheblackcottonsoilbyusingcementand sand.Inthisworktestsconductedwereplasticlimit, liquidlimits,specificgravity,standardproctortest, unconfinedcompressiontest,andCaliforniabearing ratio for the proportion of sand was taken 10%, 20% 30%, 40 and cement was taken 2% of black cottonsoil.

IV. Puneeth A, Ajay Nagaraj*, Aravind Sagar B(2021): Puneeth A, Ajay Nagaraj*, Aravind Sagar B(2021): The ground granulated blast furnaceslagandthe cementwereusedinthiswork for the laboratory test was carried out for the different proportion combinations of black cotton soilandbinders.Andinthispapershowanincrease inthebearingcapacityofsoil

2. OBJECTIVE

Conducting the detailed laboratory tests to find the propertiesofsoil

Increasing stabilization of the soil by adding cement, sand,andlime

3. MATERIAL

I. Cement: - Weused5%Portlandpozzolaniccement(250 gm) of 5 kg of black cotton soil for the experiment. The additionofcementtosoil,whichactsasabindingagentand produces a weak form of concrete called soil cement. The amount ofcementtoberequiredisdependsuponthetype

ofthe soil.Thecementiscanbeusedforthemosttypesof soil

II. M Sand: - Weused10%,15%,and20% manufactured sand of 5 kg of black cotton soil. M-sand is manufacture artificialbycrushinghardstonesintosmall.Wehavetaken the size of manufactured sand (M-sand) as less than 4.75 Sand used for the work is clean and coarse sand passing through a 4.75 mm sieve was oven dried for 24 hr. and cooleddown

III. Lime: - Weused5%Limeof5kgofblackcottonsoilthe limeprovideshighwaterretentionthatallowsformaximum earlycuringofthecementitiousmaterials.WeusedFinelime forthisexperimenttheovendryfor24hrs.andcooleddown thelime.

4. EXPERIMENTAL PROCEDURE

Theprimarypropertiesofblackcottonsoilaredetermined. Thenthesoilisthenstabilizedwithsand,cement,andlime. Theamountofsandforstabilizationistakeninthedifferent proportionsof10%,15%,and20%bydryweightofsoil,and theamountofcementandlimewastakenas5%respectively bydryweightofsoil.Usingtheseproportions,mixsamples werepreparedasgivenbelowandasetoflaboratorytests were performed specific gravity, liquid limit, plastic limit, and moisture content. The CBR and modified proctor test valuesofbothnaturalsoilandmixedproportionsamples.

1)BlackCottonSoil(5kg)

2)Soil+10%Sand+5%Lime+5%Cement

3)Soil+15%Sand+5%Lime+5%Cement

4)Soil+20%Sand+5%Lime+5%Cement

4.1 Modified Proctor Test:

The 3 kg of black cotton soil was taken. Then the sample passedby4.75mmsievedthendriedinanovenfor24hours. After this, the sample was left to cool down at room temperaturefor30 minutes and then filledin threelayers intoastandardmold.Eachlayerwascompactedbyahammer with25blows,andaftercompaction,thecollarwasdetached, andtheextrasoilwasremovedfromthetopofthemold.The total weight of wet soil with the mold is measured. A representative portion ofthe soil in the moldisutilizedto obtain the value of moisture content. Repeated tests are conductedbyintroducingadditionalwater,roughly2%ata time, until the weight of the mold stacked with wet soil decreases.Thistestprocedureisalsoperformedforvarious soilsamplesthatcontaindifferentpercentagesofsand,lime, andcement.thesampleofsoil+10%Sand+5%Lime+5% Cement, Soil + 15% Sand +5% Lime + 5% Cement, Soil + 20%Sand+5%Lime+5%Cementrespectively

4.2 Specified Gravity Test

After obtaining a 200-gram sample, it is passed through a sievewithaporesizeof4.75mmandthendriedinanoven for 24 hours. Once removed from the oven, the sample is allowed to cool to room temperature for 30 minutes. The specificgravityisthenmeasuredusingadensitybottle,using theprocedureoutlinedinIS2720(partII)1980.

4.4 Plastic Limit Test

Intheplasticlimititisthemoisturecontentinthesoilwere thesoilisbehavelikeaplastic.

4.3 Liquid Limit Test

The50gmofsoilsamplewastakenanditwasovendriedfor 24hoursafter24hoursletcooleddownatroomtemperature for30minutes.Anditistakenintothecupcloserto10mm andgiventhe20blowinthestandardmanner.

4.5 Moisture Content Test

Wetakeasampleofsoilweighing50gramsandplaceitinan empty container. The container is weighed and then oven driedfor24hoursatatemperatureof1100.Afterdrying,the containerisallowedtocooldowntotheroomtemperature

4.6 California Bearing Ratio Test

IntheCaliforniabearingratiowehavetaken5kgsamplefor eachtestweconducted4testinCaliforniabearingratio(soil, Soil+10%sand+5%cement+5%lime,Soil+15%sand+5% cement+5% lime, Soil+ 20% sand+ 5% cement+5% lime) comparethemwitheachother.Firstweovendriedthesoil for 24 hours after 24 hour cooled down the soil in room temperaturefor30minutesthenmixeditwithdesiredwater thenfixedtheextensioncollartothetopthemoldandthe vaseplatetoitsbottom.Afterinsertthespacerdiscoverthe baseandthenputafilterpaperonthetopofthespacedisc and compact the soil in the soil the we use heavy compaction. We used 5 layer of soil in mold compacted it with 56 blow for each layer then removed the excess soil

thenturnthemoldupsidedownandthenremovedthebase plate and the displacer disc. Then weight the mold for determinationofbulkdensityanddrydensity.Thenputthe filterpaperonthetopofthecompactedsoilandperformed theCaliforniabearingratio. Chart -1

6. CONCLUSIONS

Accordingtotheresultsoftheearlierstudies,material

cement, sand, and lime can be used to strengthen the stability of black cotton soil. The region of BC soil will be suitableforlayingpavementsifthedensityofthesoilgrows sinceitsupportsanincreaseinCBRvalue.

7. REFERENCES

1) Stabilization of Black Cotton Soil by Admixtures by Shreyaskrishnappa,augest2017

2) Case study on an Improvement of bearing capacity of sandysoilbygroutingbyBeenishJehan2017

3) Strength Improvement of Loose Sandy Soils Through CementGroutingbySanthosKumar,India Instituteof ScienceCase

4) Studyonimprovementofbearingcapacityofsandysoil bygroutingbySrinivasGanta,IJITR2017

5) Study on improvement of bearing capacity of soil by groutingbyGopalsamy.P,IRJET2017.