“DESIGN OF WTP FOR NASHIRABAD MUNICIPAL COUNCIL”

1, 2, 3, 4,5Student-Tech Civil Engineering, Government College of Engineering Jalgaon-425001(MS), India. 6Assistant Professor, Dept. of Civil Engineering, Government College of Engineering Jalgaon-425001(MS), India. ***

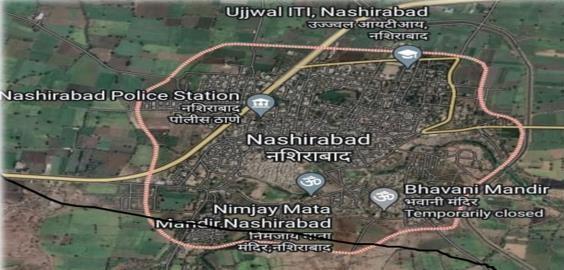

Abstract - Nashirabad, town in the district of Jalgaon; today dealing with the problems like water scarcity and untreated water. The population of that is around 26,131(census 2011) but not getting fresh drinking water, the town also facing low frequent water supply and there also irregularity in supply of water always. Due to those women and child facing more problems. There are sufficient sources available for collecting raw water such as Waghur river, Waghur dam and infiltration wells near town. In 2020 the project of WTP was proposed and ignoring above sources raw water is being collected by Tapti River but it fails only just in 6 months due to wrong design and poor maintenances. And due to unawareness about water borne diseases and lack of provision of funds for proposing water treatment units; there is not a good scheme for water supply even today. Population density of town is 571.02 persons/ sq.km and we can’t ignore such a huge population and design of WTP is must there.

Key words: Nashirabad, water supply scheme, WTP, Wagur river, Tapi river .

1. INTRODUCTION

Even in countries with adequate water resources, water scarcity is not uncommon. As a result of collapsed infrastructure and distribution systems, contamination, conflict, or poor management of water resources, children are increasingly denied the right to safe water and sanitationduetoclimatechange,aswellashumanfactors. Waterscarcitylimitsaccesstosafewaterfordrinkingand for practicing basic hygiene at home, in schools and in health-care facilities. When water is scarce, sewage systemscan failandthethreatofcontractingdiseaseslike cholerasurges.Scarcewateralsobecomesmoreexpensive. Waterscarcitytakesa greatertoll on womenandchildren because they are often the ones responsible for collecting it. When water is further away, it requires more time to collect,whichoften meanslesstimeatschool.Particularly for girls, a shortage of water in schools impacts student enrolment, attendance, and performance. Carrying water long distances is also an enormous physical burden and canexposechildrentosafetyrisksandexploitation.

Indiagivesreasonfor2.45%oflandfieldand4%ofwater possessions of the realm but represents 16% of the globe people. With the study of human population-rate (1.9 per insignificant value done yearly), the population proper to

cross the 1.5 billion marks by 2050. The Planning Commission,Governmentof India hassupposedthewater demand increase from 710 BCM (Billion Cubic Meters) in 2010 to nearly 1180 BCM in 2050 accompanying household and industrialized water consumption wonted to increase nearly 2.5 occasions. The style of urbanization in India is striving stress on community authorities to specify fundamental necessity to a degree secure quaffing water, sanitation and foundation. The hasty progress of populacehasappliedtheconvenientwaterdemand,which demands investigation of inexperienced water beginnings, expandingsituationanddistributionorders.

1.1 Aim

ThegoalistoprovidewatertreatmentplanttoNashirabad municipalcouncil.

1.2 Objective

1) The decreasing availability of freshwater has generated the need for purification of wastewater on earth. Water treatment is important to earth because the availability of fresh water is limited in the earth andthedemandishigh.

2) It is important to protect the health the harmful chemicals, metal and other contaminants present in water are dangerous for the health of humans and other organisms living on this planet. These harmful substancesandtoxinsleadtovarioushealthproblems like asthma, cholera, diarrhoea, asthma, cancer, skin disorders and even death. Hence, this will reduce the annual death rate of people caused by drinking contaminatedwater.

3) It helps to ensure that water is not wasted – The wastewater treatment plants use water discharged from households and industries which is purified and discharged back to the community and natural environment.Thusitreducesthewastageofwater.

4) Ithelpstorestorethewaterwiththisprocess;wateris reintroducedbacktothecycleofnature.

5) To protect the environment– Water treatment is very much helpful for the environment. It helps to balance

the water cycle by maintaining groundwater and surfacewater.

6) Thewaterpurifiedatthetreatmentplantscanbeused for various purposes like drinking, households use, industrial application, agriculture, and irrigation purposes, etc. This will solve the problem of water shortage and countries with limited access to safe waterwillbebenefited.

7) Water purification plants are also important as they fulfiltheincreasingdemandforwater.

8) Desalination is another way of water purification. It is important as it converts the saline water (which is of no use and is available in abundance on the earth) to potable water. Thiscanhelpin solving the problemof waterscarcityintheworld.

2. LITERATURE REVIEW

1. A International Journal of Innovative Research in Science,EngineeringandTechnologypresentedaresearch paper Study of Water Treatment of Jalgaon City on “Performance of Drinking water treatment Plant” and concludedthat,ThewatertreatmentplantofJalgaonneeds some changes in their working process for providing betterandsafewatertreatmentforJalgaoncity.

a)The current workers and officers working in water treatmentplantarequitelessandshouldbeincreaseto requiredlevel.

b)TheSecuritySystemsoftheplantshouldbeupdated.

c) The SCADA (Supervisory Control & Data Acquisition) Systemshouldbeimplementedinplant.

d)The need of water will be 175.4 MLD in 2030 therefore certain measures should be taken to increase the capacity of plant or it should come with one more secondaryplant.

e) The pipeline in area of Bali ram peth and Shanipeth should be repaired and uniform diameter pipes should beplacedtoavoidheadloss.

f) Currentlythe operationof manhole isdone manuallyat plant. This should be operated by a definite system automatically.

g)The maintenance of components at water treatment plantshouldbeupdated.

h)The basic objective of the water treatment plant is to supplysafeandadequateamountofwatertothehuman society in economical form. To attend this it is very importanttohaveinstallationofsafeguardinstruments

as well as safe guard monitoring system for plant operations. The water treatment plant of Jalgaon is operatedbyMunicipalCorporationofJalgaon.

The plant has the capacity to treat 132MLD water per day and supplies water to Jalgaon city with a population of.6 laths (approx.) the intake source of water treatment plant is from Waghur dam located 6 km away from the plant. The objective of this paper is to have a brief study of the working efficiency of water treatment plant. The main focusofthestudyistosurveythebriefspecificationsofthe equipment’s used in the water treatment plant. The paper will also contribute to identify the solutions for better efficiencyofwatertreatmentplant.

2. Research paper on KRISHNA WATER DISTRIBUTION TAILS The main object is the supplying of Krishna treated water to Hyderabad from Kodandapur water treatment plant by the help of mechanically pumpingandbygravity.TodrawingrawwaterfromAMRP canal through MS pipe line from the canal intake to the threeWTP’s(watertreatmentplant’s)(phase-IofstageI& stage-II of 45 MGD+45 MGD and phase –II OF 90 MGD) total 180 mgd of water for Krishna drinking water supply project.To pump out the clear water after filtration by the pumps from the pump house of Kodandapur to Nasarlapally a distance of 34 km with 157 m through 8 pumps. The pumping of clear water from pump house at NasarlapallytoGodakondla witha distanceof24kmsand head of 163 m.To pump the clear water from Godakondla to Gungal with distance of 20 Kms and head of 148 m.To pump the clear water from the Gungal to Sahebnagar reservoirbygravity.Thecurrentdemandforwatersupply in the city is 460 MGD, but the Water Board is supplying only 340 MGD, a major shortfall, that deprives the surrounding municipal areas, many of which get water onceinthreedays,someonlyonceinsevendays.Godavari water will come to the city a few months before the Assemblyelectionsin2014.AlwalwouldbethefirstGHMC circle to get Godavari water, which would traverse 186 Kmsfrom

Yellampally (Karimnagar) barrage. Subsequently, Qutubullapur, Rajendranagar, Kukatpally, Serilingampally, Kapra and Malkajgiri circles and the Secunderabad cantonment would get Godavari water treated at the Ghanpurmegabalancingreservoir.

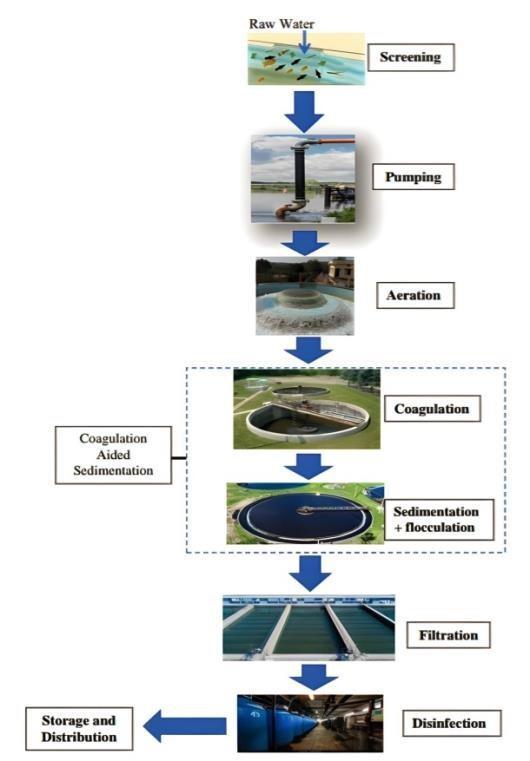

3. International Journal of Innovative Research in Science, Engineering and Technology presented a review paper on “Review on Optimization of Conventional Drinking Water Treatment Plant”, and concluded that, Watertreatmentisaprocesswhichconsistsofseveralsub process which works on the motto of converting the nondrinkableformofwaterintodrinkableform.Conventional drinking water treatment plant consists of coagulation,

flocculation, sedimentation, filtration and disinfection units. Depending on water quality influent, each unit can beoptimizedtoachievethedesiredwaterquality effluent, both in design and operation stages. A typical water treatment plant has the combination of processes needed to treat the contaminants in the source water treated by thefacility.Thepresenceofunbeatableorganicormineral substances causes some problems in obtaining drinking water.

Understanding these phenomena requires considering the physical and chemical natures of the water to be treated. Optimization of conventional drinking water treatment plantmeans“toattainthemostefficientoreffectiveuse”of your water treatment plant regarding some principles, there are: achievement of consistently high-quality finishedwateronacontinuousbasisandtheimportanceto focusonoverallplantperformance,insteadoffocusingtoo muchonindividualprocesses.Thepaperpresentsareview on optimization of conventional drinking water treatment plant that eventually proposing a method to maximize process efficiency with less risk. Overall optimization was carried out by dynamic programming to meet drinking waterqualitystandard.

3. METHODOLOGY

Themethodologyconsistsofthreephases,asbelow:

3.1. Questionnaire survey:

1)NameoftheCity:Nashirabad.

2)Population:

a.AsperYear1991:17,532

b.AsperYear2001:22,212

c. AsperYear2011:26,131

3)YearofestablishmentofWTP:2020

4)Treatment Plant Installed Capacity: MLD Quantity of watertreated:4.5MLD

5)Whether water treatment plant is adequate to meet presentdemand:No

6)Source of Water Supply: River: Waghur, Tapti. Dam: WaghurDamGroundwater:Wells(5Nos)

7)Type of Treatment: No Disinfections only by bleaching powerandsedimentationwithcoagulationbyalum.

8)Plans for additional water treatment plant: water treatment plant should be redesign by considering high demandofwater.

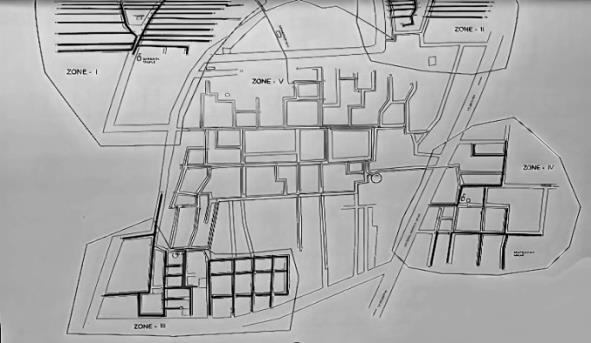

9)Distribution System: Distribution systems available today do not meet the requirement of population and

discontinuity in the water supply. There is only three Elevatedsurfacereservoirs.

NASHIRABAD WATER SUPPLY SCHEME

TAL- JALGAON, DIST- JALGAON

A) Main Features of the Scheme:

1) Name of the Scheme: Nashirabad Water Supply Scheme

2) Town:NASHIRABAD

3) District:JALGAON

4) SourceofSupply:JackwellinWaghurDam

5) Population in person as per 2011 Census: 26131 Souls

6) PopulationinpersonsdesignedStage(2055year): 48060Souls

7) RateofWaterSupply:135LPCD

8) DailyWater Supply at designed Stage (Net):7.461 MLD

9) Dailygrossdemandwithlosses:8.720MLD Existing water supply is not adequate to satisfy the needs of water during dry weather. In summer people do not get at: 0.000 MLD RequiredDailyDemand:8.720MLD

10) Rateofpumping(ImmediateStage2039):85136 Litres/Hr

11) Dailypumping(PureWater):20Hrs

12) Cost of the scheme as per DSR 2022-23: a) Net Cost Rs. 420956105.20 b) Gross Cost Rs. 496728204.20 13)Per Capital cost of designed stage(2054):Rs.8759.00

14)Cost of Water 1000 Litres.Rs.5.51 15. Water tax perhouseperyear:1)Specialwaterconnectiontaxhouse connection/year.: Rs. 1600.00 B) Design data of water supply scheme:

1)NameofMunicipalCouncil

Taluka:JALGAON

District:JALGAON

2)Population

2011:26131Souls

2040:38753Souls

2055:48060Souls

3)RateofWaterSupply:135LPCD

4)Dailyrequirementofwaterwithlossesetc.:8.72

5)Source of Supply: Jack well in Waghur Dam 6) Hours of Pumping:20Hours.

Rate of Pumping Raw Water (Immediate 7) Stage)319636

Litres/Hr

8)DetailsofSubwork

a)Head works(Ultimate Stage 2054): Jack well in Waghur Dam

IntakeWell-3mDia, ConnectingMain-350mmdia JackwellWell-23.59m

Depthwithpumphouse8mDia, ApproachBridge-30m

b)Raw Water Pumping Machinery (Immediate Stage year 2039)Rate of Pumping: 393750.00 Litres/Hr. Total Head:60.00m

BHP:140BHPSubmersiblepumps1Working+1 Standby

c)RawWaterRisingMain(UltimateStage:2054)

Pipe:DIPipeDia:350.00mmLength:1730.00mK9Class

d)TreatmentPlantwithautomation

Capacity:4.00MLD

Type:conventional

WorkingHours:20Hrs.

Av.G.L.atsite:226.600M.

Lipofaerationfountain:232.10M.

e) AtWTP

HoursofPumping:20Hours

RateofPumping:369166.67Litres/Hr.

TotalHead:35.00M

BHP:80.00BHP-2No :Oneinuse&otherstandby TypeofPump:SubmersiblePump

f) PureWaterRisingMain(UltimateStage2054)At WTP

Pipe: DI Dia: 350.00 mm Length: 50.00 M.

i)MBRProposed

Capacity:6.70LakhLit.

AvG.L.:226.600M

StagingHeight:25.000M

LWL:251.600M

FSL:255.600M

ESRProposed Location:BhuvaneshwarNagar

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 10 Issue: 05 | May 2023 www.irjet.net

ESRCapacity:1.06LakhLit.

AvG.L.:218.580M

StagingHeight:15.000M

LWL:233.580M

FSL:236.580M

j) ESRProposed Location:NPOFFICE

ESRCapacity:5.14LacLitters

AvG.L.:217.750M

StagingHeight:18.000M

LWL:235.750M

FSL:239.750M

MBR @ WTP PureWater Pumping

Machinery (Intermediate Stage year 2039)

k)ESRProposed

Capacity:227000.00LacLitters

AvG.L.:214.000M

StagingHeight:20.000M

LWL:234.000M

FSL:238.000M

ESRProposed Capacity:751000.00Laclitters

AvG.L.:217.000M

StagingHeight:15.000M

LWL:232.000M

FSL:236.000M

l) Distribution System (Proposed) 1110 mm dia. Total Length of Distribution System 50293.00 m100%connection

m)Substation&ExpressFeeder-proposed

n) Road reinstating provision is made in this scheme

o) Miscellaneous work electrical connection at headworksandWTP&ESRCompoundWall AqualonSolutionMunicipal EngineerChief Officer NashikNashirabadNagarpanchayat, NashirabadGaothanESR StaffQuarter,charges for road crossing, Forest Permission provision is madeinthisscheme.

C) Cost of Scheme

1) WorkingSurvey:Rs.488983.00

2395-0072

2) Intake Channel (Length 30 M): Rs. 1979511.00

3)Intakes Well (3 M Dia): Rs. 2585397.00

4)Inspections Well (2.50 M Dia) (1 Nos): Rs. 1544607.00

5) Intake Pipe (Length 30 M &Dia 600 Di K-7): Rs. 5259196.00

6) Jack well With Pump House (8 M Din): Rs. 20662824.00

7) ApproachBridge(Length30M):Rs.3190001.00

8) Raw Water Pumping Machinery- 20 Hp (1W +1 Standby):Rs.18831418.00

9) Raw Water Rising Main 350 Mm Dia Di K-9, L1730M (Jackwell To Bpt) Bpt Of Capacity 131000Lits-15MStHt:Rs.15438035.00

10) BptOfCapacity131000Lits-15MStHt: 3649824.00

11) Gravity Main (Dik-7 Pipe 400 To 450 Mm Dia L16200M):Rs.133660156.00

12) Water Treatment Plant Of Capacity 4 Mld: Rs. 21347920.00

13) Pure WaterRisingMain250MmDiaDiK-9,L-50 M(SumpToMbr):Rs.755663.00

14) PureWaterPumpingMachinery15Hp(1W+1S) (From WTP To MBR) 15 Mbr @Wtp Of Capacity 670000 Lits-25 M St Ht : Rs. 9490355.20 15)Mbr @ Wtp Of Capacity 670000 Lits- 25 M St Ht : Rs. 10707754.00

16) Feeder Main (Dik-7 Pipe 150 To 350 Mm Dia L3220M):Rs.14078996.00

17) NpOfficeEsrOfCapacity514000Lits18MSt.Ht 18 Bhuvaneshwar Nagar Esr Of Capacity 210000 Lits-15MStHt:Rs.7102735.00

18) Bhuvaneshwar Nagar Esr Of Capacity 210000 Lits-15MStHt:Rs.4598694

19) Swami Samarth Nagar Esr Of Capacity 227000 Lits

18MSt.Ht:Rs.3140059.00

20) GaothanEsrOfCapacity751000Lits-15MStHt

21) Distribution Systems(110 To250 MmDiaHdpe& D.IPipeL-50.29Km):Rs.70411017,00

22) Road Reinstating-45.23 Km 23 Solar Power Plant 180KWPCapacity:Rs. 4581997.00

23) Solar Power Plant 180 KWPCapacity:Rs. 6911592.00

24) StaffQuarter-1Nos:Rs.996733.00

25) Miscellaneous Work (Road Crossing, Irrigation PermissionEtc):Rs.4000000

A. COST : RS 420956105:20

B. ADD 18% GST CHARGES: RS 75772099.00

C. NET PROJECT COST : RS 496728204.20

D. TOTAL GROSS COST: RS 496728204.20

FinancialForecasts

a)GrossCostRs.496728204.20

b)DesignPopulation2024Souls31386

c) PerCapitaCostonnetcostRs.15826.00

AnnualBurdens:Rs379.00

TaxationProposal:ThustheSchemeisself-supporting. CostofWaterper1000litters

a) AnnualrequirementofWater2079.00MLDFor populationof(2024)

b) Quantityactuallyused85%ofAbove1767.15 MLD Annual burden = Design Population Average Establishment, electricalenergychargesandsundries( asperstatement)

c) Costofwater/1000litres:Rs.6.72/1000Ltr

4. CONCLUSIONS

1) Population forecasting has been done for 3 decades by using Incremental Increase Method. From calculated data, the population is as follows: 2031:-38199

2041:-45771

2051:-54844

2) From calculated population data, for 2051 population forecasting, design of water supply schemewasdesigned.

3) From the designed data, estimation has been workout. The total cost of this project is Rs.496728204.20/-

4) From present population point of view the cost oftheprojectpercapitawillbeRs.15826.00

5. REFERENCES

1.https://www.google.com/url?sa=t&source=web&rct=j &url=http://www.ijirset.com/upload/2018/april/128_St udy.pdf&ved=2ahUKEwiA4rbtoP37AhUZ1GEKHTktBioQ FnoECCUQAQ&usg=AOvVaw2oKbTdAeNkG0rJ8KXxhnSs

2. Mudassir M Inamdar1, Salman sheikh2. “Performance ofDrinkingwatertreatmentPlant”,InternationalJournal of Innovative Research in Science, Engineering & Technology,Vol7Issue3,March2018.

3. EndahAngreni. “Review on Optimization of Conventional Drinking Water Treatment Plant”,

International Digital Organization for Scientific Information(IDOSI),2009Publications.

4. Fiftheditionof“WaterTreatmentPlantDesign”–PublishedbyAmericanwaterworksassociation.

5. Water Treatment Plant of Jalgaon Records by Jalgaon Municipal Corporation. 5. Environment Engineering 1 – Nirali Publication Book by authors Dr. Ravi. K, Dr. Edition published by Ministry of Urban Development. 7. www.gaurankpatil.blogspot.in –Post “VisitExperienceatWaterTreatmentPlant.

6. omelia,c(1998)."Coagulationandsedimentation in lakes, reservoirs and water treatment plants". Water scienceandtechnology.

7. 129. [2] Bholea.g., bogawatn.g. (1978) significance of sludge re circulation in the process of flocaulation, jour. Indian wat. Wks. Asscn., x, 1, jan/march,119-125.

8. Chaudhuri m., engelbrechtr.s. (1970) removal of viruses from water by chemical coagulation and floaoulation,3our.aww'a,sept.,563-566.

9. Manwaringj.f., chaudhuri m. ,engelbrechtr.s., (1971) removal of viruses by coagulation and floaoulation,jour.awwa,march,298-300.

10. Shelton s.p., drewryw.a. (1973) tests of coagulants for the reduction of viruses, turbidity and chemicaloxygendemand,jour.awwa,oct.,627-635.

11. Qasemy, nawid. "rapid sand filtration". Authorstream.com.Nawid11.Retrieved27january2015.

12. http://outsidethesink.rtu.lv/documents/principl es%2 0of%20water%20treatment.pdf http://www.lenntech.com/history-watertreatment.htm

13. www.epa.gov/safewater

14. https://en.wikipedia.org/wiki/water_treatment

15. G.S.Birde and J.S.Birde (1980) Water Supply and Sanitary Engineering. Dhanpat Raj Publishing CompanyDelhi.

16. Garg, S.K. (2004) Water Supply Engineering. 18th Edition,KhannaPublishers,Delhi.