SHEAR RESPONSE OF DUAL STEEL COMBINED COMPOSITE COLUMNS IN NON PRISMATIC CONDITION

Abhina Meenu M.N.1 , Nikhil R.21Student,Dept.of civil Engineering, Universal Engineering College, Vallivattom, Kerala, India

2Assistant Professor, Dept. of Civil Engineering, Universal Engineering College, Vallivattom, Kerala, India ***

Abstract - Concrete-filled double-skin steel tube (CFDST) is a composite structure, in which concrete fills the gap between the inner and outer steel tubes. It was firstly guided as a new form of construction for deep water vessel to resist external pressure. Compared with the solid concrete-filled steel tube (CFST), CFDST is featured by its large bending stiffness, light weight, and good fire resistance. With the great prospect for engineering applications, CFDST is suitable to be used as the construction of bridge piers, power transmission towers, offshore platforms, and super high-rise buildings. As the CFDST members frequently used, researchers found that in some cases, for example during the earthquakes, the liquefaction and lateral spreading of soils caused by earthquakes may lead to extremely high shear force on drilled-shaft foundations. Moreover, with the occurrence of impact accidents or earthquake, the bottom columns of structures, such as the piers of bridge and columns of building, will be inevitably endure significant shear force, making them prone to suffer shear failure. This project attends to analyse the shear response of CFDST of various cross sections in primatic and non-prismatic conditions. A total of thirty-five specimens had tested to investigate and compare the shear response. The influence of shear span ratio, hollow ratio, type of cross section, dimensions of columns were studied. Numerical modelling of CFDST columns are doing in finite element modelling software ANSYS Workbench.

Key Words: CFDST, shear span ratio, mechanical performance, material properties, sustainability.

1. INTRODUCTION

Concrete-filled double-skin steel tube (CFDST) is a composite structure, in which concrete fills the gap between the internalandoutersteeltubes.Itwasfirstlyguidedasanewformofconstructionfordeep watervesseltoresistexternal pressure. Compared with the solid concrete-filled steel tube (CFST), CFDST is featured by its large bending stiffness, increase in section modulus, enhancement in stability, better damping characteristics, better cyclic performane, light weight,andgoodfireresistance.Withthegreatprospectforengineeringapplications,CFDSTissuitabletobeusedasthe construction of bridge piers, power transmission towers, offshore platforms and super high-rise buildings. CFDST commonly is used and have different outer shapes e.g., circular-in-circular, circular-in-square, and square-in-square according to structural type and function. For instance, specimens with outer circular section are widely used in the construction of bridge piers or power transmission towers because of the strong confinement effect that outer circular steelprovidedwhileoutersquaresectionofspecimensiscommonlyadoptedinthehigh-risebuildingsconstructionowing toitseasyforbeam-columnjointconnection.

2. PROPERTIES OF SECTIONS

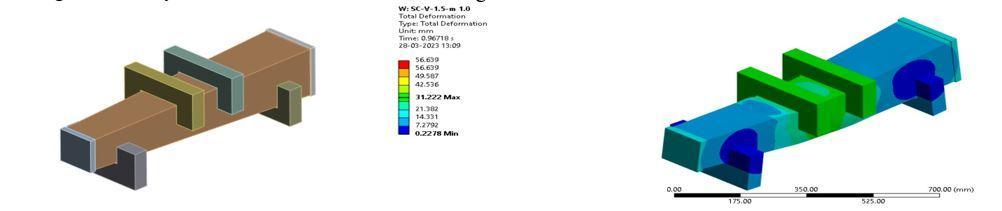

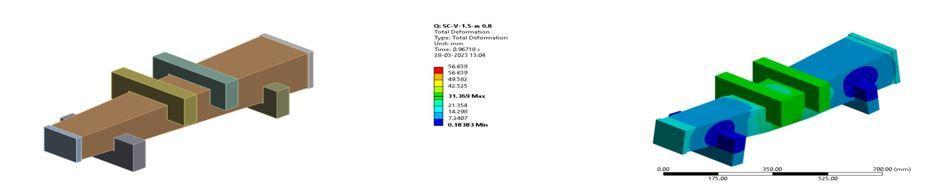

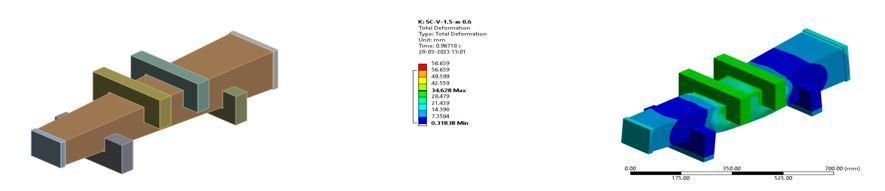

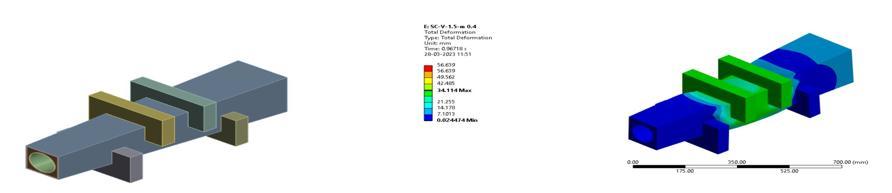

ANSYSWorkbenchwasusedtodevelopthethree-dimensionalmodelandnonlinearsimulations.Atotalof24modelswere developed in order to find the optimum shear span ratio for the shear capacity. Shear span ratios 0.4, 0.6, 0.8, 1.0 were selected for comparing the shear capacities. A tapered ratio of 1.5 is used in the models. The dimensional parameters of studiesareshownintheTable1.

3. ANALYZED SPECIMEN

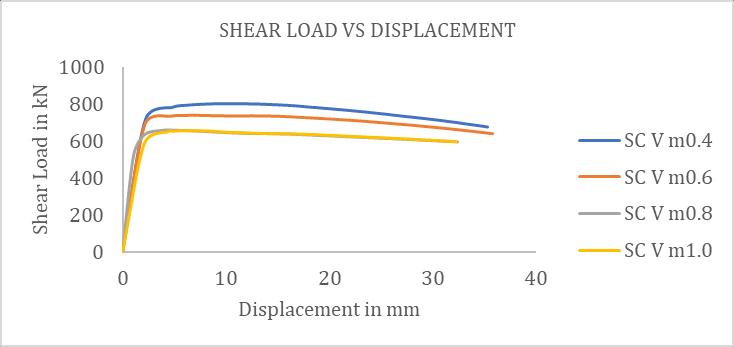

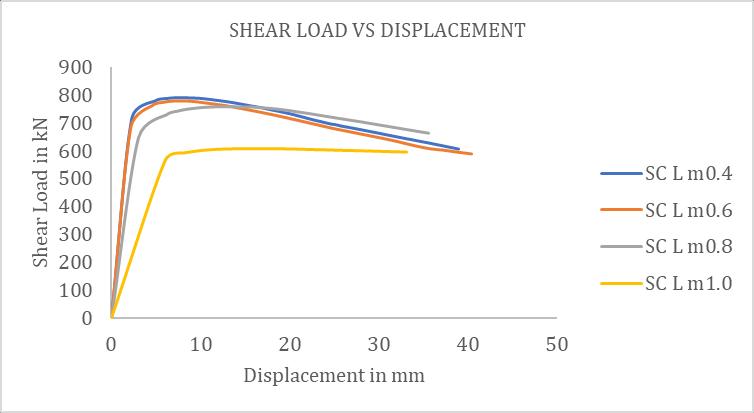

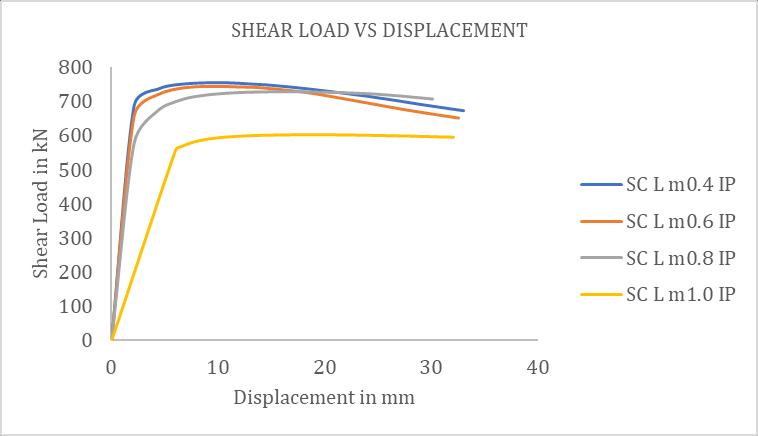

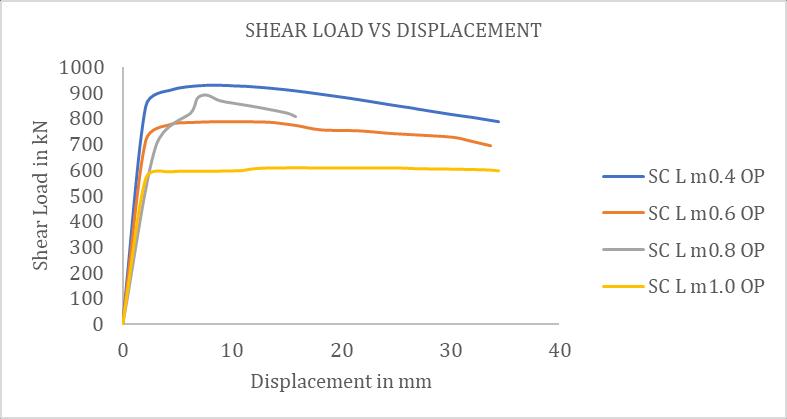

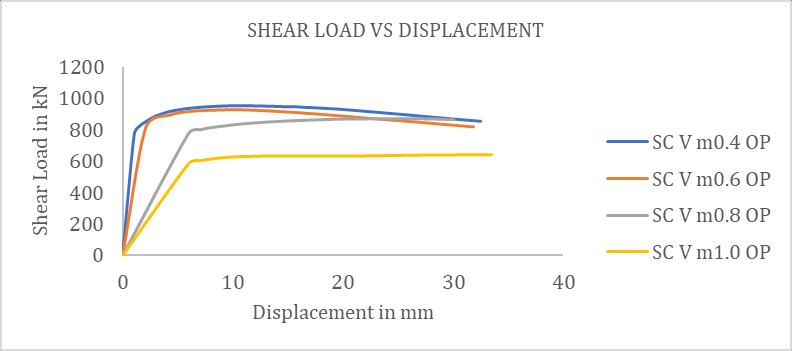

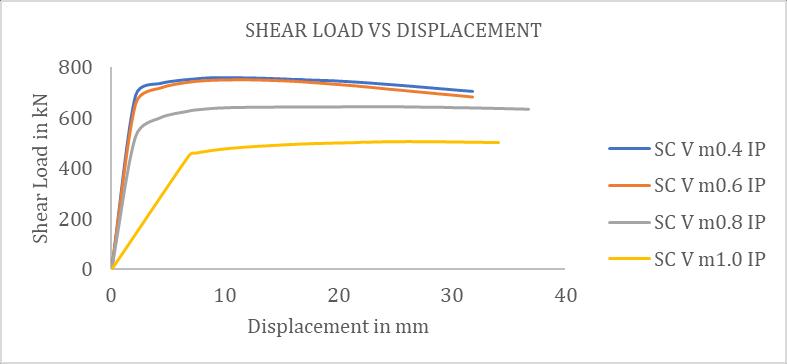

The models of SC sections are formed in L, V, L IP, L OP, V IP and V OP conditions. Then the obtained models were analysed. The figures below shows the geometry and total deformations of sections to study the influence of shear span ratio on shear capacity of columns. Boundary conditions are fixed at both ends with reference of the base journal. The material properties are selected based on theliterature reviews etc. The length of column is900mm and the meshing of sections are 40mm which is selected after the mesh sensitivity analysis. The loading is provided by keeping the section horizontally and axial load is applied. Non linear static structural analysis was done using ANSYS software. The effect of stressanddeformationonthevariouscross-sectionalshapedcolumnsareanalysed.

Thegraphgivenaboveshowstheloadvsdisplacementgraph,afterthatdifferentmodelswithdifferentshearspanratios areanalysed.

4. CONCLUSIONS

Ananalyticalinvestigationaimedtostudytheshearresponseofdualsteelcombinedcompositecolumns.Theperformance atdifferentshearspanratiosandthedifferentshapedsectionswasevaluatedintermsofshearcapacity.Thefollowingare someoftheimportantconclusionsdrawnfromthisstudy:

1. Fromtheanalysisatdifferentshearspanratiosofsectionsshapedsubjectedtoshearloading,itis observedthat sectionswithshearspanratio0.4havemoreshearcapacitythansectionswithhighershearspanratios.

2. Shear span ratio significantly affects the load transfer mechanism, Specimen with lower shear span ratio exhibit strongerconfinementeffectandincresestheshearcapacity.

3. Circle in square and square in circle sections have more initial yield and maximum ultimate load than circle in circleandsquareinsquaresections.

ACKNOWLEDGEMENT

I wish to thank the Management, Principal and Head of Civil Engineering Department of Universal Engineering College, Thrissur,AffiliatedbyallIndiaCouncilforTechnicalEducationNewDelhiandAPJAbdhulKalamTechnologicalUniversity fortheirsupport.Thispaperisbasedontheworkcarriedoutbyme(AbhinaMeenuM.N.),aspartofmyPGcourse,under theguidanceofNikhilR.(AssistantProfessor,CivilDepartment,UniversalEngineeringCollege,Thrissur,Kerala).Iexpress mygratitudetowardsherforvaluableguidance.

REFERENCES

[1] Li-Xin Duan, Wen-Da Wang, Wei Xian and Yan-Li Shi (2022) "Shear response of circular-in-square CFDST members: Experimentalinvestigationandfiniteelementanalysis", Journal of Constructional Steel Research 190107160.

[2]C.Z.Xiao,S.H.CaiandC.L.Xu(2005)"Experimentalstudyonshearresistanceperformanceofconcretefilledsteeltube columns", China Civil Eng. J.38(4)5–11.

[3] D. Lehman, C. Roeder, A. Heid, T. Maki and B. Khaleghi (2018) "Shear response of concrete filled tubes part 1: experiments", J. Constr. Steel Res. 150528–540.

[4]HunaitiYM(1991)"Bondstrengthinbattenedcompositecolumns", J Struct Eng 1991;117:699–714.

[5]HusseinGhanimHasanandTalhaEkmekyapar(2021)"Bond-slipbehaviourofconcretefilleddoubleskinsteeltubular (CFDST)columns"

[6]J. Chen, W.L. Jin and J. Fu (2008) "Experimental investigation of thin-walled centrifugal concrete-filled steel tubes undertorsion", Thin-Walled Struct. 461087–1093.

[7]K.Uenaka,H.KitohandK.Sonoda(2010)"Concretefilleddoubleskincircularstubcolumnsundercompression", ThinWalled Struct. 48(1)19–24.