METHODS OF INCREASING CALORIFIC VALUE OF BRIQUETTES USING BIOMASS

Ravi Prajapati1 , Sahil Jha2 , Shubham Sawant3 , Rohit Gaikwad4Diploma students Department of Mechanical Engineering, Thakur Polytechnic Kandivali (East),Maharashtra, India.

Abstract- The use of biomass as fuel source is becoming increasinglypopularduetoitsrenewablenatureandlower environmental impact compared to production of briquettes,whicharecompressedblockofbiomassthatcan beusedasafuelsource.Howeverthecalorificvalue(CV)of this briquettecan be lower than that of traditional fuel making them less attractive to consumer. This paper explores the potential for increasing the CV of briquettes using biomass. The study examines various techniques for increasing the CV, including the use of densification methods, additives, pre treatmentprocesses. The result of the study indicates that this techniquescan be effective in increasingtheCVofbriquettes.Densificationmethods,such as pelletizing and briquetting, canincrease the density of biomass, resultingina higherCVadditives,suchasbinders and fillers, can also increase the density and combustion properties of the briquettes. Pre treatment processes such astorrefactionand carbonization, can also increase the CV by removing the moisture and increasing the carbon contentofthebiomass.

Keywords: carbonization, cow dunk, cashew nuts, charcoal, Coconut flakes and shell, saw dust, rise husk.

I. INTRODUCTION

There are several reasons why biomass is needed as source of energy. First and foremost biomass is a renewable energy source which means that it can be replenished relatively quickly compare to traditional fossil fuels which are finite resources thattake million of years to form. This makes biomass a more suitable and environmentally friendly option for meeting our energyneeds

Another important need for biomass is its potential to reduce greenhouse gas emissions. Burning fossil fuels releases carbon dioxide and other pollutants into the atmosphereto,contributingclimatechange.Incontrast, using biomass as a fuel source can reduce net carbon emission by sequestering carbon in plants and trees by displacing fossil fuels. Biomass can provide energy security, particularly for communities and countries

that rely heavily on imported fossil fuels by producing theirown biomass wasteenergythesecommunitiescan reduce their dependence on foreign oil and gas, which cansubjecttopricevolatilityandgeopoliticaltensions.

Finally, the use of biomass can provide economical benefits particularly in rural areas where farming and forestry are important industries. The production and use of biomass can create jobs and stimulate local economicsprovidingasourceofincomeforfarmers and forest owners. Overall, the need for biomass as asource of energy is driven by its potential to provide sustainable, environmentally friendly, and economically viableenergysolutionsforthefuture.

II. THE PRESENT STUDY WAS UNDERTAKEN WITH THE FOLLOWING OBJECTIVES :

1) To increase the energy efficiency: A higher CV means the briquettes can produce more energyperunitofmass.Thiscanhelpimprove their energy efficiency and make them more competitivewithtraditionalfossilfuels.

2) To reduce emission: A higherCV means that less biomass is needed to produce the same amount of energy. This can help reduce the emissions of greenhouse gases and other pollutants associated with the production and useof biomassbriquettes

3) Education and outreach: Educating others about the benefits of biomass briquetting and how to increase the CV of biomass briquettes canhelpraiseawarenessandgenerateinterest in this field. We can participate in outreach programs, develop educational materials, or giftpresentations toshareourknowledge with others

4) Research and Development: Participating in research and development initiatives related to biomass briquetting technology can be a

great way to increase your knowledge and experience in this field. We also contribute to the development of a new and innovative methods to increase the CV of biomass briquettes.

III. METHODOLOGY

India is heavily dependent on fossil fuel particularly coal which accounts for over 70% of the country electricity generation this reliance on coal has led to issuessuchasairpollutiongreenhousegasemissionand environmental degradation despite significant progress in recent year a large portion of India population still lack access to model energy sources this has implications for health education and economic development. Biomass a renewable and sustainable source of energy as it is derived from organic matters such as agriculture waste wood chips and other plant material unlike fossil fuels which are finite and non renewable biomass can be continually replenished sustainable harvesting and cultivation practices. We address the problems that are pollution and energy demand running through worldwide and try to resolve it.

IV. The whole study was conducted in two phases:Phase 1: Analysis of Briquettes.

Phase 2: Upcoming opportunities for biofuels (briquettes) in India

Phase 1:- Analysis of Briquettes History of Briquettes

Briquettes are blocks of compressed biomass or coal dust that are used as fuel. The history of briquettes dates back to the late 19 century when a Frenchman named Eller and Swiss named Rane Antoine Gauthier developed a briquette making process using sawdust and cuttings from wood mills. This process was pa in Switzerland in 1895 andintheUnitedstatesin1896.

Briquette Gained popularity during the early 20th century as of way to use waste materials from sawmills and other word processing industries. Thebriquettemakingprocesswasrefinedoverthe years, and different types of briquettes were developedusingdifferentmaterials,includingcoal dust and various types of biomass such as straw, ricehusks,andevencoffeehusks.

DuringWorldWar2briquettes becameevenmore popularas fuel shortages led to rationing and the need for alternative sources of energy. In Europe, briquettes were used for used extensively for heating and cooking, and in some cases they were evenusedascurrency.

In the post war era, briquettes continued to be a popular source of fuel, particularly in developing countrieswheretraditionalsourcesofenergywere scarceofexpensive.Today,briquettesarestillused aroundtheworldasasourceoffuelforcookingand heating, and they are also used in industrial processes, such as production of steel and cement. With growing concerns about climate change and theneedtoreducegreenhousegasemissionsthere has been renewed interest in briquettes as a sustainableandrenewablesourceofenergy.

Briquettes are different from other fuel

Environmental impact breakwater considered to be more environmentally friendly fueled and traditionalsourcessuchascoaloilorwood.

Theyaremadefromrenewableresourcesandhave a lowercarbon footprint than fossil fuels efficient burning requests are designed to burn more efficiently and produce less smoke and ash than traditionalfuels.Thismakesthemapopularchoice for cooking and heating in developing countries whereindoorairpollutionfromtraditionalfuelisa significanthealthconcern.

Ease of use requests are easy to use and transport astheyarecompactanduniforminsizeandshape. They are also convenient to store as they do not require large amount of space. Cost brick can be costeffectivefueloption.

Versatility Briquettes can be used in a variety of applications including cooking eating and industrialprocesses. They can also be used as a replacement for charcoalinbarbecuegrills as they burnlongerandproducelesssmoke.

The production process for biomass briquette be optimized to improve efficiency, reduce waste and minimize environmental impacts by following methods:-

result is high quality briquettes that burns cleaner and longer

Torrefaction: This process involves eating the biomass material in the absence of oxygen, which reduces its moisture content and increases its energy density. The torrefied biomass can then be compressed into high quality briquettes that have higher energy content and bettercombustionproperties.

Carbonization: This is a process that involves heating the biomass material in the presence of limited oxygen to produce charcoal. Charcoal briquettes have a higher energy content andburn longer than regular biomass briquettes.

Densification: This technology involves compressing the biomassmaterial toincreasethedensityandreduce itsvolume.Theresultismorecompactandtransportable productthatiseasiertohandleandstore.

Raw material selection: Choosing the right raw material is crucial for producing high quality biomass briquettes. It’s important to select materials that have consistentsize, lowmoisturecontent,andhighcalorific value to ensure optimal combustion efficiency and reducewaste.

Drying: Drying the raw materials before briquetting can significantly reduce the moisture content and improve the efficiency of briquetting. Using waste heat from production process or renewable energy sources like solar energy can helpreduce energy consumption andenvironmentalimpact.

Briquetting: The briquetting process itself can be optimized toimprove efficiency and minimize waste. Using the right pressure, temperature, and binders can help produce briquette with high density and low ash content, While minimizing the amount of material that islostorwastedduringtheprocess

Energy recovery: Recoveringenergyfromwasteheatof gasesenergy of gases generated during the briquetting process can help reduce energy consumption and environmentalimpacts

New technologies which helps to improve the calorific value of biomass briquettes Binder-less briquetting: This technology involves the use of high pressure and temperature to compress the biomass material without the need of binders or additives. The

Pelletization: Pelletization involves compressing the biomassmaterialintosmallpelletsusingthepelletmills. Pellets are denser and more uniform product than briquettes which makes them easier to handle and transport. They also have a higher energy content and moreefficiently.

Pyrolysis: Pyrolysis is a thermal process that involves heating biomass at high temperature in the absence of oxygen. This process can breakdown biomass volatile gases, liquids and char.The char produced through this processcanbeusedtomakehighcalorificvaluebiomass briquettes.

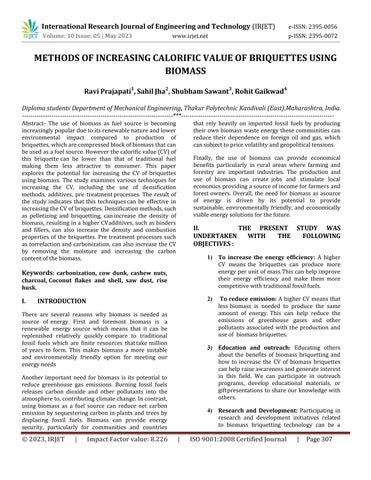

Briquettes making process

Here are 5 key steps involved in the process of making briquettes:

Preparation of raw materials : The first step is to collect the raw material, which can be agricultural waste, sawdust, wood chips, or charcoal dust. The raw materials is then dried to reduceits moisture content, whichisimportantforachievinghighqualitybriquettes.

Grinding the raw materials: Thedriedrawmaterialis then ground into a fine powder. The grinding process helps to breakdown the raw materials into small particles, which makes it easier to compress into briquettes.

Mixing the raw materials: Thegroundrawmaterialis then mixed with binder, such as starch or clay, to help hold the briquette shape together during compression process.Watermayalsobeaddedtothemixturetohelp withbinding.

Compression of mixture: The mixture is then fed into a briquetting machine, where it is compressed under highpressureandtemperaturetoformbriquetteshape. The compression process helps to remove excess moisture and bind the raw materials and binder together.

Drying and storage: Once the briquettes are formed, theyarecooledandthendriedtoremoveanyremaining moisture. The driedbriquettes arethenstoredforlater usedortransportation.

resources can be used to produce biomass briquettes, whichcanbeusedasasourceofrenewableenergy.

Increasing demand for energy:- India is one of the fastest growing economies in the world, with a rapidly increasing demand for energy. Biomass briquettes can help meet thisdemand by providing a renewable and sustainablesourceofenergy.

Economic benefits:- Biomass briquettes can provide economicbenefits to farmers and rural communities by providing a source of income from waste biomass resources.Thiscanhelppromoteruraldevelopmentand reducepovertyinIndia.

Government schemes and incentives for renewable energy

The Indian government has implemented various policiesand incentivestopromotetheuseofrenewable energy sources, including biomass briquette. These policies and incentives provide financial support and other benefits to entrepreneurs and organizations for settingofbiomassbriquettesproductionunits.

Subsidies: Some governments provide financial subsidies to manufacturers of biomass briquettes to encourage the production of this renewable energy sources.

Tax incentives:- Governments may offer tax credits or deductions to individuals or companies who use biomassbriquettesasanalternativetofossilfuels.

Energy credits:- In some countries, biomass briquettes are eligible for energy credits, which can be sold to companies or individuals who need to meet their renewableenergytargets.

Phase 2:

Scope of biomass briquettes in India

Biomass briquettes have a great scope in India due to theirpotentialtoreplacefossilfuelsandcontributetoa moresustainableenergymix.Herearesomefactorsthat contributetothescopeofbiomassbriquetteinIndia:-

Availability of biomass resources:- India has large amount of biomass resources, including agricultural waste, forestryresidue and municipal solid waste these

Grant programs:- Some governments offer grant programs that provide funding for research and development of new biomass briquette technologies or for the installation of equipment to produce or use biomassbriquettes.

Awareness campaigns:- Governments may run awareness campaigns to promote the use of biomass briquettesasarenewableenergysource,andtoeducate consumersonthebenefitsofthesealternativefood.

Subsidies for users:- Some government may also providesubsidies for financial incentives to households or business thatuse biomass briquettes for heating or cooking, to make the renewable energy source more affordableandaccessible.

Machinery, Land requirements, Plant cost, Product cost

Thetotalcostofbiomassbriquetteproductionmachine andthelandrequirementcanvarydependingonseveral factorssuchastheproductioncapacity,typeofmachine, automationlevel,andlocation.

to 1000 square metres, while a large scale unit may require several acres of land. The land should have properaccesstoroads,water,andelectricity.

In addition to the machine and land cost, other factors such as rawmaterialcost,laborcost,andtransportation costshouldalsobeconsidered while estimatingthetotal cost of producingbiomass briquettes. It is important to do through cost benefit analysis before starting a biomass briquette production units to ensure its profitabilityandsustainability.

Biomass briquette production machine cost:- The cost of biomass briquette production machine can vary from around INR 1lakh to several crores depending on the capacity, automation level, and type of machine. Small manual machine can cost around INR 1-2lakh, while the larger fully automated machines cancause to severalcrores.

The cost of briquettes in India can vary depending on the several factors such as the location, the type of briquettes, and the quantity purchase. However, as generalestimate,thecostofbriquettesinIndiacanrange fromaroundINR3,500toINR5,000permetricton(MT) for non processed biomass briquettes. According to report by research and Markets published in August 2021theIndianbiomassbriquettemarketwasvaluedat USD698.2millionin2020andisprojectedtoreachUSD 1,797.8 million by 2026, growing at a CAGR of 17.4% during the forecast period (2021 2026 ). Around 326 firmsproducingdifferenttypesofbriquettesinIndia.

Types of briquettes

Land requirement:- The land requirement for a biomass briquette production unit will depend on the production capacity and the location. A small scale production unit may require a land area of around 500

Charcoal briquettes:- These are made from charcoal dustmake with a binding agent such as clay or starch, and then compressed into blocks. They are commonly usedforgrillingandbarbecuing.

Biomass briquettes:- These are made from various organic materials such as sawdust, rises husk, and other agricultural waste. They are compressed without the use of binding agent and are used for heating and cooking.

Paper briquettes:- These are made from shredded paper mixedwith a binding agent such as water and thencompressedintoblocks.Theyareusedasafuelfor fireplacesandstoves.

Lignite briquettes:- This are made from lignite coal, whichisalowgradecoalthatisabundantinmanyparts of the world. They are commonly used for heating and cooking.

Coconut shell charcoal briquettes:- These are made from coconut shells that are burned and then compressed into blocks.They are commonly used for grillingandbarbecuing.

Wood briquettes:- These are made from compressed wood shavings and sawdust. They are commonly used for heating andcooking and are popular alternative to firewood.

Briquette market industry in India

Increasing demand for renewable energy sources and thegovernmentsfocusoncleanenergy.

According to a report by ResearchAndMarkets.com, the Indianbiomass briquette market was valued at around $575 million in 2020 and is expected to grow at a compound annual growth rateof over 10% during the forecastperiodof2021to2026.

ThedemandforbriquettesinIndia isdrivenbyseveral factors,including the rising cost of the traditional fuels suchascoalandpetroleum, increasing awareness about the environmental benefits of using renewable energy sources,atthegovernment’sinitiative to promote clean energy.

The market for briquette in India is fragmented, with many small and medium sized player operating in the sector. Some ofthe major players in Indian briquette market include Green Energy Biofuel, Biomass power, Jay Khodiyar Machine Tools, and Radhe Engineering Corporation.

Overall,thebriquettemarketintheIndiaisexpectedto continue its growth trajectory in the coming years, driven by the increasing demand for clean and sustainableenergysources

Hypothesis and Postulates:

1. We can use different biofuel crop waste in order to increase calorific value (CV) of biomass briquettes. For example:

Jatropha : Jatrophaisacropthatisoftengrowfor its oil, which can be used as a biofuel. There are several other crops that can also be used for biofuelproduction.

Soybeans: Soybeans are a versatile crop that can be used foravarietyofpurposes,includingbiofuel production.Theoilfromsoyabeancanbeextracted andconvertedintobiodiesel.

Corn: Corn is another crop that can be used for biofuel production. Corn ethanol is a popular type of biofuel that is made by fermenting the stars in corn.

Sugarcane: sugarcane is the popular crop for biofuel production in countries like Brazil. The juice from sugarcane can be fermented and distilledtoproduceethanol.

Switchgrass: Switchgrassisthetypeofgrassthatis nativeto North America and is being studied as a potential biofuelcrops. The plant can be grown on marginal land and can beconverted into biofuels usingvarietyofprocesses.

Algae: Algae a promising crop for a biofuel production because it grows quickly and can be grown in variety of environments including ponds and tanks.The oil from algae canbeextractedand convertedintobiofuels.

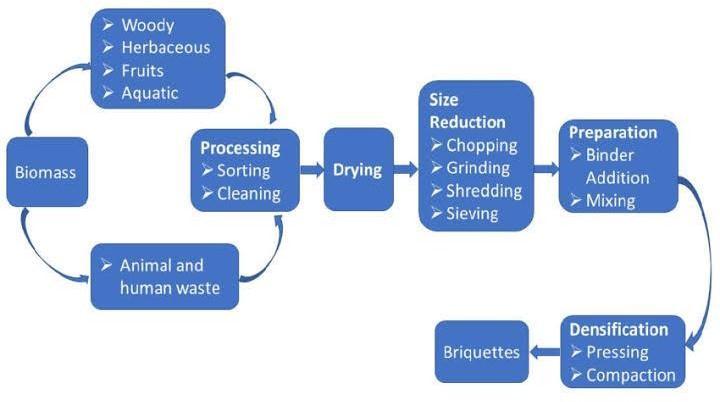

2. Making charcoal by using local methods to increase the calorific value of biomass briquettes.

Carbonization: This is a process that involves heating thebiomass material in the presence of limited oxygen to produce charcoal. Charcoal briquettes have a higher energycontent and burn longerthanregularbiomassbriquettes.

Here are some examples for making charcoal with the helpoftraditional ways incheapprice.Wecanusethis methodtoincreasethecalorificvalueofbriquettes.

Conclusion:

Weconductedourresearchintwophases.

In Phase 1 we did analysis on briquettes in which we dealswithhowbriquettesaredifferentfromotherfuels, process of making briquettes other than that new technologieswhichenhanceitscalorificvalue.

In phase 2 wedidstudyonupcomingopportunitiesfor biofuelsin India in which we studied government has implementedvariouspoliciesandincentivestopromote the use ofrenewableenergysources otherthanthatwe also studied about machinery, land requirement, and briquettemarketindustryinIndia.Afterresearchingon topicwegivesomethesisinthatwebelievethecalorific value ofbriquette will increase ifwe use itin briquette makingprocess.

References:

1. Brandt H. J. 1990. Biomass Densification Research Project, Phase one, Main Report, Technology and DevelopmentGroup,Enschede,TheNetherlands.

2. Hall, D.O., Overend, R.P., 1987. Biomass. New York: JohnWiley&Sons.

3. Woods J and Hall D.O. 1994. Bioenergy for Development: Technical and Environmental Dimensions, FAO Environment and Energy Paper 13, Rome.

4. Aqa,S.,1990,AStudyofDensificationofPre-heated Sawdust,MastersThesisNo.ET-90-4,AsianInstituteof Technology,Thailand.

5. Aqa,S.andBhattacharya,S.C.,1992,Densificationof Preheated Sawdust for Energy Conservation, Energy, Vol.17,No.6,pp.575-578.

6. Grover, P.D. and Mishra, S.K., 1996, Biomass Briquetting: Technology and Practices; RWEDP Field Document no. 46, Food and Agricultural Organization oftheUnitedNations,Bangkok,1996.

7. Joseph, S., Hislop, D. and Errey, S., 1985, The Development of a Energy Production System to Briquette Papyrus Through Partial Pyrolytic Conversion, Biomass Energy Services and Technology, BEST,December.

8. Joseph, S. and Hislop, D., 1985, Residue Briquetting in Developing Countries, Energy From Biomass 3, pp. 1064-1068,Elsevier,London.

9. Mishra, S. K., 1996, Hardfacing of Screw for Wear Resistance, Proceedings oftheInternational Workshop on Biomass Briquetting, New Delhi, India, 3-6 April 1995.

10. Reed, T.B., Trezek, G. and Diaz, L., 1980, Biomass Densification Energy Requirements, Thermal Conversion of Solid Wastes and Biomass, American ChemicalSociety.