Integrating Project Management Information System and BIM for Inspecting and Coordinating In All Phases of Construction

S.Keerthi1, V.Vidya21M.Arch (construction project management) student, Faculty of Architecture, Dr .M.G.R Educational and Research Institution, Chennai, India.

2 Associate Professor, Faculty of Architecture, Dr .M.G.R Educational and Research Institution, Chennai, India.

Abstract - The Construction industry has been transformed through the adoption of digital technologies, particularly Building Information Modeling (BIM) and Project Management Information Systems (PMIS). It explores the benefits of integrating these systems in all phases of construction, from pre-construction to post-construction, includingimprovedprojectefficiency,reducedcosts,increased quality,andenhancedcollaboration.Thechallengesthatneed to be overcome, such as data management, software compatibility,andstakeholderresistance,arealsoaddressed. The abstract concludes by highlighting the need for a coordinatedapproachamongstakeholderstofullyrealizethe potentialofthesetechnologiesandimproveprojectdeliveryin the construction industry.

Key Words: Project Management Information System (PMIS), Building Information Modeling (BIM), Improved project efficiency, Reduced cost, increased quality

1. INTRODUCTION

Theconstructionindustryhasincreasinglyadopteddigital technologies to improve project delivery, communication, andcollaborationwhilereducingcostsanderrors.Among the most popular digital tools are Project Management Information Systems (PMIS) and Building Information Modeling (BIM). PMIS manages project information, resources,schedules,andcosts,whileBIMoffersadetailed 3Dmodelofabuilding'sdesignandconstructionelements. The integration of these systems offers numerous advantages, including better coordination and communication among project teams, improved decisionmaking,andreducedprojectdelaysanderrors.Thispaper aims to explore the integration of PMIS and BIM for inspecting and coordinating throughout all phases of construction.Thepaperexaminesthebenefitsofintegration and addresses challenges such as data management, software compatibility, and the need for standardization. Additionally, the paper presents case studies and best practices from industry leaders to provide insights on successful integration. Overall, this paper provides a comprehensive overview of integrating PMIS and BIM for inspecting and coordinating in all phases of construction, includingthebenefits,challenges,andbestpractices.

2. METHODOLOGY

LiteraturestudyaboutPMISandBIM

PMISandBIMIntegratedCasestudies

Comparativeanalysis

Baselineschedulingformonitoringtheproject

ComparativeAnalysis

Results

Recommendations

Conclusion

3. PROJECT MANAGEMENT INFORMATIONSYSTEM (PMIS)

A Project Management Information System (PMIS) is an essential tool in the construction industry due to the complexity of construction projects. With multiple stakeholders, large volumes of data, and various interconnected activities, construction projects require a centralized platform to manage project information, resources,schedules,andbudgetsefficiently.

PMIS plays a critical role in construction project managementbyenablingprojectmanagerstomonitorand controlallaspectsoftheproject.UsingPMIS,construction project managers can effectively manage communication among project team members, stakeholders, and clients, optimizeresourceutilization,controlprojectcosts,manage project schedules, identify, assess, and mitigate risks, monitorqualitycontrol,andgeneratereportsandanalytics on project progress, resource utilization, budget performance,andotherkeyprojectmetrics.

4. BUILDING INFORMATION MODELING

Inthearchitecture,engineering,andconstructionindustry, Building Information Modeling (BIM) is utilized as a collaborative tool to create and manage digital representationsofphysicalandfunctionalcharacteristicsof buildingsorinfrastructure.Thisinvolvesusing3Dmodeling softwaretogeneratedigitalrepresentationsenrichedwith

information such as material properties, energy consumption,andmaintenancerequirements.

BIM provides a platform for visualization, simulation, and analysis of building designs and performance, improving communication and collaboration among project stakeholders.Italsoenhancesconstructionprojectquality and efficiency by reducing errors and rework, improving cost estimation and project scheduling, and fostering communicationamongstakeholders.

AutodeskRevit,ArchiCAD,BentleyMicroStation,andTekla StructuresaresomeofthepopularBIMsoftwaretoolsused in the industry. Due to its potential for reducing costs, improvingconstructionquality,andensuringbetterproject outcomes,BIM'suseintheAECindustryisincreasing.

5. PROCESS IN INTEGRATING PMIS & BIM

1. Identifyprojectgoalsandrequirements

2. SelectPMISandBIMsoftware

3. IntegratePMISandBIM

4. Trainprojectteammembers

5.

Monitorandevaluateperformance

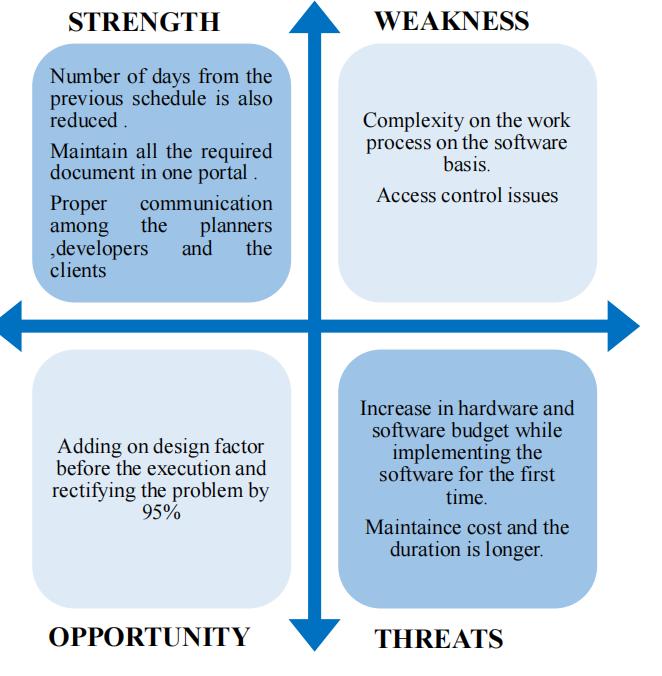

andBuildingInformationModeling(BIM)intheconstruction industryoffersseveraladvantages,including:

1. ImprovedCollaboration:IntegratingPMISandBIM allowsprojectteamstoworkcollaboratively,share information,andmakeinformeddecisionsinrealtime.

2. Enhanced Visualization and Simulation: BIM provides a 3D model of the building, allowing projectteamstovisualizeandsimulateconstruction activities and identify potential issues before constructionbegins.

3. ImprovedCostControl:PMISandBIMintegration enablesbettercostcontrolbyprovidingreal-time information on project costs, resource utilization, andbudgetperformance.

4. Better Quality Control: PMIS and BIM integration allows project teams to monitor project quality, track performance metrics, and identify areas for improvement.

5. Reduced Risk: PMIS and BIM integration allow projectteamstoidentifyandmitigateprojectrisks,

reducing the likelihood of project delays and overruns.

Overall, integrating PMIS and BIM in the construction industry improves project efficiency, reduces costs, and enhances project quality, resulting in better project outcomes.

7. DISADVANTAGES

WhileintegratingProjectManagementInformationSystem (PMIS) and Building Information Modeling (BIM) offers manybenefits,therearealsosomepotentialdisadvantages toconsider:

1. High Initial Cost: Implementing PMIS and BIM integration requires significant investment in software,hardware,andpersonneltraining,which canbeexpensive.

2. TechnicalChallenges:Theintegrationprocesscan be complex and challenging, requiring technical expertise and experience. Integration issues can leadtodelaysandincreasedcosts.

3. Resistance to Change: Integrating PMIS and BIM may require changes to traditional project management practices, which can be met with resistancefromprojectteamsandstakeholders.

4. Security Concerns: Integrating PMIS and BIM requires sharing sensitive project information amongprojectstakeholders.Thiscanraisesecurity concerns related to data privacy and intellectual propertyprotection.

5. Limited Adoption: Not all organizations in the construction industry have adopted PMIS or BIM, making it challenging to integrate these systems intoprojectmanagementprocesses.

Itisimportanttocarefullyevaluatethepotentialdrawbacks of PMIS and BIM integration and implement strategies to mitigate them to ensure successful integration and maximumbenefits.

8. CASE STUDIES

1. Masstransit:Stationssouthchennai

2. Masstransit:Stationsnorthchennai

3. Masstransit:Stationseastchennai

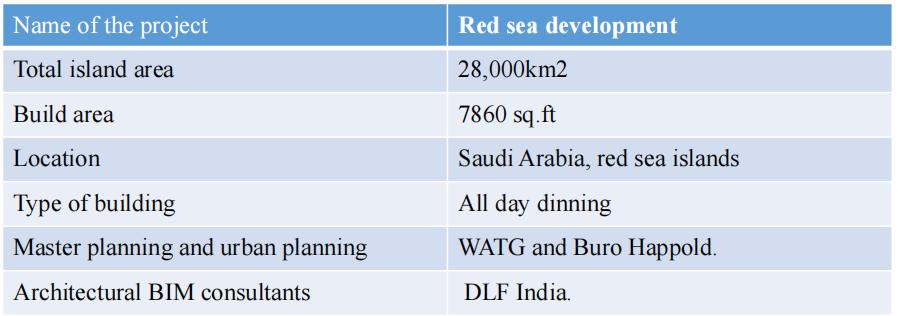

4. IslandDevelopment–SaudiArabia

5. IslandDevelopment –SaudiArabia-SpaandRetreat space

6. IslandDevelopment –SaudiArabia-Alldaydinning space

8.1.

8.2. MASS TRANSIT : STATIONS NORTH CHENNAI

Conventional method

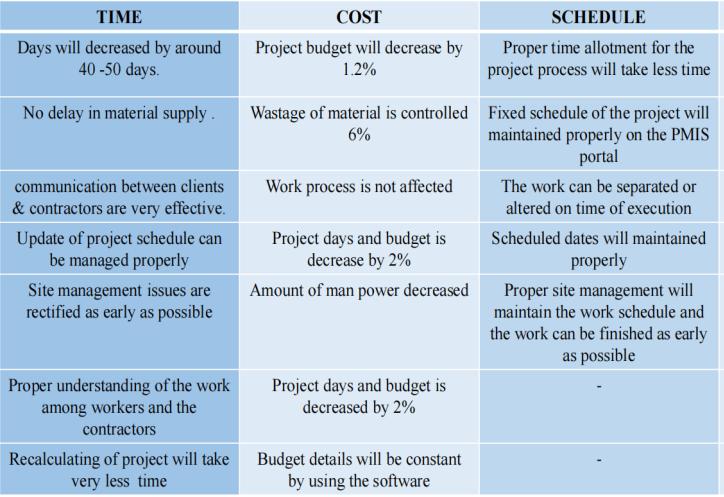

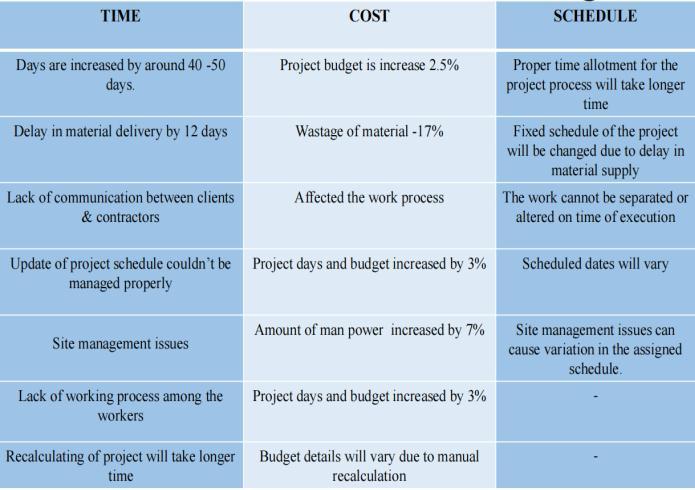

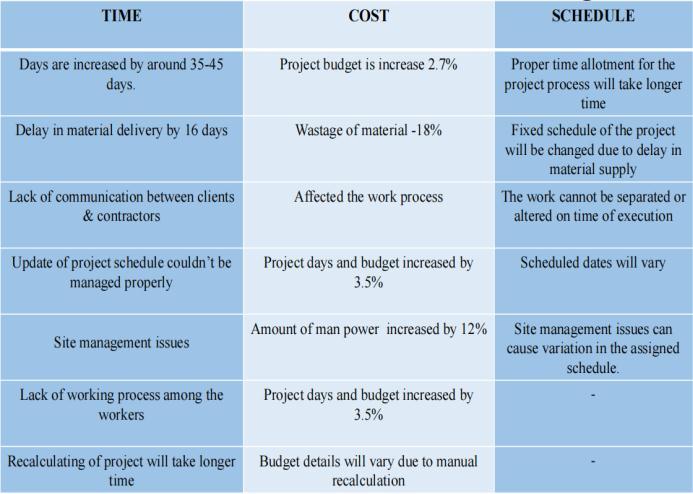

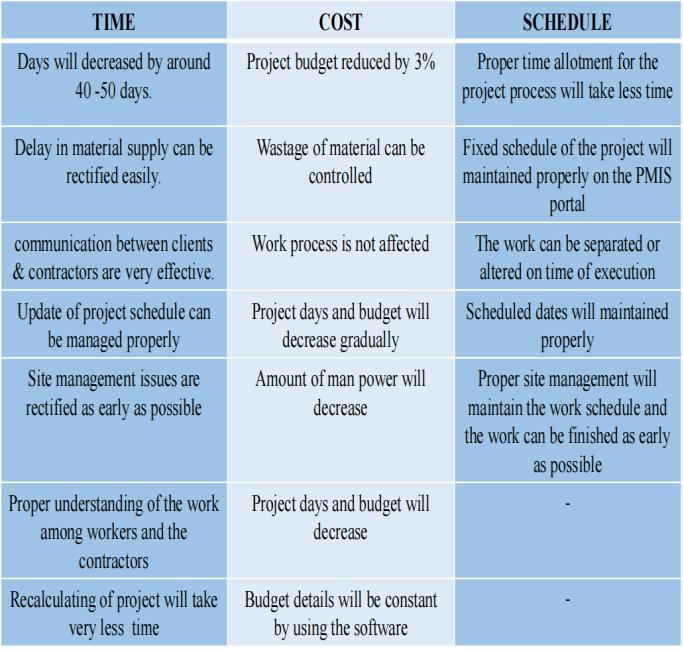

This passage highlights the challenges faced in a constructionprojectrelatedtotime,cost,schedule,safety, andmanagement.Thedelayinmaterialdeliveryandpoor communicationbetweenclientsandcontractorsresultedin a significant increase in the project timeline and budget. Safetymeasureswerenotupdatedregularly,andindividual safety issues could not be analyzed correctly. Site management issues led to variations in the assigned schedule, and a lack of working process among workers caused further delays. Recalculating the project is a timeconsumingprocess,andthebudgetdetailscanvarydueto manual recalculation. The passage emphasizes the importance of proper time allotment, effective communication,andefficientsitemanagementtocompletea constructionprojectsuccessfullywithinthesetbudgetand schedule.

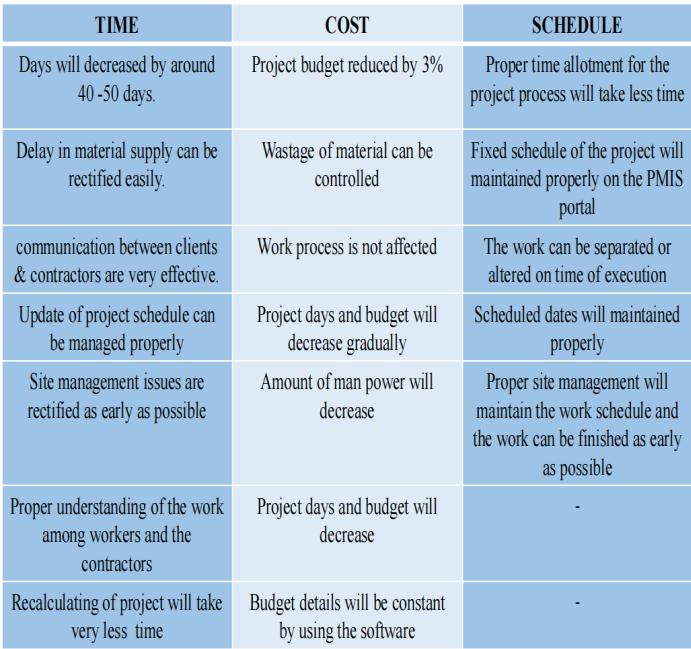

Using PMIS Method

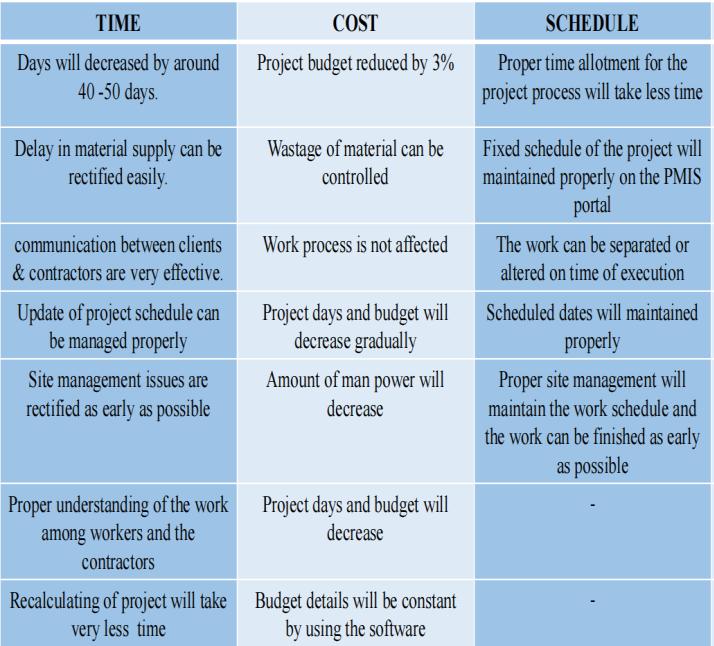

Thegiventextsuggeststhataprojectcanbecompletedmore efficiently by reducing the number of days by 40-50 and reducingthebudgetby3%.Thiscanbeachievedbyproper time allotment, daily monitoring, controlling wastage of materials,andmaintainingafixedscheduleonaPMISportal. Safety measures can also be updated daily, and effective communication between clients and contractors can be maintained.Theworkprocessandschedulecanbealteredif required, and individual safety issues can be analyzed properly.Sitemanagementissuescanberectifiedearly,and the amount of manpower required can be reduced. With proper understanding of the work among workers and contractors,theprojectdaysandbudgetcanbedecreased, and project recalculation can be done quickly by using software.

8.3. MASS TRANSIT : STATIONS EAST CHENNAI

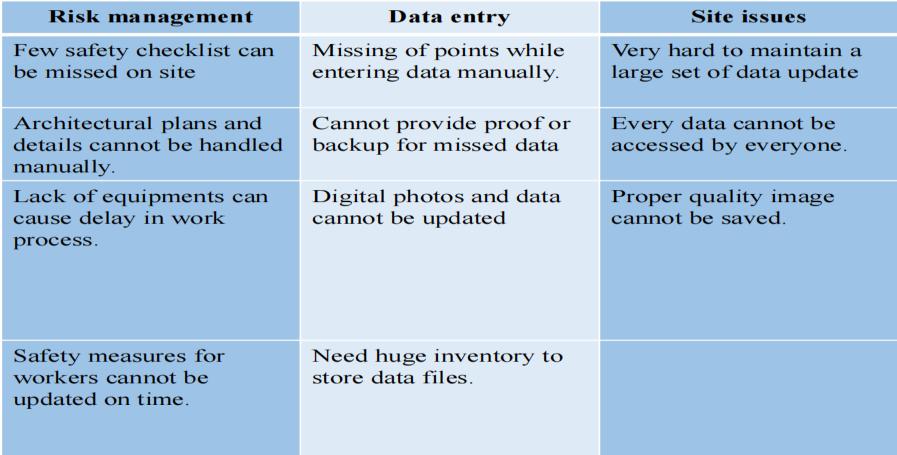

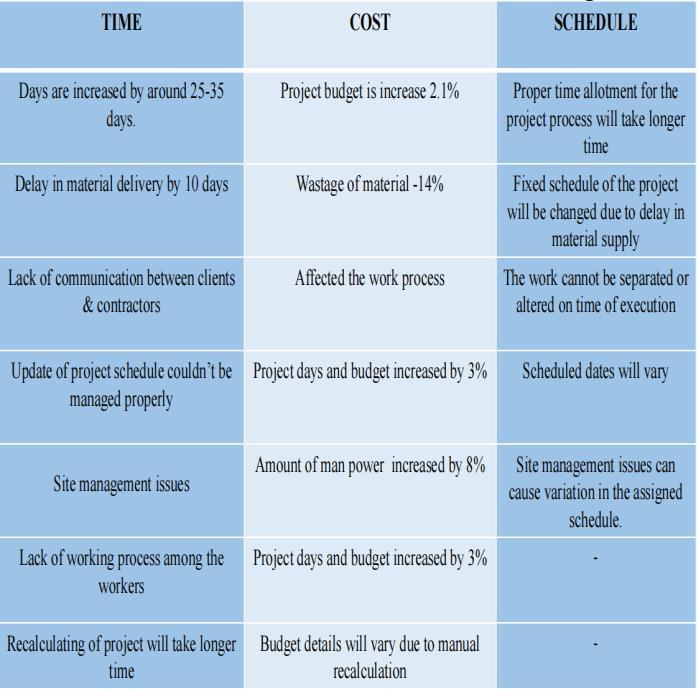

Conventional Method

8.5.

PMIS Method

8.6.

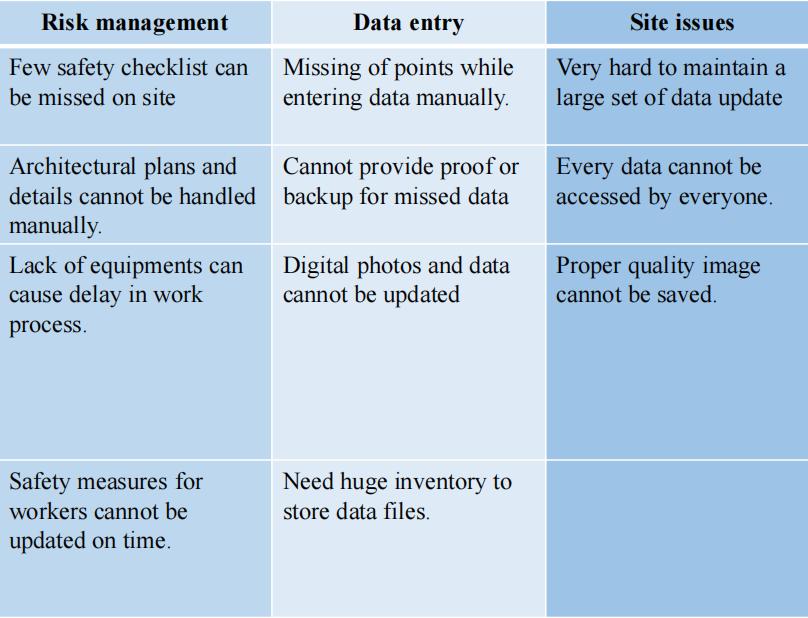

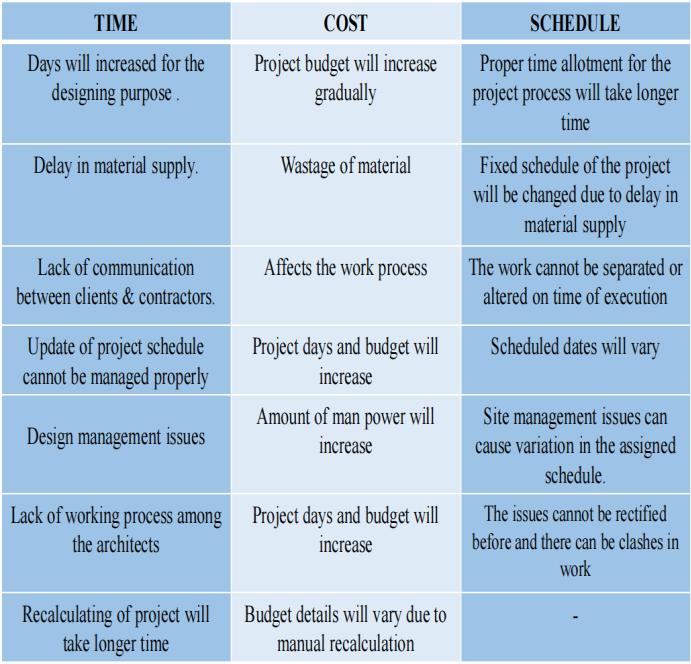

Effective time, cost, schedule, and safety management is critical for construction projects, but various issues can hinderprogress.Delaysinthedesignprocesscanincrease project duration and costs, while delayed material supply can result in schedule changes and material waste. Daily safety checklist updates may be challenging, and poor communicationbetweenclientsandcontractorscanaffect workprocesses.Sitemanagementanddesignissuescanalso require more manpower and impact safety inspections, while a lack of architect collaboration can cause work clashesandlongerprojectrecalculationtimes.

Conventional method

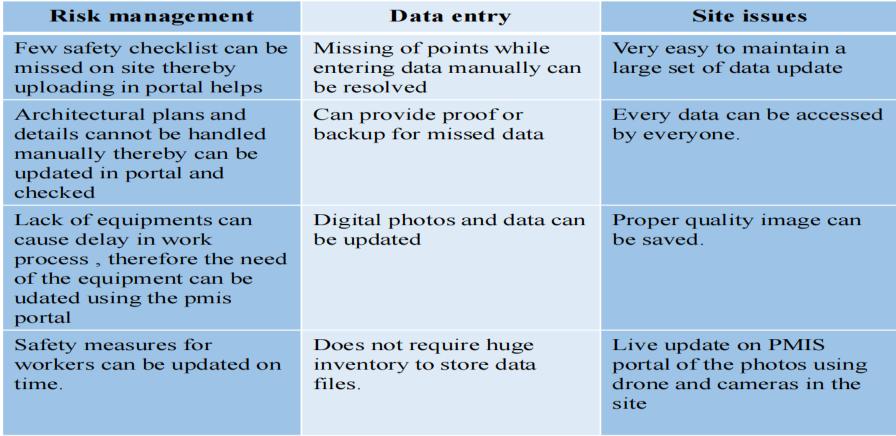

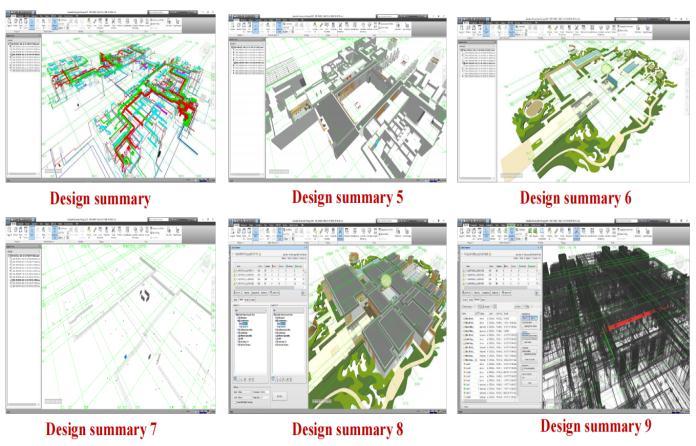

Using BIM 360 software

Toachievesuccessfulconstructionprojects,itiscrucial to manage time, cost, schedule, and safety efficiently. By reducing the project duration by 60-80 days and cutting down the budget by 3%, proper time allocation for the project process can be achieved more efficiently. Material supply delays can be rectified swiftly to control material wastage.

TheBIM360portalcanbeusedtomaintainthefixedproject schedule, and safety checklists can be updated daily. Effective communication between clients and contractors ensures work processes are not affected, and individual safety issues can be analyzed appropriately. The project schedulecanbemanagedefficiently,resultinginagradual decreaseinprojectdaysandbudget.

Scheduleddateswillbemaintainedcorrectly,pre-planned safetymeasuresinspectedaccurately,andsitemanagement issuesresolvedassoonaspossible,leadingtoadecreasein requiredmanpower.Propersitemanagementensuresthat the work schedule is maintained, and the project can be completedearlier.Animprovedunderstandingofthework amongworkersandcontractorsleadstofewerprojectdays andreducedbudgets.

Recalculatingtheprojectwillbequicker,andthesoftware willensurethatbudgetdetailsremainconsistent.

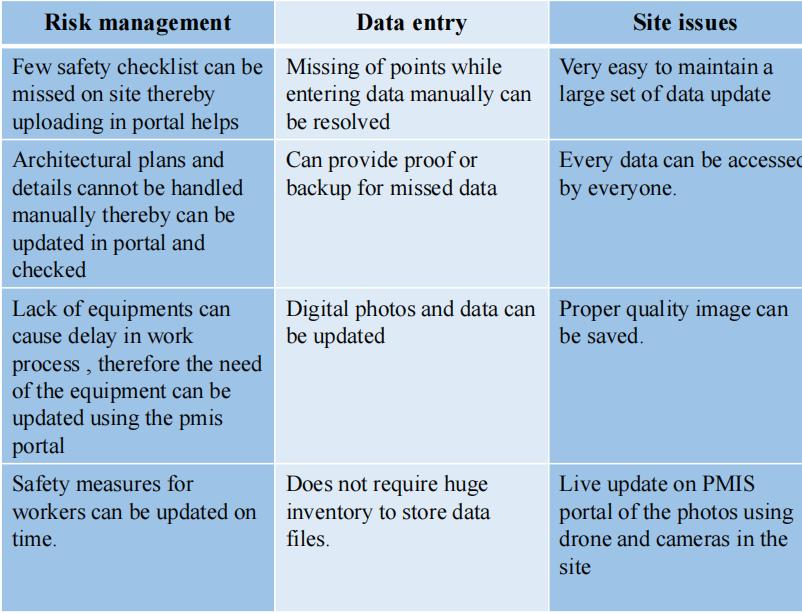

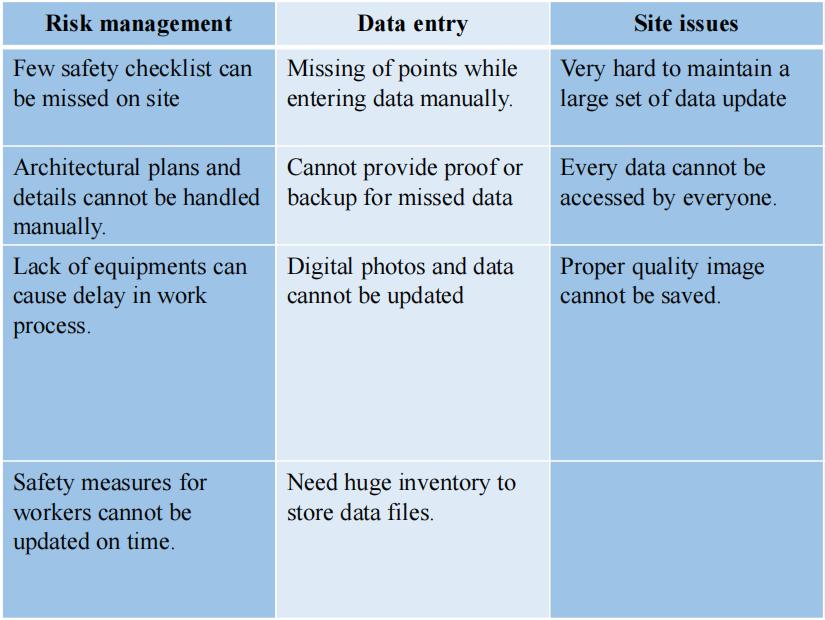

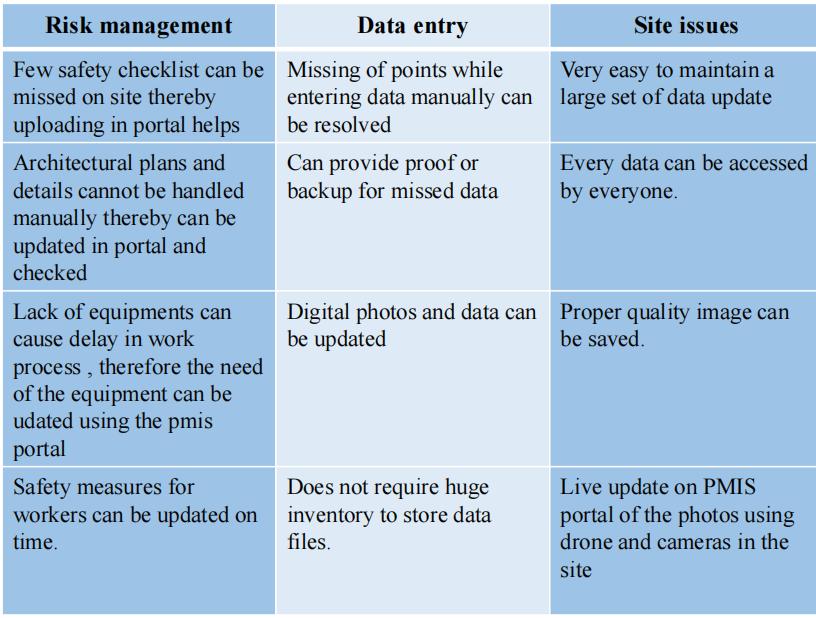

TheuseofaBIM360portalcanhelpwithriskmanagement, dataentry,andsiteissues,whichcancausedelaysinwork. By uploading safety checklists and data manually into the portal,missingpointsanddatacanbeavoided.Theportal canalsobeusedtoupdateandmaintainalargesetofdata, including architectural plans and details, which cannot be handled manually. The reason for work delays can be updated in the portal with proper photos and proof, and approvals for any changes can be made quickly. Lack of equipment can also be updated using the BIM 360 portal, and safety measures for workers can be updated on time. Live updates on the BIM 360 portal can be made using drones and cameras on the site, and the portal can be accessedbyeveryone,makingunderstandingofissuesand changeseasier.TheuseofaBIM360portalalsoreducesthe needforlargeinventorytostoredatafiles.

9. USING PRIMAVERA SOFTWARE

Primaverasoftwareisaprojectmanagementtoolthathelps usersplan,monitor,andcontrolcomplexprojectsefficiently. Byinputtingprojecttasks,dependencies,anddurations, a network diagram is created to represent the project schedule and the critical path. Using Primavera tools , project managers can optimize the schedule by adjusting task durations, rearranging tasks, or adding additional resourcestocriticaltasks,andthesoftwarecancalculatethe impact of changes and provide recommendations. This process helps identify areas where time can be saved, resulting in a faster completion time and reducing the number of days required to finish the project. Overall, Primavera software facilitates project management and helpsidentifyopportunitiestoreduceprojectduration.

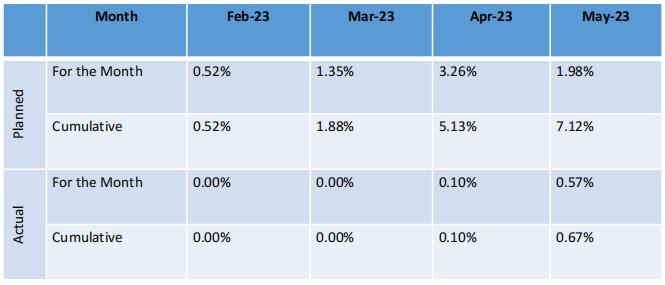

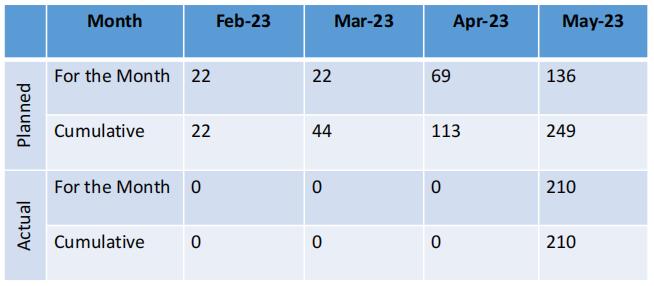

9.2. CONSTRUCTION RESULTS

Integrating Primavera and a Project Management Information System (PMIS) can streamline project management,provideaccurateprojectforecasting,improve communication and collaboration, enhance risk management, and increase productivity. PMIS manages projectdocumentation,tracksprojectcosts and risks,and

automates project management tasks, while Primavera plans, schedules, and tracks project progress. The integrationofthesetwosystemscanbenefitorganizations managingcomplexprojects.

TointegratePrimaveraandPMIS,youneedtoensurethat thetwosystemsarecompatible.Thiscanbedonebyusinga third-party integration tool or custom developing an integrationsolution.Oncetheintegrationiscomplete,users can access both systems from a single interface, allowing themtomanageallaspectsoftheprojectinoneplace.

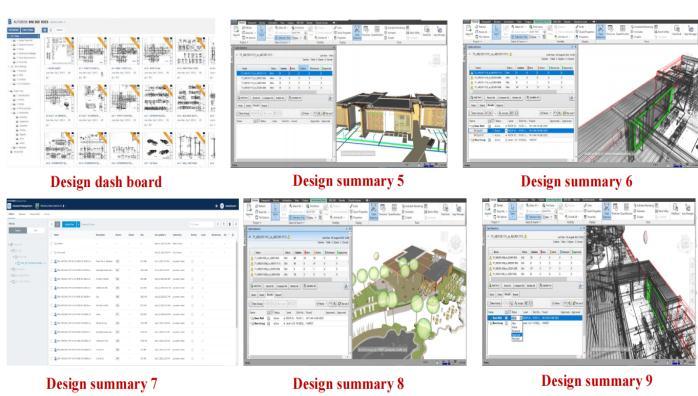

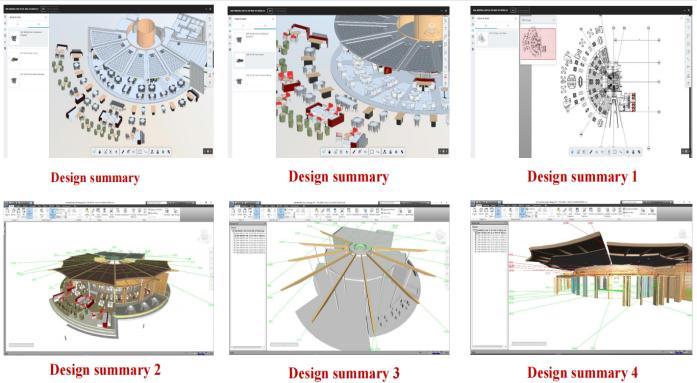

10. INTEGRATING PMIS AND BIM

ThedatafromPMISandBIMmodelscanbemadeavailable toprojectmanagementand ownerstounderstandproject progress. The screen shows a plant with work packages dividedbasedonprojectscope.ThePMISwebpageonthe leftisconnectedtoBIMandprovidesalistofpackagesand boxesrepresentingdifferentpartsoftheworks.Clickingona boxprovidesdetailsoftheindividualparts.Thetimelineis also available, filtered by discipline. The portal allows checkingotherdisciplinesaswell.

project.WiththeongoingintegrationofBIMandPMISalong withPrimavera,theconstructionindustryispoisedtosee evengreaterefficiencygainsandcostsavingsinthefuture.

RECCOMENEDATIONS

SeveralrecommendedpluginscanintegrateBIMandPMIS, suchasBIM360,Revit,Navisworks,AutoCAD,andSynchro. BIM360connectsBIMmodelsdirectlytoPMIS,whileRevit allows users to export BIM models to PMIS. Navisworks helpsvisualizeandanalyze3Dprojectdata,whileSynchro provides 4D simulation. Using these plugins can improve productivity, communication, collaboration, and risk management,leadingtobetterprojectoutcomes.

REFERENCES

[1] Jaehyun Choi, "Validation of project management informationsystemforindustrialconstructionprojects ",https://doi.org/10.1080/13467581.2021.1941999

[2] Seul Ki Lee, "Critical success factors for project managementinformationsystem",www.jcepm.org

[3] Seul-Ki Lee, "Success model of project management information system in construction " , www.elsevier.com/locate/autcon

[4] JungHoYu,“AssessmentofASP-PMISQualityinKorea “,www.jcepm.org

[5] GageChristianson,“Cloudbasedprojectmanagement :Selecing IT solution for construction companies”, In: Proc.Lean&ComputinginConstructionCongress(LC3), Vol. 1 (CIB W78), Heraklion, Greece, pp. xx-xx. DOI: xxxx/xxx/xx

FINDINGS

The application of PMIS software resulted in a significant improvementinconstructionefficiency,asevidencedbythe completion of a 45 km stretch using the conventional methodtaking8years,whereasintegratedPMIS,aimedto completea128kmstretchwithin5years,with85%ofthe workcompleteddespiteaone-yeardelay.TheuseofPMIS reducedcostsandtimeby3timescomparedtoconventional constructionmethod.TheintegrationofBIMandPMISwith Primaveraiscurrentlyinprogress.

CONCLUSION

Inconclusion,integratingPMISandBIMcanbringsignificant benefitstotheconstructionindustry,includingstreamlined projectmanagement,accurateprojectforecasting,improved communicationandcollaboration,betterriskmanagement, and increased productivity. The use of PMIS and BIM can also help in reducing costs and time, as evidenced by the successful implementation of PMIS in the construction

[6] SeongMin-woo11)KimGa-ram,”EffectofPMISQuality on Intention to Use and User Satisfaction “, www.jkibc.org

[7] Alaa, G., Fitzgerald, G., 2013. Re-conceptualizing agile information systems development using complex adaptive systems theory. Emergence:Complexity & Organization,15

[8] A. Lupasc. 2016. Project Management Information System Based on Web Technologies. in The European Proceedings of Social & Behavioural Sciences,Pitesti.

[9] Mardiani, G. T. 2018. Construction industry project planninginformationsystem.In IOP Conference Series: Materials Science andEngineering, 407(1),pp.012093.

[10] Luo, S., Lu, Y., Peng, Y., Le, Y., 2011. Developing cost controlinformationsysteminthecomplexproject.2011 InternationalConferenceonBusinessManagementand ElectronicInformation(BMEI).IEEE,pp.99–105.

[11] Caniëls, M.C., Bakens, R.J., 2012. The effects of Project ManagementInformationSystemsondecisionmaking ina multi project environment. Int.J. Proj.Manag. 30, 162–175

[12] Hass, K.B., 2009. Managing Complex Projects: A New Model.ManagementConceptsPress.

[13] Aritua, B., Smith, N.J., Bower, D., 2009. Construction client multi-projects a complex adaptive systems perspective. International Journal of Project Management27(1),72–79

[14] Azhar S, Hein M, Sketo B. Building Information Moeling(BIM):Benefit, Risks and Challenges. Proceedingsofthe44thASCNationalConference;2008 April 2-5; Auburn University. Auburn, Alabama.: UniversityofSouthernMississippi;2008.11p.

[15] KimJG,HyunKM,KimW,KimOK.ExampleAnalysisand Development of Project Management Information System-CaseStudyofSubwayConstructioninD.Area. Journal of Architectural Institute of Korea. 2005 Nov;11(1):593-6.