THERMAL ENERGY STORAGE SYSTEM FOR GRID APPLICATION

Akhil Hayash M1 , Gokul PS2 ,

1Dept. of Electrical Engineering, College of Engineering Trivandrum, Kerala, India

2Dept. of Mechanical Engineering, College of Engineering Trivandrum, Kerala, India ***

Abstract - The world is aiming for carbon neutral by 2030 which results in shutting down all the coal power plants which results in un-employment of thousands which results in economic unsustainability. The current scenario is going behind Li-ion battery storage system for grid energy storage which is not adequate and sustainable. This article deals with the problem of energy storage for grid application and sustainable development. The proposed energy storage system is based on thermal energy storage

Electricity is stored thermally during off peak hours and retrieved back to electric energy on peak hours. The energy is stored in a cubical structure. The results are optimized for a course of 24 hours and the results are promising the consistency ofthe proposedsystem.

Key Words: Thermal Energy Storage System, Li-ion Battery Alternative, Grid Storage System.

1.INTRODUCTION

The green concept is emerging and getting engaged exponentiallyfromlastdecade.Bythestartoflastdecade, industry got a kickstart for the electric era by transforming transportation and logistics systems to electric system. The demand for the energy is increasing day by day. This concept results in zero carbon emission strategy which cause un employment of thousands. The grid storage system which are operational these days is alsonotadequate.IndustrystandardLi-ionbatterieshave muchseriousproblemsliketheyarepronetofirecatching, lower charging cycle, and the Li-ion battery made from muchexpensiveandrareearthmetalsarenotsustainable. The ideology of thermal energy storage system which has emergedalongtimeagocomeintoplaynowingridlevel energy storage application. A new technique has been proposed whichcanholdtheenergyforovera timeof 24 hourswithdecreasedlossesandwillbeasourceofincome forthousandswhowilllosetheirjobduetogreenconcept andalsogivelifetothedyingcoalpowerplant.

In this research, the discussed areas are the fatal flaws of Li-ion batteries, Economic unsustainability created by the green initiative and utilization of resources. There are many alternatives to the Li-ion battery storage system which are not promising in future so far now. This paper deals with the application of conventional energy storage system with new technology. This paper proposes the ideology of thermal energy storage system with the application of binary cycle, electromagnetism and also

thermodynamics. The proposed system could be made intorealitywithease.

1.1 Characteristics

The proposed system will promote the term of sustainabilitybytheconceptsofreduce,reuseandrecycle. Theuseofrecycledsteelwillpromotethesustainabilityas well as reduce the cost and increase the efficiency. The proposedsystemwillhelpthestallingcoalpowerplantsto get back in operation in a different way so that the large capital and land can be utilised for productivity without a considerable modification The coal power plant will promote the employment opportunities to an extent. The proposedsystem will ensure the storage of electric power inlargevolumewithnodustandfumes.

2.LITERATURE SURVEY

Thenumberofstudiesintheapplicationofthermalenergy storage in the grid application are quite low. The recent studies on the Li-ion batteriesareshown, howvulnerable they for both environment and for economy of the world. Somestudiesinthebinarycyclehaveshownitspromising future for the application of this system. From the study Fernandes, Nereus. (2018). “Induction Heating - Theory and Applications”, The concepts of induction heating is obtained. [1]. From the work done by O. Lucía, P. Maussion, et. al "Induction Heating Technology and Its Applications:PastDevelopments,CurrentTechnology,and Future Challenges," (2014), The design and development concepts of induction coil for heating purposes [2] From the insight of Fokin, L.R., Popov et. al (2011) “Equation of state and thermodynamic properties of saturated and superheatedmercuryvaporsupto 1650 K and 125MPa” , The characteristics of mercury under higher temperature [3]. From the review done by Sarbu, et. al, “AReview on heat transfer analysis in thermal energy storage using latent heat storage systems and phase change materials” Thepropertiesandmechanismsofheattransfer[4].From the study conducted by Ketul M Patel et.al (2019) “An Overview of Applications of Induction Heating” design parameters of induction heating are obtained [5] From the work conducted by HengyunZhang (2020) “Thermal modeling, analysis, and design”, the working of thermal power plant is [6]. From the work conducted by Bavane, Vikas et. al (2017) “Energy Analysis of Thermal Power Plant”, analysis of thermal power plant is done [7]. Akhmetovet.al(2016).“Thermalenergystoragesystems” ,

the concepts of thermal energy storage system [8]. From the work conducted by Al-Taha, Wadhah et. al. (20180 “Performance Analysis of a Steam Power Plant” the parameters affecting performance of a thermal power plant[9].FromtheresearchworkconductedbyGangLiet. al,“Thermalenergystoragesystemintegrationformsfora sustainable future” (2016), the concepts of future energy storage systems. [10]. From the work done byAlessandro Francoet.al,“Optimaldesignofbinarycyclepowerplants for water-dominated, medium-temperature geothermal fields” , the design of binary cycle for discharging system [11]. From the study by Hasanuzzaman, M, et. al (2017), “Global electricity demand, generation, grid system, and renewable energy polices”, the data denoting global energydemandcollected.FromtheinsightofAlbers,et.al (2008) “High-Temperature Properties of Nuclear Graphite”, the characteristics of graphite under elevated temperatures is noted [13]. From the work by Yu Zhiwu, et.al (2005) “Experimental research on the mechanical propertiesofsteelafterhightemperature”,Theproperties ofsteelunderelevatedtemperatureisnoted[14].

3. METHODOLOGY

The data that are used for optimizing the parameters and research works has been collected from various sources such as from research papers and other statistical data available from trusted websites and govt: bodies. The collecteddataareoptimizedontheAnsyssoftwareandall thesimulationsaredoneintheAnsyssoftware.

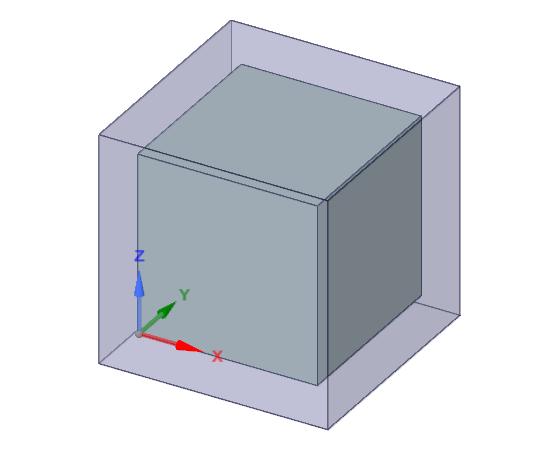

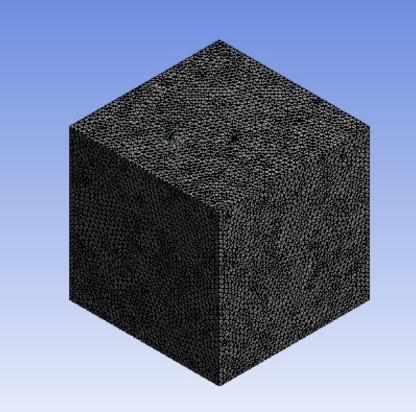

gapof50MMbetweentwosteelsections.Thegapisfilled with graphite. There is a distance of 325 MM from both sides of wall of the cube. All the data are optimized for solarphotovoltaicsinwhichadequatelightingfor8hours is available. The losses are optimized for 24 hours. The cubeconsistsof26392784nodesand70594499elements. The simulation is done for 1000000 iterations. The simulation is done at 0.01 pascal pressure condition to satisfythevacuumcondition.Theelement sizeisgiven as 0.01 to get better results. The simulation is done for 24 hours

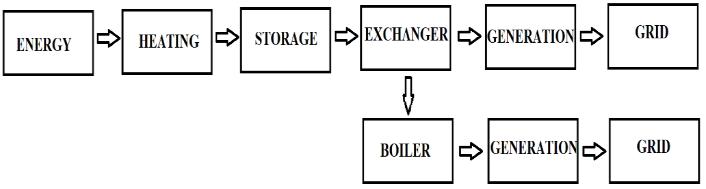

Figure 1 represents the block diagram of the system. During the off-peak hours, the energy is consumed from the grid, used to heat the cubical structure using an inductiveheatingcoilandenergyisstoredasheatenergy. Energy is retrieved back using binary cycle. The system contains 3 types of boilers at 1800, 1000, 200 degrees Celsius to increase the efficiency. The turbine will rotate the alternator and there by electricity is generated and suppliedaftermeetinggridparameters.

Theproposedsystemhasacubicalstructurewithasizeof 3650 milli meter. The cube is surrounded with a layer of vacuum of thickness 500 MM which is made of polyurethane and then one more layer of vacuum of thickness 500 MM. The cube is a mix of both steel and graphite. The steel sections are cylindrical in shape and having 100 MM diameter and 100 MM length. There is a

3.1 Heating System

Thesystemheatedandsteelsectionsarebringdowntoits moltenstatefortheenergystorage.Thesteelsectionscan bemelteddownat1538degreeCelsius.Thegraphitelayer over the steel sections will prevent the flow of molten steel from its mold to surroundings. The heat is given throughinductionheating.

Thedepthofpenetrationofmagneticfieldcanbeobtained by

D= (1)

Thepowertransferredtosteelsectionscanbeobtainedby theformula (2)

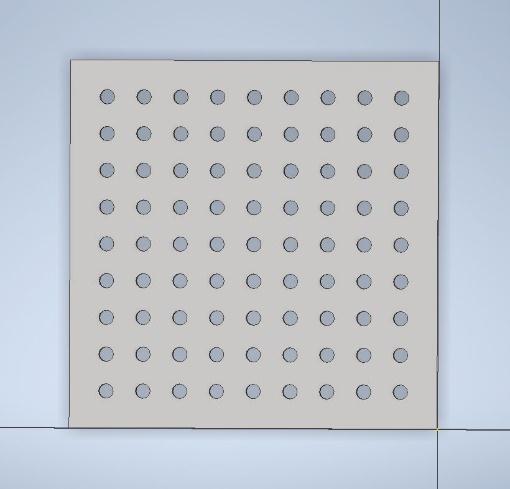

Thepictureofthecoilhasgivenbelow

Thecoilhasouterdiameterof3.65meterwhichislocated inthe4facesofthecubicalstructure.

3.2 Storage System

The energy thus stored in the form of heat need to be retainedforovera courseof24hours.A thick layerof 10 MM of vacuum is provided in between the outer wall and the cube. The vacuum will insulate the cube with the outsideworldresultinglonger retentivityoftheheatwith minimum loss. The only heat loss is due to the radiation whichcanaccountedasfollowing.

Q=εσA(T1^4 - T2^4) (3)

3.4 Discharge System

Once the structure is energized and stored via vacuum insulation, The energy will get discharged as needed to deliver the power requirement during the off-peak hours when there is no or least supply and demand is high. The dischargingisdonebyusingbinarycycle.Thebinarycycle usesthemercuryastheworkingfluidtoretrievetheheat energytoconverttheenergyintoelectricity.

Heat Exchanger Effectiveness Equation: This equation describes the effectiveness of the heat exchanger used to transfer heat from the geothermal fluid to the working fluid.Itisgivenby:

ε=(T1-T2)/(T1-T3) (4)

Net Power Output Equation: This equation describes the netpoweroutputofthepowerplant.Itisgivenby:

Wnet=(m2*(h2-h4))-(m1*(h1-h3)) (5)

Heat Input Equation: This equation describes the heat inputfromthegeothermalfluid.Itisgivenby:

Qcube =m1*(h1-h3) (6)

Thermal Efficiency Equation: This equation describes the thermalefficiencyofthepowerplant,whichistheratioof the net power output to the heat input from the geothermalfluid.Itisgivenby:

ηth=Wnet/Qcube

3.RESULT

(7)

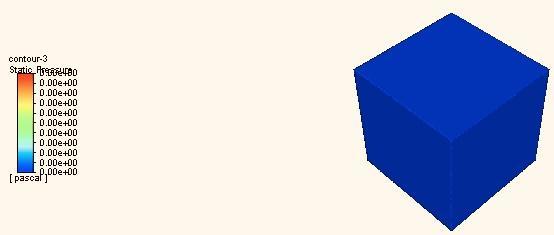

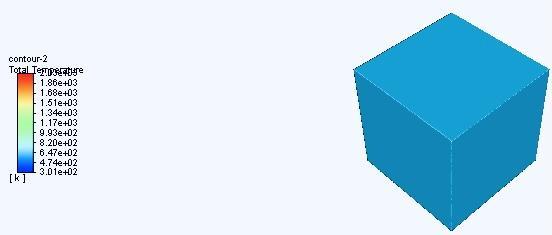

AllthesimulationshavebeendoneinAnsys software.The system is heated towards 1538 degree Celsius. The radiation from the cubical structure over a course of 24 hours is noted. The temperature retentivity over a time period of 24 hours is noted. Pressure loss in the cabin which is made vacuum is also noted. The temperature of internal, enclosure, also the vacuum space is also noted. Theobtainedresultsaregivenbelow.

Figure 7 shows the simulated result shows, The pressure consistency of the structure under operation, as the structureisabletomaintaintheinitialconditiongiven.

Fig -5:Temperaturecontouroftheinnercube,the temperaturethussimulatedis1800Kelvin.

Figure5showsthesimulatedresultshowsthestateofthe cubeaftertheheatingprocessisdone. Thecubeisheated uptothemeltingpointofthesteelie:1811K.

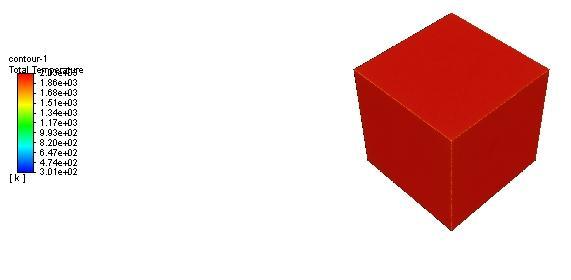

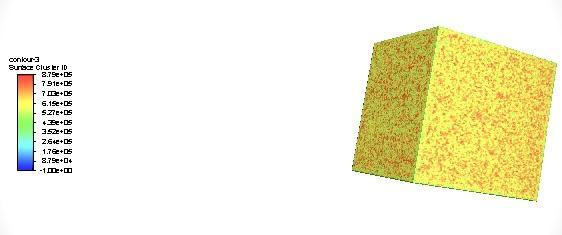

Fig -8:Contourmappingofradiationcomingoutfromthe surfaceofthecube.

Figure 8 shows the radiation coming out from the cubical structure after the heating is done. The radiation coming outisnotuniformanditresemblestheironpelletsplaced init.

All the contour mappings are given above. The following graph will give the behavior of the proposed system over time.

Fig -6:Temperaturecontouroftheoutsidecubical structure,thesimulatedtemperatureis573Kelvin

Figure 6 shows the simulated result shows the temperature outside the temperature the structure after thetwo-stageinsulationofvacuumandpolyurethane.

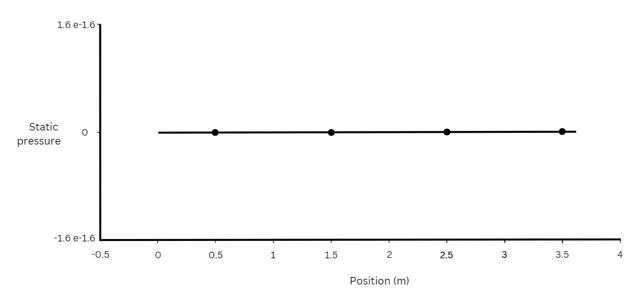

Chart -1:PressurevsPosition.

From the chart 1, the obtained result is there is no increase in pressure over the positions. The pressure is uniform everywhere which ensures the complete vacuum over the intermediate system which ensures the minimal

loss of heat due to radiation and also no heat transfer ratherthanradiation.

CONCLUSION

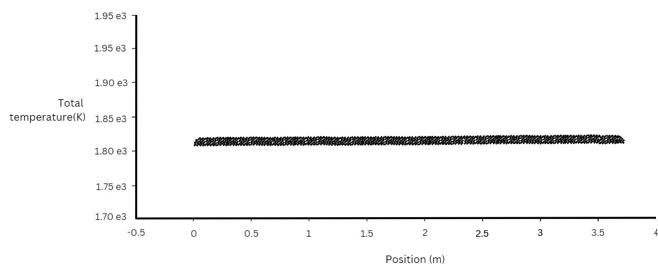

Chart -2:TemperaturevsPosition

From the chart 2, temperature vs position will give how the cube is getting energized with the inductive coil. The heat is distributed uniformly all over the cube over the dimensionof3650millimeter

Theproposedsystemcanbeanalternative forthe energy storage in the grid application as an alternative to the Liion batteries which are in the market as of current standard. The proposed system could hold the temperature and heat energy stored for over 24 hours without much losses and could deliver maximum output or the heat from the cube to the binary cycle system and thentothesteamcyclesystemwherewhichtheenergyis extracted. As the system proposed to practice in a coal power plant with in built setups such as boiler, cooling tower, turbine, generator and connection to the grid, the proposed system will give an employment to the people who are working in this field and for people who are losingtheirjobinthisfieldduetothegreenconcept.

REFERENCES

[1] Fernandes, Nereus. (2018). Induction HeatingTheory and Applications [1], The theory and applicationofinductionheating.

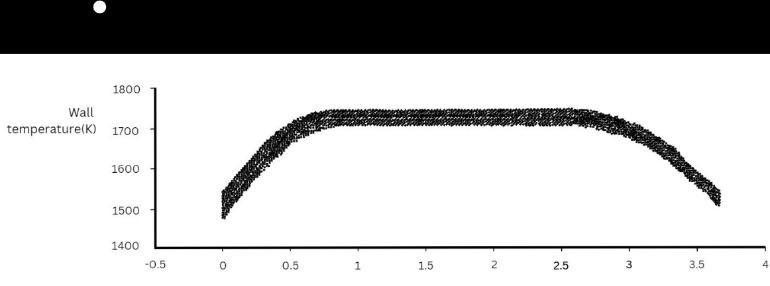

Chart -3:WallTemperaturevsPosition

From the chart 3, wall temperature vs position which givestheresultoftemperatureretentivityoveracourseof 24 hour. There is a drop in temperature in the corners due to radiative losses. The radiative losses are more pronetocornerorthesharpedges

[2] O. Lucía, P. Maussion, E. J. Dede and J. M. Burdío, "Induction Heating Technology and Its Applications: Past Developments, Current Technology, and Future Challenges," in IEEE Transactions on Industrial Electronics, vol. 61, no. 5, pp. 2509-2520, May 2014, doi: 10.1109/TIE.2013.2281162.

[3] Fokin, L.R., Popov, V.N. & Naurzakov, S.P. Equation of state and thermodynamic properties ofsaturatedandsuperheatedmercuryvaporsup to 1650 K and 125 MPa. High Temp 49, 832–840 (2011).

https://doi.org/10.1134/S0018151X11050075.

[4] Sarbu, I,Dorca, A Review on heat transfer analysis in thermal energy storage using latent heat storage systems and phase change materials Int J Energy Res 2019;43:29–64 https://doi.org/10.1002/er.4196

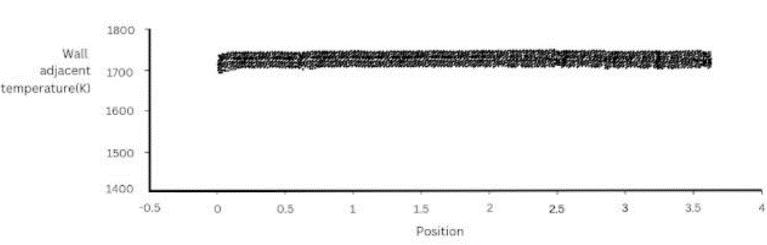

Chart -4:WalladjacenttemperaturevsPosition

From the chart 4, the outside wall temperature which is almost constant after 24 hours which ensures the energy retentivity of the system which ensures the efficiency of thesystem.

The results obtained after the simulations are very satisfying.Theproposedthermalenergystoragesystemis holding the energy without much losses under laboratory conditionasgiveninsimulation.

[5] Patel, Ketul M, An Overview of Applications of Induction Heating (2019). International Journal of Electrical Engineering and Technology, 10(2), 2019, pp. 81-85, Available at SSRN:https://ssrn.com/abstract=3536945

[6] Hengyun Zhang, Faxing Che, Tingyu Lin, Wensheng Zhao,3 - Thermal modeling, analysis, and design,Editor(s): Hengyun Zhang, Faxing Che, Tingyu Lin, Wensheng Zhao, In Woodhead Publishing Series in Electronic and Optical Materials, Modeling, Analysis, Design, and Tests for Electronics Packaging beyond Moore, Woodhead Publishing,

2020, Pages 59-129, ISBN 9780081025321, https://doi.org/10.1016/B978-0-08-1025321.00003-2.

[7] Bavane, Vikas & Rindhe, Pooja. (2017). Energy AnalysisofThermalPowerPlant.

[8] Akhmetov,B.&Georgiev,Aleksandar&Kaltayev, Aidarkhan & Dzhomartov, A & Popov, Rumen & Tungatarova, Madina. (2016). Thermal energy storage systems – review. Bulgarian Chemical Communications.48.31-40.

[9] Al-Taha, Wadhah & Osman, Hassan. (2018). Performance Analysis of a Steam Power Plant: A Case Study. MATEC Web of Conferences. 225. 05023.10.1051/matecconf/201822505023.

[10] Gang Li, Xuefei Zheng,Thermal energy storage systemintegrationformsforasustainablefuture,

[11] AlessandroFranco,MarcoVillani,Optimaldesign of binary cycle power plants for waterdominated, medium-temperature geothermal fields, Geothermics, Volume 38, Issue 4, 2009, Pages 379-391, ISSN 0375-6505, https://doi.org/10.1016/j.geothermics.2009.08. 001

[12] Hasanuzzaman, M., Zubir, U.S., Ilham, N.I. and Seng Che, H. (2017), Global electricity demand, generation, grid system, and renewable energy polices: a review. WIREs Energy Environ, 6: e222.https://doi.org/10.1002/wene.222

[13] Albers, Tracy. (2009). High-Temperature Properties of Nuclear Graphite. Journal of Engineering for Gas Turbines and Power. 131. 064501.10.1115/1.3093995.

[14] YuZhiwu,DingFaxing,WenHailin,Experimental research on the mechanical properties of steel after high temperature, Editor(s): Z.Y. Shen, G.Q. Li, S.L. Chan, Fourth International Conference on AdvancesinSteelStructures,ElsevierScienceLtd, 2005, Pages 1071-1076,ISBN 9780080446370, https://doi.org/10.1016/B978-0080446370/50158-X.