Electromagnetic Design of a 7kW Permanent Magnet Synchronous Motor for a Two-Wheeler

Gareema Waraich1 , Dharamraj Saini2 , Dr. C.S. Boopathi3ABSTRACT

The focus and interest on Permanent Magnet Synchronous Motor has been continuously increasing, thanks to their properties which are deemed suitable for a variety of applications especially in automobiles. This paper presents an approach to electromagnetically design of a 7kW PMSM that will in turn be responsible for propelling a two wheeled electric vehicle. The nominal parameters like air gap, structure dimensions, slot size, pole number, etc have been calculated mathematically during the design of the motor and accordingly a 12s8p Interior Permanent Magnet motor has been presented. The approach taken to make an integrated design has been explained and the results have been quantitatively verified .The proposed design has been optimised and simulated using Flux Motor Software

Keywords: PMSM, magnet, winding, air gap, magnetic circuit, electromagnetic

I.INTRODUCTION

In an era where the industry is gradually shifting towards electric vehicles due to increasing concerns pertaining to climate change, the focus on development and design of motors has increased a lot. The growing demandofelectricvehicleshasfuelledanincreaseinthe demandof PMSMs. Vehicularmotorsshouldhavea high power density [1], high torque to current ratio and well asbehighefficiency.PMSMsareaveryattractiveoption due to their compactness, high performance and low maintenance.Alotofconstraintshavetobekeptinmind while designing a light weight motor that caters to the requirement and is within a particular cost bracket. Along with this, the primary goal is to develop a highly efficient motor that will in turn contribute to lower losses and lower carbon emissions while reducing the motor volume, decrease the space occupied by it and improve material utilization. Along with this, ease of manufacturability, installation, maintenance, raw materialrequiredandthetechnologyusedtoimplement are a few things that are considered while selecting or designingamotor.

Thedesignandanalysisofamotorcanbedividedinto4 sub categories namely preliminary assumptions, electromagneticdesign,thermalandcoolinganalysisand mechanical design and dimensioning. In this paper we focus only on the electromagnetic design aspect. The electromagnetic process can be further categorized into designandcalculationsofthemagneticcircuit,thesizing andtheslotleakagereactance.

Firstly we compute and fix the basic geometrical data and the motor topology [2]. According to this, the electromagnetic design and analysis is done. Optimization is a vital part in designing a high performance machine. A variety of applications with different performance requirements may be improved by selecting optimum geometry dimensions, material propertiesandexcitations.Inthispaperwefocusonthe electromagneticdesignandanalysisofaPMSMmotorin theelectricpowertrainofa twowheeler.Itincludesthe evaluation of various factors including rotor topologies ,winding patterns, air gaps amongst a few. The specifications of the motor designed are mentioned in table1.

II.DIFFERENT MOTORS USED IN ELECTRIC VEHICLES

a)

These motors were popular before the age of development[3] in the power electronics sector. Ease in controlandarobuststructureiswhatmadeitattractive. But the downsides include their large structure and low reliability. The presence of brushes in them also cause decrease in efficiency and an increase in the cost of maintenance.Thisalsoactsasa hinderanceto reachthe maximum speed. So, these are a good choice in low powerapplications.

b)

Squirrel cage IMs have a simple yet sturdy structure which has the ability to be to be highly reliable and cheap. The torque produced has a low ripple and this motor can be used in high speeds too. But a relatively complex circuitry , lower efficiency and power density hasledtoadecreaseinitmarketshare.

c)

PMSmotorshaveovertakeninductionmotorsespecially in traction applications owing to their highly efficient energy output [4]. Their high power density and a great torque quality have made it a likeable option to quite a few automobile manufacturers like Toyota and Nissan. Buttheirconsincludeacomplexconstructionandahigh price.

d)

When it comes to high-speed applications, these motors are generally the most suitable. They are capable of performingathighspeedswhilekeepingtheweightlow. The absence of brushes makes its maintenance easier andcheaper.Anaveragefieldweakeningabilityofthese motors implies an accurate speed control only at higher speeds. These motors have a better overload capacity thantheirPMSMcontemporary.

III. MOTOR SIZING

Before we begin the sizing process, we have to keep in mind the required specifications that the motor has to meet including its performance requirements and sizing constraints. Machines are usually sized for the rated torque capability (not the power). And there is a direct dependencyofthetorqueontherotorvolumeandshear stressthathastobeconsideredduringthesizing.Thecodependency of various other parameters are cited in Table3.

Decreases Increases Decreases Increases Nochange Nochange

PHASES Increased Decreased Decreases Increases Nochange Nochange Nochange Nochange

Primary Dimensioning

Thisstepmainlyinvolvesfixingthevaluesofparameters likestatorouterandinnerdiameter,theairgaplengthas well as the core size. Establishing these dimensions basicallyactasa baspointfrom where wecanbuildthe further constraints. Usually this process starts with a knownormaximumvalueofstator[5]ODwhichactsas a basefortherestofthe parameters. While fixing these ,a fewassumptionshaveto be made regarding thelevel atwhichonewillbeworkingwiththematerialsandthat inturnisdependentonthefluxdensitiesinthemagnetic circuit.

TRV(Torque/Rotor Volume) is an archaic but dependablemethodusedfor thesizingofmachinesand is related to the air gap shear stress according to the followingrelation.

TRV=��=2��Nm/m3 (i) ��r

Where,��istheairgapshearstress.

A smaller rotor can be designed for high speed applications for the same power as the torque is quite low.

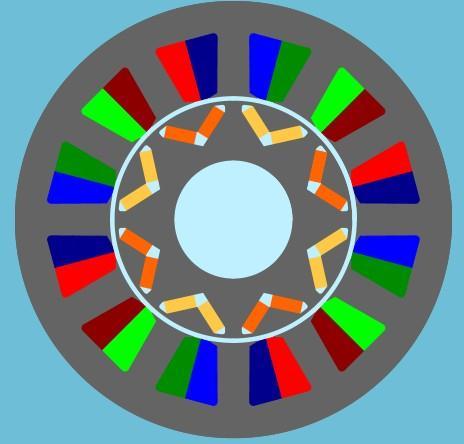

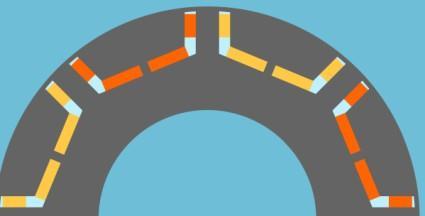

ThecrosssectionofthePMSMmotorthatisdesignedfor the mentioned specifications is shown in fig 1. We have chosen a 12s8p PMSM based on various iterations as well as analysis of motors that are available in the market.

All the dimensions that play a role in the sizinghave a clear correlation with the required torque specification, air gap stress, air gap flux density and current density, the type of colling employed, and the duty cycle of the load.

Number of Poles

Apart from performing various iterations and analysing

the performance variations due to modification in the numberofpoles,afewguidelinesshouldbekeptinmind before fixing the pole number [6]. With the increase in the number of poles, there is a proportional decrease in the amount of iron required in the construction as the total flux is now lay out over more poles and hence reducing the density. And due to the decreased use of iron, the number of windings incorporated can be increasedwhichwillalsoplayamajorroleindecreasing thecopperlossesincurred.Butanobviousdownsideofa larger pole number is the increased cost of manufacturing.

eddy current losses in the surfaces. In Permanent MagnetSynchronousMotorsthisairgapisselectedafter analysingitsdependencyonmechanicalconstraints.The magnet dimensions, the inductance and the air gap are allcorrelatedtoeachother.Usually,theairgapiskeptat aminimumtoreducethematerialrequiredformagnets. The air gap harmonics are also a contributing factor to the losses incurred. The methods taken for calculating the air gap in surface mounted magnets and embedded magnets are a little different. For surface magnets, its calculatedusingtheformulabelow

Where,ℎ���� is the surface magnet height, �������� is the PM relativepermeabilityand���� isthecorrectedairgapwith carter’s coefficient. On the other hand, for IPM as in this case, they have a different effect on the reluctance and otherintricatemethodshavetobeapplied.

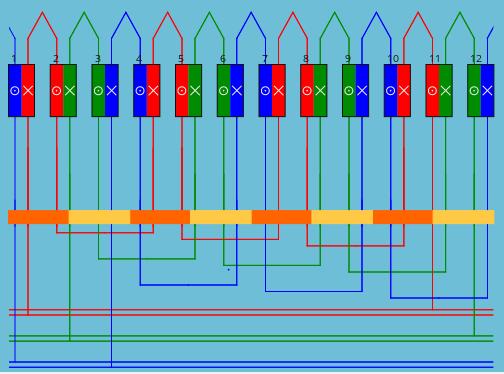

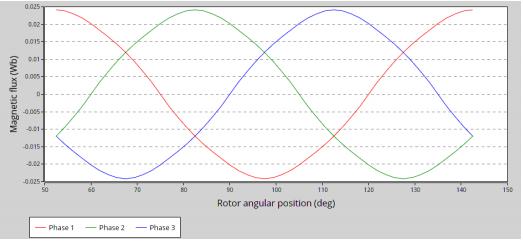

Winding Selection

The entire foundation of the machine lies on the interaction between the magnetic field and the electric fieldproducedbythewindings[8].Themainaspectsthat are looked into during the selection of the winding patternisthenumberofphases(��),numberofslots(����) andnumberofpoles(��)

importancehastobegiventothewinding factor(esp.the winding factor of the fundamental,��w1) .During the selection of winding constraints like the number of turns, thenumberofwiresinhandandthepitchshouldbekept in mind. Also, usually a lower pitch is preferred for a smaller machine and vice versa. The choice of windings (which is broadly categorised into distributed and concentratedwindings)isdiscussedinthefollowingtable

POLES 2 4 6 8 10 12

R/S% 50 53 56 60 65 70

Air Gap

Theairgaplengthiscalculatedandchoseninsuchaway that the production of magnetising current is at a minimumvaluewhileproducingadesirableefficiency.In theory [7] , a small air gap is synonymous to a low magnetising current but it goes along with increased While selecting the winding of a machine, utmost

Distributed winding Concentrated winding

The value of q is an integer The value of q is not aninteger

Longerendwindings

Produce higher reluctancetorque

Have a greater q axis inductance[9] than the d axis inductance which increases the reluctance torque parameter w.r.t saliency

Lossesarehigher

Amount of torque rippleislower

Have higher torque constant and winding factor

Exhibit more sinusoidally flux densitywaveforms

Smallerendwindings

Produce lower reluctancetorque

Saliency ratio is comparatively low due to lower difference between d andqaxisinductance

Comparatively lower losses and easier manufacturing

Higher torque ripple ispresent

Lower torque constant and winding factor

Sinusoidal nature of the waveforms is lesser as compared to the distributed windings

Determination of slot dimensions

A prior knowledge about the rotor and stator currents is requiredbeforewestartwiththedimensioningoftheslots.

Where,

=statorcurrent,P=shaftpower, =statorphasevoltage , =efficiency, ���� =powerfactor

The flux density always decreases at the slot opening, and thereforeitisnoteasytodefinetheaveragefluxdensityof theslotpitchbetweenthestatorandtherotor[10].Asthe slots will house the windings of the machine, the space requiredcanbecalculatedbykeepingparametersliketotal magnetising current, the areas of the conductors, the resistivelossesandtheparallelpathsinmind.

Area of conductors, (v)

Wherein, I stands for the stator current and a and J stand fortheparallelpathsandthecurrentdensityrespectively.

The next step that has to be employed after this is to calculate the slot area by keeping the space factor into consideration

Area of slot, (vi)

Where, �� isthespace factor whichprimarilydependson thewindingtypeandmaterialandthevoltagelevel

IV.MAGNETIC CIRCUIT

Whiletalkingaboutmagneticcircuitofamotor,wegenerally refertothemagneticmaterialandtheairgappresentinthe machineandthepresenceofthemagnetizingeffectisdueto the winding and the magnets involved. In other words, a magnetic circuit can also be referred to as the part of the machine through which the passage of the main flux takes place. In anisotropic machines, it is the rotor saliency that makesthecircuitasymmetricalasisdependentonthedand qaxisinductance.Generallythenumberofmagneticpathsis moreorlessequivalenttothenumberofpoles.

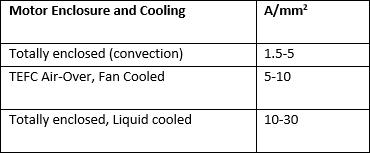

Air Gap and Carter’s factor

Airgapshearstressisoneofthebestparameters(especially for PMSM) around which you can manipulate your circuit parameters. This air gap shear stress is proportional to magnetic and electrical loading. The permissible loading levelsarebasedonthecoolingandtheinsulationemployed. Effective cooling of a machine increases the loading while decreasingtheoverallweightofthemachine.

a. ElectricalLoadability

Thecurrentdensityinthephaseconductorsisa measure of current loading and determines the dutycycleor/andthecoolingrequirements.The linear current density around circumference of the air gap can be used as a measure of this parameter.

The unit of measurement for the same factor is A/masthisistheunitforcurrentdensitytoo.

b. MagneticLoadablilty

Magnetic air gap loading analysis is usually undertaken duringsizingthatisbasedontheaveragefluxdensityin the air gap. The air gap flux density and the supply frequencyofthemachinedeterminethisparameter.This should be in accordance with the cooling technique employedinthemachine

To ease the calculation of the voltage over an air gap, a simple and a uniform geometry is preferable. With the surfaces of the machine being occupied by slots and teeth the calculation of the flux density between the rotorandstatorisabitcomplicated.Thedecreaseinthis value is clearly visible in the slot opening area. So, Carter’sfactor[11]comesintoplayduringthecalculation according to which, the length of air gap increases with increaseinthefactor.

Magnetic Material

Neodymium magnets are one of the most widely used magnets in motors[12]and their strength has been further enhanced after the development of alloys with rare earth magnets. Neodymium-iron-boron (NdFeB) is one ofthepopularalloys thathavea greatperformance. Moreover,thedownsideofpureNeodymiummagnetsi.e. temperature sensitivity can be improved by the above mentionedmethodofalloying.

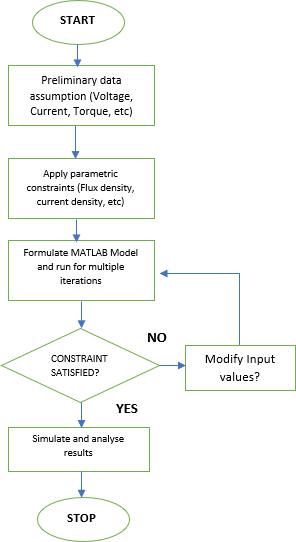

IV. METHODOLOGY

The design of a motor is commenced[13] by defining a set of basic characters like the type of motor required according to the application to get the best possible results, the type of construction method to be employed (externalorinternalpole,axialorradialflux).

The other vital specifications include rated power, rotationalspeed, pole pairs, frequency, etc. A MATLAB model was developed to calculate the base parameters usingtonsofrelatedformulae.

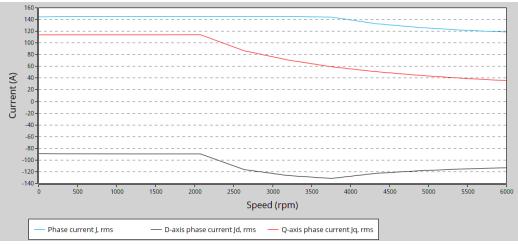

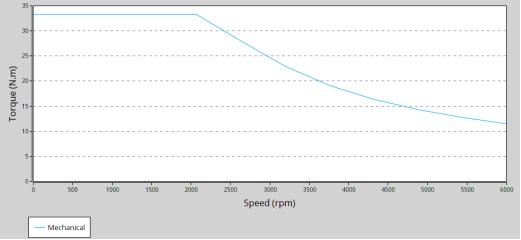

Theseparametricconstraintswereappliedasinputsin theFluxMotorSoftware toobtaintheproposeddesign to get the desired results from the motor. Multiple iterations were performed to get to the final values of the various parameters. Apart from this the enclosure class,manufacturabilityand the standards applied also hadtobekeptinmind.

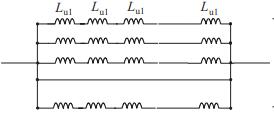

VI.LEAKAGE INDUCTANCE

Leakage Flux

The total flux that is present in a machine is constituted by a main field flux and leakage flux. The leakage flux component [14] does not account for the energy conversion process and is generally considered an unwanted phenomenon but it can be used in a positive way too according to the requirement. This component can be found in the stator or rotor windings and even in the magnets present in the machine. The main field flux on the contrary is responsible for electromagnetically connecting the stator and rotor together by passing the air gap of the machine. The primary feature of leakage flux is that it does not cross the air gap of the machine andafewoftheleakagefluxcomponentsareslotleakage flux,toothleakageflux,endwindingleakageflux[15].

Generally , the stator and rotor are placed in a skewed mannertoavoidtheinfluenceofslotharmonicswhichis alsoacontributorofleakageinductance. Whenitcomestoslotleakageinductance,theunderlying causeofthisphenomenonisthetotalcurrentflowingina slotwhichisdeterminedby thenumberofconductorsin the slot and hence the current flowing through each of them.

‘a’ parallel paths

slots in series

Fig 5:Total slot inductance

Thegeometryoftheslotalsohasaveryimportantrolein decidingtheslotpermeancefactor.

VIII.CONCLUSION

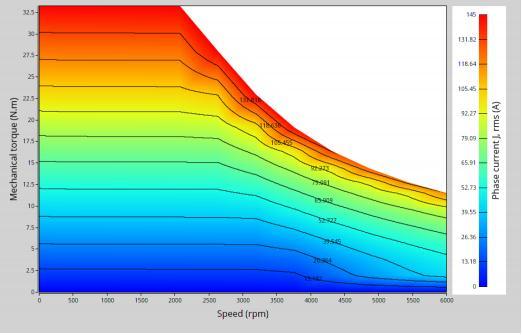

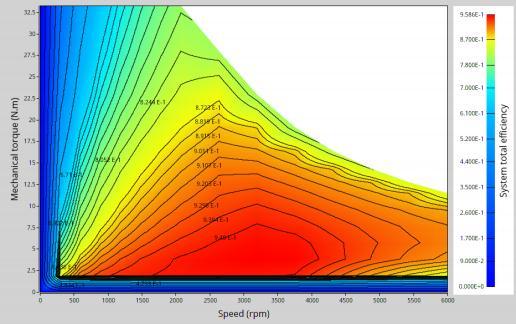

In this paper we have gone through a range of design decisions to be considered while designing a motor for automotive purposes. A 7 kw motor with a high efficiency of 90% was designed ,optimized and analysed using a software and the results were experimentally verified. The entire approach taken while designing the motorhasbeengoneoverinthispapermethodologically startingfromdimensioningtovariouscircuitparameters aswellasleakageinductances.

REFERENCES

[1]QiangFei,YongtingDeng, HongwenLi,JingLiu,Meng Shao. "Speed Ripple Minimization of Permanent Magnet Synchronous Motor Based on Model Predictive and IterativeLearningControls",IEEEAccess,2019

[2] Wawan Purwanto, Risfendra, Donny Fernandez, Dwi Sudarno Putra, and Toto Sugiarto,” Design and comparison of five topologies rotor permanent magnet synchronous motor for high-speed spindle applications”, International Journal of GEOMATE, Dec., 2017, Vol. 13, Issue40,pp.148-154

[3] Cai, W., Wu, X., Zhou, M. et al. Review and Development of Electric Motor Systems and Electric Powertrains for New Energy Vehicles. Automot. Innov. 4, 3

22(2021).

[4] Nasser Hashernnia and Behzad Asaei,” Comparative Study of Using Different Electric Motors in the Electric Vehicles”,IEEEXplore,2009

[5] Fang, L., Lee, B. H., Lee, J. J., Kim, H. J., & Hong, J.-P. ,”Study on high-efficiency characteristics of interior permanent magnet synchronous motor with different magnet material”, 2009 International Conference on ElectricalMachinesandSystems

[6]Yoneda,M.,&YongjaeKimHideoDohmeki,M,”Novel SelectionoftheSlot/PoleRatioofthePMSMforAuxiliary Automobile.”,Conference Record of the 2006 IEEE Industry Applications Conference Forty-First IAS Annual Meeting

[7] Juha Pyrhönen Tapani Jokinen Valéria Hrabovcová,”Design of Rotating Electrical Machines”, SecondEdition

[9] A. Yamada, H. Kawano, I. Miki, M. Nakamura. "A Method of Reducing Torque Ripple in Interior Permanent Magnet Synchronous Motor" , 2007 Power Conversion ConferenceNagoya,2007

[10] Bellal Zaghdoud, Abdallah Saadoun,” Slots Geometry InfluenceontheAirgapMagneticFieldDistribution”,WSEAS Transactions on Circuits and Systems, Issue 12, Volume 12, December2013

[11]Ioan-AdrianViorel,KayHamemeyer,LarisaStrete,“On theCarter’sFactorCalculationforSlottedElectricMachines”, AdvancesinElectrical andComputerEngineering,Volume7 (14),Number2(28),2007

[12] K. Hameyer and R. J. M. Belmans, “Permanent magnet excitedBrushedDCmotors,”IEEETransactionsonIndustrial Electronics,vol.43,no.2,pp.247–255,1996.

[13] R. Rong and D. A. Lowther, “Applying response surface methodology in the design and optimization of electromagnetic devices,” IEEE Transaction on Magnetics, vol.33,pp.1916–1919,March1997.

[14] Galina Mirzaeva, Khalid Saad,“AC motor instrumentationandmainairgapfluxmeasurementforfault diagnostics”, 2013 Australasian Universities Power EngineeringConference(AUPEC),2013

[15] Peng Gao, Yuxi Gu, Sayyed Haleem Shah, Usman Abubakar,andXiaoyuanWang,”CalculationandAnalysisof Flux Leakage Coefficientof Interior Permanent Magnet Synchronous MotorsWith Fractional Slot Concentrated Windings”, IEEE Transactions on Applied Superconductivity, Vol29,March2019

,Luk´aˇs Kalamen , Pavol Rafajdus , Mat´uˇs Onufer, “Ferrites and Different Winding Types in Permanent Magnet Synchronous Motor”, Journal of Electrical Engineering,VOL.63,NO.3,2012,162–170