Performance enhancement through design and analysis of All Terrain Vehicle

Aditya Khotte1

1Academic Scholar

1Department of Mechanical Engineering

1PES Modern College of Engineering, Pune ***

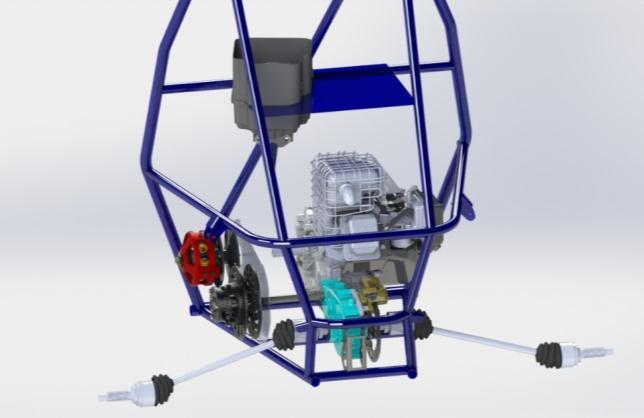

Abstract - Designing an ATV (All-Terrain Vehicle) involves 5 major sub-systems, Chassis, Suspension, Steering, Brakes and Powertrain. Each system is designed with considering current cons in regards of available ATVs in market. Primary objective is to manufacture a lightweight ATV without compromising on performance whilst conforming to all safety standards. Suspension system, being one of the crucial assemblies of any ATV is designed for better driver comfort and light weight yet robust assembly. Steering system is designed with an objective to provide better maneuvering characteristics to the ATV. The powertrain is designed for higher acceleration as well as speed. Braking system is designed to ensure stable operation during braking at all dynamic conditions. This unique class of four-wheeled vehicle is utilized for amusement and exploration purposes.

Key Words: Vehicle, All terrain, Performance, Suspension,Steering,Singleseat,CAE,Manufacturing

1. INTRODUCTION

BAJASAE,theATVdesigneventprovidesaplatformfor undergraduate students to apply the principles of engineering science to expose their proficiency in the automotiveworld.TeamPegasusalwayshadthesoloaimof reelingofftheracebydesigningthebestperforming,rugged andeconomicalvehicle.

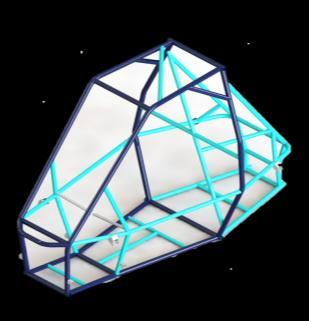

First,abasicdesignprototypewascreatedwhilekeeping inmindtheSAErulesandARAIguidelines.Inordertoassess the ergonomics of the driver, a design mockup with anthropometric measurements (including allowances for clothing)ofsmallandlargemalesandfemales,fromBIFMA ErgonomicGuidelines,2002wasusedandIndianstandards ofsafetywereapplied.The chassisandothercomponents weremodeledinCAD.Thedesignwasrigorouslyanalyzedin variousconditionstoobtainoptimumsafetyandexcellent durabilitywithminimumweight.Toassuresafetyinsucha scenario,arolloveranalysiswasthenperformed.Evaluation of static stability and confirmation of adherence to the relevantIndianStandardswerepartoftherolloveranalysis. Therefore, the design was completed after safety was established.

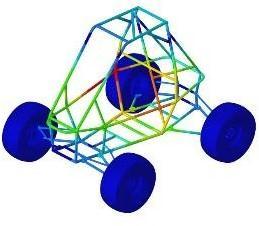

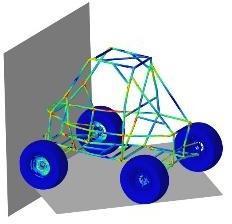

ThequalityofdesignandthetruepotentialoftheATVis discovered only after a deep CAE analysis of all the

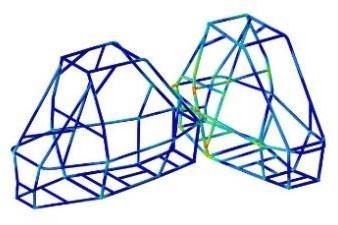

componentsindividuallyaswellasacompleteunit.Modern CAEtechnologyhasmadeitpossibletobeabletoperform number of complex analysis with ease.The first and most crucial step for performing any finite element analysis is meshing.Thegeometryandpropertiesofthecomponentto beanalyzedhavetobestudiedindetailtoselectthemeshing methodwhichwillprovidemostaccurateresults.Afterthe meshing was done, the roll cage was tested in numerous iterations of bump, roll-over, torsion as well as modal analysisasshownhere.Tosimulatereallifeconditions,also performed dynamic impact analysis of roll cage from all sides.

2. ROLL CAGE

Therollcageorbodyofthevehicleiswhatdetermines the perspective of any onlooker as well as the fate of the vehicle in external conditions. all points of scrutiny have beenworkeduponinmultiplestagesofactionandrevision andtocomeupwiththebestpossibledesignforthevehicle. To verify the design parameters and to make the vehicle more efficient, extensive CAE analysis of roll cage is performed.Theresultsoftheseanalysiswereusedtomodify rollcageinmultipleiterationsofdesign.

2.1 Design Objectives

a. To build a tubular space frame with rigid construction whilemaintaininglowoverallweight.

b. To fabricate a frame considering driver safety & ergonomicsinaccordancewiththerulebook.

2.2 Design Consideration

a.Rulebookspecificationsanddriverclearances

b.Theoriesoffailure

c.Structuralmechanicsoftubesforvariousmaterialsfor optimumrigidityandweight

d.Dynamicanalysisofbodyunderapplicationofvarious loadsforvalidationofthedesign

e.Providesufficientspaceformountingofdrivetrain, suspension&steeringassembly

2.3 Material Selection

Sincetheobjectiveoftherollcagedesignistoreducethe overallweightofthechassiswithoutcompromisingstrength, extensive survey of materials is done in order to select a cross-section that provides sufficient strength as well as lesserinweightthanpreviousdesign

AISI4130materialisselectedforprimary&secondary tubesforitshighstrengthascomparedtoPCS.

Table -1: MaterialProperties

A2dimensional‘Quad-only’meshisgeneratedforfinite elementanalysisoftherollcage.Thoroughelementquality checkisperformedtoensureageometricallyaccuratemesh generationwhichwillyieldreliableresults.Startingwiththe modal analysis, the roll cage is simulated under various bump,torsionalaswellascrashconditions.Explicitdynamic analysisisperformedoverarangeofspeedsfrom30kmphto 60kmphtotesttheperformanceofrollcageinallpossible circumstances.

1.5 Fabrication:

A.ACNCpipebendingmachineisusedtobendthemembers asperthedesignandavoidspringbackactionofthebent members.

b. Fixtures and profile tracing using templates for precise manufacturingandtoavoiddistortionwhileweldingisdone

c. TIG welding with filler material ER70-S2 is used for its betterweldstrengthandsurfacefinish.

3. SUSPENSION

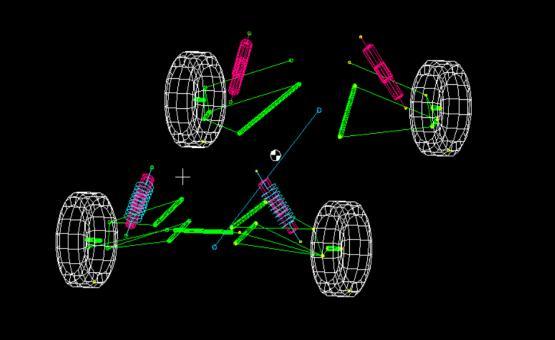

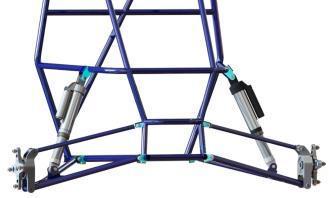

Once inside the cockpit of the vehicle especially in an ATV,everythingthatcanmakeormarthedriversexperience is the vehicle stability and vehicle controls. The dynamic stabilityonanATVinallkindsofobstaclesandharshterrain is directly governed by the suspension system. To get the bestresultsintermsofvehicledynamics,afullyindependent double wishbone suspension system for each wheel that givesamaximumwheeltravelof9inchesincludingjounce andbumpisdesignedwithagroundclearanceof15inches whichisadequateenoughforallchallenges.

Performedmultibodydynamicsofthesuspensionsystem and came up with satisfactory results of camber and toe change.Rigorousanalysisofthewheelendcomponentsand anoverallweightreductionof30%hasdonethusreducing theunsprungmass.

Themotionratioof0.7isdesignedinsuchawaythatthe driverwillexperienceminimumshockstowhichthevehicle isexposed.Thus,byconsideringandrevisingeach&every parameter,anenduringsuspensionsystemisachieved

2.1 Design Objectives

a.Tomaintaintraction(constantcontactofwheelswithroad surface)inallterrains

b.Tooptimizeridequalityandvehiclehandling.

c.Toensurestabilityofthevehiclewhilepitchingorrolling.

2.2 Design Consideration

a.Typeofterrain

b.Drivecomfort

c.HighFatiguelife

2.3 Design Specification

Fullyindependentdoublewishbonesuspensionsystemis selected for required performance of the vehicle. After surveyingtheglobalmarketandfrompreviousperformance experience,FOXFLOAT3EVOL(Rseries)isselectedforfront and AFCO (rebound adjustable coil over shocks) for rear suspensionsystem.

The sprungmass is calculated as 150kgand un-sprungas 48kgalongwithdampingratioof0.93

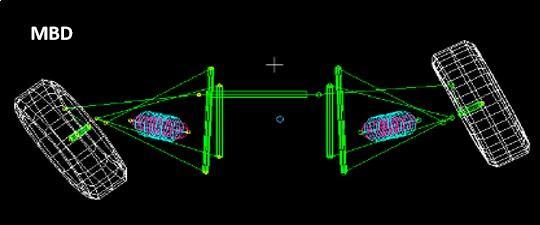

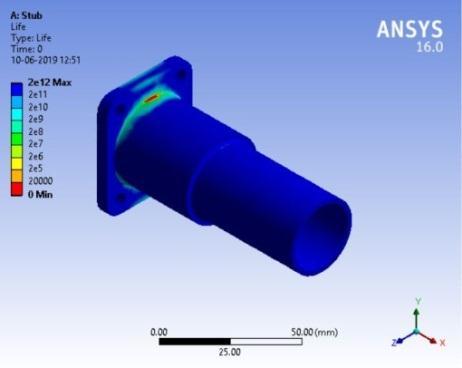

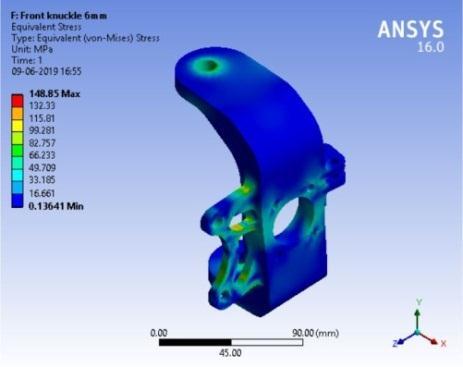

Toensurethatthesuspensiondesignprovidessufficient driver comfort, multi-body dynamics (MBD) analysis is performed.Thesuspensionsystemistestedunderdynamic conditionsandtheperformanceofeachpartisrecordedover arangeofspeeds.Fatiguetestingisdonetodeterminethe

durabilityofallpartsandtoconfirmthatthevehiclewillnot showfatiguebreakdownattheevent.

3.3 Design Specifications

Ackermann steering geometry is selected for better performanceandoversteeringcharacteristicsdependingon whichtheturningradiusofthevehicleisachieved.

The assembly at each side of the vehicle consists of 3 major parts which are controlling arms (wishbones), Uprights&hubs,andshockabsorbers.Thecontrollingarms were made from AISI 4130 tubes of thickness 1 mm and weldedbyTIGweldingprocess.ForUprightsandwheelhubs Aluminum 7075-T6 is used and the components were manufactured on VMC. Also stub axle is made from same materialandmachinedusingCNCLathem/c.

3.

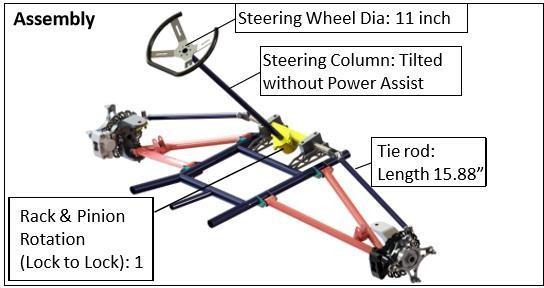

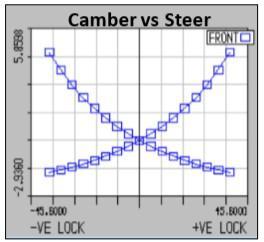

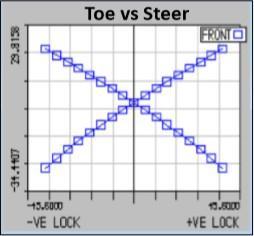

SteeringThemaneuveringcharacteristicsofthevehicleis directlygovernedbythesteeringsystem,whichalsoplaysa major role in primary functioning of the vehicle. After analyzing and optimizing years of technical data, a noteworthybenchmarkinthesteeringsystemisachieved.A rackandpinionhaving1turnlocktolockisused.Therack and pinion are self-designed and has been analyzed with manyiterations.Ackermangeometryofsteeringmechanism is incorporated as it gives one of the best results for all terrain purpose.Multibodydynamics ofsteeringsystemis performedandgottheresultsintermsofthesegraphs.Both leftandrightturnscontributeinalimitedanda minimum changeincamberandtoe,mostofwhichisaresultofbump steer. Care has been taken to keep the steering effort for vehicle low,sothatthedrivermustnotneedtobeworking hardforturningthevehicle.Theturningradiusofvehicleis 1.5m,wellsuitedforagoodcommandoverthevehicle.

3.1 Design Objectives.

a.EaseofManeuverabilityofthevehicle.

b.Reductioninturningradiusofthevehicle

3.2 Design Considerations

a.CasterAngle

b.Lowsteeringeffort

Table -5: SteeringSpecifications

Non-linearcontactanalysisisimplementedtoobtainthe performance of rack and pinion steering under actual conditions. Multi-body dynamics is done to validate the designparametersandcheckforaccuratesteeringmotionat alltimes.

-10 SteeringCharacteristics

3.5 Material selection & Fabrication

Theassemblyconsistsofsteeringwheel,steeringcolumn, rack & pinion, tie rods and steering arms. Steering wheel (increaseddiameter thanpreviousvehicleforreductionin steering effort) is made from aluminum pipes bent using handbendingandweldedtogetherbyTIG welding.Steering column is made from AISI 4130 tube with 2mm thickness. 20MnCr5isselectedforrackandpinionandmanufactured usinggearteethcuttingTierodsweremadefromAISI4130 tubesofthickness2mmandsteeringarmsweremadefrom MS(MildSteel)usingCNClasercutting

POWERTRAIN

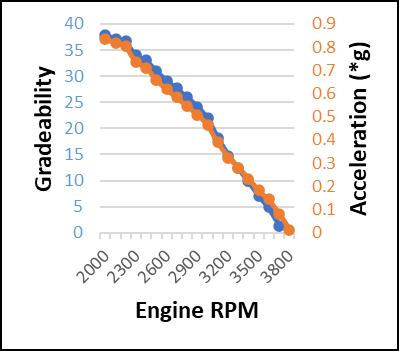

A roaring powertrain is what the ATV needs and the samehasbeenaccomplishedduringthedesigningaswellas themanufacturingphase.JITCVT,alongwiththestandard BriggsandStrattonengine,asthelowratioof3.9:1provides ampletorqueandaccelerationduringpickupandhighratio of0.9:1bringsgreatspeedunderrunningconditionisused TotransmittheoutputpowerfromtheCVTtothewheels,a single speed two stage reduction gearbox which has a reductionratioof7.79isdesigned.Weighingjustbelow4.5 kgs,thegearboxdesignisverycompactandiscalculatedto giveamaximumspeedof58kmphfortheATV.Analysisof the entire gearbox is done more than once to validate the design. For further transmission, a tripod joint at the gearboxsideandrzeppaballjointatthewheelendside is incorporated Asingleunitshaftisusedtoincreasetheshaft strength, that also reduces the weight. This layout has a calculatedinitialwheeltorqueof559Nmandagradeability of 84% which is adequate for all the dynamic situations Rubberisolatorsareusedtoarrestanddampentheengine vibrations.Alltheparametersareiterativelycalculatedand comparedwithalloftheavailableresources

4.1DesignObjectives

a.To produce optimum power at the wheels from engineoutputandlimitvehiclespeedto60kmphasper rulebook.

b.To get ample torque at the wheels for maximum accelerationandgradientnegotiation

c.Toprovidesufficientspeedforracing

4.2DesignConsideratins:

a.Reducedweightoftheassembly

b. Maximum transmission efficiency with CVT tuning for enhancedacceleration

c.Theoriesoffailure

ThedrivetrainconsistsofrulebookstandardBriggsand Stratton 4stoke, single cylinder, 305cc, air cooled engine which produces a maximum power of 10bhp with speed governorwhichlimitstheoutputspeedofengineto3800rpm accordingtowhichdesignandselectionoffurtherassembly isdone.

ItwasselectedJITSolutionscustomCVTforATV.TheCVT hasalow-endratioof3.9:1andahigh-endratioof0.5:1.The CVT has efficiency of approximately 85%. The CVT is lightweightandweighs5kg.

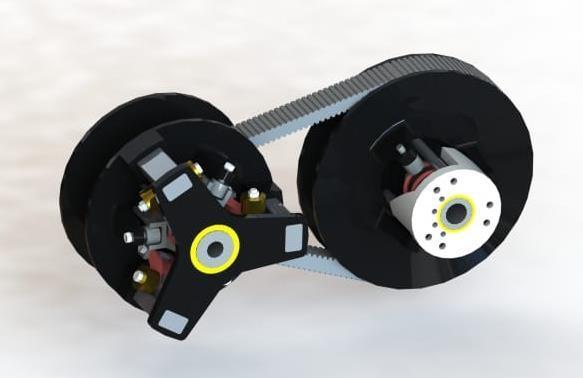

4.4 Gearbox:

A single speed 2 stage (unequal speed ratios) reduction gearboxisdesignedtoproducetherequiredtractiveeffortat thewheelsaswellaslimitthespeedofthevehicleto60kph. Itis designedconsideringgrossweightofvehicleas200kg andwheeldiameterof23”

4.5 Axle

Accordingtotheplungeandarticulationrequirementsfor jounce and bounce conditions, TATA Nano Tripod Joint is selectedforthegearboxsideandMaruti800RZeppajointis selectedforthewheelendside.Aftercalculatingthelength from the line geometry, custom half shafts were designed withmaterialSAE8620.

4.6 CAE

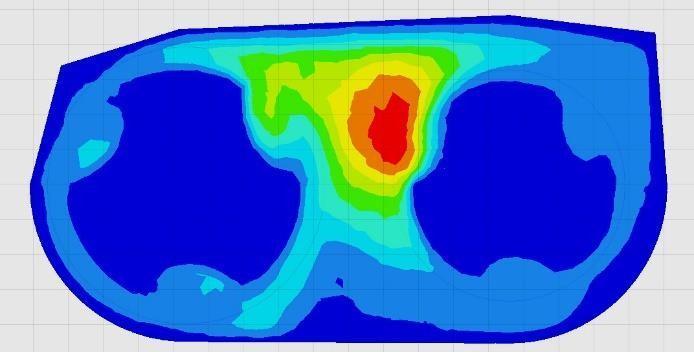

Designed a robust gear-train to improve the overall performance of the transmission system. Topology optimization is performed on every gear to maintain optimumgearperformanceevenafterblankingoperationis done.ComputationalFluidDynamics(CFD)underturbulent flow conditions is implemented on CVT casing to ensure propercoolingofCVTduringitsoperation.

a.Gears:

Spurgeardriveisselectedforitshighestefficiencyandthe materialselectedfortheseis20MnCr5foritsstrengthand availability in the market. (Manufacturing with the help of UMM & hardness up to 55HRC obtained by surface hardening)

b.Shafts

Input, intermediate and output shafts were designed considering maximum shear stress theory of failure. The materialforshaftsisselectedsameasthatofthegearsand featherkeys(Material:MildSteel)wereusedtomountthe gears

c.Bearings:

Selectionofsinglerowdeepgrooveballbearingsandroller bearing

d.Lubricant:

SAE20W40oilisselected

e.Casing:

Aluminum 6061-T6 is selected for the casing and FEA of casingconsideringbearingreactionsisperformedtocheck thefunctionality.

Fig -13 ComputationalFluidDynamics

5. BRAKES

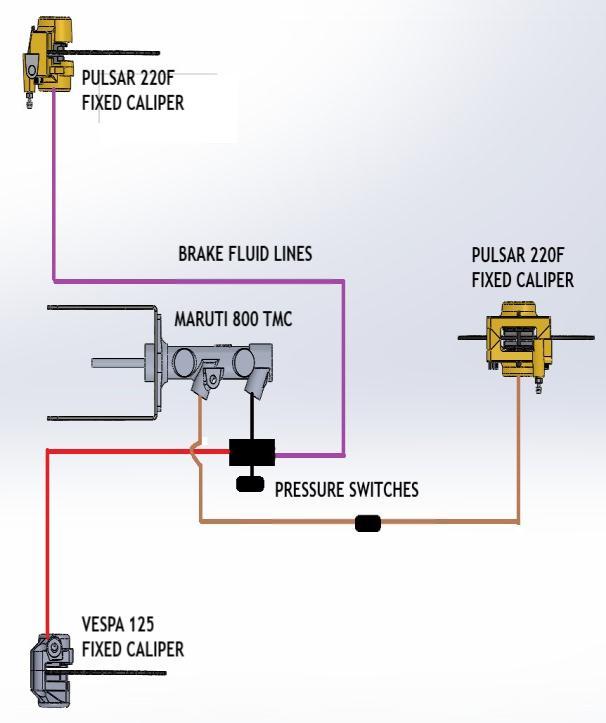

Brakesystemisofhighpriorityinthevehicleasanybreach ormiscalculationcandirectlyaffectthesafetyofthedriver. Withkeepingthesameperspectiveinmind,acombinationof OEMandself-designedcomponentsisused,tokeepthebrake systemasreliableaspossible. Designeda Front/Rearsplit circuit with inboard braking on the rear side. A 2 port Tandemmastercylinderwiththeborediameterof19mm andfixedtypebrakecalipersofborediameter30&32mmas theyarecompact,lightweightanddurableisused Thebrake discsaredesignedof160mminthefrontand190mminthe rearthatarecapableoftransmittingthebraketorqueaswell asdissipatingtheheatthatisgenerated.Keepinginmindthe ergonomicconsiderationswhiledesigningthepedalwhich alsosustainsrepeatingcyclesofpanicbrakingasshownby theanalysis.Therefore,byhavingabrakingtorquewhichis morethantherequiredtheoreticalvalue,ATVwillbeeasily abletostopwithinadistanceof4.9m.

5.1 Design Objectives:

a.Tostopthevehiclebyallwheellockingwithinminimum possibledistanceusingdiscbrakesystemprovidedstability ofthevehicleisintact.

b. To design the rotor for optimum heat dissipation and sufficientbrakingtorque.

c.Toselectappropriatefluidcircuitryandcomponentsalong with electrical wiring for tail lamp (according to the rulebook).

3.2 Design considerations:

a.Brakingforcebythedriverforbrakedesign.

b.Stablebraking

c. Stopping distance with 5m when vehicle is running at a speed50kmph

3.3

Design specifications:

ItisdecidedtouseanOEM2portTMCwith19mm(3/4”) borediameter,adheringtothecalculationsalsoitisdecided tousefixedtypecaliperswhichhaveborediametersof30mm and32mmwhicharerigid,compactandreadilyavailablein theIndianmarket.

By reverse calculating the values after selecting the componentsandbyanalyzingtherequiredvalueofbraking torque,therotordiameterswerecalculated.

b.C45stainlesssteelisselectedformanufacturingofrotor

c.Mildsteelisusedforbrakepedal

3.4 Components and material selection:

a. Tandem Master Cylinder (double piston, 2 port, bore*stroke=19*21),fixedtypebrakecalipers,DOT4brake fluidwereselectedfromperformanceandcostpointofview

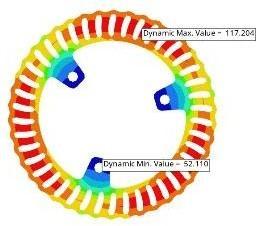

5.5 CAE:

Transientthermalsimulationisdoneforthebrakerotorto determinetheriseintemperatureduringbraking.Totestthe vibrationalperformanceofdiscbrakeassembly,non-linear contacttype‘Brakesqueal’analysisisperformed.Itisfound that the braking system showed stable, vibration-free operationwhilebrakingatallpossiblevehiclespeeds.

6. CONCLUSION:

Thisproject'sprimarygoalwastodevelopandproducean all-terrain vehicle employing design and assembly knowledge.RigorousAnalysiswascrucialingettingoptimum results.Thebest-optimizeddesignisproducedthroughout thedesigningphaseinordertoincreaseperformance,reduce weight, and take cost-cutting factors into account. The combinedextensiveresearchonautomobiledesignhasledto thecreationofATVwhichisworthyofalltheextremeterrain conditions.Properattentionisgiventoevenminutedetailsin thevehicletomakeittrulycustomized.

7. ACKNOWLEDGEMENT

Iwouldliketotakethisopportunitytoacknowledgeand thank the whole “Team Pegasus Racing” of PES Modern CollegeofEngineering,Pune,whosevaluablesupportand contributionhashelpedmepatchthisprojectandmakeita full-proofsuccess.

I hope my thesis and analysis can provide meaningful conclusionsanddojusticetothetopic.

8. REFERENCES

[1] Milliken, WilliamF.,andDouglasL.Milliken.RaceCar Vehicle Dynamics. Warrendale, PA, U.S.A.: SAE International,1995.Print3.Smith,Carroll.TunetoWin. Fallbrook,CA:

[2] ‘DesignofMachineElements’V.B.BhandariMcGrawHill EducationIndiaPrivateLimited;Fourthedition(1July 2017)

[3] Nordhoff,LarryS.“MotorVehicleCollisionInjuries: Biomechanics,Diagnosis,andManagement”/Lawrence S.Nordhoff,Jr.-SecondEdition

[4] Gillespie,ThomasD.FundamentalsofVehicleDynamics. SAEInternational,1992.

[5] Vikas Sharma and Divyanshu Purohit. (2012). SIMULATIONOFANOFF-ROADVEHICLEROLLCAGEA STATICANALYSIS.InternationalJournalofEngineering ResearchandApplications(IJERA),2(4),126-128

[6] Nayak, A. O., Ramkumar, G., Manoj, T., Kannan, M. A., Manik,D.,&Chakravarthy,S.(2012).Holisticdesignand softwareaidedfiniteelementanalysis(FEA)ofanAllTerrain Vehicle. Journal of Mechanical Engineering Research,4(6),199-212.

[7] Design & Manufacturing of All Terrain Vehicle (ATV)Selection, Modification , Static & Dynamic Analysis of ATV Vehicle, Upendra S. Gupta,Sumit Chandak,Devashish Dixit,International Journal of EngineeringTrendsandTechnology(IJETT)–Volume 20Number3–Feb2015.

[8] Designing of All Terrain Vehicle (ATV) by Deep Shrivastava , International Journal of Scientific and Research Publications, Volume 4, Issue 12, December 2014

[9] ATextbookofMachineDesignbyR.S.KhurmiandJ.K. Gupta.

[10] FundamentalsofMotorVehicleTechnology,(BOOK2) byV.A.W.HillierandDavidR.Rogers

[11] MATERIAL SELECTION IN GEAR DESIGN Radinko Gligorijević,JeremijaJevtić,DjuroBorak

[12] Automotive Transmissions by Herald Naunheimer, BerndBertsche,JoachimRyborzandWolfgangNovak.

9. BIOGRAPHY

Mr. Aditya Khotte

B.E.MechanicalEngineering, PESModernCollegeofEngineering, SavitribaiPhulePuneUniversity.