Design and development of cooling system of battery in an electric two wheeler

Atharva Hiwanj1, Aniket Dhobale2, Arnav Paltewar3, Atharva Khotpal4 , Akash Pounikar5 , Homeshwar Nagpure61,2,3,4,5UG Student, Department of Mechanical Engineering, St. Vincent Pallotti College of Engineering and Technology Nagpur, Maharashtra, India

6Assistant Professor, Department of Mechanical Engineering, St. Vincent Pallotti College of Engineering and Technology Nagpur, Maharashtra, India ***

Abstract - This project is based on designing a casing with fins of battery for cooling of a two-wheeler electric vehicle battery using forced convection. In the recent years, electric vehicles have a boom in the industry due to its zero emission of gases and also electric vehicles is four times as energy efficient than of IC engine Electric vehicles (EVs) are becoming more and more popular as the automotive industry develops around the world. Due to their benefits, including their outstanding energy density, good power density, and low self-discharge, lithium-ion (Li-ion) is commonly used in electric vehicles (EVs). To enable an increased lifespan, cheaper costs, and for better safety, the batteries must be operated within their optimal range for safety and excellent thermal management. The primary goal is to develop a fin design that can speed up heat transfer in an electric vehicle battery. A proper management is needed in order to achieve the maximum performance when operating at different conditions. A proper cooling is always necessary for a battery in order to control the battery thermal behavior. The aim is to analyze the temperature rise in Lithium-ion batteries due to charging and discharging in electric vehicles and to provide an engineering solution for the same.

Key Words: Thermal Runaway, management, module, simulated,fins,lithium-ion.

1. INTRODUCTION

1.1 Electric Vehicles:

For many years the internal combustion engine has dominated the transportation sector, now the electric vehiclesareonthevergeofhavingrapidgrowthinvehicle markets.Thewidespreadadoptionofelectricvehiclesmight have a huge impact on society, not just in terms of the technologyweuseforpersonalmobility,butalsointermsof shiftingoureconomiesawayfrompetroleumandreducing transportation'senvironmentalimprint.Themechanicsofan electricautomobileareoftensignificantlysimplerthanthose ofaconventionallydrivenvehicle.

ThefollowingareafewinstancesgivenbyEV:

1). Anelectricmotorhasfewermovingpartsthanagasoline engine.

2).Anelectriccarisfittedwithasingle-speedtransmission. Electriccars,unliketraditionalautos,arenotequippedwith manyofthecommonpartsthatbreakdownandneedtobe replacedorrepaired

1.2 Lithium-Ion Batteries:

Becauseofitshighenergyperunitmasscomparedtoother electricalenergystoragemethods,lithium-ionbatteriesare presently employed in most portable consumer gadgets 1 suchasmobilephonesandlaptops.Theyalsofeatureahigh power to weight ratio, excellent high-temperature performance, and minimal self-discharge. Lithium-ion(Liion)batterieshaveriseninprominenceinrecentdecadesas aviablepowersourceforavarietyofapplications,including electric and hybrid cars, power grids, and solar energy storage. Li-ion batteries are widely recommended as a power source in extended driving ranges and quick acceleration because of its high power density, dependability,andlongevity.Li-ionbatteries,ontheother hand,createheatduringquickchargeanddischargecycles at high current levels. Furthermore, temperature and inhomogeneity have a significant impact on their energy storagecapabilityanddurability.

1.3 Battery:

ThehightemperatureofLi-ionbatterycellshasbeenshown inseveral studies toacceleratecapacitydeteriorationand limit battery life. Heat buildup in batteries causes safety concerns and abnormalities across the electric vehicle system. Overheating, scorching, and battery explosion are justafewofthedangers.Thus,thedesignanddevelopment ofaneffectivethermalmanagementsystem(TMS)remainsa crucialchallengeintheelectricvehiclesindustry.ForLi-ion batteries,theidealworkingtemperaturerangeis25–40°C. TheLi-ionbattery'stemperaturerangeachievesabalance between performance and longevity. Fast

charging/discharging modifications have put an urgent challenge on battery power performance and the battery TMS in order to achieve faster speed, acceleration, and shorter charging time of the battery pack Degradation is strongly temperature-dependent, with a minimal degradationaround225°C,i.e.,increasingifstoredorused at above or below 25 °C. High charge levels and elevated temperatures(whetherfromchargingorambientair)hasten capacityloss.Tofulfilltheheatdissipationrequirementof Li-ion batteries, different cooling solutions in the form of active,passive,andhybridareinvestigated.TMSareusedto manage the heat generated by electrical devices and batteriesduringoperation,suchasphasechangematerials (PCM)andnanomaterials,heatpipes,air,andliquidcooling systems.

1.4 Thermal runaway:

Thermal runaway in lithium-ion (Li-ion) batteries occurs whenacell,oraportionofacell,reachesdangerouslyhigh temperaturesasaresultofthermalbreakdown,mechanical failure,internal/externalshortcircuiting,orelectrochemical abuse.Exothermicbreakdownofthecellcomponentsbegins at high temperatures. When the cell's self-heating rate exceeds the rate at which heat can be dispersed to the surroundings,thetemperatureofthecellrisesexponentially, and stability is lost. As a result of the loss of stability, all remainingthermalandelectrochemicalenergyisdischarged intotheenvironment.

1.5 Causes of thermal runaway:

As the name suggests, internal short circuit is basically a short circuit which takes place inside of the cell. We also knowthatshortcircuitreleaseshugeamountofenergyand thisenergyisgeneratedintheformofheat.Internalshort circuitinLi ionbatteriesisaprocessbywhichanodeand cathode meet each other internally. So, when anode and cathode come into contact then huge amount of heat is generatedandthisleadstothermalrunawayinacell.There aremanyreasonshowinternalshortcircuittakesplaceina cellofabattery.Internalshortcircuittakesplacebecauseof someaccidentormechanicalfailureleadingtodeformation ofabatterymaterial.Thisbatterymaterialdeformationmay leadtobreakageofseparatorwallthusallowingbothanode andcathodetomeeteachother.So,whentheinternalshort circuithappensbycollisionorcrushthatisbymechanical abuse then there are chances of leakage of flammable electrolytefromthecellagainthisisaveryseriousissueand cancausethermalrunaway

2. MATERIAL SELECTION

Oncethebasicdesigniscomplete,itisnecessarytoperform its analysis to determine its viability for the specified parametersandtochoosetheappropriatematerialwithan eyetowardsoptimizingthevehicle'sperformance.Wehave chosen three materials from the research in the literature

study that are typically used to make battery fins because theyarelightweightandgoodheatdissipation.Al2024T6, steel,andcopperarethematerialsthathavebeenselected.

ThematerialforcasingisselectedasAluminiumalloy2024 T6,thereasonbehindselectingthematerialishighthermal diffusivity,highthermalconductivity,highstrengthtoweight ratioandthemainreasonisbecauseoflightweight.Thefins are also considered as the same material as that of casing whichisAluminiunalloy2024-T6.

3. CALCULATION

Heatgenerationinabattery:

Thebatteryisdischargeata2Crate

Thecurrent(I)for2Crateis30A

TotalheatgenerationinBattery(Energy)

Power=60×30=1800W Energylossasheat

%ofheatloss=288/1800=16%

Energylossasaheat=288W

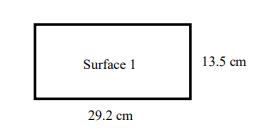

A1=27.2×12.5=340cm2

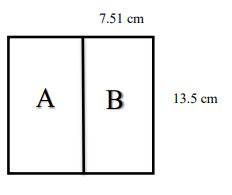

A2=13×12.5=162.5cm2

�� 1/�� 2 =2.09

��˙=2(�� 1 +�� 2)

�� 2=46.6W

�� 1 =2.09x�� 2=97.39W

Conductive heat transfer through surface 1:

Thegapbetweentwofinsis0.58cm

Conductive heat transfer through surface 2

Ts issurfacetemperatureofprofile

��∞ =Tempofair=30℃

U∞ =Velocityofair=8m/s

MeanTemperature

Tm=35℃

Propertyofair35℃fromHTdatabook

��������=1.146kg/m3

��=18.87×10 6 Ns/m2

Asperourdesignthedimensionoffinprofileis

L=27cm

b=5cm

t=0.3cm

Re=121462.63<5×105

Flowislaminar

Nusseltnumber:

N����==0.664×(����)0.5 ×(����)0.333

Hl/kair=213

h=21.37W/��2

Heat transfer through convection from profile surface:

����=2×(��×��)+(��×��)+2(��×��)=281×10−4m2

�� fin =ℎ����(���� ��∞)

�� fin =6.0W

No.offins=�� 1/�� fins=97.39/6=16.36~16

Theoutersurfacetemperatureofcasingshouldbe45℃

So,assumeTb=45℃

TheQ2isdividedintotwopartsofequalarea

Qa =Qb =Q2/2=46.6/2=23.3W

Asairstrikethesurfaceandgetdivideintwoparts

Surface B

T∞=Tempofair=30℃,U∞ =Velocityofair=8m/s

Surface temperature & Mean temperature of surface B is sameassurface1

Ts =40℃,Tm=35℃

Propertiesat35℃arelikesurface1

Asperourdesign

L=6.51cm,b=2cm,t=0.3cm

ReynoldsNumber(Re):

Re=����∞��/��=31628.87<5×105

Flowislaminar

Where,

ρair=1.146kg/m3

����=0.7��=18.87×10-6Ns/m2

��������=0.0271W/mK

AverageNusseltnumber=Nul=0.664(Re)0.5×(Pr)0.333

Hl/kf=0.664(31628.87)0.5×(0.7)0.333 =104.86

h=43.65w/m2k

AS=2(6.51×2)+2×(0.3×2)+(0.3×6.51)=29.193×10-4

Qconv(fin) =1.27W

NoofFin=Q˙B/Q˙fin =23.3/1.27=18

Thegapbetweentwofinsis0.47cm

Thetotalheatwhichisdissipatedtothesurroundingwith thehelpofafinis288W

Totalheatdissipationfromacasingwithoutfinsiscalculated as39.2W

Theeffectiveness∈=�� withfins/�� withoutfins =288/39.2=7.3

4. DESIGN METHODOLOGY

WehaveconsideredMagnusEXelectricvehiclebatteryas our project model since it is available, having detachable batteryandwashavingscopeforbatterycoolingusingfins. Wehavefinalizedthefollowingmethodology:

1)Toselectvariousdesignparameterswhichareneededto make the basic design of fins and it should be selected in such a way that it should improve the battery life and performanceofvehicle.

2) We have first designed the battery of magnus EV by ourself because the internal resistance of the cell and cell compositionwasunknowntousduetosecretthreads.we knew that the battery is having 60 V 38 Ah output so we considered the prismatic cells (3.7 V 15 Ah each) and arrangeditinsuchamannerthat16cellsareconnectedin seriesand2suchsetsarearrangedinparalleltofrom16S2P configuration.Afterwardsweproceededforheatgeneration andcalculationsforfindesign

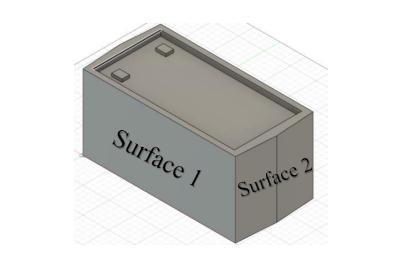

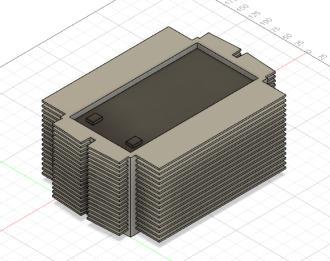

3) To design a cad model in Fusion 360 computer aided design (CAD) modeling software as per the selected parameters. The created design should be simple in construction.

4) To perform the analysis of the casing (with fins) and (without fins) with selected materials as per the material studydone.Thematerialstudytobedoneconsideringthe requirementsformanufacturingofthefinsandcasing.

5)ComparativestudyofresultsthatwegotintheICEPAK analysis of basic design of casing with fins and finalize a suitablematerialforthecasingandfinssoastoimproveits performance and to achieve the goal of faster heat dissipation.

6)Thefinalstepistocheckthesustainabilityofthedesign under the action of applied boundary conditions and to check that it is properly designed or not and make a conclusionfortheresultswegotinICEPAKanalysisofthe design.

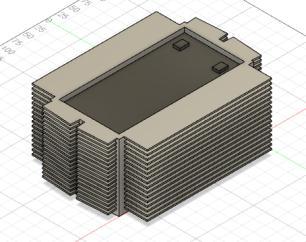

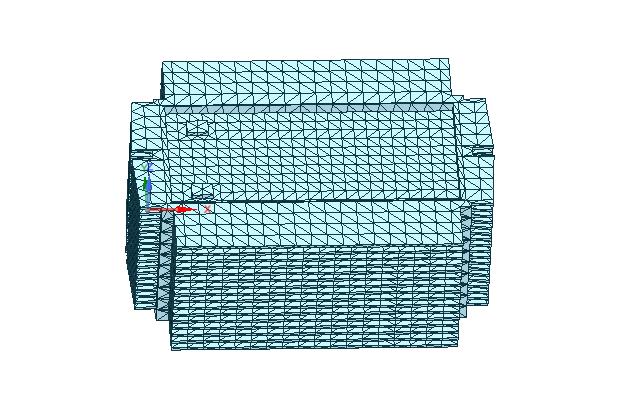

Fig.4: Basicdesignofcasingwithfins

5. ANALYSIS:

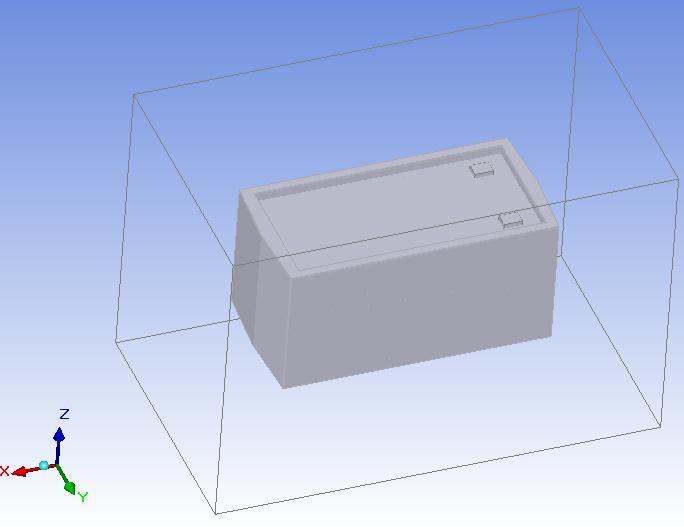

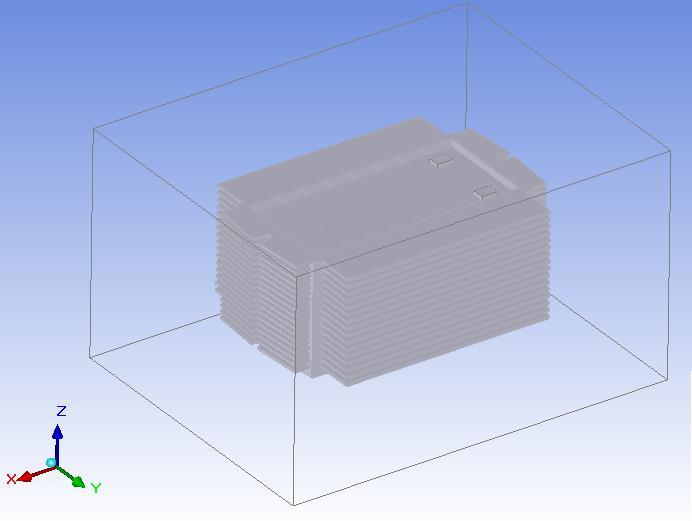

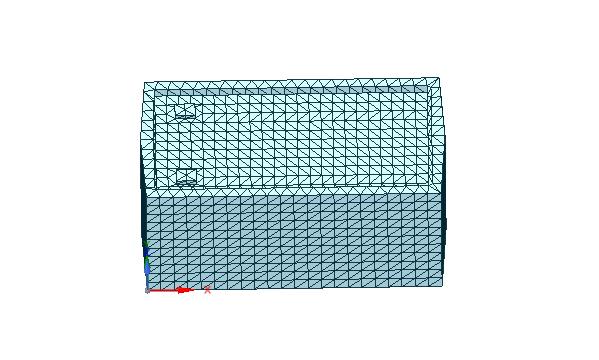

Ansyssoftwareisusedforanalysisandtobemoreprecise ICEPAKanalysisisdoneonboththegeometriesofcasingi.e., (withfins)and(withoutfins).ICEPAKanalysisisbasically done on the geometries which are subjected to forced convection.ANSYSIcepakisasoftwaretoolusedforthermal analysisanddesignofelectronicsystems,includingprinted circuit boards (PCBs), electronic components, and other electronic devices. The "Facet Quality" feature in ANSYS Icepak refers to a specialized meshing algorithm used to createhigh-qualitymeshesforcomplexgeometries,suchas thosefoundinelectronicsystems.

The Facet Quality algorithm is based on the "faceted" or "polyhedral"meshingapproach,whichinvolvesdividinga 3Dgeometryintoasetofflat,planarsurfacesorfacets.This approach can be particularly useful for modeling complex shapes and irregular geometries. The Facet Quality algorithmensuresthatthefacetsareproperlyalignedand have the correct orientation, which helps to improve the accuracyandefficiencyofthermalsimulations.

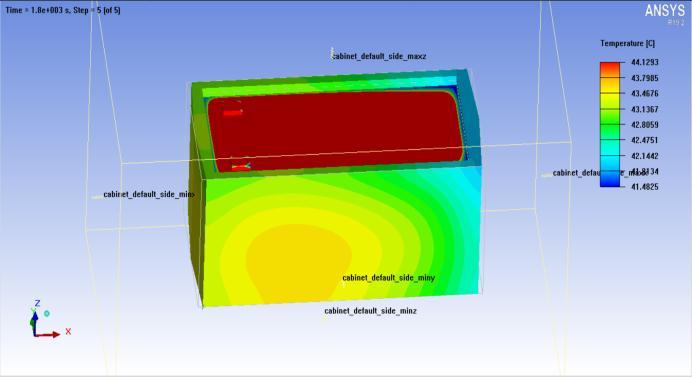

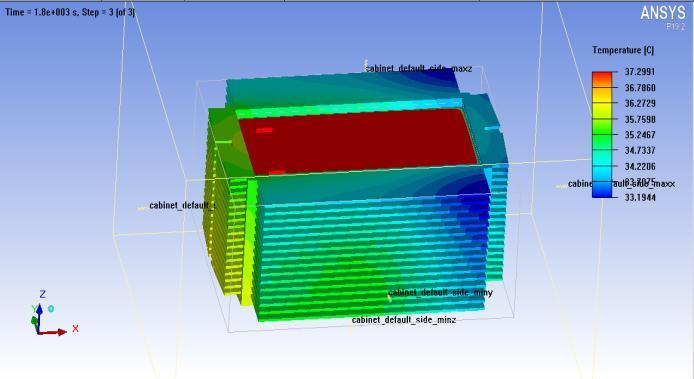

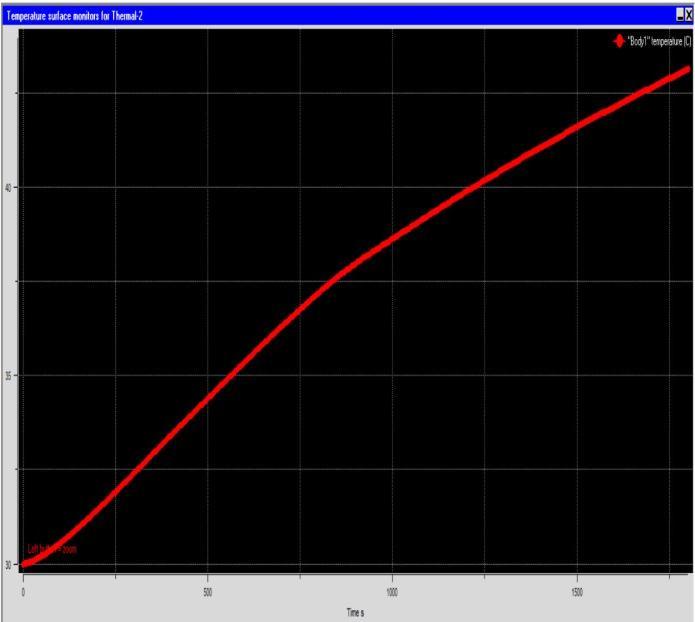

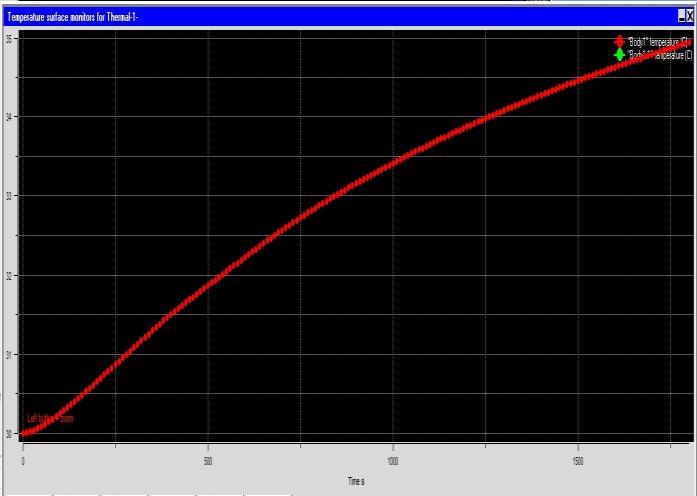

Analysisiscarriedoutinsuchamannerthatthegeometryis simplified to ICEPAK geometry by ICEPAK simplify command, facet quality is set to high as it denotes the techniqueofdividingacomplexsubjectintoitsseveralparts. Further the geometry is enclosed in a cabinet and then appliedthedifferentconditionsandparametersonthemlike ambienttemperature,velocityofmovingair,assigningthe suitablematerialandalsobyfeedingtheoverallheatlossof the battery in the surrounding. We have simulated the geometryfrom0secupto1800seckeepingthetimestepand no of iterations as 5. For meshing cutcell meshing is done takingtheelementsizeas3andthenwerunthesolutionto obtaintheresults.Analysisofthetwogeometriesaredone andcomparedwitheachothertofindtheoutputofboththe models using the fins and without using fins and effectivenessisalsoevaluated.

6. RESULTS:

1)Heattransferwithfin=288W

2)Heattransferwithoutfin=39.24W

3)Heattransferbyusingfinsonbatterycasingis7.3times morethanthatofwithoutfinonbatterycasing

4) The heat is not getting accumulated on battery surface withthehelpofusingfins,henceenhancingbatterylifespan.

5)Overallefficiencyofvehicleisincreased

7. CONCLUSION:

The temperature variation depends on surrounding air temperature,crateandmanyotherparameters.Themost weightedparameterfortemperaturevariationfoundoutto be cell capacity In this work, we identified differences betweenthesuggestedbatterycasingwithfinsdesignand withoutfinsdesign.Bothofthesuggestedcoolingfinsdesign and without fins designhave undergone analysis and simulation. Results from the simulation process were compared.Comparingtheproposeddesignstothecurrent design, the proposed designs havemaximumheat dissipationrateandfastercooling.Thisstudydemonstrated that cooling finshave the capability to boost thebattery's usefullifeandperformance.Theobjectiveofdesigningthe finsonthebatterycasingforcoolingandexcellentbattery performanceissuccessfullyachieved Thevehicleefficiency isincreasedbyimprovingthebatterylifebyfastercooling usingfinsandthusoverallheatdissipationisincreased.Also faster cooling rate is achieved by implementing the fin concept.

8. ACKNOWLEDGEMENT

Theauthorsaregratefulforalltheassistancefromourguide, Prof. H.G. Nagpure and the alumini mentors Surendra DahakeandNimishLambat.

REFERENCES

[1] ‘CFD analysis of heat transfer enhancement by using passive technique in heat exchanger’by Chunchula RajeshBabuandSKGugulothu

[2] ‘Optimal Design of an Air-Cooling System for a Li-Ion Battery Pack in Electric Vehicle’ by Mohsen Mousavi, ShaikhHoque,ShahryarRahnamayan,IbrahimDincer, GregF.Naterer.R.Nicole,“Titleofpaperwithonlyfirst wordcapitalized,”J.NameStand.Abbrev.,inpress.

[3] T.M.Bandhauer,S.Garimella,andT.F.Fuller,‘‘Acritical review of thermal issues in lithium-ion batteries,’’ J. Electrochem.Soc.,vol.158,no.3,pp.R1–R25,2011.

[4] “ADetailedReviewonElectricVehiclesBatteryThermal Management System” by Sourav Singh Katoch, M Eswaramoorthy

[5] “Comparisonofdifferentcoolingmethodsforlithiumionbatterycells”byDafenChen,JiuchunJiang,Gi-Heon Kim,ChuanboYang,AhmadPesaran.

[6] Q.Wangetal.,“ExperimentalinvestigationonEVbattery coolingandheatingbyheat pipes,”Appl.Therm.Eng., 2014.