AN EXPERIMENTAL STUDY ON STRENGTH OF CONCRETE USING RECYCLED AGGREGATES

AND MANUFACTURED SAND

Aviral tripathi1 , Dr. Pramod sharma 2, Dr. J.S Chauhan3

1.Research Scholars, Civil Engineering Department, Samrat Ashok Technological Institute, Vidisha (M.P.) 464001, India.

2. Professors, Civil Engineering Department, Samrat Ashok Technological Institute, Vidisha (M.P.) 464001, India.

Abstract - This research looks into the feasibility of using manufactured sand(M-sand) or arti:icial sand and recycled coarse aggregate (R C A) to make concrete. In this experimental programme, 44 concrete mixes were prepared in which natural coarser aggregate (NCA) is replaced with RCA in proportions ranging from 10% to 100%. Similarly, M Sand sand is used in place of natural river sand in increments of 10%, 20%, 30%, 40%, 50%, 60%, 70%, 80%, 90%, and 100%. The binder content and water content were kept consistent for all combinations. M-sand and RCA are evaluated for their effect on the fresh and hardened characteristics of CONCRETE. The study's :indings revealed that the toughened properties of concrete using 50% Msand are much higher than the control mix. The toughened qualities of the CONCRETE with 100% RCA were discovered to be less than those of Ordinary concrete. As a result, as the amount of RCA substitution grows, so does the strength decreases. The results, however, demonstrated that M-sand may generate CONCRETE with weak and medium compressive strength (20MPa - 45MPa).

Key Words: Fresh Concrete; Recycled Coarser Aggregate; Manufactured sand; Compressing Strength etc.

1.INTRODUCTION

A lack of land-illing space activities will immediatelyresult fromthelargevolumeofgarbageproduced byconstruction and demolition (C&D) and industrial by- products. Innovative and unconventional resources can help the construction industry go in the direction of sustainability. RCA has a lower density and a higher water absorption rate than natural coarseaggregatebecauseof the adhering cement mortar on its surface. It is also less expensive. Additionally, it provides extra advantages and lessens the in-luence on the environment. Concrete loses compressivestrength when mortar fragments from oldconcretearepresentinRCA.

Since ancient times, construction projects have used river sand as -ine aggregate. However, limitations placed on the usage of river sand from the riverbed as a result of a lack of availability or insuf-iciency or shortage and growing demand have motivatedresearchers to look for other materials for -ineaggregate. Riversandhasa

smoother surface than M- sand, which is more angular. M-sand is therefore becoming more and more common in the constructionsector thesedays.

1.1 RESEARCH SIGNIFICANCE

Natural river sand is extremely scarce, so substitutes like arti-icial sand, foundry sand, blast furnace slag, pulverised granulated blast furnace slag, and other minerals must be used. Even coarse aggregates are getting more and more dif-icult to -ind, so a replacement material must be used. Most nations have already made the switch to recycling and repurposing old building materials. Utilising demolished concrete is a viable option for doing this; but, before being utilised to make new concrete, the material must be quality-checked. The quality of concrete must be evaluated using a thorough experimental plan. The results of a study that used M-sand to create recycled aggregate concrete are presentedinthispublication.

Fresh properties such as slump -low test and hardened properties such as compressive strength of concretearestudied.

2. MATERIALS

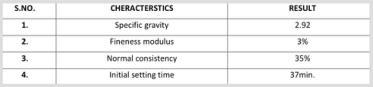

a). CEMENT: - All mixes are made with Portland pozzolanacementthatconfirmstoIS:1489Part1.

The following physical characteristics of Portland Pozzolana Cement, as determined by relevant tests in accordance with IS:4031-1988, are shown:

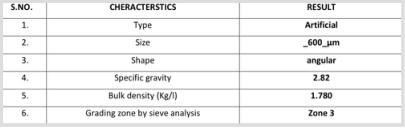

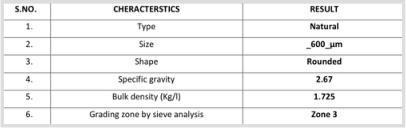

b). SAND: - both natural sand and arti-icial sand (M-Sand) wereusedwhichcon-irmtoIS383:1970.

i. Natural sand: - Natural Sand (River Sand) is a vital ingredient of the concrete mix that ensures the proper adhesionofbothcementandaggregate.

In this experiment the sand which passed through an Is sieve of 1.18 mm and retained on _600_μm as according to IS383-1963de-initionswereused.

moisture on the surface, RCA was dried. For batching, RCA, natural coarse aggregate, and -ine aggregates werecombined.

ii. Manufactured sand(M-Sand): - M sand, a sort ofarti-icial sand, is created by crushing large, hard stones most often boulders or granite into small pieces that can be then meticulously graded and cleansed. As a river sand alternative, it can be used in a variety of building projects, mostlyformakingmortarandconcrete.

In this experiment the sand which passed through an Is sieve of 1.18 mm and retained on _600_μm as according to IS:383-1963de-initionswereused.

d). WATER: - Water, which when merged with cement creates a paste that retains the aggregate together, is themost important component. Through a process called as hydration, water helps concrete to harden. Ordinary For the concrete's mixing and curing, only potable tap water devoid of all impurities including turbidity, organiccontent,and alkalinity wasused.

3. EXPERIMENTAL WORK: -

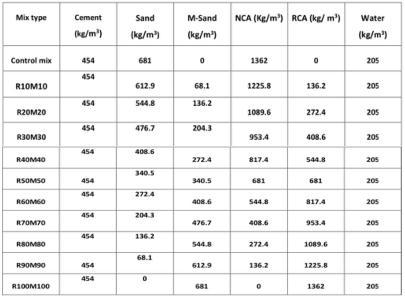

3.1.MIX PROPORTIONING: - A nominal concrete mix ofgrade M-20 was prepared for this experimental work. The ratio of cement sand and aggregates was kept as C: S: A=1:1.5:3. In each mixture, N-C-A is replaced by R-C-A in proportions of 10%,20%,30%,40%,50%,60%,70%,80%,90% and 100%, and the river sand is substituted by M sand in proportions of 10%,20%,30%,40%,50%,60%,70%,80%,90%, and 100%. Portland cement from Pozzolana was kept constant in all blends. The concrete mixes are made byreplacingMsandandrecycledcoarseraggregates.

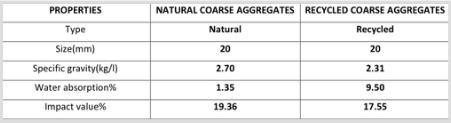

c). AGGREGATES: - both normal coarse aggregates (NCA) and recycled coarse aggregates (RCA) were used which con-irmtoIS383:1970.

I. Normal coarse aggregates (NCA): - In this study the normal coarse aggregates of maximum size of 20mm were usedwhichwereobtainedfromanearbyconstructionsite.

II. Recycled coarse aggregates (RCA): - The recycled aggregates of maximum 20 mm in size were used in this experimental study which were derived from the tested destroyedcubeswhichweretestedatlaboratory.

The -irst step was to properly wash the newly demolished RCA using water for 30 minutes. RCA wasthen submerged in water over 24 hours. To get rid of any

3.2. METHODOLOGY: -

I. Batching (by weight) & Mixing: - R C A, naturalcoarse-aggregate, -ine-aggregates and cement were mixed in a big steel tray -irst in dry condition by manually weighting meticulously for batching. Water was then addedandstirredforafurther6to8minutes.

The complete mixing process was done manually by hands.

II. Casting 0f Cubical moulds: - 44 number of cubes 150 mm x 150 mm x 150 mm in size in total were used to assess the compressive strength of the mixtures after 7 and28days.

Recycled coarse aggregate (RCA) with a 20 mm size is used to replace natural coarse aggregate (NCA). The levels of RCA replacement are 10%,20%,30%,40%,50%,60%,70%,80%,90%, and 100%. M-sand is used to replace natural -ine aggregate by 10%,20%,30%,40%,50%,60%,70%,80%,90% and 100%. Slump-low testing and compressive strength testing are two of the procedures used to determine the qualities of concretemixtures.

III. Pouring & Compacting New or Fresh concrete: - the freshly prepared concrete is then -illed into the moulds of size 150 mm x 150 mm x 150 mm. The concrete is -illed into the moulds in three different layers followed by 25 blows of compaction on each layer with the help of a tamping rod of 60cm in length. The compaction of the concretewaspurelydonemanuallybymeansofhands.

IV. Nomenclature of samples: - The symbol R stands for recycled aggregates, after which comes the proportion of recycled aggregates, and the letter M stands for M-Sand, proceeded by the percentage of M Sand, when manufacturing the test specimens. For instance, R50M50 denotesablendof50%M-Sandand50%RCA.

V. Demoulding of cubes: - After casting the cubes were demoulded after 24hrs carefully by not damaging the edgesofthecubes.

VI. Curing of test specimens: - all the test specimens were cured by completely submerging into the water in a curing tank for 7-days and 28-days. The water for curing should be changed after every 7 days. The curing wasdone con-irming to IS 456-2000 up to the date or day of testing viz7and28days.

4. Results and discussions

The concrete so manufactured was tested in its fresh and hardened state. First of all the fresh property of concrete I.e workability was determined by means of slump cone test and followed by the test on hardened concrete I,e

compressive strength test by a compression testingmachine.

4.1. Workability test: - Un-inished or freshly mixed concretehasatraitcalledworkability.Concrete that can be compacted and poured without experiencing any segregation is considered to be workable. Simply said, positioning convenience determines workability. Theslumpconetest,which measurestheworkabilityoffreshlypreparedconcrete, canbeused.

The result of slump cone test shows that the Workability was reduced when manufactured sand and RCA were both replaced in greater percentages. Thetestwasperformedonlyonthemixescontaining 25%,50%,75%and100%

recycled aggregates and M - Sand because of the veryminutereadingswererecordedforothermixes.

Table

conclusionsforworkabilityin termsofslumpvalue

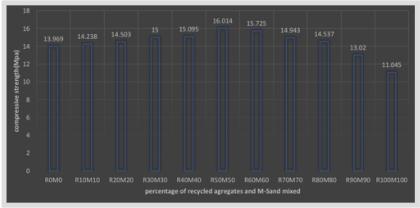

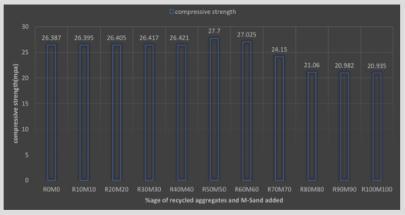

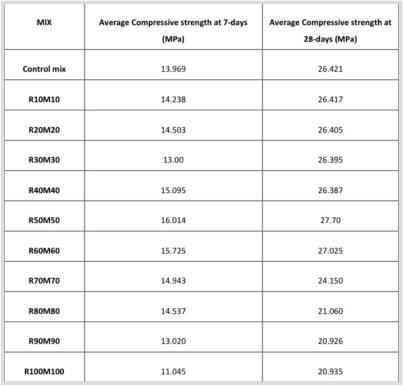

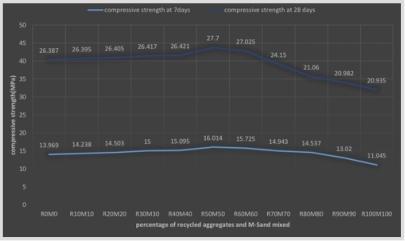

4.2 compressive strength test: - Compressive strength was assessed using a computerised testing machine with a 3000kN capability. A total of 44 cubes were tested inwhich 22cubes weretestedat 7 days and 22 cubes were tested at 28 days. The averageof compressive strength oftwo cubes were taken into account to measure thecompressive strength. The compressive strength of mixes is reduced when NCA is replaced with RCA, as it can be observed from -ig. Compressive strength declines asRCA%rises.

5. CONCLUSIONS: - The fresh and hardened qualities of the concrete mixes were evaluated through tests. The following conclusions can be drawn as a result of theexperimentation.

• The objective of the current experimental work is to assess whether M-sand can completely replace natural -ine aggregate, and as a result, the consequence of M-sand on the mechanical and fresh qualities of concrete employing M-sand is assessed. With an increase in the percentage of both M- sand and RCA, more water is needed to produce a certain levelofworkability.

• The compressive capacity of concrete mixes is increased by up to 50% when M-sand is used in place of natural -ine aggregate. Its maximum compressive strength was 27.700 N/mm2. The compressive strength of concrete mixes is signi-icantly affected byafurtherincreaseintheM-sandreplacement%.

• We can see that a 50% replacement mix has more strength than a 20% or 60% replacement mix, hencetheoptimumvalueis50%.

• Nowadays, river sand is in short supply. M-sand meetsthesandrequirementsinconcrete.

• Recycled coarse aggregate can be utilised in place ofnaturalcoarseaggregate,butonlytoalimited extent.

• Based on this Ginding, it is stated that reutilising andreusing RCA and M-sand in concrete could aid in theresolutionofitshandlinganddisposalissues.

6. ACKNOWLEDGEMENT

We would like to express our heartfelt appreciation to everyone who gave us the

opportunity tocomplete this dissertationwork.Wewould alsolike tothank Headof theDepartment Dr. Rajeev Jain sir, PG Coordinator Dr. J.S.Chauhansir,andProfessorof Civil Department for their comments and support in organising our dissertation study, especially in drafting the research. I am eternally grateful to my research advisors, Professor Dr. PramodSharma sir and Professor Dr. J.S. Chauhan sir, for allowing me to work under their expert guidance, closely monitoring this dissertation, and providing numerous technical ideas andhelpfuladvicethathelpedmetobetterandsuccessfully completethisdissertation.

REFERENCES

1.Code IS: 4031 (Part 6) – 1988. “METHODS OF PHYSICALTESTSFORHYDRAULICCEMENT”.

2. BIS Code IS 383 (1970): “SpeciGication for Coarse and Fine Aggregates from Natural Sources for Concrete andMortar”.

3.BIS Code IS 456 (2000): - “Plain and Reinforced Concrete-CodeofPractice”.

4. IS 1489:2015 Part 1 & 2. “Requirements of PortlandPozzolanaCement”.

5 I S 1 0 2 6

PROPORTIONING”.

6. Vysakh Suthan Pelath, Galanga, N. Ganapathy Ramasamy “Experimental study on strength characteristics of concrete with recycled aggregates and analysis of its effective uses in road works” (IJERT) Volume:04Issue:03|Mar-2015

7. 1996. Alexander, M. G. the impacts of deterioration on the concrete's interfacial region. Interfacial ConversionZoneinConcrete,RileReport11,150–171.

8. Development of Self-Compacting-Concrete with Different Mineral Admixtures: Venkataraman Pai, B.H., K. A. Maitreya Nandy, P. K. Sarkar, C. PramodhGanapathy, and P.George.American Journal of CivilEngineering2(3): 2014.

9. The European Federation of National Trade Associations Representing Producers and Applications of Specialist Building Products (EFNARC) is a trade organisation. 2005. Concretethat self-compacts: speci G ications and recommendations.UK,Farnham:NBSPublication

10. Evangelista, J. de Brito,” Durability performance of concrete made with Gine recycled concrete aggregates”, Cement & Concrete Composites 32 (2010)9–14.

11. M.L. GAMBHIR (2006), Concrete Technology, Tata McGrawHillPublicationCo.Ltd.,India.

12. SarathChandraKumar.Bendapudi.“Contribution-of Fly ash to the properties of Mortar and Concrete”. International Journal of Earth Sciences and Engineering, ISSN 0974-5904, Volume 04, No 06 SPL, October2011,pp1017-1023.

13. Rakesh Soni. “Behaviour of FLY ASH in CementConcrete Pavement”,Volume: 02 Issue: 05 | August2015.